When operating a diesel engine, especially one that is already thoroughly worn out, a situation may arise when increased engine oil consumption begins to annoy. These are normal consequences of changes in the geometry of the cylinder-piston group, but a significant contribution is made not only by the penetration of oil into the combustion chambers through problematic rings and increased clearances, but also by its entry along with the air entering through the intake valves.

Diesel engine breather - what does it mean?

To understand where the name came from, it’s worth understanding some of the principles of engine operation. During operation, excess pressure is created in the crankcase due to fuel combustion and high temperature. Over time, it can reach such levels that it begins to squeeze out lubricants wherever the seal is not very reliable.

To eliminate this problem, all engine manufacturers include a special ventilation valve called a breather in the design. It operates on a simple principle - when the pressure in the crankcase exceeds the set level, the unit is activated and releases it, leveling the indicators with atmospheric pressure. Due to this, the lubricant is not squeezed out, and the internal components are not subject to increased loads.

On a note!

The term “breathing” refers to engine oil leaks and other symptoms that occur when there is excess pressure inside the engine. Moreover, this definition applies to both diesel and gasoline cars.

How to troubleshoot

If you are sure of the reasons why your diesel engine began to breathe, it’s time to start eliminating them.

Problems with crankcase ventilation are relatively easy to fix; it is necessary to adjust or replace the relief valve along with the filter responsible for cleaning the exhaust gases. It is also possible that the problem will be solved by slightly cleaning the breather itself, if the reset mechanism functions correctly. If oil leaks through loose connections, it is necessary to replace the gaskets and seals in the corresponding parts of the structure. In other cases, you will have to almost completely overhaul the engine.

But, do not forget that small oil leaks on the body of a diesel engine are a natural process, which is due to the design features of this unit. Therefore, if oil consumption is moderate, and no deviations are observed in the behavior of the motor and electronics, then there is no point in overhauling the motor.

A diesel engine wheezing is a fairly common occurrence and is often found on both new and used cars. It is almost impossible to completely overcome this problem. The main thing is to monitor the current oil consumption and, if obvious symptoms of excessive consumption appear, immediately perform a full diagnostic of the engine.

Serious consequences for the vehicle can only occur if you completely ignore the problem, and the level of exhaust gas pressure in the engine is several times higher than the standards established by the manufacturer.

Symptoms

To determine this malfunction, you do not need to be a professional mechanic, nor do you need special equipment. The first sign is oil leaks, which can form on the seals or in the area where the dipstick is located. There are many options for leaks, it all depends on the design features of the engine and the so-called “weak points”. But if oil appears where it was not there before, you need to deal with the problem.

The easiest way is to warm up the engine to operating temperature. You can simply stop after a trip and open the oil filler neck on the valve cover with the engine running. After this, you need to carefully observe it; if a bluish smoke is visible, then the problem has been confirmed and the internal combustion engine is indeed breathing.

KamAZ engine vibration

Engine vibration on KamAZ is caused by the following malfunctions:

- Crankshaft imbalance: Vibrations are usually observed after installing a new crankshaft. Rarely does vibration occur due to a broken crankshaft.

- Engine Trouble: Vibration is usually caused by a faulty cylinder or several of them. This often occurs due to an incorrectly secured motor.

- Unqualified repairs: unreliable installation of parts provokes their mobility, which causes vibration during engine operation.

Why does a diesel engine bleed: reasons

There may be several options, but three reasons are the most common, so it is best to understand them. And if the search does not produce results, you can check additional nuances. The most common problems encountered are:

- The crankcase ventilation system is not functioning. The design is a breather with a valve, which, during normal operation, equalizes the indicators. But if the unit fails or becomes dirty, oil will be driven out due to excess pressure.

- Worn or stuck piston rings are a common cause that causes serious problems.

- Problems with cylinders and pistons. Also a significant problem that disrupts the normal operation of the engine and causes it to breathe.

Important!

You can carry out initial diagnostics yourself, but if complex problems have been identified, it is better to contact specialists.

Reasons why oil leaks through the breather, gaskets and seals

When the breather is heavily clogged, such high pressure is created in the sub-piston space that oil can be squeezed out of the crankcase even through the inspection hole for the dipstick, oil seals and engine gaskets. Therefore, at the first sign of a malfunction, it is necessary to establish the reasons for the release of oil through the breather. The main problems and their consequences are listed in the table below.

| Cause of oil release | Why is this happening | Consequences |

| Critical wear of the piston rings, less often burnout of the valve or piston | Gases from the combustion chamber break into the sub-piston space. The ventilation system cannot cope with the increased volume. | A drop in compression, a noticeable decrease in engine power, difficulty starting, tripping, oil squeezing out through the seals. |

| Wear of valve stem seals | Excess oil enters the combustion chamber and the piston ring grooves become clogged. Due to the loose fit of the valves to the seats, gases penetrate into the space above the valve, creating excess pressure and disrupting the operation of the crankcase ventilation system. | Increased oil consumption, carbon formation on valve plates and seats, oiling of spark plugs, burnout of valves, accelerated wear of piston rings. |

| Oil deflector clogged | Due to the blockage, the oil particles contained in the crankcase gases are not separated, as a result of which they, along with vapors, enter the intake. | Oiling of the air filter, carburetor jets, throttle valve, deterioration of engine performance due to a violation of the air-fuel mixture. |

| Clogged breather pipe | Oil is released along with crankcase gases as a result of an increase in pressure in the crankcase due to the inability to discharge it through the breather. | Squeezing oil through the dipstick hole, pan gasket, crankshaft oil seal and other seals. It is possible for the pipe to break off from the breather outlet or for gases to penetrate through cracks formed in it. |

| Failed breather valve | Due to the jamming of the valve, pressure does not release when it increases above permissible limits. | Oil squeezing out through seals due to a non-working ventilation system, tripping, deterioration of engine performance due to excess pressure in the sub-piston space. |

| Clogged air filter | Due to the reduced filter capacity, suction occurs along with oil particles from the crankcase ventilation system. | Oiling of carburetor jets, throttle valve (in injection models), violation of the composition of the air-fuel mixture. |

| Oil level exceeded | Excess oil along with gases enters the breather, and the oil separator cannot cope with their removal. | Rapid clogging of the oil separator, formation of oil clots in the hose, and its entry into the intake manifold. |

Cylinder-piston group

Most often, this option is found on cars with high mileage, where wear on structural elements can be significant. During operation, various components are damaged. They can lose shape and change sizes, which leads to disruption of normal operation. It’s easy to check - you need to measure the compression readings in each cylinder. To do this, use a special device called a compression meter. It can be either mechanical or electronic, there is no fundamental difference.

The measurement process is simple and you can figure it out in a couple of minutes; there are many videos and instructions that describe each action in detail. Everything is quite simple - one person controls the indicators under the hood, and the second at this moment rotates the engine with the starter. It is imperative to take measurements in all cylinders, since it often happens that in three everything is fine, but in one the value does not correspond to the norm.

The generally accepted lower figure is 22 kg/cm2. But the optimal values may vary in different models; the easiest way is to study the operating instructions. If the number is about 30 or slightly higher, the condition of the cylinder-piston group is almost ideal and there is no point in worrying. But when one or more cylinders have values below the minimum, the problem may be one of the following:

- Damage to cartridges. Here you will have to do a major overhaul of the engine, grind and hone the liners, and also select repair rings. In addition, you have to do a number of additional works and replace all components that are worn out or damaged. In some cases, it is necessary to bore the engine and select pistons of larger diameter.

- Problems with pistons. During operation, they may become slightly deformed or damaged. Even a small piece that breaks off from the piston will cause serious problems that will lead to costly repairs. The elements may also burn out.

- Malfunctions can also be caused by other components - valves, bushings, seals, etc. It all depends on the situation and the cause can only be discovered by disassembling the motor. So there is not much difference in what exactly fails - the repair always looks about the same.

Important!

Individual engine models have their own characteristics and characteristic “sores”, so it is advisable to study the available information. For example, the D 245 tractor engine will be very different from the 1.9 TDI version from Volkswagen, both in design and layout. Therefore, it is worth understanding all the nuances.

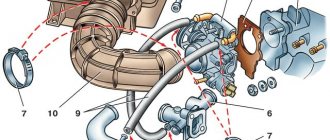

Disassembling the breather

In order to clean the breather, you need to remove the valve covers from the engine. Unscrew the two bolts shown in the photo below.

Photo. VAZ valve cover, arrows indicate bolts.

After you have unscrewed the breather, you will see a stack of meshes; they need to be cleaned, but it happens that there is a lot of black carbon in the breather itself; it needs to be removed. In the photo, the breather is not clogged with carbon deposits, but the mesh is clogged, so I will clean it.

Photo. Disassembled VAZ breather.

Usually the meshes are fastened together with a rivet; you need to bite it off, separate the meshes, clean each mesh with an iron brush, then wash it in gasoline.

Photo. Disassembled breather mesh.

After the grids have been cleaned, they must be installed in place as shown in the photo, and the breather cap must be screwed on. The grids can be riveted again, or not, the main thing is that they alternate with each other, so there are grids with longitudinal slits and vertical ones, you need to install the first grid with vertical slits, the second with longitudinal slits, etc. That's it, the breather has been cleaned.

A fairly common problem on many domestic and foreign-made cars is that oil flows through the breather. In winter, especially with the onset of significant cold weather, you can encounter a malfunction when the breather freezes, oil is squeezed out and streaks are visible on the outer surface of the power unit. Let us immediately note that this symptom, as well as smoke and oil from the breather, are a reason for immediate engine diagnostics, since ignoring this problem can lead to quick and expensive engine repairs.

Note that if there is oil coming through the breather, diagnosing the root cause may be difficult. To accurately determine the underlying problem, skills, special equipment, etc. will be required. However, in some cases, the driver can understand why oil is leaking from the breather without the involvement of third-party specialists. In other words, diagnostics are carried out independently in a garage environment. In this article we will talk about why oil drips from the breather, as well as what a car owner should do if oil comes out through the breather.

Piston rings

Another detail that often causes diesel to breathe. The rings are designed to seal the gap between the pistons and cylinders; they are selected with a high degree of precision and provide them with good compression. But, if for some reason they do not perform their functions, exhaust gases penetrate into the crankcase. The problem is also detected when measuring compression and most often occurs for two reasons:

- Wear of elements, as a result of which they become thin and cannot properly seal the space. Sometimes the rings become so thin that they simply break, which can damage other components and complicate repairs.

- O-ring jamming occurs most often in cars that have been standing for a long time. That is, the elements stick to the pistons and do not seal the clearance, which is why the engine begins to breathe heavily. Also in this case, the engine malfunction lamp may come on periodically or constantly work.

In some cases, the oil can be squeezed out very strongly, it all depends on the extent of the problems with the rings and the amount of exhaust gases entering the crankcase. The main difficulty is that the cause is revealed only after removing the cylinder head.

Way to solve the problem

When starting to clean the breather, first of all we look for a device under the hood and remove the air filter from it. Before doing this, de-energize the car by disconnecting the negative terminal from the battery and turning off the ignition. There is an intake manifold under the filter - we will also dismantle it. After this, you can see the prompter itself - as a rule, its cover is secured with two bolts, which will have to be unscrewed. After removing the cover, the oil bumper will become visible - it is secured with a pin.

Read more: 220 Volts in Watts

It is necessary to unscrew the nut located on the stud, but there is no need to remove the stud itself, because it will be difficult to put it back without dismantling the pan. We make a cleaning rod out of wire, which we use to clean the tube. There is a brush on the breather cover to extinguish the flame - we clean that too.

All that remains is to check the device. We start the engine, remove the plug from the oil filler neck, and cover the neck itself with your palm. You can feel with your hand whether there is pressure. Then the assistant should press on the gas until the speed reaches 100-130 km/h and check the compression again by applying the palm of his hand. A little pressure should already be felt.

To avoid problems with the release of working fluid through the prompter, it is necessary to constantly monitor its level

It is also important to pay attention to checking the filter and gearbox

Owners of old domestic cars, after several years of ownership, can easily write a directory of “diseases” of a particular car model. One of these “sores” is an engine malfunction in which engine oil is squeezed out through the breather. This phenomenon is most often simply called by people: “oil is driven through the breather” or “oil is thrown out through the breather.”

The problem is quite unpleasant and is accompanied by a large number of engine-related problems. It is this problem, as you probably already guessed, that we will talk about in this article. You will learn why oil comes out of the breather and how to solve this problem. Go.

As a rule, the problem occurs with the onset of cold weather, the breather freezes and the oil is squeezed out. This manifests itself in the form of oil drips that are visible from the outside of the engine. Failure to respond to this phenomenon in a timely manner can lead to serious engine damage.

Crankcase ventilation

First you need to understand the design of the breather. Everything is quite simple - a hose or metal tube connects the crankcase and the upper part of the engine, creating a system for compensating pressure and reducing it, if necessary. The system also usually includes an oil separator, which prevents lubricant from escaping and returns it back to the engine.

Gas ventilation is usually designed so that air from the crankcase is supplied to the intake tract and used for operation. The design includes a crankcase ventilation valve (CVGV), which, when the pressure is exceeded, opens the membrane and releases the excess, thereby ensuring normal operation. If for some reason the valve is stuck in the open position, then air will be supplied to the intake, creating a vacuum in the engine, which has a bad effect on its operation and increases diesel fuel consumption.

If the valve fails in the closed position, excessive pressure will be created inside the crankcase and the oil will begin to be squeezed out through the seals, dipstick, etc. Also, large quantities of lubricant can enter the cylinders, which is also undesirable. In this case, oil consumption increases and blue smoke often appears.

Important!

The reason may also be clogging of pipes or other elements of the system; here it is important to check all components to eliminate the problem.

Diagnostic methods

Low compression indicates a malfunction. Pay attention to which cylinder performs worse than others, and which spark plug is flooded with oil. We offer the simplest but most reliable diagnostic tools that are easy to use in any garage:

• To clarify the area of failure, you can create pressure in the combustion chamber with compressed air from the compressor. It is pumped through the hole of a spark plug or nozzle. • A hiss from the open crankcase (from the oil filler neck), holes for the dipstick, and so on will indicate a malfunction. In this case, the camshaft must be in a position corresponding to the closed valves. • Hissing noise may also come from the exhaust pipe or supply line. This is no longer relevant to our problem, but indicates leakage of the gas distribution valves. • The tightness of the piston group is also checked by pouring kerosene through the spark plug holes. If it is leaky, it quickly flows into the pan.

Professionals also use more sophisticated and expensive devices. One of them is an endoscope. A probe with a camera at the end allows you to look into the cylinder and inspect all the details. Excessive carbon deposits, cracks or scoring marks appear on the computer. The image can also be photographed.