I glanced briefly at the voltmeter on the instrument panel, but it was in the negative and did not respond to an increase in the speed of the engine, I thought: the belts had come off again (my crankshaft pulley beats in a figure of eight, this happens), so I thought that the pump was not spinning either. I made it home; there were only 150 meters left. I looked - the belts are in place, the generator is turning but there is no voltage. Lately it has been stuck to me not at 3 points, but at two, due to the loss of a fastening bolt in the lower far eye, as a result of which it wobbles quite badly at idle in relation to the engine. Well, apparently something shook in him. In 15 minutes I changed the relay regulator, which is located in the engine compartment on the wing. No changes. I went to dig the Internet and forum.

Below is a diagram of checking the charging system on the 402 engine.

Malfunctions of the charging system of group 1-2 GAZ-2410, 3102, -029, -10, 3302 with the ZMZ-402 engine

1. broken contact in the wire from the battery terminal to the power fuse block near the battery - the battery will not charge, but the voltage from the generator will remain for other consumers, the voltmeter will show the voltage of the on-board network

2. the fuse in the battery charging circuit has blown - the battery will not charge, but at the same time the voltage from the generator will remain for other consumers, the voltmeter will show the voltage of the on-board network

3. the contact in the wire from the generator to the power fuse block is broken - the battery will not charge and the voltage in the on-board network will be determined by the battery voltage, the voltmeter will show the battery voltage

4. the contact is broken in the wire that supplies “+” from the ignition switch to the relay-regulator and one of the generator brushes. There will be no charging, the voltmeter will show the battery voltage

5. The contact in the wire from the second brush of the generator to terminal “Ш” of the relay regulator is broken. Charging will not occur, the voltmeter will show battery voltage

6. The relay-regulator has failed - break. Charging will not occur, the voltmeter will show battery voltage

7. there is no electrical contact with the brushes in the brush assembly or brush holder. Charging will not occur, the voltmeter will show battery voltage

8. There is no contact between the brushes and the slip rings on the armature. Charging will not occur, the voltmeter will show battery voltage

9. break in the rotor winding. Charging will not occur, the voltmeter will show battery voltage

10. break in at least one of the phases of the stator winding. Charging will not occur, the voltmeter will show battery voltage

11. At least one of the rectifier unit diodes has failed. Charging will not occur, the voltmeter will show battery voltage

How to check (a control or a tester with a DC voltage measuring scale of at least 15 V can be used to check):

1, 2, 3. control: one end to the battery minus, the other to the wire terminal on the power fuse block - the control should be on, then to the terminal after the power fuse and, finally, to the terminal of the generator with the tester nut: negative terminal of the tester to negative battery, the positive terminal of the tester to the wire terminal on the power fuse block - the tester should show battery voltage, then to the terminal after the power fuse - the tester should show battery voltage and, finally, to the generator terminal with the nut - the tester should show battery voltage

4. disconnect the block from the generator brush holder and the block from the relay regulator, turn on the ignition. Control: one terminal to ground, the second to each of the blocks for each of the two wires. On one of them in each block the control light should light up. We insert the block on the generator into place and check for the presence of “+” on the second terminal in the relay-regulator block. The control should light up, but not at full intensity. This means that faults 5, 7, 8 and 9 are absent. After this, we disconnect the block from the generator again and connect the relay-regulator block. We switch the control with one terminal to “+”, and connect the second terminal to the second terminal of the generator block. The control should light up. This almost certainly means the absence of fault 6 and the complete absence of fault 5. Tester: the negative terminal of the tester is to ground, with the positive terminal of the tester we check for the presence of “+” on one of the wires in each block - the tester should show battery voltage. We insert the block on the generator into place and check for the presence of “+” on the second terminal in the relay-regulator block. The tester should show a voltage slightly lower than the battery voltage. This is explained by the voltage drop across the resistance of the rotor winding. This means that faults 7, 8 and 9 are absent. After this, we disconnect the block from the generator again and connect the relay-regulator block. We disconnect the negative terminal of the tester from ground, connect the positive terminal to the “+” of the battery, and connect the negative terminal of the tester to the second terminal of the generator block. The tester should show the battery voltage. This almost certainly means no fault 6 and no fault 5 at all.

5. The main check is only with a tester: remove the blocks from the relay-regulator and the generator and “ring” the terminals of the blocks among themselves. The test is carried out in resistance measurement mode, the measurement limit is units of ohms. On both wires of the blocks in the corresponding pairs of terminals, the tester should show zero or the resistance of its measuring probes.

To watch online, click on the video ⤵

What if the charging relay malfunctions and charges the battery incorrectly? Using the GAZ-2705 as an example Read more

No charger for your gazelle? there is a solution! More details

Charging gazelle. Car repair of a gypsy chaise. Linen-factory. Kaluga Read more

Everyday life of a sovkovod. No charging. Gas 2410 dvs 402 Read more

Charging, Volga 402 engine Read more

WEAK CHARGING? SOLUTION IN 5 MINUTES AND THE GENERATOR WILL BE LIKE NEW. More details

Low voltage on the gazelle generator Read more

Low battery charge | ZMZ 406 More details

How to increase the charging current on a gazelle is one way. More details

Replacing the Gazelle Volga voltage relay with a three-level voltage regulator relay Read more

How to increase the voltage in a GAZelle car Read more

How to check the generator on a car. Basic malfunctions. Simply about the complex Read more

Never do this and there will be no problems. And if it's already done, here's how you can detect it. More details

we increase the voltage of the generator VAZ 2110-2111-2112 Priora Kalina, etc. Read more

Reasons for the battery not charging. More details

Diagnostics and repair of Generator VAZ, Gazelle, Volga, Sable, Lada, Priora Read more

The generator does not charge. Bad charging. Generator repair. More details

Quick check of the generator outside the car Read more

How to increase generator voltage Read more

Troubleshooting

Let's look at the most common reasons why the battery of GAZ cars with ZMZ 402, 405 and 406 engines cannot be charged, and we will also tell you what can be done in each specific case.

Checking belt tension

Over time, the drive belt can stretch and begin to slip. To check its tension, you need to apply a force equal to 40 N (4 kgf) to the middle of its upper section. In this case, the belt should bend by 8-10 mm.

To adjust the belt tension on a GAZ car with a 402 engine, you need to:

using a wrench, loosen the two bolts that secure the generator to the bracket;

loosen the bolt securing the adjusting bar;

Using a wrench, loosen the adjusting bolt;

- increase the belt tension by turning the generator in the direction opposite to where the engine cylinder block is located;

- tighten the adjusting bolt and check the tension; if it is within the normal range, tighten all the other bolts.

On machines with a ZMZ-406 engine under a load of 80 N (8 kgf), the deflection should be 15 mm. To achieve this you need:

using a wrench, loosen the tension roller bolt;

tension the belt by turning the adjusting bolt clockwise.

Wiring problems

Sometimes the reason why charging fails can be a bad contact. The most common cause of contact failure is oxidation of the battery terminals. To clean them you need:

disconnect the wires from the battery;

wipe the battery;

- prepare a cleaning liquid (dilute 30 g of soda in 0.5 liters of water);

- soak a toothbrush in the prepared liquid and clean the terminals;

clean the contacts from the cleaning liquid and wipe them with a dry cloth;

connect the wires to the battery.

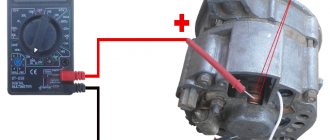

How to check the generator

Without removing the generator, you can check the rotor winding for an open circuit. To do this, remove the brush assembly, set the ohmmeter measurement limit to 10 Ohms and measure the electrical resistance of the rotor. It should be between 2.5 and 3 ohms.

To check the generator after removal, perform the following steps:

- connect the battery negative to the generator housing;

- we connect the positive terminal to the rotor brushes;

- We connect one output of the control light to the negative terminal of the battery, and the second to the power output of the generator.

Now when the generator pulley rotates, the light should light up.

Video of a quick check of the generator:

Diagnostics of the relay regulator

To check the relay regulator, you need to start the car engine and turn on the headlights. After 25 minutes, you need to measure the voltage between terminal “B+” (for motors ZMZ 405 and 406) or 30 (for ZMZ 402) of the generator and ground. The voltage should be in the range from 13.6 to 14.6 V. If it goes beyond these limits, then the regulator does not perform its functions.

You can see another way to check a relay regulator removed from a car in the video:

Currently reading:

Charging lost on Niva: main reasons and repair instructions for all models

Why the charger on the VAZ 2107 disappeared - we look for and fix problems

There is no charging on the VAZ 2114 - the main reasons and ways to eliminate them

How to repair a computer power supply with your own hands

Why won't my laptop turn on without a battery?

The main reasons why there may be no charging

There are several reasons why charging problems occur. They can be divided into several types depending on the place where they originated:

- wiring malfunction (for example, broken contacts, broken wire, blown fuse);

- generator breakdown (for example, one of the diodes of the diode bridge burned out, a short circuit or break in the stator winding, bearing wear);

- insufficient tension or belt rupture;

- The voltage regulator has failed.

These problems and ways to eliminate them will be discussed in more detail below.

Checking and repairing the generator on GAZ 3110 vehicles with 402 and 406 engines

Every modern car is equipped with a generator device, which is used to power electrical equipment connected to the on-board network. And Gazelle cars are no exception. What is a GAZ 3110 402 engine generator, what elements does it consist of and what do you need to know about malfunctions? Read about it below.

What elements does the engine generator unit 406 consist of, what is its connection diagram and what is the principle of operation? First, let's look at the description of the mechanism.

Design and principle of operation

The generator unit in Gazelle is a three-phase synchronous electric motor with electromagnetic excitation, as well as a built-in diode rectifier.

The rotor mechanism is driven into rotation from the crankshaft pulley of the power unit via a V-belt. The stator device, as well as the mechanism cover, are tightened with four bolts.

The shaft of the rotor mechanism rotates in bearings, which are located in the covers. By the way, bearing devices are lubricated for their entire service life.

The rear bearing is installed in the shaft of the rotor mechanism; it is pressed using the rear cover through a plastic sleeve. The front bearing element is located on the inside of the front cover. It is secured with a washer and four bolts.

The stator mechanism contains two three-phase windings that are connected to each other in parallel. A diode bridge or rectifier includes six diode elements that are mounted in two steel or aluminum plates. The plates themselves are combined into a rectifier unit, which is fixed inside the rear cover of the unit.

The mechanism is equipped with excitation windings, which are installed on the rotor mechanism. Their leads are soldered to two copper slip rings, which, by the way, are located on the mechanism shaft.

Power to the windings is provided by two carbon brushes connected to them and located in the brush holder.

Under the expansion tank, on the mudguard in the area of the right side member, there is a voltage regulator for the ZMZ Chrysler engine.

Why Chrysler? Because the first gazelle engines were equipped with these motors. The regulator operates in conjunction with the generator set and if this element fails, it must be replaced.

Also, the connection circuit involves the use of a capacitor device. This element is designed to protect the Gazelle's electrical equipment from possible impulses in the ignition system.

The capacitor also serves the function of reducing radio interference.

Cooling of the rectifier unit, as well as the windings of the mechanism, is carried out through the air flow entering through the holes in the centrifugal fan covers.

Device components

The node consists of the following elements:

- the housing in which the entire structure is enclosed;

- stator mechanism;

- rotary device or anchor;

- pulley and impeller;

- rectifier block or diode bridge;

- two bearing devices on which the rotor rotates;

- brush mechanism;

- voltage regulator.

How to check the generator?

The procedure for diagnosing a unit without dismantling is as follows:

- First you need to start the engine and let it warm up. Increase engine speed to 3 thousand per minute.

- Activate the optics - high beams, rear window heating system, stove, radio, light alarm and turn on the wipers. This is done in order to ensure operating conditions as close as possible to real ones.

- Next, using a voltmeter or multimeter, measure the voltage value at the battery terminals; this parameter should be at least 12 volts. If the obtained value is not the same, then this indicates that a problem has occurred in the operation of the windings - a short circuit or break. Or the fault lies in the voltage regulator or brushes. The problem may also lie in the oxidation of the winding rings.

Generator 2022.3771 for UAZ-3151x with ZMZ-402 engine

The easiest part in terms of connection is the rear part of the car, where you only need to secure the harness and connect the rear lights and the fuel level sensor in the gas tank.

Generator device

The higher the speed, the greater the EMF, which means the voltage can rise to unacceptable values. The needle on your own voltmeter should be on the green scale.

Since the belt drive also ensures the rotation of the water pump, when the generator belt is too tight, noise appears from the bearings of the pump and the generator itself. A device that maintains voltage at the same level is called a voltage regulator. Generator 90A for UAZ - G287

About classic UAZ SUVs and off-road vehicles

In subsequent models, the tachometer received a signal from the ignition system, and the generator phase output was no longer needed; if the generator has one, it is simply not connected.

The video above just shows the option of starting a car unprepared for winter. The generator rotor is driven by a V-belt from the engine crankshaft pulley. Similarly, the excitation winding receives power through the brush voltage generator.

But there were some bugs. Summary Although there is still time before winter, you should worry about the electrical components of your Gazelle in advance. That is, the battery begins to charge at lower speeds than in the standard version.

The starter turns hard, cannot start the engine and there is not enough battery for the second attempt. All this can be avoided if you know what exactly you need to do... Technical aspects of winter operation The most obvious and pressing issue after a cold night in the open air is starting the engine. I give the load: long range, heater, heated glass, I also turned on the emergency lights.

22.8. Electrical circuit diagram with ZMZ-402 engine

Installation kit: generator Thus, repairing a generator means replacing the diode bridge and replacing the bearings; in other cases, it is more profitable to exchange it for a reconditioned one. The reliability of the excitation circuit does not increase: the relay-regulator is still critical to a good “ground”.

Before removing the generator, let's check it again. So, ordinary power relays come to our aid.

The conclusion from here is this: the standard ZMZ ampere generator almost does not work at lower speeds. Calling an electrician he knew, he said two cherished words and everything fell into place - Put on the light bulb! Generator First you need to install a test battery.

Voltage regulator type The generator rotor is driven by a V-belt from the engine crankshaft pulley. Generator brushes Voltage regulator The generator must provide a constant voltage level to the network. By the way, the Gazelle Business wiring diagram is also not immune from such cases. Three-level generator voltage regulator. Three-level generator voltage regulator.

Source

Battery charging circuit diagram

The first GAZ cars were equipped with ZMZ 402 carburetor engines. For its operation, it was necessary to power the ignition coil, the ignition distributor-distributor (distributor) and the switch. Afterwards, the ZMZ 406 carburetor engine began to be installed on the Gazelle. Cars with it were equipped with an electronic ignition control unit. Later, these vehicles were equipped with injection engines of the ZMZ 405 model.

Generator circuit for a Gazelle with a ZMZ 402 engine

Let's look at the electrical diagram for connecting a generator to GAZ cars with a ZMZ 402 engine.

Here, when you turn the key, the current from the positive terminal of the battery through contact 15/1 of the ignition switch flows to the rotor brush, then to the winding and collector of the transistor located in the voltage regulator. Through the second wire, the current flows to the positive connector of the voltage regulator, which opens the transistor. As a result, electricity from the rotor brushes reaches the ground through an open transistor, the circuit is closed, and current flows through the rotor winding. Thanks to this, it is magnetized, and when the engine begins to rotate, an EMF appears in the generator winding. The battery begins to charge.

Generator circuit for a GAZ car with a ZMZ 406 and ZMZ 405 engine

The Gazelle with ZMZ 406 and ZMZ 405 engines was equipped with generators 9422.3701, manufactured at KZATE, and 5102.3771, made at ELTRA, as well as their analogues. The electrical circuits of both generators are identical.

When you turn the key, the ignition switch contacts close, electricity from the positive terminal of the battery through fuse 3, a light bulb on the dashboard, goes to point D of the generator. Additional diodes are connected to this point. Next, electricity flows to the voltage regulator and opens the transistor installed in it. As a result, current passes freely through the rotor windings, and a magnetic field arises. Now, when the engine rotates, the generator produces electrical energy. Part of the energy generated by the EMF is rectified and enters the rotor winding.

The dashboard light limits the current flowing from the battery to the field circuit to 100 mA. In addition, it should light up when the engine starts, which indicates that the generator is ready. After this, it goes out, which means that the generator has begun to generate electrical energy. If the light comes on when the engine is running, it means the generator is not producing current.

Repair GAZ 3110 (Volga): Checking and replacing generator brushes

You can check and replace the brushes without removing the generator from the car.

| EXECUTION ORDER | |

| 1. Disconnect the wire from the negative terminal of the battery. | |

| 2. Disconnect block 1 with wire from the brush holder terminal. Unscrew two screws 2 and remove brush holder 3 from the generator. | |

| 3. Check the ease of movement of the brushes in the brush holder. If the brushes are jammed, you need to remove the two mounting screws and remove the brush holder cover. Clean the brushes and clean the holes in the brush holder. If it is impossible to achieve the required result, replace the brush holder assembly or brushes. Brushes with chips, cracks or other defects must also be replaced. | |

| 4. Check the amount of protrusion of the brushes from the brush holder. If the value “a” of the protrusion of the brushes in a free state is less than 8 mm, replace the brush holder assembly or brushes. |

Consumables

The most important point for a GAZelle owner is that you need to train yourself to treat electrical components as consumables. The Russian mentality “it’s worth it - don’t touch it” is completely unjustified in this case.

Buy modern wires - their price is comparable to 10 liters of gasoline, and you will get much more benefits