In the practice of motorists, there are situations when you need to go somewhere, but the engine cannot be started because the starter is not working.

The reasons why the starter does not operate after turning on the ignition switch can be divided into two categories. Violation of the electrical wiring circuit and direct breakdown of the starter itself.

Before starting the test, you can check the starter by shorting the starter terminal with the positive voltage supply terminal (the presence of “+” can be determined using a tester or test light). Short circuit the circuit using a screwdriver, pry bar, etc. If the starter cranks normally, then there is a problem in the electrical circuit; if there is no result, the problem is with the starter itself.

Important! Before starting the test, make sure that the car is in neutral gear, the handbrake is on, and it is advisable to place wheel chocks under the wheels.

Malfunctions of the electrical circuit, starter power supply:

- The tips of the wires suitable for the battery terminals are loose or oxidized. In this case, the tips are removed from the battery and cleaned using a metal brush and sandpaper. After this, they are put in place and tightly tightened using clamping bolts.

- The battery is low or defective. Using a load plug, check the battery charge level. If necessary, recharge using a charger. Replace the faulty battery. It is also worth checking the density of the electrolyte, since with a low density of the solution (especially in the cold season), the battery quickly discharges.

- The nut at the voltage supply terminal to the starter is not tightened. This problem arises from the effect of vibration on the car, its solution is to tighten all the nuts using wrenches.

- The contact group of the ignition switch has failed. Using the electrical diagram, determine the contact to which voltage is supplied. Clean the terminal and tighten the fastening bolt. If it didn’t work, then connect this connector directly, with a separate wire, to the battery. If the starter spins, it means the contact group has failed. It is better to replace the ignition switch.

- The contact protection relay is faulty (additional starter relay). The supply of electricity to the traction relay occurs from the supply of voltage from the ignition switch through the starter relay. To check this relay, you can bridge the wires suitable for the starter relay (thickest in diameter). The starter is working, so remove and clean the contacts. If this does not happen, replace the relay.

- The starter “ground” is broken or poorly secured. Correct the violation of the electrical circuit, the engine with the “ground” of the car body. By securing or tightly tightening the bolt securing the ground wire.

- The fuse has blown. Check fuses and replace if necessary.

We recommend:

Replacing the fuel pump for a VAZ 2114 - step-by-step instructions

If the above check does not produce results, the starter must be removed from the car for further diagnostics. To do this, first of all, you should find out the principle of operation and what parts this part of the car consists of.

The VAZ 2114 starter does not turn - the main reasons

In the practice of motorists, there are situations when you need to go somewhere, but the engine cannot be started because the starter is not working.

The reasons why the starter does not operate after turning on the ignition switch can be divided into two categories. Violation of the electrical wiring circuit and direct breakdown of the starter itself.

Before starting the test, you can check the starter by shorting the starter terminal with the positive voltage supply terminal (the presence of “+” can be determined using a tester or test light). Short circuit the circuit using a screwdriver, pry bar, etc. If the starter cranks normally, then there is a problem in the electrical circuit; if there is no result, the problem is with the starter itself.

Important! Before starting the test, make sure that the car is in neutral gear, the handbrake is on, and it is advisable to place wheel chocks under the wheels.

Malfunctions of the electrical circuit, starter power supply:

- The tips of the wires suitable for the battery terminals are loose or oxidized. In this case, the tips are removed from the battery and cleaned using a metal brush and sandpaper. After this, they are put in place and tightly tightened using clamping bolts.

- The battery is low or defective. Using a load plug, check the battery charge level. If necessary, recharge using a charger. Replace the faulty battery. It is also worth checking the density of the electrolyte, since with a low density of the solution (especially in the cold season), the battery quickly discharges.

- The nut at the voltage supply terminal to the starter is not tightened. This problem arises from the effect of vibration on the car, its solution is to tighten all the nuts using wrenches.

- The contact group of the ignition switch has failed. Using the electrical diagram, determine the contact to which voltage is supplied. Clean the terminal and tighten the fastening bolt. If it didn’t work, then connect this connector directly, with a separate wire, to the battery. If the starter spins, it means the contact group has failed. It is better to replace the ignition switch.

- The contact protection relay is faulty (additional starter relay). The supply of electricity to the traction relay occurs from the supply of voltage from the ignition switch through the starter relay. To check this relay, you can bridge the wires suitable for the starter relay (thickest in diameter). The starter is working, so remove and clean the contacts. If this does not happen, replace the relay.

- The starter “ground” is broken or poorly secured. Correct the violation of the electrical circuit, the engine with the “ground” of the car body. By securing or tightly tightening the bolt securing the ground wire.

- The fuse has blown. Check fuses and replace if necessary.

If the above check does not produce results, the starter must be removed from the car for further diagnostics. To do this, first of all, you should find out the principle of operation and what parts this part of the car consists of.

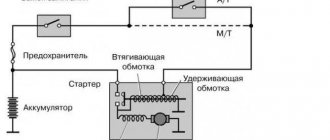

Signal diagram

Before you start talking about finding and fixing this malfunction, you should first talk about the electrical circuit of the signal (after all, without knowing it, it will be difficult to carry out repair work).

It is immediately worth noting that the electrical circuit of the sound signal is quite simple and includes:

- switch mounted on the steering column;

- fuse;

- electrical relay;

- sound signal device;

- connecting wires.

You can study the circuit diagram of the device in more detail using the following drawing:

Briefly about the device and principle of operation

The starter itself is a power electric motor operating from constant voltage. Additionally equipped with a retractor relay, an overrunning clutch and a bendix (a gear with which the starter directly engages with the flywheel).

When the starter is turned on using the ignition switch, voltage is supplied to the solenoid relay (the relay, by its operating principle, is an electromagnet). An electromagnetic field is generated due to the coil built into the relay. Under the influence of which the connecting fork moves the bendix along the rotor shaft of the electric motor and engages it with the flywheel. At this time, the armature enters the relay, closing the contacts, which turns on the electric motor itself. Which starts to rotate the flywheel through the bendix.

After starting the engine, the rotation speed of the flywheel is several times higher than the rotation speed of the bendix. It turns out that it is not the starter that turns the flywheel, but vice versa. To prevent damage to the electric motor, the overrunning clutch is activated. The gear begins to spin together with the flywheel in a “free” motion, without turning the starter shaft. This continues until the power supply through the ignition switch is stopped.

Source

What is it like - a VAZ 2114 starter?

If you decide to independently repair this small but very important part, first of all you need to familiarize yourself with its structure and operating principle. Regardless of the make and model of the car, the starter has the same design and performs the same function, only the dimensions differ.

Essentially it is an electric motor. Its stationary part is the stator, in the housing of which there are 4 magnets that act as poles, and a movable armature. And after the ignition is turned on, another important part - the retractor relay - gives the corresponding signal, and the armature begins to rotate, constantly accelerating. Bendix ensures the engine flywheel meshes.

The rated power of the starter is 1.55 kW, and the current strength depends on a number of indicators. For example, during idling it is only 80 A, under normal loads it is about 150 A. If you increase the power to the maximum, the current will reach 350 A. During frosty periods, the starter will be in an inhibited state, and the current will be 500 and even 700 A. Home The task is to create torque. It drives the crankshaft until the combustible mixture ignites. Naturally, at this time the part experiences enormous loads, and one fine day the VAZ 2114 starter no longer turns on.

To extend the life of the starter, it is necessary to operate the car correctly. When starting, you cannot hold the key for more than 15 seconds, and if the first attempt fails, you can repeat it only after 30 seconds.

How to eliminate the causes of problems starting the car engine

Buying a new starter is not always justified. The old unit can serve for a long time. It is enough to carry out qualified diagnostics and replace faulty internal parts: bushings, brushes.

If it is not possible to deliver a faulty car to a service station, then it is necessary to remove the faulty part and take it to a mechanic. Only qualified diagnostics using special equipment can identify the exact fault. Repairing internal parts is much cheaper than buying a new part.

Usually repairs do not take much time. It all depends on the workload of the repairman and the availability of the necessary spare parts. It is better to contact a service that specializes in repairing electrical equipment for cars. If circumstances are favorable, you will be able to get behind the wheel of your car the very next day.

Malfunctions and their causes - diagnostics without a service station

Now let's talk about possible malfunctions of the VAZ 2114 starter, and also discuss their causes and symptoms.

The retractor relay does not work and the armature does not turn. There may be several reasons for the malfunction. The most common is oxidation of the wiring. In addition, a discharged battery or its failure can also contribute to such a turn of events. Look at the condition of the coil of the solenoid relay; it is quite possible that a short circuit has occurred between its turns. And by checking the contact between the ignition switch and plug “50” of the electric motor, you will find out whether there is a break in the electrical wiring, which also contributes to the occurrence of such a malfunction. Another reason could be the failure of the anchor itself.

The solenoid relay works, but the armature does not turn. This turn of events may result from a malfunction or low battery charge. Also in this case, check all connections on the starter itself, the battery and the solenoid relay. Oxidized and loose bolted joints result in poor contact. As a result, not only does the starter itself not work, but there is also a high probability of a short circuit and even burning of the wiring. Another reason for this malfunction may be wear of the brushes and short circuit of the armature winding.

Checking the battery charge

If the flywheel stops turning, but the starter turns on as expected, then, most likely, the bendix or starter gears have failed. You should be alert to extraneous noise and increased vibration that occurs during startup. First of all, check the fastening of the part; it is quite possible that the bolted connections have loosened, or it was fixed askew during the last maintenance. Noise can be caused by damaged bearing shells or mechanical damage to the housing cover. A characteristic sound also appears after wear of the gears of the gearbox, crown or flywheel drive. And a bendix that does not disengage will lead to noise.

Replacement of components and other repair features

Identifying the fault is very important, but now you need to take care of high-quality repair of the VAZ 2114 starter. Of course, you can go to a company service center, where specialists will diagnose and fix all the problems, but this will cost a pretty penny. However, the peculiarity of the domestic automobile industry is that in most cases it is possible to carry out such work independently.

For all the failed elements - gears, bearings, cracked cover, gearbox, bendix, brushes and commutator - the best cure is replacement. If the mechanism does not turn due to insufficient battery charge, then you should restore it or replace the battery with a new one. The VAZ 2114 starter sometimes does not work due to a short circuit in the winding of the traction relay or armature. In this case, again the failed mechanisms only need to be replaced.

conclusions

A serviceable car is always ahead.

The VAZ-2114 belongs to the category of cars that are unpretentious in maintenance, reliable in operation, and adapted to the road conditions of the Russian Federation. A successful city car with low gas mileage, low cost of consumable parts, and large trunk volume. Reviews from car owners are more positive.

The maximum that the owner “can get” in a situation where the starter does not start the car is a new starter. It costs no more than 2,000 rubles, can be changed at any service center, and if there is a hole, do it yourself in 45 minutes.

Starter for VAZ 2114: finding, removing and troubleshooting

In the ignition system of an injection engine, the starter is one of the key components. Its functional purpose is to spin the crankshaft until gasoline ignites in the cylinder block and the engine begins to rotate the crankshaft on its own.

This article will examine in detail the design features of the starter on the VAZ 2114 and the principle of operation, its location, as well as signs of malfunction, causes and methods for eliminating typical breakdowns.

Location of the starter on the VAZ 2114

DESIGN FEATURES AND OPERATING PRINCIPLE

The starter on the VAZ 2114 (5712.3708) has an operation cycle, which can be divided into four main stages:

- After turning the ignition key, the fourteenth battery in the contact chain begins to supply power to the starter and traction relay;

- The Bendix gear drive (overrunning clutch) is connected to the flywheel;

- At the moment the gear drive is connected, power begins to be supplied to the electric motor of the unit;

- The electric motor begins to spin the drive, the revolutions of which are transmitted to the crankshaft of the car, as a result of which the engine starts. When the engine speed begins to exceed the starter speed, the drive and the crankshaft are disconnected.

Now let's look at the design features of the fourteenth starter. In the diagram below you can see the main elements of the device.

Starter device

- Housing - is made in the form of a cast steel cylinder at the ends, closed with lids, inside which the cores and the exciting winding (stator) are located;

- Solenoid relay - consists of a movable jumper and power contacts. The purpose of the solenoid relay is to close the contacts when the ignition is turned on, as a result of which power begins to be supplied to the electric motor. Upon completion of the operating cycle, the solenoid relay disconnects the power and the device turns off;

- Bendix of the VAZ 2114 starter (aka overrunning clutch) - at the beginning of the operation of the device, the bendix is connected to the crankshaft and transmits the electric drive speed to it through the engagement gear; at the end of the cycle it is disconnected. The serviceability of the entire device depends on the normal functioning of the bendix, since if disconnection does not occur at the moment when the engine speed exceeds the speed of the electric drive, the unit will be damaged;

- Anchor - is a cast axle made of alloy steel, onto which collector plates and a core are pressed;

- Brushes and brush holders are structural elements that are necessary to supply power to the armature. Properly functioning brushes increase the power of the device's electric drive;

- The starter bushing - there are three in total: the rear and front - are pressed into the body, the third is located at the junction of the armature and the bendix. The bushings are responsible for fixing the drive shaft.

SIGNS AND CAUSES OF MALFUNCTION

Like any other part that is in constant use, over time the starter wears out and fails. Let's look at the main signs that can help identify a device malfunction:

- When the ignition is turned on, the engine does not start or clicks are heard, but the engine does not turn over;

- After turning on the engine, the starter continues to spin (the bendix and flywheel are not disconnected);

- Smoke begins to come out from under the hood with the smell of burnt windings;

- When the ignition is turned on, the starter begins to buzz, and the engine starts only after repeated attempts.

To determine the reason why the unit failed, it is necessary to remove the VAZ 2114 starter.

It is worth noting that this device has good maintainability, so a complete replacement of the starter is not always required - in most cases it can be cured by changing only some components.

Let us highlight the main reasons for starter failure:

- It doesn’t turn: the winding is shorted or the armature on the solenoid relay is stuck, the contacts of the positive terminal on the battery may have oxidized;

- It turns, but at an insufficient speed: the armature or stator winding has broken or shorted, the brushes have worn out;

- It turns, but does not transmit speed to the crankshaft: idling - typical signs of a Bendix malfunction;

- Does not turn off after turning on the engine: the traction relay is stuck or the spring on the freewheel is broken.

Solenoid relay

An important element in the engine starting device circuit is the solenoid relay. Its malfunction makes it impossible to start the engine in the standard way. Checking the functionality of the element is simple - if a characteristic clicking sound is not made when turning the key to the start position, the relay is faulty.

When the machine is idle for a long time, the mechanism in the device can become sour, so tapping on the body often solves the problem. If the element is completely faulty, the procedure for replacing the part is inevitable. For a convenient replacement procedure, it is better to remove the starter completely. As you can see, all problems with the starter device can be resolved on our own, so understanding all the intricacies of diagnosing breakdowns will help save time and money.