In our short article we will talk about the VAZ-2110 fuel system (injector). Carburetor engines have long gone into oblivion. The manufacturer has not installed such motors since the early 2000s. Most of the “ten” and similar models (2112, 2111) are equipped with engines with a fuel injection system. It is more reliable, works stably, and most importantly, does not require frequent intervention from the driver. The engine will be able to operate without problems, but provided, of course, that all filters are changed in a timely manner. There is also a requirement for fuel - it is not recommended to use low-quality fuel.

Fuel hoses VAZ 2110 injector 8 valves

A possible sign of the need to replace the fuel supply hose to the fuel rail is the smell of gasoline in the cabin.

This hose begins to flow at the junction with the fuel supply line from the fuel tank (plastic tube). The location of this connection is below the battery near the partition of the engine compartment. Moreover, for many people the hose starts to leak in cold weather. I started to leak when my Kalina was 4 years old, in frosts of -25, and heavily, in copious drops. When the engine warms up, the leak in many Kalinovods disappears. It was the same for me. Since in such frost there is no point in getting under the hood yourself if there is no warm garage, and in such weather there are enough customers in the services, so I went. To be honest, it was scary, because I saw how quickly the cars were burning. Luckily there was a fire extinguisher in the trunk. When the temperature warmed up to -20, the leak disappeared when warming up.

This happens because in such frost the rubber rings in the seal become stiff, losing elasticity. When the engine warms up, they heat up, become elastic, expand, and stop leaking. This can also be caused by increased pressure in the engine power supply system - the pressure limiting valve (located in the gas tank) freezes. Since at -25 outside, the pressure in the fuel rail was somehow not ready to be measured, I couldn’t determine the reason for sure. Without waiting for the next frost, when it warms up, I decided to change the fuel hose.

The length of the original hose is 26 cm. After a long search, I found a hose of acceptable quality, but it turned out to be Chinese, and besides, it is 3 cm longer than the original - its length is 29 cm. The price is 350 rubles. For lack of anything better, I put it in. These extra 3 cm did not play a role. I was alarmed by the inscription on the hose - instead of GOST - TOAST. But I still didn’t “wash” the hose).

And I’ll immediately give you an example of what you shouldn’t put. The sealing rings of this hose are worse than those of the Chinese one. In addition, it is longer and thinner in diameter, which can lead to bending, etc. The braid of this hose is made of synthetic woven fiber

The fuel supply hose to the fuel rail from the Chevrolet Niva is also suitable, but it is almost 2 times longer. In my opinion, it’s better to just pull out the two O-rings from it and insert them into your original one if you can’t find the original one. This should only be done if it is not possible to buy an original one for Kalina. Since it is easier to change the entire hose.

When replacing the hose, it is necessary to replace the O-ring on the fuel rail, which must also be purchased. It is highlighted in red in the photo. The other two rings are precisely the cause of gasoline leakage.

To remove the hose from the plastic high-pressure fuel supply line, it is necessary to relieve the pressure in the system. To do this, remove the plastic plug near the cigarette lighter (the one under which the ECU diagnostic connector is located) and pull out the fuel pump fuse (in the middle between the outermost ones).

Next, we start the engine and wait until it stalls (for the fuel to be completely exhausted). After this, turn the starter for about 3 seconds. Remove the air supply hose to the throttle assembly. Using a 10mm socket, unscrew the nut securing the clamping plate of the fuel supply tube holder and the canister purge solenoid valve tube and remove it. This holder is located under the battery tray. Next, remove the fuel supply hose to the fuel rail. To do this, first place a rag under it so that residual gasoline does not flow through the engine compartment. In the very top first photo you can see the metal locking bracket. We press it from ourselves (if you look at the photo) and remove the hose from the fuel line. Use a previously prepared rag to remove any remaining dripping gasoline. We unscrew the hose itself from the fuel rail, holding the tip of the hose with a 17 key. An O-ring should remain on the fuel rail when the hose is removed. We replace it immediately with a new one.

We put the new hose on the plastic tube of the fuel line until it is fixed with a metal bracket and screw it to the fuel rail. We screw the bracket back, insert the fuse, turn on the ground and check for leaks. If there is no leak, you can start the engine.

If someone decides to change only two o-rings in the hose, this must be done at a positive temperature so that the plastic is not fragile (there is a risk of breaking 2 plastic clips). Outer and inner diameter of 2 o-rings

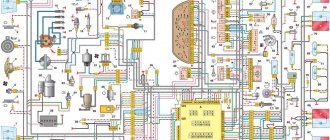

Fuel supply diagram for an engine with a fuel injection system

1 – nozzles; 2 – fitting plug for monitoring fuel pressure; 3 – injector ramp; 4 – bracket for fastening fuel pipes; 5 – fuel pressure regulator; 6 – adsorber with solenoid valve; 7 – hose for suction of gasoline vapors from the adsorber; 8 – throttle assembly; 9 – two-way valve; 10 – gravity valve; 11 – safety valve; 12 – separator; 13 – separator hose; 14 – fuel tank plug; 15 – filling pipe; 16 – filling pipe hose; 17 – fuel filter; 18 – fuel tank; 19 – electric fuel pump; 20 – fuel drain line; 21 – fuel supply line.

Fuel is supplied from a tank installed under the bottom in the rear seat area. The fuel tank is made of steel and consists of two stamped halves welded together. The filler neck is connected to the tank with a gas-resistant rubber hose secured with clamps. The plug is sealed.

The fuel pump is electric, submersible, rotary, installed in the fuel tank. The developed pressure is at least 3 bar (300 kPa).

The fuel pump is turned on at the command of the injection system controller (with the ignition on) through a relay. To access the electrical connector of the pump, there is a hatch under the rear seat in the bottom of the car. From the pump, fuel under pressure is supplied through a flexible hose to the fine filter and then through steel fuel lines and rubber hoses to the fuel rail.

Design Features

The fuel system design includes the following components:

- The fuel supply system itself consists of a gas tank, a pump, a pressure regulator, gasoline filters, a ramp and injectors, as well as connecting tubes and hoses. In other words, these are the elements in which gasoline is found.

- The air supply system is those elements that allow oxygen to pass through. This is an air purification filter, a pipe, a throttle assembly, and a flow sensor. It is with the help of these elements that purified air is supplied to the fuel rail to form a mixture.

- And the last system allows you to catch gasoline vapors. This is an adsorber and connecting tubes. With their help, couples are destroyed.

The fuel supply system is needed to ensure the presence of the required amount of mixture in the ramp when operating in any mode.

Types and design of VAZ fuel hoses

All fuel hoses used on VAZ cars can be divided into two groups according to applicability:

- For models with carburetor engines;

- For models with engines with a fuel injection system (injectors).

Hoses of the first type are used in all VAZ Classic cars (2101 - 2107), as well as on some later ones (2108, 2109, early modifications of the Lada-110 family). These are ordinary reinforced rubber hoses that do not have special fasteners; they are fixed to the fittings using clamps. All hoses used in these cars are the same, differing only in length (from 400 to 1000 mm).

Hoses of the second type are installed on some early (21099, 2113 - 2115) and all current VAZ models, starting with Lada Kalina. These hoses come in a variety of designs, applicability and mounting types.

According to their purpose, fuel hoses for injection engines are divided into the following types:

- Fuel supply hose to the ramp;

- Hoses for draining fuel from the ramp (return hoses) - usually there are two of them, one is located on the ramp side, the other is on the tank side;

- Hoses for connecting the fuel filter - one from the tank to the filter, the second from the filter to the ramp;

- Filler hose;

- Hoses for connecting the adsorber (separator), in fact these are air hoses, but they belong to the fuel system.

Structurally, hoses are divided into three large categories:

- Hoses without fasteners;

- Hoses with connectors at both ends;

- Hoses with a connector at one end and a metal tube at the other.

As already mentioned, hoses of the first type are a traditional solution used on classic VAZ models. They are attached to fuel system parts and pipelines using clamps (or wire loops).

Hoses of the second type have a connector of one design or another at both ends. There are two main types of fasteners currently in use:

- “Nut” type fastener - at the end of the hose there is a metal tip with a union nut, which is screwed onto the mating threaded fitting;

- Quick-release fastener - at the end of the hose there is a fitting (female type) with a locking mechanism that allows you to quickly install or remove the hose from the mating fitting (male type).

Today, in VAZ cars, hoses with “Nut” type fasteners at both ends are used, as well as with “Nut” type fasteners at one end and with quick-release fasteners at the other end.

Quick-release fittings, in turn, come in two types:

- With a plastic latch - such fittings are usually square in shape, and to remove the hose you need to press the button on the side of the fitting;

- With a steel spring bracket - such fittings are usually round in shape; to remove the hose you need to press on the bracket.

Purpose and place of fuel hoses in VAZ cars

The fuel system of any car consists of a relatively small number of components - a tank, filters, a pump, a carburetor (in classic carburetor engines) or a fuel rail with injectors (in injection engines), etc. All these components are connected by a network of pipelines through which fuel circulates. In this case, pipelines consist of two parts - metal tubes and rubber hoses.

The combined design of pipelines is used for a reason. The fact is that individual parts of the car and components of the fuel system, although they are fixed in strictly defined places, still do not have an absolutely rigid fixation. While the car is moving, parts, especially those located on the engine (carburetor or ramp with injectors), move relative to each other, so they cannot be rigidly connected with metal tubes. Elastic rubber hoses come to the rescue, ensuring uninterrupted fuel supply regardless of the position of the fuel system components.

If we talk about fuel hoses in general, they perform several main functions:

- Communication of vehicle fuel system components;

- Compensation for longitudinal and transverse displacements of fuel system components during vehicle operation;

- Compensates for movement of fuel system components when performing various adjustments, maintenance or repairs.

Thus, they play an important role in the operation of the vehicle. This fully applies to all cars of the Volzhsky Automobile Plant, the hoses of which will be discussed in more detail.

Fuel system on a VAZ-2110 carburetor

From 1996 to 2000, carburetor engines were installed on the “tens”. In this series of cars, a diaphragm-type pump installed under the carburetor and driven by a camshaft (via an eccentric) was responsible for pumping fuel from the tank to the carburetor. A fuel filter is installed in front of the pump, and a carburetor after it.

A carburetor is a device that mixes incoming air and fuel depending on many factors (accelerator pedal position, speed, temperature, etc.). The finished fuel-air mixture enters the intake manifold and is ignited by spark plugs.

Ramps and injectors

The ramp is a hollow bar with nozzles installed on it and a specially designed mixture pressure regulator. The ramp is mounted with two bolts on the intake pipe or directly on the cylinder head. On the left side there is a fitting with which the fuel pressure is monitored (during diagnostics). It is closed with a threaded plug.

The injectors are fixed to the ramp. The injector nozzles are located in the intake manifold openings. But on the VAZ-2112 and VAZ-21124 engine models, the injectors are installed in the holes on the cylinder head. In order to seal the mounting holes of the electromagnetic injectors, rubber rings are installed. An injector is a regular valve with an electromagnet.

When a pulse is received from the microcontroller, the valve opens for a certain time. In this case, the fuel mixture is supplied through a sprayer into the combustion chamber through a valve. The fuel begins to evaporate, comes into contact with hot elements, and in a state of steam ignites in the combustion chamber. Ignition occurs with the help of a spark plug. As soon as the pulse to the injector stops, the valve returns to its original position using a return spring.

RDT VAZ 2110

Introduction

Fuel pressure in the injection system is one of the important criteria for stable engine operation. It is when any signs of vehicle malfunction appear that you should start by checking the fuel pressure. In the VAZ 2110, the pressure is regulated using an RTD, also known as a fuel pressure regulator. It is he who determines the required pressure and discharges the excess into the return line.

RTD affects most of the symptoms in the operation of the internal combustion engine, which will be discussed in this article. All possible malfunctions of the VAZ 2110 pressure regulator, its replacement and independent testing are described below in detail.

Fuel system on VAZ-2110 injector

The VAZ 2110 injector fuel system diagram is fundamentally different from the carburetor version described above. The fuel pump is located in the gas tank and pumps gasoline through the fuel filter directly into the rail. The ramp has a mechanical valve (fuel pressure regulator) that maintains a certain pressure. Next, the injectors are switched on, opening at the command of the engine control unit for a certain time, which depends on a number of factors.

Air is supplied through the air filter and throttle assembly. The throttle assembly consists of a throttle valve controlled by the gas pedal, as well as an idle speed regulator. The air is supplied directly to the intake manifold and mixed with the fuel sprayed by the injector.

The above-described power system is used on most VAZ engines. The fuel system of the VAZ 2110 8-valve injector is practically no different from the power supply circuit of a 16-valve engine.

Differences in power systems

It is worth noting that the power supply systems for the VAZ-2111 and VAZ-2112 engines are slightly different from the VAZ-21114 and VAZ-21124. The last two do not have a return line through which gasoline returns to the tank. The reason is that the fuel pressure regulator is located in the same module as the fuel pump, in the tank. Therefore, it is possible to control the pressure in the system at an early stage, so to speak. And in this case, there is no need to lay a return line.

In addition, in order to connect various components of the line, the VAZ-21114 and VAZ-21124 engines use clamp-type tips, rather than threaded fittings. There are also differences in the shape and design of the ramp; newer injectors are installed on it. And most importantly, the pressure in the system is slightly higher than on earlier engine models.

Replacing brake pipes on VAZ 2110, VAZ 2111, VAZ 2112

Welcome! Brake pipes - unlike brake hoses, they do not crack over time, because the pipes are made of metal, and besides, they are not so easy to break (We are not talking about brake hoses at all, because they are easier to break and are more susceptible to deformation), that’s why tubes are used in a car, and hoses are only placed at the end, most often this occurs on the front wheels, because the wheels turn when the steering wheel is rotated and if tubes are installed instead of hoses, they will simply burst and you will be left without a braking system.

Note! Why do the tubes change at all? Most often this happens precisely during the replacement of brake hoses, because the tubes burst (namely their tips) and in this case you cannot do without replacement; in order to replace the tubes, you need to take: A set of all kinds of keys , as well as special Be sure to stock up on a brake bleeding wrench, a rubber bulb and everything you need to bleed your car’s brake system!

Summary:

Signs of malfunction of the VAZ-2110 power system

Considering the number of power system components, it is quite difficult to unambiguously determine the cause of the malfunction. But, if you know the main “symptoms” of a breakdown, then the process of finding the cause will speed up many times. So, we list the main signs of failure of power system components:

- The car stalls (does not start). Check the operation of the fuel pump by listening to the sound from under the rear seat (with the ignition on).

- The revolutions “float”. This may be due to a malfunction of the idle air control or fuel pressure regulator in the rail.

- The engine "troits". As a rule, the cause is faulty injectors.

The fuel system of the VAZ 2110 16-valve injector has exactly the same features as the 8-valve injector.

PRINCIPLE OF OPERATION OF THE MAIN ELEMENTS OF A FUEL UNIT

Fuel system VAZ 2114

CONTAINER FOR STORING COMBUSTIBLE MATERIALS

It is made of steel, consists of two firmly welded parts, the neck through which the fuel enters is connected to the tank with a rubber pipe and secured with clamps.

GASOLINE PUMP

This tool with an electric mechanism is located in a tank with a fuel mixture level indicator. Its actions are coordinated by the engine control box, through a special pump relay, which supplies fuel through the line to the injectors. At idle or when the engine is completely turned off, the pressure is maintained due to the action of a one-way lock, which is located near the unit itself.

The VAZ 2114 power system has a fuel pressure regulator and injectors. The voltage is supplied to them from the battery through the main relay. Thus, the amount of driving fluid is indicated by the duration of the pulses, which are generated by the engine control unit and transmitted to the injectors.

RAMP

Located on the intake manifold, it includes a fuel control element and a pressure valve with a spring-loaded diaphragm. It, in turn, divides the regulator body into 2 parts: the fuel part regulates the pressure of the combustible mixture, the air part, due to the rarefaction of the air, raises the membrane and produces constant fuel pressure readings in the rail.

When the engine starts, the vacuum behind the damper decreases, the diaphragm closes the power system valve, so the pressure increases. When the vacuum is maximum, then the fuel pressure decreases. The regulator is not dismountable, so if it fails, it is replaced with another one.

FUEL MIXTURE CONTROL SENSOR

The pump module has a float, which is located in the tank cavity. When the position of the float changes, the resistance of the unit changes proportionally. According to a certain signal, the fuel quantity indicator on the dashboard displays the presence of fuel in the system.

Why does the sensor often fail?

Due to:

- fragility of the case;

- frequent temperature changes;

- condensation formation in the tank;

- when using a low-quality combustible mixture;

- oxidation of contacts when sealing is broken.

That is why it is so important to carry out preventive maintenance on time, clean the unit, change contacts in order to prevent its destruction. Changing a device is not that easy. Many markings are original and unique, which means that the services of professionals will be required, which are also not cheap.

HOSES AND PIPES

Such irreplaceable products guarantee uninterrupted circulation of flammable liquid from the container to the main line and nozzles, and if there is excess, they transfer the residual liquid back to the tank. The pipelines are located on the bottom of the vehicle, they need to be carefully checked, cleaned, inspected for integrity, various deformations identified and promptly eliminated in order to avoid fuel leakage, as well as poor transmission to the injectors.

Another function of the pipelines is the transfer of fuel vapor from the tank to the activated carbon section, where waste is collected when the engine is turned off. After it is started, the electromagnetic device is triggered and the vapors escape into the engine, where they are destroyed.

HIGHWAY

The design of the VAZ 2114 fuel system includes a main line that guarantees the supply of fuel to all injectors. Today, the fuel pressure regulator is placed in the tank and is not located on the line; there is also a service valve, which performs the function of eliminating air after a technical inspection of the vehicle.

The fuel injection system of the VAZ 2114 includes an uninterrupted mode for collecting fuel vapors, and the gravitational unit located in the device helps prevent fuel from leaking when the vehicle is in an emergency position.

When the engine's air consumption is high, the system is purged more intensively. The filter element is made of durable paper material, after which the air moves through the mass air flow sensor and moves into the intake hose, which leads to the throttle assembly.

Thus, the operation of the fuel fluid supply mode of an engine with a fuel injection system on a VAZ 2114 car occurs.

Replacement of fuel pipes VAZ 2112 1.5 16 cells. with your own hands.

To watch online, click on the video ⤵

Replacement of fuel and brake pipes VAZ 2114,2110-12. More details

We carry out the fuel pipe (return) for VAZ 2110 - 2112. Part 2 Read more

How to repair a fuel system pipe? More details

How to replace a gasoline filter with your own hands on a VAZ 2112 1.5 16 cl for dummies. More details

Replacement of fuel pipes (VAZ 2115) More details

Installation of the tank and fuel pipes. More details

replacement of fuel line VAZ 2110 Read more

removing the VAZ 16 valve ramp without removing the manifold Read more

Repair of the connection between the plastic fuel pipe and the fitting Read more

Cleaning and removing injectors VAZ 2110-12 1.5 16kl Read more

replacement of the power system with a newer one, without return, VAZ 2110-12 Read more

THE rarest part on a VAZ 2110. Replacement of the fuel line. More details

Replacing the fuel supply hose and TRW pads are the best in the world)))Part 2 Read more

Replacing the fuel filter on VAZ 2110, 2111 and 2112 injector Read more

Replacing the fuel filter on a VAZ-2112 (10.11.) Opening the old one Read more

Replacing fuel pipes (fuel lines) on an old-style Chevrolet Niva Read more

INJECTOR EXTENSIONS 12MM FOR FUEL RAIL 1.5 16V | REPLACING STEERING POLD SWITCHES FOR VAZ 2110 More details

Replacing brake pipes. Brake tube replacement Read more

Diagnostics and repair of VAZ (LADA) 16v FUEL SYSTEM Read more

Replacing the fuel system of a VAZ 2110

We will talk about the transition from carburetor injection to injection. We will describe this process very briefly.

First of all, the carburetor lines are replaced with injection lines, as well as the gas tank is replaced. Next, the ignition coil, distributor and fuel pump are dismantled. The carburetor is dismantled along with the intake manifold, and in its place the injection manifold is installed along with a ramp and injectors. The next stage involves replacing the generator with a more powerful one, installing an electronic control unit and connecting all wires and sensors.

But everything is not so simple - in addition to all of the above, you will have to replace many more related parts (throttle cable, ignition module, sensors, air filter, etc.). For a deeper understanding of the replacement process, use a variety of photos and videos of repairs that can always be found on the Internet.

PRINCIPLE OF OPERATION OF THE SYSTEM

The fuel system of the VAZ 2114, in comparison with foreign cars, is made quite simply, thanks to which a high level of its reliability and endurance has been achieved. The 2114 has an injector for injecting gasoline into the combustion chambers. The presence of an injector provides for a complex fuel dosing system, for which the ECU controller (electronic control unit) is responsible.

The VAZ 2114 fuel pump is driven electronically. The injection moment itself is calculated thanks to sensors that determine the location of the car’s crankshaft. When the fuel pump is turned on, the fuel is supplied through the transport system to the filters, where it is cleaned of impurities, and after the filters - to the fuel rail.

The fuel rail is the part of the intake manifold in which gasoline and gas are mixed in a ratio of 1 to 15 (an increase or decrease in the amount of gas can be adjusted manually, but the optimal gasoline consumption is observed precisely at the above ratio). Next, the mixture is supplied to the injectors, after which it enters the combustion chambers.