Replacing the camshaft oil seal of the Lada Granta engine (VAZ 11183, 21116)

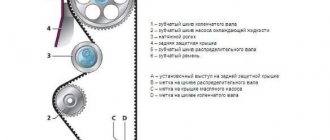

It is convenient to assess the condition of the camshaft oil seal when carrying out routine work to check the condition of the timing belt. We change the oil seal if there are traces of engine oil under the camshaft toothed pulley or on the timing belt. To prevent the camshaft from turning when unscrewing the pulley mounting bolt, insert a “10” head with an extension through the hole in the pulley and put it on the nut securing the rear timing belt cover.

Using a 17mm spanner, loosen the bolt securing the camshaft timing pulley. Set the piston of the 1st cylinder to the TDC position of the compression stroke and remove the timing belt (see “Checking the condition and replacing the timing belt”).

Unscrewing the pulley bolt...

...remove the pulley from the camshaft toe. Remove the tension roller of the timing belt (see “Checking the condition and replacing the timing belt”).

Using a 10mm socket, unscrew nut 1 and two bolts 2 securing the rear timing cover...

...and remove the cover.

Use a screwdriver to pry up the oil seal (do not damage the shaft journal) and remove it from the cylinder head socket. Unlike the camshaft oil seal of the previous generation VAZ-2108, - 21114 engines to increase the service life...

...the manufacturer installs an imported oil seal (with dimensions 28×42×6 mm), made of less elastic material and without a bracelet spring. In the absence of a new imported oil seal, you can install an oil seal (with dimensions 28x42x7 mm) for the camshaft of previous generation VAZ-2108, -21114 engines. Before installing a new camshaft oil seal, apply a thin layer of engine oil to its working edge.

We press in the oil seal using a tool head or a piece of pipe of suitable diameter. Before installing the rear timing cover, we check the condition of the rubber sealing gaskets and the rubber seals of the cover mounting bushings. If gaskets and seals are damaged (ruptures, cracks, deformation) or loss of elastic properties of rubber, the parts must be replaced. To replace...

...remove the gasket from the edge of the cover. Similarly, remove the other sealing gaskets of the cover.

We remove the bushings with rubber seals from the holes in the cover.

Rear timing drive cover with sealing gaskets and bushings for securing the cover. We carry out further assembly in reverse order.

When installing the camshaft timing pulley, align the groove in the pulley hole...

...with a key on the shaft toe (for clarity, shown on the removed camshaft). We install a new timing belt (see “Checking the condition and replacing the timing belt”).

Video on the topic “Lada Granta. Replacing the camshaft oil seal of the Granta engine”

replacing the camshaft oil seal (VAZ 2108-Kalina)

1. Replacing the camshaft oil seal on the Lada kalina engine

replacing crankshaft oil seal VAZ 8kl

When to replace the timing belt

There are several “symptoms” that indicate the need for replacement. They mainly concern changes in engine operation, namely:

- starting complications;

- noisier operation;

- the appearance of excessive vibration;

- the occurrence of third-party noise;

- reduction in power.

An exhaust with a black tint may also indicate a problem with the timing belt. The degree of wear of a given part can also be determined by visual inspection. If microcracks, worn internal teeth, delamination or other defects are detected, it should be replaced immediately.

On our website you will find:

- current information about Lada, new products in production and news related to the brand;

- statistical data on sales and the place of the Russian automobile industry in both the local and international markets;

- useful tips on operation, repair and maintenance of VAZ cars;

- all the most important information that will help you when repairing VAZ cars;

- reviews of the most common problems faced by machines.

If you have any questions regarding the repair of your car, materials and spare parts for it, you can get advice from a specialist. To do this, go to the CONTACTS section and send your question. You will find this and much more about the features of domestic cars on our portal OLADE.RU

In what cases is it necessary to replace the inner CV joint?

Replacing the internal CV joint on front-wheel drive VAZ vehicles is required if the following symptoms are present:

- Crunching and knocking noises when driving and accelerating in a straight line;

- Vibration and shock when changing gears;

- Significant play when testing by hand;

- If the “grenade” fails completely, the vehicle cannot move further.

» alt=»»> The main reason for the malfunction of the VAZ “grenade” is the entry of water and dirt through the hole in the torn boot. The second possible cause of failure is a sharp press on the gas with the wheels fully turned, although in this case you risk killing the external rather than the internal grenade.

Engine Features

Due to the design of the car's cooling system, the engine does not warm up above 80 degrees. The management of AvtoVAZ does not see anything wrong with this; they have an official information letter on this matter. You can read it in the material: What is the operating temperature of an 8 valve engine.

The engine design is as simple as an axe. There are no hydraulic compensators, no sores were noticed. Mostly problems can arise due to malfunctions in the engine management system.

Video of acceleration to 100 km per hour

I haven’t shot my video yet, it’s winter, so we’ll wait for the weather to warm up. That's when I'll post it on our YouTube channel. In the meantime, here's a video from Grantovodov.

Here's another interesting video. It is interesting because the measurement is made using an application with a navigator, which means that the speedometer readings are more accurate if the navigator is well calibrated. Everyone knows that the higher the speed, the more the car’s speedometer lies.

Replacement of camshaft oil seal VAZ Lada Granta in auto repair shops in Moscow

18 car repair companies

- TTS Motors

- Pyatnitskoe highway, 2

- +7 (495) 24… show all

- The site of the company

- Lorant

- Tolex tuning Lexus on Taganka

- Bers-auto

- Lexus on the market

- Auto-rad

- Ddcar

- Nivus

- Technical center gm east

- Auto complex

- Psrservice

- Atlant-m

Popular companies

Causes of malfunctions

The main cause of the malfunction is simple mechanical wear. Any oil seal is, by its nature, a consumable - after a certain period of time it begins to deteriorate, since it is made of an elastic material.

The malfunction may manifest itself in the form of changes in shape, swelling, scarring, rupture or chipping of the material from which the consumable is made. Another manifestation of a malfunction may be the cuff being completely squeezed out of the seat.

Other causes of problems with the camshaft oil seal are incorrect selection of consumables, manufacturing defects, or incorrect installation. In these cases, the oil seal also does not perform its functions and needs to be replaced.

Sporty on the outside and no less sporty on the inside

The gearshift lever and steering wheel are now covered with very high-quality leatherette, a seven-inch touch (!) display has appeared on the console, and the front windows are electric “already in the base.” By the way, the 2022 Lada Granta Sport is comparable in cost to a “non-sport” car, but in the “Lux” specification. However, even in the previous generation, the Granta Sport version was never cheap.

Lada Granta Sport 2020 – interior/front

Today's sports "civilian" Grant has a 1.6-liter engine, boosted to 120 horses and 160 Nm, against the "former" 145. This power unit was designed on the basis of a serial engine with the VAZ 21126 index - a very productive engine. Among other things, this version was equipped with brake components from AP-Racing with 200 mm 4-piston ventilated front disc brakes and 135 mm 2-piston rear disc brakes.

So-called semi-sports seats with pronounced lateral support are installed here. They have a long cushion, but are also designed in a “sporty” way.

Consequences of element failure

If the drive seals are not replaced in a timely manner, the following occurs:

- An oil leak occurs.

- Contamination of spare parts located nearby occurs, since the oily coating is a magnet for dust and dirt, which is subsequently difficult to get rid of.

- The oil used in a car is a rather aggressive substance and, when it gets on parts and mechanisms, it significantly reduces their service life.

In other words, timely replacement of the drive oil seal is the price for long-term and high-quality operation of the mechanism.

Replacement instructions

The sequence of actions when replacing the front and rear oil seals is slightly different. This is because the front oil seal can be replaced directly on the engine itself. Getting to the rear seal is usually more difficult.

Front oil seal

The sequence for replacing the front camshaft oil seal looks like this.

- The car is placed in neutral and the parking brake is applied.

- As with any work performed in the engine compartment, the battery terminals are disconnected.

- The plastic timing belt cover is removed.

- The valve cover is removed, for which you need to unscrew the fastening bolts with a screwdriver.

- A marker marks the location of the belt relative to the camshaft.

- Then you need to remove the timing belt. You don’t have to completely remove it - just remove the belt from the camshaft timing pulley. To remove it, you need to unscrew the fastening bolt with a 17 mm wrench, securing the pulley from turning. You can use a pry bar for fixation.

- Using a puller, the pulley is removed from the camshaft shank. If the camshaft has 2 pulleys, then both are removed, and the locations of the pulleys are also marked so that they are not confused during further installation.

- The key located behind the camshaft pulley is removed.

- Then, using a screwdriver or tweezers, remove the used oil seal. You should remove it carefully so as not to scratch the working surface of the camshaft to which the oil seal is attached.

After dismantling the old oil seal, you can proceed to installing a new one and reassembling it.

- The working edge of the new oil seal adjacent to the camshaft is lubricated with engine oil, and the outer part is treated with sealant.

- The oil seal is placed on the camshaft and then pressed using a pressing mandrel.

Further collection of the timing belt is carried out in reverse order.

- A key is placed on the camshaft.

- Then the pulley is installed. If there are two pulleys, then each is installed in the place where it was located.

- The pulleys are tightened using a torque wrench. The voltage torque can be found in the vehicle owner's manual. When tightening, it is necessary to secure the pulleys from turning using a pry bar. First you need to engage fourth gear at the gearbox.

- Then you need to put the belt on the pulleys according to the previously marked marks. You should first inspect the belt for damage, abrasions, etc. Since oil seal leaks are detected when replacing the timing belt, it is often necessary to install a new belt. In this case, it is mounted according to the factory marks.

- The tension roller mounting bolt is tightened. The tension torque can again be found in the car's owner's manual.

- Then the crankshaft is manually turned several revolutions clockwise. This checks the belt tension. If any irregularities are noticed, the tension is further adjusted.

- At the end, the valve cover is secured back and the plastic belt cover is installed.

- After replacing the oil seal, you need to add engine oil to the oil tank to the upper mark.

Rear oil seal

Rear oil seal replacement may vary from vehicle to vehicle. For some models, access to the rear oil seal is only possible when driving the car onto a lift or inspection hole and disconnecting the clutch and gearbox drive.

For other car models, access to the oil seal is limited by the camshaft position sensor, which must be removed. To do this you need:

- disconnect the electrical connector of the sensor;

- Unscrew the fastening screw and remove the sensor;

- Using a 10mm wrench, unscrew the bolt securing the gas hose holder to the sensor wire bracket;

- Unscrew the screws securing the sensor cover, remove the cover and the bundle of wires;

- remove the sensor rotor;

- Remove the sensor cover mounting plate.

After this, you can use a screwdriver to remove the rear camshaft oil seal. Replacement is carried out in the same way. After replacing the cuff, the sensor is assembled in the reverse order.

After installing the new oil seal, you must make sure that no oil leaks appear. If the oil seal is installed correctly, then even at high engine speeds the oil should not leak. Otherwise, the sensor is installed or pressed in incorrectly, or there is a manufacturing defect in the product.

Eliminate camshaft knock (axial runout) with your own hands

Many already know that the VAZ 2111 injection engines have the following disease: “Axial camshaft runout”. This disease does not progress and does not cause damage to other timing components, but it manifests itself in the form of an unpleasant camshaft knock. It just so happened that the developers of the 2111 engine missed this point.

Where carburetor engines used to have a fuel pump and distributor, injection engines have a regular plug into which the camshaft rests. The camshaft axial play set by the manufacturer should not exceed 0.15-0.20mm. Over time, as the camshaft pastel wears out, the axial play increases, and a distinct knock begins to be heard from under the valve cover. Of course, you can continue to drive with this knock and not worry, but not every car enthusiast will be pleased.

I am sure that almost any auto repair shop will tell you: “Either ignore this knock, or change the entire head!” But there is one simple and absolutely free way to eliminate this annoying knocking noise by placing a washer between the camshaft and its side cover! Below is a detailed description and photo report of the work done.

Checking the camshaft axial play.

Remove the timing belt cover and start the engine. Then, with the engine running, press the handle of a screwdriver into the camshaft gear bolt. If the knock disappears when pressed, the reason is: Axial runout of the camshaft.

How it works?

The oil seal consists of a rigid (outer) surface that is mounted in a hole. Often the kit includes a metal ring that is hermetically connected to the rubber seal. It fits tightly into the landing niche.

The inner part is softer, it seems to envelop the rotating shaft. The oil seal leaks from the inside of the circle. Manufacturers are constantly looking for compromise:

- hard material is more durable, but does not fit tightly around a rotating object;

- soft, elastic rubber provides excellent sealing, but wears out quickly.

To enhance the girth, a ring spring is often installed on the inner side. If it comes off, the grenade seal will leak.