One of the main systems that ensures safety when driving a car is the braking system. The most widespread are brake mechanisms that use the frictional force of different materials. Such mechanisms are installed on all cars, including VAZs belonging to the “Classic” family.

As an example of a classic VAZ, model 2107 will be used. The brake system of the VAZ-2107 includes working and parking systems. The task of the working component is to reduce the speed of movement of the car until it is completely immobilized.

It consists of two components: the first is the brake mechanisms, which act on the wheels, which is why their rotation decreases. The second component is the drive, through which the driver operates the mechanisms.

The parking component ensures that the wheels of one of the car's axles are locked, in the case of the VAZ-2107 - the rear axles, while the car is immobilized. The use of this brake prevents spontaneous movement of the car. This system uses a separate drive that acts on the rear axle mechanisms.

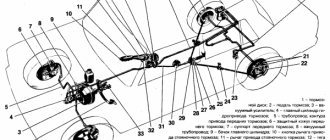

In more detail, what the brake system of the VAZ-2107 looks like is shown in the diagram:

Now let's take a closer look at the design of the VAZ-2107 brake system. First, let's go through the working component. Its drive is hydraulic and includes:

- Control pedal;

- Vacuum booster;

- Main cylinder;

- Tank for working fluid;

- High pressure pipelines;

- Rear axle bellows pressure regulator;

The use of liquid as a working element of the drive is due to a number of positive qualities: a complex system of levers for the drive is not required, the wiring of pipelines to the mechanisms is facilitated, the transmission of force from the driver’s foot is enhanced several times due to the vacuum booster.

Related link:

Insulation of VAZ-2107 for the winter

The working mechanisms on the VAZ-2107 are of two types: disc brakes are installed at the front, using calipers; drum-type mechanisms are used on the rear axle, which also includes a parking mechanism.

Now in more detail about the elements of this system. So, the pedal that the driver presses is located on the same axis as the clutch control pedal. To ensure that it can be returned to its original position, it is spring-loaded.

Vacuum brake booster

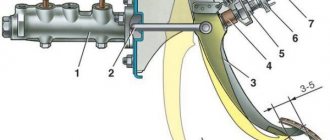

A rod connected to the amplifier is connected to the pedal. The design of the VAZ-2107 vacuum brake booster is quite interesting; it is shown in the figure:

The amplifier is a sealed container, internally divided into 2 chambers by means of a membrane. The chamber located closer to the pedal is called atmospheric, and the chamber separated from it by a membrane is called vacuum. The diaphragm itself is connected to the piston rod of the master cylinder.

The vacuum chamber is connected by a pipe to the intake manifold of the engine, where the vacuum comes from. The design also includes a follower valve controlled by the pedal rod, which does all the work.

When the pedal is released, this valve connects the chamber cavities through a channel, providing identical pressure. When the pedal is applied, the valve closes the channel connecting the chambers and opens the channel connecting the atmospheric chamber with the atmosphere. Since a vacuum is maintained in the second chamber, atmospheric pressure begins to put pressure on the membrane. Since it is connected to the piston rod of the master cylinder, due to the movement of the piston, fluid is displaced from the cylinder into the pipelines.

How to change rear pads on Kalina

The brake systems of different variations of the LADA Kalina are distinguished by the absence or presence of an anti-lock braking system. Changing the rear brake pads of a Kalina with or without ABS is equally simple. The only difference is that in the first case, before dismantling the pads, you must disconnect the wires from the sensors so as not to damage them. To prevent brake fluid from spilling out of the reservoir and getting on the paintwork or rubber parts of the Kalina when replacing the pads, it is necessary to take some of the fluid from the reservoir into a prepared container. This operation should be carried out only when the brake fluid level in the reservoir is close to the maximum level. Replacement of the rear pads is carried out one by one: first from the left, then from the right side (or vice versa, the order is not important here). Some operations, for example, loosening the tension of the handbrake cable or adjusting it, are more convenient to carry out from the inspection pit or using a lift. Therefore, the work must be performed in an equipped garage.

Replacement of rear brake pads of LADA Kalina is carried out as follows:

- install wheel chocks under the front wheels;

- lower the handbrake lever down as far as it will go in order to loosen the tension on the Kalina handbrake cable as much as possible;

- by rotating the adjusting bolt under the bottom of the car, loosen the handbrake cable;

- use a wheel wrench to loosen the wheel bolts;

- jack up the wheel;

- Unscrew the wheel bolts with a wheel wrench;

- remove the rear wheel;

- unscrew the pins that simultaneously serve as fastening of the brake drum and guides for installing the wheel;

- Use a wire brush to clean the rear wheel hub where the drum fits;

- treat the place where the drum fits on the hub with WD-40, wait according to the instructions; tap the drum with a rubber hammer to “break” it out of place;

- evenly screw the M8 bolts into the mounting holes of the drum, pulling the latter off the hub;

Attention: if you press the brake pedal with the drum removed, the piston of the brake cylinder may fall out, which will lead to depressurization of the circuit, the need to bleed the brakes or even replace the brake cylinder.

- check the condition of the brake drum: it should not have chips, uneven wear, cracks or marks;

- if necessary, replace the brake drum with a new one;

- bring together the rear Kalina pads using pry bars (mounting blades);

- pry the end of the upper spring, which tightens the pads, with a slotted screwdriver and remove it from engagement with the pad;

- remove the upper spring from the second block, put it aside;

- remove the lower tension spring using a screwdriver or pliers;

- remove the “front” block located closer to the front of the car;

- remove the spacer bar installed between the pads;

- remove the end of the parking brake cable from the hook of the rear shoe spacer lever;

- using pliers, disengage the spring holding the second block;;

- remove the block located closer to the rear of the car;

- undo the pin securing the spacer lever;

- remove the spacer lever;

- clean the brake mechanism parts from dirt;

- secure the spacer lever to the new block;

- pin the finger;

- install the “front” brake block;

- put the spacer bar in place;

- install the “rear” block by putting the lower tension spring on it;

- put the end of the handbrake cable on the spacer lever of the block;

- Using a screwdriver or pliers, hook the lower and upper tension spring onto the pads;

- reinstall the brake drum;

- tighten the guide pins holding the drum;

- secure the wheel with wheel bolts;

- lower the jack so that the wheel is on the ground;

- Use a wheel wrench to tighten the wheel bolts.

Then the same operations must be done on the second wheel. Now you know how to change the rear pads on a Kalina.

Remember: after replacing the rear pads, you need to adjust the handbrake of the LADA Kalina.

- Increased disc wear. For new ventilated discs it must be at least 17.8 mm

- Furrows and surface irregularities left by pads or foreign particles (stones, sand, etc.)

- Bent surface - does not happen so often, but this may cause such features as vibration during braking and runout

If you notice at least one of the above symptoms, you need to check the condition of the brake discs and, if necessary, replace them. To perform this DIY repair you will need the following tool:

- Balloon wrench

- Jack

- 7, 13 and 17 mm wrench

- Torx head t12

- Ratchet and extension

- Hammer

- Copper grease

Brake master cylinder

The master cylinder is connected to the booster. This element is a housing to which the supply and return pipelines from the fluid reservoir are connected, and 3 pipelines leading to the brake mechanisms exit. There is one pipeline leading to the front brake mechanisms, and only one to the rear, leading to the regulator.

Inside this housing there are pistons that push the liquid into the pipelines. One of them is connected to the amplifier diaphragm rod. These are the main elements of the drive. The detailed design of the brake master cylinder is shown above.

Related link:

Homemade pre-heater for a VAZ car engine

Rear brake cylinder replacement:

To replace the brake cylinder on the rear wheel, you will need to carry out similar operations to remove the brake pads described earlier. Next, the following operations are carried out:

- Unscrew the brake pipe nut. You will need to thoroughly clean the mounting area and use an open-end wrench with the ability to grasp all edges of the nut.

- There are also two bolts (may differ on old and new models) for securing the cylinder, which will also need to be removed.

- The new cylinder assembly is installed in the reverse order.

Caliper device

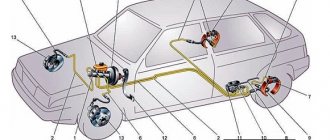

Let's move on. The front axle mechanisms are disk ones, consisting of calipers with the main brake elements - pads, and brake discs.

A caliper is a body with cylinders made in it for the pistons. This model has two of them, one for each block. The support structure is shown in the figure.

The caliper pistons have the form of a glass, which is placed in their cylinders, but they can move along it. To prevent fluid leakage, the pistons are equipped with o-rings.

Pads are small metal plates onto which linings made of friction material are glued.

The brake disc is made of metal for better adhesion to the surface of the pads; its side surfaces are well processed so that there are no protrusions or shells on them.

The VAZ 2107 brakes work like this: the fluid moves into the caliper cylinders, where it begins to push out the pistons. They come out of the cylinders, pressing the pads against the disc.

Replacing the main (main) brake cylinder:

The need for such replacement occurs much less frequently. Basically, the reason for such interference is the appearance of brake fluid leaks, or the passage of fluid between different cavities through the sealing cuffs.

To remove the barrel, you will need to disconnect the battery and the electrical connector of the tank cap. Then remove the cap and pump out the brake fluid completely. The tank is attached to plastic clips and can be easily replaced.

Work on this brake cylinder (or installation after repair) is carried out after disconnecting the high pressure pipes. The main brake cylinder is attached to the body with two bolts. After reinstalling the cylinder, the brake system must be bled.

Rear axle brake mechanism

The brake system of the VAZ-2107 rear axle has a different device. All its elements are hidden inside the brake drum:

The working brake cylinder of the VAZ 2107 has the following device: there is a body, also known as a cylinder, with two pistons placed in it. When exposed to fluid pressure, they come out of the cylinder.

The pads are metal, made in the shape of crescents, with friction clutches glued to their upper edge. The pads installed on the hub form a ring.

In the lower part, the pads are installed in the seats made under them, and in the upper part - in the grooves made in the pistons. To prevent the pads from moving apart spontaneously, they are tightened with springs. The parking brake mechanism is also located there.

On top of all this there is a drum mounted on the hub shaft. When braking, the fluid pushes the pistons, and since the pads fit into their grooves, this movement of the pistons is accompanied by the divergence of the pads. At the same time, they are pressed towards the drum and the rotation slows down.

Related link:

Causes of detonation of VAZ engines and solutions

Absolute vehicle malfunctions

During operation, the braking functions of the system deteriorate. This is due to wear and tear of components, assemblies and parts that require repair. Some vehicle malfunctions are included in a special “List...”, and driving with them is prohibited.

Inefficiency of the working vehicle

The most common malfunction of the brake system (including the VAZ-2107) is inefficiency, which is diagnosed by two main parameters (when carrying out a specialized instrumental study):

- increasing braking distance;

- increase in steady deceleration during braking.

Parking system

Although it engages the mechanism of the rear axle wheels, it is in no way connected with the working mechanism. It uses a cable as a drive connected to the handbrake located inside the car.

Under the car, this cable is divided into two parts, going into the rear axle mechanisms. Inside, the ends of the cable are connected to the drive lever, which in turn is connected to a spacer bar. The drive lever is connected to one of the pads.

When the handbrake is engaged, the cable pulls the lever, and since it rests against the bar, the pads are released. The toothed sector of the handbrake fixes the position of the lever when the pads are spread apart.

Brake system in Lada cars of the 2101-07 family

The braking system (TS) of any vehicle is designed to control the speed of movement, stop and hold it stationary for the required period of time.

It is one of the most important vehicle control systems, since road safety functionally depends on the degree of serviceability and efficiency of the braking system.

Pressure regulator

It is installed in the rear wheel drive and not only distributes fluid to the mechanisms, it also prevents possible skidding due to different forces on the mechanisms. This is done by limiting the supply of pressure to the mechanisms, depending on the position of the car body relative to the bridge.

The regulator is driven by a rod, one end of which is fixed to the rear axle, while it itself is fixed to the body. As the load on the rear axle increases, the body changes position relative to the axle; as a result, the rod puts pressure on the regulator piston, which adjusts the pressure supplied to the mechanisms.

Instructions for installing the HCD on VAZ 2101 – 2107

The package includes:

- Left caliper VAZ 2108 – 1 pc.

- Right caliper VAZ 2108 – 1 pc.

- Shoe guide VAZ 2108 – 2 pcs.

- Front brake flexible hose – 2 pcs.

- Faceplate – 2 pcs.

- Distance washer – 2 pcs.

- Brake disc boot – 2 pcs.

- Half ring – 2 pcs.

- Brake pads Ladasport VAZ 2108 – 1 set.

- Brake disc VAZ 2108 – 2 pcs.

VAZ 2101 axle shaft, modified – 2 pcs.

Work order.

Place the car on a level surface. We install wheel chocks. Loosen the rear wheel mounting bolts. We jack up the car, completely unscrew the wheel mounting bolts and remove the wheel from the car. Remove the brake drum. We turn the axle shaft until the large holes coincide with the two nuts securing the brake shield. Using a 17 mm socket wrench with an extension, unscrew the nuts securing the brake shield. Turn the axle shaft and unscrew the remaining 2 nuts in the same way. We remove the semi-axle from the car. This can be done with a special puller or by securing the wheel with 2 bolts to the axle shaft.

With a sharp movement towards ourselves, we pull out the axle bearing from the flange of the rear axle beam. After unscrewing the bolts, remove the wheel. We take out the axle shaft. Remove the brake pads. Using a 10mm wrench, unscrew the brake pipe from the back of the brake shield. Remove the brake shield completely. We inspect the axle shaft seal and replace it if necessary. Take the modified axle shaft from the delivery kit. Install a half ring between the bearing and the oil reflective shield. Put the faceplate on and orient it so that the holes on the faceplate and the oil deflector plate line up. Place the brake disc boot on the rear axle beam. Install the axle shaft with the faceplate into the rear axle beam. Attention! The holes for attaching the brake mechanisms should be oriented so that the brake mechanism is located in front (in front of the bridge), the holes should be directed downward, as in the photo below. Tighten the 4 axle nuts. Attach the brake disc boot to the faceplate. Place the spacer on the axle shaft. Orient the washer so that the holes in the washer and the axle shaft line up. Install the brake disc and secure it to the axle flange. Install the caliper assembly onto the faceplate and tighten it with two M10 bolts. Attention. The fitting on the brake cylinder should point upward. Connect the brake hose to the brake pipe. Secure the brake hose with plastic ties

Secure in such a way that the hose does not have constant contact with other parts. Install the wheel. To secure the wheel, you must use extended bolts. Or replace the bolts with studs. Lower the car. Tighten the wheel bolts. Repeat steps 4-27 on the second side. Check the oil level in the rear axle gearbox. Add oil if necessary. Bleed the brake system.

The principle of operation of the VAZ-2107 brake system

If it is necessary to reduce speed, the driver presses the pedal. Its force is transmitted to the amplifier valve, which opens the required channel to supply atmospheric pressure to the membrane. The membrane is connected to a rod connected to the piston of the main cylinder. This rod displaces fluid into the pipelines leading to the operating mechanisms. Since the liquid is not compressed, all force is completely transferred to the mechanisms.

The liquid presses on the pistons of the working cylinders, and as they move out, they unclench (on drum bellows) or press the pads (on disk bellows) to the disk or drum connected to the wheel hubs. Due to the friction of the pads on the discs (drums), the rotation slows down.

Related link:

How to start a VAZ engine in winter

Relative vehicle malfunctions

This list of faults does not apply to absolute (or categorical) faults. Their presence is associated with the convenience (or inconvenience) of driving.

Increased hydraulic pedal travel (as an option - a “soft” pedal)

The reasons for the “sinking” of the pedal are determined by the presence of air in the system; extreme wear of brake pads; failure of the main or wheel cylinders. The action plan for eliminating technical problems includes checking and repairing all components and assemblies of the system; and, if necessary, replacing failed ones and bleeding the system.

Shift towards the vehicle's trajectory when braking

The malfunction is due to either a failure of the working (wheel) cylinder or wear of the pads. Replacing them (or repairing them) will solve the problem.

Increased background noise, friction (grinding) in the brake mechanism

Deficiencies are localized mainly in the rear mechanisms and are determined by contamination of the mechanism, critical wear of the pads, breakage of spring elements, uneven wear of discs or drums. Fault repair involves washing and replacing mechanism parts.

Vibration when braking

This is a fairly common malfunction that is associated solely with critical or uneven wear of the discs or drums, and the repair will consist of replacing them. » alt=»»>

Types of maintenance work

Despite the fact that the system is not so complicated structurally, it requires periodic maintenance, including:

- Checking the fluid level in the system;

- Checking the degree of wear of friction clutches, pads, discs, drums;

- Bleeding the system to remove air;

- Checking the condition of the handbrake cables;

- Adjustment of cable tension;

- Adjusting the rear brake adjuster;

Before each trip, you must always check how much brake fluid is in the VAZ-2107 system. An insufficient amount of it can lead to the fact that the efficiency of the system can be significantly reduced due to air getting inside the pipelines. In addition, a decrease in level may indicate damage to pipelines and fluid leakage.

The elements of the mechanism should be checked every few months, this is especially true for the pads, since they wear out quite intensively. If necessary, worn elements are replaced.

If air gets inside the drive of the working system, pumping is performed, as a result of which the air is expelled from the system.

Loosening the tension of the parking brake cables can lead to its failure, so you need to periodically monitor it and, if necessary, restore the tension.

Replacing the parking brake cable:

In most cases, the tension of the handbrake cable is adjusted by its tension at the point of attachment to the equalizer. However, if adjustment cannot be made, replacement will be required:

- Remove the brake drum.

- Remove the muffler from the hanging clips and lower it to the ground.

- Dismantle the equalization device.

- Remove the cable end from the equalizer.

- Release the cable attachment to the body elements.

- Remove the opposite end of the cable from the brake mechanism by disconnecting it from the drive lever. Pull the cable out of the stationary shield.

- Carry out reverse laying, fixing and tensioning of the cable.

Features of the braking system

One of the features of the VAZ-2107 brake circuit is the presence of a dual-circuit system. The essence of a dual-circuit system is that the working drive is divided into two parts, each of which supplies fluid to only two mechanisms, while the circuits do not interact with each other.

The presence of two circuits ensures the operability of the brakes of at least two wheels in the event of depressurization of one of the circuits. That is, even if the pipelines of one circuit are punctured, the second will remain fully operational, which will ensure the functioning of the brakes.

In the VAZ-2107, the circuits are divided in such a way that the drive of the front axle mechanisms is separated from the drive of the rear mechanisms. This allows you not only to maintain the functionality of the system when one of the circuits fails, but also to pump each circuit separately. That is, if one of the circuits is airy, then it needs to be pumped, but it is not necessary to service the second one.

Related link:

Choosing a battery for a VAZ-2107 car

This is only general information about how the VAZ-2107 brake system works, and does not include all the details on its maintenance and repair. In general, the brakes of this car work quite well, although some elements of it cause complaints from car owners.

Article on the topic - Bleeding VAZ brakes

Problems and their solutions

There are several common problems associated with brakes on a VAZ 2110 car. The reasons for their occurrence may be different, but the solution is always the same - timely and high-quality repairs.

- The brakes have completely lost their effectiveness, pressing the pedal does not cause any reaction. In such a situation, it is categorically impossible to drive anywhere under your own power, even if we are talking about a trip to a service station? How do you brake? About a wall or pillar? Call a tow truck and start repairs. In some situations, the problem can be solved on the spot, but these are temporary measures.

- During braking, strong vibrations are observed, most often in the steering column. At the same time, when you press the pedal, it is difficult to hold the steering wheel in your hands. There may be several reasons for this: If you have non-ventilated discs installed, similar situations may arise during rain or when braking through a puddle. Such devices do not like moisture, so to get rid of vibrations, replace the disks with ventilated ones;

- Another cause of vibrations is faulty drums. If there are dark spots on the working surface of the drums, the unit wears unevenly. Immediate repair or complete replacement of mechanisms is required;

- Be sure to check for signs of deformation on the front brake discs. They often cause vibrations.

- The vacuum booster air filter may be clogged, causing the brake pedal to feel stiff;

As you can see, the brake system of the VAZ 2110 car is far from perfect in its factory version, but it performs its functions effectively and reliably. All possible malfunctions can easily be fixed independently, but in some situations it is advisable to contact a professional service station.