VAZ engines have two, slightly different modifications of the torsional vibration damper and crankshaft hubs, in other words, the pulley. On a VAZ 2110, the crankshaft pulley can be made as a block, or also have a separate system with a hub - a damper.

Cast iron crankshaft pulley

When the production of the “ten” had just begun, the crankshaft vibration damper was a single unit, and was secured with only one central bolt. Along with the injection VAZ 2110, a damper appeared. It is bolted to the hub.

Crankshaft damper pulley

Crankshaft damper pulley

Crankshaft damper pulley

Crankshaft damper pulley

Purpose

The crankshaft pulley serves to transmit rotation from the crankshaft to such important vehicle components as the generator, power steering and air conditioning. In addition to this function, in the injection engine there are special teeth on the damper-type pulley, which are read by the crankshaft sensor.

This is one of the most important indicators for the electronic motor control system, which is responsible for the correct operation of the entire unit.

If it fails (beating and deformation, cracks and tears), the VAZ crankshaft pulley will most likely need to be replaced. This part of the car can be repaired, but in very rare cases (if minor defects are detected).

It is not necessary to go to a specialized car workshop; if you have free time and skillful hands, you can do the replacement yourself, which will not only save money, but also increase your self-esteem.

Lada 2109 › Logbook › 17. Replacing the damper pulley and crankshaft gear

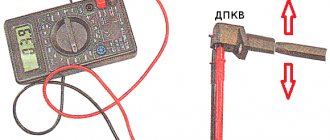

Let me briefly remind you of what I wrote in the last entry. It's been 2 days since I replaced the timing belt and the car refused to drive at speeds above 2000 rpm. More precisely, it drove, but when the revolutions rose above 2000, it began to twitch and did not drive at all. The bortovik showed an error - incorrect DPKV signal. On the side of the road, I checked the DPKV chip and wires (at one time they were blowing my mind!) I realized that something was wrong here and decided to leave it as is until the morning. In the morning I decided to check my favorite sore! Crankshaft gear pin! And how he looked into the water! Once again it was torn off. More precisely, it broke halfway, but due to the fact that I also drove a self-tapping screw there, to be sure, the damper pulley did not turn due to this.

Preparatory work

Before removing the crankshaft pulley, you need to prepare the necessary tool and perform preliminary procedures. In your work you will need the following tools:

- overlay key 19;

- pipe section;

- special pulley puller or pry bar.

Place a support under the front wheels, remove the connector from the ignition coil and set the gear shift lever to neutral. Unscrew the tension bolt of the generator by 3-3.5 cm, loosen the fastening bolts to allow it to move freely and remove the belt. After this, you can remove the crankshaft pulley 2110.

Reverse actions

After removing the pulley, you can carefully examine it and put it aside for garage scrap metal. Take the new part in your hands and lubricate the key seat well with grease. Slightly tilting the key towards the hub, we slowly push the pulley onto the shaft. For this purpose, you should have a hammer in one hand, and in the other a piece of soft rubber, which is placed between the hammer and the body and prevents the hammer from damaging the crankshaft pulley.

Once the hub is in place, you need to tighten the fixing bolt. This must be done without any tricks: a wrench and a pipe will help tighten this bolt until it stops. To avoid turning the crankshaft when you begin to apply significant force to tighten the bolt, you need to lock it using a metal pin (large screwdriver), inserting the latter between the teeth of the flywheel ring. To do this, you need to open the clutch housing ventilation plug.

It is not recommended to tighten the bolt to the limit; you may miscalculate the effort and break it, and this is almost a disaster. To do this job correctly, you will need a torque wrench. As soon as the sensor shows a tightening torque of 400 N/meter, no further force is allowed.

After this, put the belt on the crankshaft pulley and tighten it using the tension bolt on the generator. Don't forget to tighten the generator mounting bolts and reconnect the connector on the ignition coil.

If you followed everything described above, then you now not only know how to remove the crankshaft pulley, but also know how to do it yourself.

Unscrew the locking bolt

The only bolt that secures the pulley to the crankshaft is not so easy to unscrew. The threads of this bolt coincide with the direction of rotation of the crankshaft, so if you do not have a pneumatic impact wrench, you will have to cope with this task with some trickery.

The crankshaft pulley bolt can be easily unscrewed using a spanner, a piece of pipe and your car's starter. We put a 19mm head on the bolt, and using a pipe we extend the handle of the key to the surface, and in such a way that it rests on the floor on the side opposite to the direction of rotation.

After that, we get behind the wheel, ask the nervous neighbors in the garage to leave and start the car with a quick movement of the key. The starter should not turn for more than a split second. After making five or six such attempts, you will be able to unscrew the “stuck” bolt without making titanic efforts. Be prepared to be accused of wasting the starter's resource, damaging your property, etc.

Yes, this method is not used in service centers, but there are witnesses to its effective implementation. Nothing was spoiled by this, except the mood of those who opposed this method of unscrewing bolts.

Which way does this damn pulley unscrew?

I'm trying to unscrew the pulley, this task is in my opinion not feasible. In which direction does this slope unscrew? And how can I actually unscrew it? I’ve already built such shoulders, but he doesn’t move.

What pulley? If on the heads and in general try with a pneumatic impact wrench, it should work

In my opinion there is an ordinary carving. those. twist clockwise. turn on the first one, press the brake, and let someone turn it. or better, of course, with a pistol.

Crankshaft The engine is lying in the corridor, the brake will not work (

Insert something into the flywheel between the teeth and the housing (a large screwdriver or a mounting tool) and unscrew the regular thread there

there was no flywheel, I had to remove the pan and block the connecting rod%) (I removed it somehow, the exhaust manifold helped me with this, serving as a super shoulder. The last task remained, how to separate the block, unscrew everything, but apparently the sealant holds it tightly. Tomorrow I’ll try to jack it up.

check all the bolts again.. the half-blocks don’t stick so much that you can halve them with a jack =)

Here's the deal, turn the starter a little, first putting the head with a ratchet or other crap on the pulley nut, but so that it rests somewhere.

But I wonder, before halving, did you remove the piston?[/code]

It happens that when replacing the timing belt, too much thread glue is applied to the bolt that the pulley is tightened. Only a heating pad (gas burner) helps. It takes a long time to heat, half an hour. Unscrews counterclockwise.

The piston does not need to be removed. the block splits in half and so, I drove a wide screwdriver between the half-blocks. If you forgot to unscrew something somewhere, it won’t come apart completely. you halve the block, untwist the yoke (that’s what it’s called) of the 1st and 3rd cylinders, then everything will collapse, because the pistons will no longer interfere. Just clearly mark what you unscrew from the connecting rods, and where is the top, where is the bottom, each connecting rod is individual, it seems, i.e. You can’t put it from 1st to 3rd and it’s also better not to confuse top and bottom. everything is just done there. But in general, everything can be found in a search, even with a photo you can find it.

I’ll add that the r/shaft pulleys are easier to twist when the belt is still standing, I haven’t found an easier way. you block the c/shaft pulley (by this very bolt) and twist the c/shaft bolts (I took a pipe about one and a half meters to help, it could have been smaller, of course, but it wasn’t possible) when I tightened it in this way, it flew by a tooth, I had to catch all the marks again.

Fuck you are gesturing))) You disassemble the engine with a jack and muffler))))

We press the button, holding circles in our hands

People, thank you all for your advice! The very last frontier remains. Remove the pins from the connecting rod through the access hole. In the manual they write about a special device for this, what can this device be replaced with? I unscrewed the holes themselves, removed the retaining ring, all that remains is to pick out the finger

Exactly, I heated that pulley normally and then somehow with a lever of almost 1.5 meters and a ratchet it burned with a bang

This is how fables like this are born: in order to change spark plugs, you need to remove the engine. I wonder how it will end. There's still popcorn. on topic: is there a book?

A person who understands cars will spend no more than 20 minutes on fastenings. But if the driver does not have experience, difficulties may arise that cannot always be overcome. The machine repair manual contains a lot of useful information. But even this cannot always help when unscrewing a pulley.

Pulley removal

A special key confidently holds the pulley hub on the shaft even with the bolt removed. A special puller allows you to perform this operation quickly with minimal effort. If you don't have it, you'll have to tinker a little longer. First, treat the interface between the pulley and shaft with a special liquid (like WD-40).

After this, you need to wait a little for the liquid to do its job. Using a pry bar, pry the crankshaft pulley around the circumference and swing it in the direction away from the engine. The procedure is long and tedious. The main task is not so much to remove the pulley hub as to avoid damaging the keyway.

Reverse motion can significantly complicate the dismantling process

But it also happens that the engine works, as they say, “in the other direction.”

We are talking about the fact that the motors are installed with belts to the right. So, they will spin in the opposite direction, that is, counterclockwise. This difference may seem insignificant, but it greatly complicates the search for an answer to the question of how to unscrew the crankshaft pulley.

Moreover, such a procedure may be required every hundred thousand kilometers. We are talking about the need to replace the timing belt. And this does not apply to emergency situations, such as replacing the oil seal or other repair work.

For example, a seventeen bolt can be tightened to a torque of up to one hundred and eighty-five Nm, which can be considered simply a huge indicator.

And to unscrew it you will need even more force. The second method described above will not work, since the starter will spin the motor in the other direction, only tightening the bolt more . Pressing the brake pedal will lead to a similar result, since the transmission will spring back, but the bolt itself will remain in place.

Some modifications of the car may have a window opposite the flywheel crown, through which many try to stop the system using a mounting tool or a regular crowbar with a thin tip. But this risks causing you to turn the crankcase or be very seriously injured.

In the pulley itself there is a special cutout for a proprietary hexagonal key. But such keys are quite expensive, since they need to be ordered, and not just purchased on the market.

After this, you can begin further work, for example, replacing the timing belt

More information about replacing belts for Lifan car models:

- Replacing the timing belt on Lifan Solano

- Replacing the timing belt on Lifan Smiley

- Replacing the timing belt on Lifan Breeze

- and the Lifan X60 does not have a timing belt, there is a chain!

Purpose, design and replacement of the VAZ 2110 crankshaft pulley

VAZ engines have two, slightly different modifications of the torsional vibration damper and crankshaft hubs, in other words, the pulley. On a VAZ 2110, the crankshaft pulley can be made as a block, or also have a separate system with a hub - a damper.

When the production of the “ten” had just begun, the crankshaft vibration damper was a single unit, and was secured with only one central bolt. Along with the injection VAZ 2110, a damper appeared. It is bolted to the hub.

Possible faults

Removal and, if necessary, replacement of the pulley may be required in the following cases:

- If the hub has turned. It must be said that most often this happens due to previous inept repairs. The fact is that the VAZ 2110 has a fixing sleeve in the seat for the damper, pressed into the gear. It tends to fall out of the gear, causing the hub to rotate;

- Oil leaked from under the front crankshaft oil seal;

- The lightweight crankshaft began to resonate strongly;

- The old-style pulley or damper is loose;

- The damper seat broke. In case of such a breakdown, a replacement is needed, preferably together with the crankshaft gear;

- If it is necessary to remove the crankshaft - for repairs, replacement of liners, half rings, converting it into a lightweight one, etc.

Removing the damper

On a VAZ 2110, the damper is removed in the following sequence:

- Disconnect the ground from the battery;

- Remove the radiator fan and fluid coupling;

- After loosening the bolts securing the fan pulley, remove the belt;

- It is advisable to remove the radiator, but if it does not interfere, you can leave it, protecting it from damage from the engine compartment with a sheet of plywood or cardboard;

- Remove the pulley from the radiator fan;

- We gain access to the damper, unscrew the bolts, dismantle it;

- When removing the hub, you need to secure it from turning (for which there is a special tool).

Next we proceed depending on the purpose of the analysis. If you only need to replace the damper, we do it and assemble everything in the reverse order.

You should know that replacing the liners on a VAZ 2110 can be done either with or without removing the crankshaft. But this requires a special device, and besides, it is better to entrust such work to an experienced mechanic - a mechanic.

If the crankshaft was dismantled to replace the liners or half rings, then we continue:

8. Remove the lightweight or regular crankshaft; 9. We remove the half rings; 10. We evaluate the condition of the liners, and if they do not need replacement yet, then be sure to remove them and mark each of them; 11. But, unfortunately, no matter how carefully the owner treats his VAZ 2110, sooner or later the time for physical wear comes for the liners - they need replacement.

- Four repair kits of inserts are produced for the VAZ 2110. You need to buy them only as a set, and only in a strict sequence of sizes. Sometimes, however, situations are possible when you have to purchase them “through size”;

- thus, the crankshaft only lasts for four (and sometimes even three) overhauls;

- replacement of liners cannot occur without grinding the crankshaft. The only exception is if it is replaced with a new one. At the same time, an experienced craftsman can turn the crankshaft into a lightweight one.

Dismantling and replacement

Regardless of the design, where the part is located, it is important to remove and install it in the same order. Depending on the location of the motor, the part is located in the front part behind the cooling radiator. But if the motor is placed across the engine compartment, then your hand will not reach the part. Because to remove the crankshaft pulley, you need to remove the right wheel. If it is difficult to change, it makes sense to pay attention to the drawing, the work will speed up.

The vehicle is rolled onto the inspection hole and secured so that the car does not move from its place. To get there and remove the structure, you need to unscrew all the parts that impede access (air filter, mud flaps, etc.). Remove the generator belt. Next, open the clutch block plug and insert a pry bar into the hole to lock the flywheel.

The elements of the part are characterized by strong fixation, so they are not easy to remove. To turn a part, it is necessary to make a lot of effort. If dismantling is performed for the first time, it will be difficult to unscrew the crankshaft pulley. The reason is that factory production is characterized by strong tightening of the component parts.

Important! The right screw pattern means that the unscrewing process occurs counterclockwise. The car part spins in the other direction, so if it has oxidized, it is not so easy to disassemble it; it is useful to use additional means.

How to unscrew the crankshaft pulley nut

When turning fasteners, it is important to follow the recommendations, then the process will take at least 15 minutes. The effort should be applied as close to the camshaft as possible:

- use a pry bar to pry it up from all sides;

- If necessary, use a special universal crankshaft pulley puller for this part.

The device is presented in the form of a hairpin with 2-3 grips. The end of the gripper is secured to the edges of the part, and the end of the pin is placed in the middle of the shaft.

Scroll clockwise. But not all brands of cars turn clockwise; in some cars, the work must be done in the opposite direction. In this case, it is important to put your gear lever in 4th speed and turn on the handbrake.

If you can’t turn it, the lever should be in the neutral position. The next step is to remove the candlesticks. The key is placed on the floor or on the rear side member and turned in the direction of movement of the device.

All maneuvers make it easier to scroll, so further actions must be performed manually; if necessary, lubricate with brake fluid or WD grease. In addition, tapping the edges of the head can make your work easier.

How to remove the crankshaft pulley bolt

To do the job efficiently, the disassembled machine is placed on a stump. The pin holds the part together and is usually found in front-wheel drive automatic cars. The thread is designed in such a way that it is tightened during the torque when moving.

It is necessary to perform actions that open access to the base. To do this, it is important to stop the rotation well. A mount is used as a fixation. The tool is inserted into the flywheel gears. It must be adjusted securely so that it does not fall out during the turning process. Therefore, it is better to do the work with an assistant. Next, put a socket head of the same diameter as the pin onto the pin, attach a lever and an extension (a piece of durable pipe). After this they begin to slowly unscrew it.

Important! The longer the extension, the easier it is to unwind.

People's automobile experience

The difficulty of dismantling lies in the specially selected strong connection, without play. The fasteners are tightly screwed. They practice using a pry bar, while slowly pressing on the back surface of the part.

We recommend: How to replace and remove the fuel pump on a Lada Kalina with your own hands?

When purchasing a part, you must have new fasteners. You will need a front oil seal and suspension belts. When purchasing, you need to pay attention to the grooves and marks. They must be free of defects. Otherwise, after a while you need to replace everything with a new one.

Important! When performing work, you need to pay attention to the crankcase ventilation system. If contaminated, under the influence of excess pressure, the oil seal will leak lubricant. When screwing, you need patience and, as a rule, you can achieve results after 3-4 attempts.

Installing the pulley on the crankshaft

To properly install the crankshaft pulley, it is necessary to lubricate it with grease or other viscous agent. This will make the fastener installation process easier. To put it on, tilt the washer slightly to the side and pull it onto the base. Next, you can use a tapping motion with a hammer to process the hub through a soft rubber gasket. Then, in the reverse order, you need to tighten the other parts of the car.

Important! If you do not fit it tightly into the groove, then everything will hang out, so you will need to replace it with a new one soon.

How to unscrew and remove the crankshaft pulley of a VAZ 2110

From the very first release in June 1995, the VAZ 2110, or “ten” in common parlance, won the love of middle-class people. This model was produced for 12 years. Not difficult to maintain and easy to break down, as well as replacing some parts is easy to do yourself, without resorting to the services of a car service. This will save not only time, because the wait for the service center to take on the car can vary depending on the workload of the technicians, but also money. Engine VAZ 2110 8-valve injector, volume – 1.5 liters, front-wheel drive, M5 gearbox. Engine power 56 kW, torque 118 Nm. A huge plus is low fuel consumption.

The maximum speed is 170 kilometers per hour, while acceleration is 14 seconds. Very well suited for urban heavy traffic. Starts even at -25 degrees below zero. The chassis is made of high quality, excellent for holes and potholes. The suspension is strong. Power steering can be installed, but to order. The components are not expensive, even original ones can be purchased by a middle-class car enthusiast.

The interior is not very roomy, but it has a trunk capacity of 450 liters. The rear backrest reclines, the middle one reclines completely, and the side ones have a smaller deviation. Long loads can be easily transported. An internal combustion engine equipped with a belt drive, sensors and an electrical engine control unit control the operation of the systems. The most common breakdown for VAZ 2110 8 valves is engine friction.

- Poor quality fuel; as a result, one of the fuel system parts became clogged. In this case, you will have to study the fuel supply circuit and fix the problem. Doing this on your own is difficult and can take a lot of time. In this case, it is better to contact a car service.

- Damage to spark plugs and wires. You need to visually inspect everything and check the fragments with a tester.

- Malfunction of the electronic control unit and sensors. Home renovation enthusiasts cannot solve this problem. You will have to turn to craftsmen who have experience and special equipment.

VAZ 2110 8 valve injector has high technical characteristics. But, like all cars, over time some parts tend to wear out. The main breakdowns that car enthusiasts can fix themselves are replacing the Kalevala pulley of the VAZ 2110 8 valves. The gear or pulley of the VAZ 2110 crankshaft is one of the most frequently replaced parts. Their good service life is on average 3 years. Car owners will not find it difficult to replace it themselves as the process is simple. Having understood how to change the crankshaft gear, the driver will gain experience in repair work in the manual drive system of the gas distribution mechanism, but will also be able to further adjust the valve or make modifications.

Replacing the generator drive pulley on front-wheel drive VAZ and Lada cars

The generator drive pulley changes in the same way on cars of the “tenth series” (VAZ 2110, 2111 and 2112), the “Samara” series (VAZ 2113, 2114 and 2115), as well as the “new” models of Lada Kalina, Priora and Grant.

The generator drive pulley is located on the “toe” of the engine crankshaft on the side of the first cylinder (right wheel) and drives the generator and, if equipped, air conditioning and power steering using a belt.

The main reasons for replacing a pulley are damage to the ring gear or delamination of the pulley itself.

Damage to the ring gear leads to unstable operation of the motor. If the teeth are broken, the car may not start because the crankshaft sensor (CSS) cannot determine the top dead center (TDC) for the ignition count.

Delamination occurs on damper pulleys (not cast iron). The fact is that on these pulleys the outer part is attached to the central part through a rubber spacer. It acts as a vibration damper (anti-resonance) on the engine crankshaft. It happens that the outer race rotates a little. Then the toothed pulley moves relative to the dead center and, as a result, the car becomes “sluggish” during acceleration, and the idle speed becomes unstable. If the pulley is too misaligned, the car cannot be started. Also, the car will not start with the upper race completely peeled off from the central part of the pulley.

Such damage is easily diagnosed by the lack of rotation of the alternator belt.

In rare cases, the seat key on the shaft breaks, and the pulley begins to vibrate and rotate. If the movements are small, then the ECU does not display an error on the instrument panel, but at the same time the engine at idle is unstable and “troits.”

Checking the condition of the pulley is quite easy. To do this, you need to inspect the condition of the ring gear for chips and cracks. The ring gear is located on the outer race closer to the engine (indicated by an arrow) and is clearly visible from above:

After this, you need to set the first cylinder to TDC. To do this, in an 8-valve engine, remove the rubber plug on the gearbox and ensure that the mark on the flywheel aligns with the slot on the plate:

Purpose and role of the crankshaft pulley

Purpose and role of the crankshaft pulley

Each drive of this car brand has 2 types of pulley:

- Block type.

- With a disconnected system with a bushing - a damper (acts as a shock absorber under heavy loads on the crankshaft).

At the very beginning of VAZ production, the pulley was one-piece and was fastened with one bolt. But with the advent of the injector, a damper was also mounted on the hub.

What's stopping you from removing the mechanism?

So, diagnostics showed that the crankshaft pulley needs to be replaced. In any book on car repair, this procedure is described very briefly, which makes you think about the simplicity of the operation. However, it is not.

The process is complicated by the inconvenient location of this pulley under the hood of the car. The mechanism is hidden behind the generator. Access to it is severely limited. Pulleys can be damper or conventional - the former are equipped with an outer ring to dampen vibrations. In order to gain access to the pulley mounting, loosen the belt tension bolts on the accessory drives. When dismantling, care must be taken with regard to the application of force. It is important not to break the elements that surround the pulley.

When installing a pulley at the factory, it is clamped with a bolt or nut with great force to ensure reliable fastening. During operation of the internal combustion engine, the right-hand thread on the crankshaft and, accordingly, the nut or bolt of the pulley further strengthens the clamping. High temperatures, environment, time - all this accelerates the destruction process. It is also worth adding oil exposure and corrosion. It can be quite difficult to unscrew the crankshaft pulley nut without knowing special techniques.

If you disengage the clutch, you can easily turn the crankshaft with a key. Therefore, before trying to unscrew the nut, you need to securely fix the pulley - this will prevent rotation while unscrewing the nut. The service station has special devices for this - the element is screwed into the technological holes and a stop is formed against turning.

If there are no devices, then the problem is solved by reliable wheel chocks and engaging fourth gear at the gearbox. You can also secure the flywheel with a large screwdriver or pry bar.

How to remove the damper

- It is necessary to disconnect the wire that connects the negative terminal of the electrical element to the body of the product from the battery.

- Remove the fan and coupling.

- Lightly undermine the choke pulley rod and remove the belt.

- Carefully, so as not to damage the heat exchanger, remove the gear from the fan.

- The approach to the damper opens. Then tighten the bolts slightly and remove it.

- When the hub is removed, it must be secured against rotation.

All engines consist of several systems and operate using a source of mechanized energy - the crankshaft. Some part of the tacking moment is redirected from it and driven into action by the shafts, generator, pump, etc.

The crankshaft pulley 2110 is one of the engine parts of the gas distribution mechanism and additional components. Located in the front half of the crankshaft.

• Monitors angular velocity and shaft position. • Reduces noise. • Reduces the swing of the crankshaft.

The pulley is one of the most important parts of a typical engine.

What problems might you encounter?

There is a possibility that you may not immediately notice the characteristic disc part under the hood of your car. It may also be difficult to access. It will be difficult to fix the shaft. Over a long period of time, the joints of fasteners will “stick” and you will have to use special liquids.

To perform all the necessary steps step by step, you will need the following tools:

- impact wrench;

- puller set;

- jack;

- a set of wrenches or other tools for removing bolts;

- presence of an inspection hole.

Reason for changing the crankshaft pulley

The crankshaft pulley of the VAZ 2110 is a reliable car part, but it can become faulty.

If you observe at least one item with the ones listed below, it’s time to change it:

- If oil leaks from the shaft.

- Feeling of increasing resonance.

- A crack in the damper seat (mechanism for reducing or preventing vibrations). Needs replacement along with the crankshaft gear.

- Hub rotation.

- If the crankshaft is removed for any repair work.

Tools for work

In the case of a manual gearbox, the crankshaft pulley bolt can be unscrewed using a spanner or socket. It's better to take a regular wrench. In most cases, the ratchet cannot withstand such a load (even if it is the strongest) and as a result falls apart. It is not recommended to use an open-end or gas wrench when dismantling the crankshaft pulley.

The first tool may break, but the second will only damage the edges of the bolt, and next time it will be even more difficult to unscrew it. In case of severe damage to the edges, it will have to be drilled out and removed in parts, which will be unpleasant for the car owner. This will increase the time it takes to replace the element.

Source

How to unscrew the crankshaft pulley of a VAZ 2110

For a good overview and access to the car pulley, it is best to use an inspection hole or overpass. It would be a good idea to take an assistant because it is difficult to cope with some processes alone.

If there is no inspection hole, lift the car using a jack and you can begin dismantling, which consists of the following steps:

- To avoid breaking the bolt while unscrewing it, you need to treat it with some means (for example, WD-40) for better scrolling, since it can become rusty under the influence of temperature and other factors. As a result, it is very difficult to twist.

- Unscrew the bolt and carefully remove the right wheel, since the engine is located transversely, you will have to remove it to access the pulley.

- Remove the air filter present there.

- Unscrew the screws and remove the shield to protect the engine from dirt. [BR]• Remove the alternator belt, as well as all mechanisms that complicate access.

- Open the plug on the clutch box and insert a pry bar into the opened space to jam the gear teeth.

- Place a wrench with an extension on the bolt and turn it. Carefully remove using a special puller.

- We mount the new one, making sure that the notch on the pulley coincides with the tooth.

Often, beginners, when repairing their car on their own, are faced with not knowing how to remove the crankshaft gear.

The crankshaft gear is a part that powers the mechanisms in the drive. It has the shape of a gear with teeth; a chain or belt can be put on them. Typically, timing gears and oil pump drives are attached to the crankshaft. The gears are placed with a tight fit and secured with a connecting rod with threaded fasteners.

Reasons for replacement

The crankshaft pulley is located on the right side of the engine compartment and is best accessed from below

Before proceeding directly to the process, it is necessary to consider the main reasons why it may be necessary to dismantle this part. In fact, everything is much simpler than it seems. So, let's look at the main reasons for dismantling:

- Major repairs will require removal of the pulley.

- Wear of the product (wear or broken teeth).

- Some repair operations will require dismantling the pulley ( setting valve timing , etc.).

Should we unscrew the crankshaft pulley?

So, when the reasons are considered, let's proceed directly to the process itself. It is worth noting that this operation cannot be completed alone, so you need to ask for help, in other words, you will need an assistant . Let's consider the immediate sequence of actions for removing the crankshaft pulley:

- We place the car on a pit or overpass.

- We dismantle the front right wheel. The car must be well secured in this position, since when unscrewed it may fall off the jack. Therefore, you need to install a stump under the threshold, and anti-roll bars under the rear wheels; you can use the removed wheel.

Car after wheel removal

Remove the plastic fender liner by unscrewing the 5 fastening screws

Generator drive circuit

We insert a crowbar into the flywheel so that it does not rotate when the nut is unscrewed

It is worth noting that the cutout on the crankshaft pulley, during installation, must coincide with the protrusion on the crankshaft itself.