The design of manual and automatic transmissions is constantly being improved. Each of these design types of transmissions has both its advantages and disadvantages. The main disadvantage of the classic automatic transmission is the disconnection of power when changing gears. That is why many automakers have developed and are developing modernized automatic transmissions that allow gear changes without a loss of power.

Features of the S-Tronic gearbox on Audi cars

New 1.8-liter VAZ engine: which Lada models will it be used in and how much can be squeezed out of it?

Audi’s S-tronic gearbox was based on the operating principle of a manual gearbox; it has a pair of shafts and a pair of clutches. This feature allows you to change gears very quickly, since the power flow at this time is interrupted with a minimum interval.

The gearbox has a highly complex design, but despite this it can be combined well with quattro all-wheel drive, as well as with different engines, for example, TDI or TFSI, and its compact dimensions allow it to be installed on any model, even one that has a very small engine compartment space.

The S-tronic gearbox on Audi is designed for 7 speeds, and the torque is maintained up to 550 Nm. Such fast gear changes are possible thanks to the tiptronic system, while one gear is set, the system simultaneously keeps the next gear almost engaged, so the transition to the next speed is practically unnoticeable. The box has a self-diagnosis system; if any faults are detected, the driver receives an error notification.

Exterior of S-Tronic Audi

Compact dimensions

One of the strengths of the preselective 7-speed gearboxes created by the Volkswagen concern is the relatively small overall dimensions of the unit. Thanks to this feature, this robotic gearbox can be used on compact cars with limited engine compartment space. That is why S-Tronic is in demand today in various small cars, where installing a full-fledged six- or seven-speed automatic transmission is extremely difficult.

Thus, in a city compact car of the Audi brand, thanks to the development of a preselective unit, it has become possible to use multi-stage automatic transmissions or manual transmissions, which contributes to the realization of the dynamic potential of the engine, economical fuel consumption, and increased safety.

Pros and cons of the DSG S tronic robot box

What tires to install on the Lada Granta: basic size, replacement options, choice of model

A high-tech robotic box has all the positive qualities inherent in both traditional mechanical devices and automatic machines. Thanks to the electronic control unit, which operates using complex circuits and algorithms, driving the vehicle is more comfortable.

Car owners who own a vehicle with a DSG S tronic preselective gearbox note the following advantages of their cars:

- Relatively small dimensions and weight of the mechanism.

- Improved car dynamics.

- Smooth and, at the same time, fast acceleration of the car.

- Instant speed switching (takes no more than 0.8 seconds).

- Economical (fuel consumption savings - at least 10%).

- The absence of a clutch pedal makes it easier to control the gearbox.

If some problems occur during operation of the robotic gearbox, the driver receives appropriate warnings. By contacting the service center in a timely manner, repairing the entire device is simplified. Using special diagnostic devices, qualified workers quickly find problems that have arisen in the vehicle and fix them in a short time.

Among the observed shortcomings, the following factors are noted:

- the relatively high cost of the mechanism, which is reflected in the price of the entire car;

- expensive qualified maintenance of the si-tronic, since partial or complete oil changes, as well as the oil filter, should be carried out only in specialized service centers;

- complicated box design.

When the working units and parts of the differentials wear out, various negative symptoms begin to appear:

- Dips, shocks during acceleration and transition to high speeds.

- Vibrations when switching from first to second speed.

Advice: Experienced car owners recommend regularly changing the oil in the preselective transmission. In their authoritative opinion, the maximum mileage between these procedures should not exceed 40 - 50,000 km. Ignoring these recommendations may cause failure of the friction discs of the clutch mechanisms and malfunction of the solenoids. The s-tronic uses only original gear oil of the brand recommended by the car manufacturer. Simultaneously with replacing the lubricant, it is necessary to replace the oil filter so that the wear elements that are on the metal mesh of the filter element do not get back into the fresh ATP oil.

Recommended consumables and devices:

- ATF oil G052529A2 - 6 liters.

- Filter 0B5325330A.

- Filter seal WHT005499A.

- Pan gasket 0B5321371E.

Differences between S-Tronic and DSG

Structurally, the units of the S-Tronic and DSG systems are very similar, but there is only one significant difference - in the gearbox itself, the DSG has a less reliable electric unit, while the product from Audi has a valve body. These devices regulate oil pressure and build an algorithm when sending signals from the control device. The hydraulic unit of the system is considered a more complex and advanced design, while its reliability has been tested not only by sea trials, but also by practice. Cases of failure of the unit of this unit are rare in practice and most often occur due to improper operation of the system itself.

Carrying out adaptation of the speed box

Blog mini Boriskhof

S-Tronic repair is necessary if there are shocks (impacts) when shifting gears, or the vehicle accelerates worse. In some cases, special adaptation can normalize the functioning of the box. This procedure is relevant after scheduled repair work and begins with checking the clutch and mechatronics. Also, adaptation in motion is necessary.

Adaptation helps extend the life of this box. The need to carry out this procedure arises every 15,000 km. During this time period, deviations from normal operation may be observed. In particular, the car may begin to jerk when changing gears.

Explanations and causes of the most common BMW automatic transmission errors

The most popular fault codes are:

- 4F81, 4F82, 4F83, 4F84, 4F85 – control of the gear ratio of individual clutches (in order A, B, C, D, E). They appear mainly due to combustion or severe wear of friction clutches. When the box tries to switch to the next gear, the speed increases and, as a rule, it goes into emergency mode. Often these errors appear with the errors from point 2.

- 4F87, 4F88, 4F89, 4F8A, 4F8B, 4F8C, 4F8D, 4F8E, 4F8F, 4F90, 4F91, 4F92, 4F93, 4F94, 4F95, 4F96, 4F97, 4F9B – gear ratio control when shifting gears. These errors, just like in point 1, occur due to slipping when changing gears. The cause may be burnt or heavily worn friction clutches, worn mechatronics (valve unit) and its electromagnetic valves (solenoids), or worn sliding bushings.

- 4E84 – 4EE9 - error codes associated with malfunction of solenoid valves and sensors. Most often they occur due to an internal electronic malfunction of the automatic transmission control unit (located on the mechatronics electrical board), less often due to an electrical malfunction of the circuit of the solenoids themselves.

Is it worth buying a car with Audi S-tronic?

This transmission is designed for the premium Audi segment and is installed only on cars with engines with high power potential. S-tronic is ideal for a weekend car, intended for dynamic use or traveling on the highway and highways; purchasing a car with this transmission for daily use within the city is extremely impractical.

In addition, before purchasing a car with S-tronic Audi, it is important to calculate the cost and regulations for servicing or repairing the transmission. In the Russian Federation, you can find a certified car service center that will fix transmission faults with a guarantee only in large cities.

Pros and cons of the S-Tronic gearbox

Like any complex unit, such a box has both its pros and cons. The positive features of the s tronic system audi a6 c7 include:

- Quick gear changes of the unit due to the design features of the transmission and the operation of the electronic unit. The average reaction time of the unit both when moving to the upper and lower stages is about 0.7 seconds.

- Significant fuel savings of the unit compared to competitors. Based on the design of the system itself, in fact such a box is mechanical with an electronic control unit that independently depresses the clutch (one of two) and changes gear. This allows you to reduce fuel consumption, regardless of the class of the car, by an average of 15-18%, which also depends on the correct operation of the S-Tronic electronic unit.

- Dynamics of car acceleration. Taking into account the reaction time of the box when switching, the dynamics of acceleration to 100 km/h are no different from mechanical competitors and are quite superior to their automatic counterparts - torque converters and CVTs. In combination with powerful engines, the difference between a tronic and a classic automatic is more dynamic acceleration.

Despite the technological advantage of the box and the undeniable positive aspects, this box also has negative features that may become an obstacle for some category of owners to purchase the unit. These include:

- Uncomfortable unit switching in traffic jams. This feature also comes from the design. When driving at low speed for a long time, the S-Tronic clutch can overheat, which when shifting can lead to jolts, kicks, as well as chaotic “jumping” from 1st to 2nd gear.

- Compared to competitors, the service life of the main parts of the system and, above all, the clutch, which some drivers have to change even before reaching 100 thousand km, are shorter. Designers are constantly improving the unit and this part of the system, but at the moment, in terms of the overall level of reliability, the robotic gearbox with Audi tronics has certain problems with long-term reliability.

Important! When choosing a used car with such a gearbox, close attention must be paid to the troubleshooting of the unit, since such cars are often sold with problematic gearboxes

Advantages and disadvantages of checkpoints

Each type of automatic transmission has its own advantages and disadvantages, which it is recommended to familiarize yourself with before using it. The Audi S-tronic transmission, thanks to its special structure, has the following advantages:

- Fast gear shift speed, about 4 - 1.8 seconds, which is achieved thanks to the parallel squeezing of the next stage by the second clutch set.

- Good fuel efficiency - up to 18% compared to identical cars equipped with a manual transmission.

- High dynamics - achieved thanks to a paired hydraulic clutch system and a two-shaft arrangement, with the help of which torque is realized, even on more powerful engines.

- Small dimensions and light weight make the device more versatile and also allow you to significantly save space under the hood of your car.

Read also All about the characteristics of the Audi A7 with reviews from owners

Despite its good characteristics, the Audi C tronic transmission has several disadvantages due to the complexity of its design:

- The high cost of a manual transmission, since it is necessary to use a complex ECU and install a valve body, which directly affects the price of a car with this automatic transmission and its maintenance.

- The difficulty of maintaining S-tronic Audi is that it requires the installation of only “original” certified components and consumables, and diagnostics and adjustment of the system must be carried out using dealer equipment.

- Operation in the city is not always convenient - since one of the main features of this gearbox is the high speed of gear shifting, when driving at low speeds (20-30 km/h) or in a traffic jam, jerks and jolts may be felt during gear changes.

It is worth noting that all shortcomings are very individual, their presence can only be noticed under certain conditions.

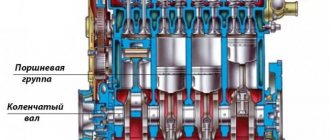

Audi S-Tronic device

Reliability of the X-Tronic CVT box

Now let's talk a little about the reliability of the variator, because... This is practically the most common question among those who want to purchase a car with this transmission, and it is most relevant for those who want to buy a car on the secondary market. We spent a long time studying the forums of owners of cars with a CVT, and practice has shown that with proper operation and timely maintenance, the transmission runs 150,000 km without any problems. Next, maintenance and replacement of some parts are required, the cost of which is not that high, after which the continuously variable transmission can go the same distance.

Today, classic gearboxes are slowly fading into the background. If you look at the current market for new cars, you can identify two main vectors of development - robotic transmissions and CVTs. Robotic boxes are installed mainly on German cars; relatively recently they began to be installed on Korean models. CVTs are more the prerogative of Japanese manufacturers. Note that, for example, until recently, Audi equipped some of its cars with a CVT, but refused in favor of robots, citing greater reliability of the design.

For a more detailed study of this topic, we suggest you read the articles:

- Owner reviews on the reliability of the X-Tronic CVT for 2018

- We service the X-Tronic CVT variator: oil change

How long will it last and what can break?

X Tronic will operate normally for approximately 150,000 km. After such a run, its resource begins to deplete. As a rule, during this time the mechanism works properly, which is guaranteed by the manufacturer. Of course, its service life will depend on the vehicle on which it is installed and on operating conditions. But after the specified mileage, the variator may break down.

If you do not follow the operating rules of the vehicle, then after a while the box installed on it will begin to make sounds reminiscent of the noise of a moving trolleybus. It is impossible to indicate any one reason for this malfunction - there can be a lot of them, and for an accurate determination it is necessary to carry out diagnostics.

The belt drive may also suffer some damage. The belt simply breaks if the operating rules of the machine were not followed, and no one monitored the condition of the belt drive. A belt rupture can also lead to other damage, since its particles can damage other elements of the unit.

Another typical variator malfunction is bearing failure.

The cause of this defect is also, as a rule, improper operation of the power unit. When this happens, a loud, uncharacteristic noise will be heard from the box.

Signs of pump failure and troubleshooting

The following signs may indicate that the VAZ 2114 fuel pump is not pumping:

- The engine will not start.

- After working for a short time, the motor stalls.

- The engine is tripping.

- The engine often jerks at low speeds.

- The pressure in the fuel rail (rail) has dropped. Normally, it is: for a volume of 1.5 l - about 300 kPa (+/-20 kPa), for a volume of 1.6 l - 380 kPa (+/-10 kPa).

- After turning the ignition key, the vibration of the fuel pump is not heard.

If your car has the above “symptoms”, then you should not immediately rush to conclusions. Many of them are quite general, characteristic of a number of problems, and only the last three signs clearly indicate a fuel pump malfunction.

There may be several reasons why this particular device failed, including:

- fuse burned out;

- Fuel pump relay 2114 broke;

- the mass contact has come off or oxidized;

- the fuel pump contacts have oxidized;

- the electric motor burned out;

- The pump itself has failed.

The search should begin, as in most other cases, by checking the fuse. The VAZ 2114 fuel pump fuse is located in a small black box located on the housing of the electronic control unit. It is designed for a maximum current of 15 A, and its socket is marked fuel pump. The fuse should be carefully removed and checked. If it turns out to be burnt out, you just need to replace it with a new one designed for the same current.

If the reason is not in the fuse, then the next step is to check the condition of the relay. True, here many motorists may ask a logical question - where is the fuel pump relay on the VAZ 2114, because it is not in the common unit? You can find this electronic device next to the handbrake lever, under the dashboard. To open access to it, you will have to remove the plastic around the handbrake.

To check the serviceability of the relay, simply turn the ignition key in the lock and listen carefully. If the relay is working properly, a characteristic click will be heard. If it fails, the device will not make any sound. A broken relay should be replaced with a new one, since this device is not repairable, and it does not cost much.

After checking the relay, you should also check the ground contact located not far from it (when manipulating the relay, it will be clearly visible). The contact should be cleaned and its fastening to the steel body of the car tightened.

If after all the above steps the fault cannot be found, it is worth checking the condition of the contacts in the fuel pump wiring and the wiring itself. The latter can be done by regular testing using a multimeter. If a wire break is detected, it should be repaired - there is nothing complicated here. If it turns out that the wiring is working properly and voltage is supplied to the pump, but it does not work, you should check its contacts.

On the fuel pump body there are not two, but three connectors - positive, negative and control (for the fuel level). Connect a 12 volt light bulb to the positive and negative connectors and turn the ignition key. If the contacts are working properly, the light will light up.

If this does not happen, you should thoroughly clean the contacts with fine sandpaper or a cloth with kerosene, and then carry out the experiment again. If the light does not light up again, then the reason lies deeper.

The next step in troubleshooting the pump should be to check the functionality of its motor. This can be done using the same lamp - by connecting the lamp contacts to the motor connected to the on-board network, you should turn the ignition key.

If the light bulb does not react, you need to thoroughly clean the contacts of the electric motor, and then repeat the experiment. If the light blinks and the motor does not react in any way to the incoming voltage, then it is out of order and it’s time to buy a new one.

Reliability of S-Tronic from Audi

At the same time, car owners need to take into account the fact that the Audi S-tronic automatic transmission is not without its drawbacks. First of all, such disadvantages include a significant complication of the design. It was possible to achieve the smoothest possible shifting without a loss of power through the use of additional shafts and clutches. As a result, there are more moving elements inside the transmission, which, despite the use of fairly durable materials, are susceptible to breakdowns. In addition, car owners need to take into account the fact that preselective gearboxes, which include s-tronic, require qualified service. It is necessary to regularly change the oil in the transmission, which is done after a mileage of 40 - 50 thousand kilometers. The desire of the car owner to save money on service work inevitably leads to breakdowns of clutches and problems with solenoids. Oil in s-tronic must be used exclusively original.

Structurally, this gearbox has a slightly different design than classic automatic gearboxes. For this reason, many specialists in service centers simply refuse to service and repair the s-tronic automatic transmission. All this somewhat complicates the performance of repair work and service of the preselective automatic transmission.

Reviews from car owners about this gearbox vary significantly. Some people are absolutely delighted with the use of the s-tronic preselective gearbox, while other car owners negatively evaluate their experience of using cars with similar transmissions. Certain complaints are caused by the reliability of the gearbox and the complexity of its repair. Even the slightest breakdown requires dismantling the transmission and repairing it at a special stand. At the same time, qualified repairs can only be performed at certified Audi and Volkswagen service centers. Whereas in most universal repair shops they simply refuse to repair this transmission and problems with the S-tronic have to be fixed in specialized workshops.

In general, it must be said that the indicators of handling comfort, dynamics and fuel efficiency of the Audi s-tronic gearbox are at a high level. Whereas, due to its structural complexity, this automatic transmission places increased demands on service work and at the same time does not have the required reliability, which is typical for Audi Volkswagen automatic transmissions.

conclusions

It should be noted that the indicators of controllability and dynamics, the level of comfort and economical fuel consumption are the strengths that convince us of the advisability of choosing the S-Tronic robotic gearbox.

But at the same time, buyers of Audi cars with this unit, especially used cars, should take into account that the complex design places high demands on service and repair, and the level of reliability in comparison with other transmissions of the Volkswagen concern cannot be called optimal. The Volkswagen concern began work on creating preselective automatic transmissions back in the first half of the 80s of the last century. In 2002, the developed S-Tronic transmission with a pair of clutches made its debut in mass production. During this time, this unit has been significantly refined and improved, and even its new generations, due to a long period of operation, periodically require qualified repairs and maintenance (for example, replacing the automatic transmission oil pump). We’ll talk in more detail about the features of S-Tronic and reviews from owners of cars with it.

X Tronic CVT gearbox: what is it?

X-Tronic is a CVT gearbox, which is gradually replacing the automatic transmission, since, unlike it, it is reliable, durable and economical. It would be a stretch to consider it a gearbox, since it has no gears, but does have a continuously variable transmission. Such a box is called continuously variable due to the fact that during operation it gradually changes the gear ratio.

The first of these boxes were not very reliable - they quickly exhausted their resources if drivers practiced extreme driving. But the new Xtronic does not have the shortcomings of its “predecessors”. Now there are modernized options that meet technological standards. Now it is a V-belt variator, which has its own characteristics:

- The pulleys in it are adapted for operation under increased loads.

- The belt has become less flexible, but its service life has increased significantly.

- The oil pump has become more efficient.

The dimensions of the box have decreased. Cars equipped with such gearboxes begin to move more smoothly and consume fuel much more slowly. The unit no longer experiences overloads, which is why its service life has increased significantly. The box feels more confident at high speeds.

The modernization also affected the firmware. We added some adaptive modes - for use in rural areas, sports, etc. All these changes made it possible to use boxes even with high-power motors.

Explanations and causes of the most common automatic transmission errors for Audi, Volkswagen, Skoda

The most popular fault codes are:

- P0729, P0730, P0731, P0732, P0733, P0734, P0735, P0736 (17113 - 17120) - incorrect gear ratio of individual gears (P0729 - 6th gear, P0730 - general for automatic transmission, P0731- P0735 - 1st to 5th -th gear respectively). These errors appear as a result of slipping in certain gears. The cause is usually burnt out friction clutches, problems with the hydraulic unit, wear of the sealing elements of the friction clutch pistons (typical for automatic transmission 09G). Sometimes these errors are recorded together with errors P0780-P0784 (gear shift control).

- P0740, P0741 (17124, 17125) – malfunction of the torque converter lock-up clutch, no torque transmission. In this case, the problem most often lies in severe wear of the torque converter lock-up clutch. When driving, this problem can be expressed in the form of floating speed (100-200 rpm) in partial load mode, deterioration of acceleration characteristics.

- P0746, P0747, P0748, P0749, P0750, P0751, P0752, P0753, P0756, P0757, P0758, P0761, P0762, P0763, P0766, P0768, P0771, P0773, P0776, P0777, P077 8, P0779 (17130 – 17163) – malfunctions in the electrical circuit of solenoid valves (solenoids). When these errors appear, the automatic transmission goes into emergency mode (all control electronics are turned off). The causes of the malfunction usually lie in the electrical wiring and the solenoid valves themselves. Less commonly, the cause of the malfunction may be the automatic transmission ECU (VW Passat B5+, Audi 97-04 with ZF automatic transmission).

- P0705, P0706, P0707, P0708, P0710, P0711, P0712, P0713, P0714, P0715, P0716, P0717, P0720, P0721, P0722 (17089 – 17106) – malfunctions associated with the automatic transmission input and output shaft speed sensors ( G182, G195), automatic transmission oil temperature sensor (G93) and gear engaged sensor (inhibitor) (F125). On different models of boxes, these problems are solved in different ways: from simply replacing sensors to replacing the mechatronics unit.

Main problems of DSG 7 (DL501, 0B5)

In terms of the complexity of its design, the DL501 (0B5) automatic transmission is significantly superior to classic hydromechanical automatic transmissions. Imagine a traditional dual-clutch manual transmission with a dual input shaft (one shaft is located and rotates inside the other), the operation of which (clutch release, gear shifting) is carried out by an electronic-hydraulic system. To dampen torsional vibrations, the DSG 7 (DL501, 0B5) uses a dual-mass flywheel. In addition, there is a lubrication system that supplies oil (transmission fluid) to the shaft bearings, center differential and front cross-axle differential. Transmission fluid is also used here to cool friction couplings (clutches) and control the hydraulic gear shift system.

The S tronic transmission oil (DL501, 0B5) is cooled in a heat exchanger (radiator) built into the engine cooling radiator. If the seal of the automatic transmission radiator fails, coolant enters the transmission oil. Its presence in the automatic transmission oil leads to problems in the clutch control system.

Malfunctions of the DSG 7 (DL501, 0B5) box can be divided into hydraulic, mechanical and electronic. In other words, literally all the important components of this S tronic automatic transmission turned out to be weak and short-lived.

Electronic problems with DSG 7 (DL501, 0B5) include destruction of mechatronics boards. These boards are plastic structures with conductive tracks connecting the mechatronics with solenoids, an input shaft speed sensor and a friction clutch temperature sensor. The boards are closed and immersed in oil, the temperature of which is very high. Over time, due to temperature exposure, the plastic of the boards is deformed and bent, which immediately causes a break in the conductive paths.

Also, the Hall sensors, which are part of a separate module that reads the rotation speed of the input shafts and determines the engaged gear, fail. Oil pressure sensors and gear fork travel sensors are also short-lived. Electrical symptoms manifest themselves in the lighting of errors on the instrument panel, sudden hard gear shifts, shutdown of one part of the gearbox (even or odd gears remain operational), complete shutdown of the automatic transmission for a while, inconsistency of the selected mode with the position of the automatic transmission selector.

In addition, the solenoids that control the DSG 7 gearbox (DL501, 0B5) are also susceptible to premature failure.

The DSG 7 (DL501, 0B5) box may fail due to problems with the car's battery. One unsuccessful “light” (either your car or someone else’s) is enough to encounter a burnout of the control unit of this automatic transmission. If the battery is weak (and it usually does not last more than 5 years), it must be replaced.

Hydraulic problems are primarily related to the operation of the oil pump, especially on DSG 7 (DL501, 0B5) gearboxes manufactured before 2010. Due to the poor design of the oil pump, a crack appeared in its thin body, through which oil leaked, directed to the pistons of the friction clutches. Because of this, both clutches (both clutches) engaged simultaneously and overheated. The “improved” pump has thicker walls, which was achieved at the cost of reducing the thickness of the steel bushing in which the compression rings operate. Now the oil begins to escape through the bushing, which is deformed under the influence of hot oil. The problem with engaging both clutches also appears on the new pump, but to a lesser extent.

There is also a problem with the ejection pump, due to the destruction of the seals of which the amount of oil supplied to cool the clutches (friction clutch) is reduced. As a result, the clutch “burns out” and the entire automatic transmission overheats. All this leads to severe wear of clutches (friction clutches) and the appearance of strong jerks when changing gears.

The mechatronics itself fails due to wear of its walls by the plungers.

Mechanical failures primarily include clutch wear: the friction linings turned out to be quite delicate, and their service life may become even shorter due to problems in the DSG 7 box itself (DL501, 0B5) .

We often see wear on the front clutch support bearing: it simply breaks the seat race in the clutch cover. There is a backlash, a misalignment of the entire clutch relative to its shafts.

A dual-mass flywheel can indicate the end of its life with a characteristic knock or vibration.

Even the body of the DSG 7 box (DL501, 0B5) is not particularly durable. Often the clip under the front left axle shaft breaks.

Problems in the operation of DSG 7 (DL501, 0B5) may be associated with a malfunction of the power unit. Banal misfires in at least one cylinder affect the smoothness and adequacy of gear shifting. Any discrepancy in the torque developed by the engine is immediately reflected in the operation of the S tronic automatic transmission.

Design and principle of operation of Tiptronic

The Tiptronic device is practically no different from the device of a classic automatic transmission. And the movement in a car with tiptronic is identical to the movement of a car in which a conventional automatic transmission is installed. The only difference is that the Tiptronic box allows the driver, if necessary, to quickly switch the control selector to manual mode.

The Tiptronic system operates using switches in the gearbox selector and switches (if equipped) on the steering wheel.

The gearbox selector can be equipped with one to three switches: one for switching on the mode, the second and third for switching to lower and higher gears. Signals from the switches are transmitted to the electronic transmission control unit, which runs the program algorithm and ensures gear shifting.

The peculiarity of the gear change algorithm in the Tiptronic gearbox is as follows: when increasing gears, the selector takes the front non-fixed position, when downshifting, the selector moves to the rear non-fixed position. This algorithm differs from conventional gear shifting, where the selector is pushed back to upshift and forward to downshift.

The Tiptronic box operates in two modes: full automatic and manual control. In manual mode, the driver does not simply limit the automatic transmission to using a certain range of gears (for example, no higher than third), but independently decides which specific gear should be engaged.

Automatic mode has the same positions - D, N, R, P, but there is a special cutout on the side for manual mode. When the selector moves into this groove when changing gears, manual control of the gearbox operation is carried out. You can adjust the gear by moving the lever to the “+” or “-” position.

Tiptronic is switched off by moving the gear selector back to position D. On some car models, switching is done using the steering column switches (paddle shifters). The set gear is displayed on the instrument panel.

When you press the steering column switches, the control system switches the box to manual mode, bypassing the selector lever. If the steering wheel paddles are not used by the driver, the control system itself switches the box to automatic mode.

Tiptronic repair

Like any other technical unit with complex moving parts, a tiptronic box periodically requires repairs. Of course, if you use the box in accordance with the manufacturer's recommendations and undergo regular maintenance, most problems can be avoided.

Most breakdowns of automatic transmissions with tiptronic are associated with drivers who have extensive experience, but are driving for the first time with tiptronic. The most common breakdowns of such gearboxes are:

- Wear of parts. More often than others, the oil seal and oil supply pump fail. Usually they are simply replaced with new ones. However, the price of the pump and oil seal is not very affordable.

- Problems with the electronic control unit. The ECU is the most vulnerable part of these boxes. Even with careful use, software errors periodically occur, which are eliminated through computer diagnostics. For example, common problems associated with the ECU are that the tiptronic box jerks at a traffic light or the tiptronic shifts third gear into neutral.

- Oil. The complete absence of oil or its low quality greatly harms parts, especially planetary gears. You need to understand that in the box the slightest deviation from the rules will cause a malfunction in the future. There are often cases when car enthusiasts, in pursuit of savings, pour cheap oil from unscrupulous manufacturers or dilute the oil themselves with water and additives.

Important! Tiptronic oil should only be filled with oil recommended by the manufacturer. It must correspond to the required viscosity and boiling point. You can change the oil in the tiptronic box yourself, following the instructions

You can change the oil in the tiptronic box yourself, following the instructions.

Most breakdowns cannot be solved by the car owner on their own, since problems associated with the tiptronic gearbox can only be solved with the help of expensive technological equipment. Independent intervention and adjustment of the tiptronic can lead to complete malfunction of the gearbox and even the engine.

S tronic - What is it

Audi S tronic is a robotic gearbox with unique properties, capabilities and qualities. The design of the S tronic preselective gearbox includes two rows of modes (essentially, these are twin shafts with gears from independent manual transmissions combined into one mechanism) and two clutches, each of which is responsible for the operation of its gears - even and odd rows.

For example, when the car accelerates, second gear is engaged, then the automatic transmission is activated and instantly switches to third by opening the clutch discs of the (even) row and connecting the next one. The process of switching to another mode occurs very quickly, with no characteristic jerks or delays; power from the power unit is transmitted in a continuous flow through a preselective transmission to the vehicle's chassis.

wear of the mounting hole of the left drive bearing

The owner can guess the problem by the characteristic knocking or vibration of the box under load (starting from a standstill and acceleration). Oil leaks that appear on the box are a sign of the same problem; it flows out through the left crankcase oil seal.

Other problems with the box, such as damage to the oil pump, leaks in seals or wear of the mechanical part - in particular bearings - are less common.

In general, this box can be easily repaired. The cost of such interventions, however, cannot be called budgetary.

- We talked in detail about the design, pros and cons of DSG “robots” here.

- We looked at the features of VAG CVTs here.

Pros and cons of the DSG S tronic robot box

A high-tech robotic box has all the positive qualities inherent in both traditional mechanical devices and automatic machines. Thanks to the electronic control unit, which operates using complex circuits and algorithms, driving the vehicle is more comfortable.

Car owners who own a vehicle with a DSG S tronic preselective gearbox note the following advantages of their cars:

- Relatively small dimensions and weight of the mechanism.

- Improved car dynamics.

- Smooth and, at the same time, fast acceleration of the car.

- Instant speed switching (takes no more than 0.8 seconds).

- Economical (fuel consumption savings - at least 10%).

- The absence of a clutch pedal makes it easier to control the gearbox.

If some problems occur during operation of the robotic gearbox, the driver receives appropriate warnings. By contacting the service center in a timely manner, repairing the entire device is simplified. Using special diagnostic devices, qualified workers quickly find problems that have arisen in the vehicle and fix them in a short time.

Among the observed shortcomings, the following factors are noted:

- the relatively high cost of the mechanism, which is reflected in the price of the entire car;

- expensive qualified maintenance of the si-tronic, since partial or complete oil changes, as well as the oil filter, should be carried out only in specialized service centers;

- complicated box design.

When the working units and parts of the differentials wear out, various negative symptoms begin to appear:

- Dips, shocks during acceleration and transition to high speeds.

- Vibrations when switching from first to second speed.

Recommended consumables and devices:

- ATF oil G052529A2 - 6 liters.

- Filter 0B5325330A.

- Filter seal WHT005499A.

- Pan gasket 0B5321371E.

Problems with the box and their solutions

Owners of cars with this box need to know the most common problems with the Audi S-tronic and how to fix them.

Read also: Step-by-step instructions for replacing silent blocks in an Audi 80 yourself

Jerking when starting

This problem most often occurs due to a malfunctioning clutch; before going to the salon, you can use a few tips to fix the problem yourself. First, the engine warms up to standard operating temperature, after which you need to make sure that the ignition and power system is working properly. If the tremors do not go away, you need to check options with minor breakdowns that can be repaired independently:

- deformation of the driven disk - it will need to be replaced;

- jamming of the gearbox input shaft hub - you should clean the splines from dirt and eliminate minor damage with a file; if it is significantly damaged, it is better to replace the disk and/or input shaft, and also apply CV joint-4 lubricant;

- damage on the surface of the flywheel or pressure plate - replace the flywheel or clutch “basket” (clutch housing with pressure plate);

- wear of the fastening of the friction pads or the elasticity of the springs of the driven disk - replace the driven disk.

Photos of Audi Q5 2.0 TDI quattro S-tronic

Strange sound when accelerating

Most often this may be due to clutch malfunctions, of which the S-tronic gearbox has two. If you have the skills and abilities, you can check the clutches yourself and replace them; if necessary, this procedure is performed in several steps:

- The parts blocking access to the transmission are removed, after which it must be unscrewed and inspected for deformation. The condition of the dual-mass flywheel is also checked; if it is severely worn, it must be replaced.

- The clutch is removed, if it is damaged or already badly worn, it should be replaced with a new one. It is better to replace both clutches at the same time.

- The transmission is connected to the engine, everything is installed in its place.

Before purchasing an Audi car with S-tronic, you need to realistically assess your capabilities so that in the future its operation and maintenance do not seem difficult.

This video will tell you what the S-tronic automatic transmission from Audi is:

The video below will tell you about the features and common causes of automatic transmission failure of the Audi A5 DSG7 0B5 (DL501 S-Tronic):

Comparison with A4 CVT

Nowadays, it is increasingly rare to find cars equipped with a CVT gearbox if their engine capacity is more than 2.0 liters. This is due to the fact that its main disadvantage is severe overheating, which especially negatively affects the performance of SUVs or sedans that drive in difficult conditions (mud, snow). Another serious problem with CVTs is that they have weak torque, and for high-power engines this is a serious hindrance.

Not all drivers were satisfied with the use of CVT, since it was repeatedly noted that its optimal mileage is about 100 thousand km, and after overcoming this indicator, malfunctions may occur, and this system is not very simple to maintain, both financially and physically.

It cannot be said that CVT is the worst option, it also has a number of its advantages, but as for the S-tronic, all serious shortcomings were taken into account and corrected, which in many ways make owning such a car easier.

S-tronic in the Audi A5 coupe

Pros and cons of the DSG S tronic robot box

A high-tech robotic box has all the positive qualities inherent in both traditional mechanical devices and automatic machines. Thanks to the electronic control unit, which operates using complex circuits and algorithms, driving the vehicle is more comfortable.

Car owners who own a vehicle with a DSG S tronic preselective gearbox note the following advantages of their cars:

- Relatively small dimensions and weight of the mechanism.

- Improved car dynamics.

- Smooth and, at the same time, fast acceleration of the car.

- Instant speed switching (takes no more than 0.8 seconds).

- Economical (fuel consumption savings - at least 10%).

- The absence of a clutch pedal makes it easier to control the gearbox.

Concept and design of preselective boxes

Every transmission has certain strengths and weaknesses. The main disadvantage of the classic “automatic” is the disconnection of power when moving from one gear to another. To eliminate this drawback, representatives of the automobile industry are developing modernized automatic transmissions, where it is possible to change gears without this disconnection (break). This led to the appearance of preselective boxes.

Their idea is quite simple. The operation of a manual transmission with a pair of shafts was taken as the basis for its creation. In fact, this box has two clutches to eliminate power gaps when changing between gears. This solution not only helped improve dynamic performance, reduce gasoline and/or diesel consumption, but also increased the safety of the car when overtaking and performing other maneuvers at speed.

Today, Audi cars are equipped with 7-speed preselective robotic gearboxes, which are called S-Tronic. This unit has proven itself well in the market, is considered reliable, technologically advanced and one that contributes to increased comfort when driving a car.

How does S-Tronic work?

In its design, such a preselective s-tronic gearbox is closer to mechanical transmissions, which are equipped with a special device for fully automatic gear shifting. There are special steering column switches for manual gear changes. In this case, switching occurs in a fraction of a second, and the power is not interrupted due to the presence of two clutches. It is possible to activate a fully automatic operating mode, when the electronics independently decide to change gears. Audi's seven-speed s-tronic transmission is fully computer controlled, which monitors the transmission parameters. If there are any problems with the automatic transmission, a corresponding warning is displayed. This not only increases the ease of operation of the transmission, but also simplifies subsequent S-tronic repairs in Moscow. Using special diagnostic equipment, a service technician can easily identify an existing breakdown and fix it in a short time.

The box allows you to reduce the understeer of the car by compressing the clutch packs in the right turn, and when turning left, the hydraulic drive locks, and as a result, the right wheel receives more torque

Story

The 5G-Tronic automatic transmission, the sixth in the company's series of automatic transmissions, was introduced by Daimler AG in 1990. This is the first Mercedes-Benz automatic transmission with electronic control and torque converter locking. The 5G-Tronic gearbox received the internal designation NAG1

(“new 1st generation automatic transmission”).

In the first releases and until 1999, the 5G-Tronic automatic transmission used a sliding bushing to interface the input and output shafts, which was clearly too weak for the loads. It quickly broke and due to the loss of oil pressure and the resulting strong play of both shafts, the planetary gear failed. In 1999, as part of the modernization of the gearbox, this problem was corrected by replacing the problematic bushing with a needle bearing with a Teflon ring. In addition, the sliding bushing in the sun gear was replaced with a bearing.

In 2001, the 5G-Tronic gearbox was again slightly improved. In order to increase fuel economy and reduce switching time, some modifications of the 722.6 automatic transmission began to use thin one-way clutches (friction disks), which quickly fail under increased loads (such as sudden acceleration or slipping).

Despite the release of the 7G-Tronic automatic transmission in 2003, the five-speed gearbox continued to be used, for example on the W211 (until 2009), as well as on the W164 (only in combination with the M113 V8 engine until 2006) and vehicles with V12 engines, such as R230 (until 2011), C216 (until 2014), S600, and others. This is because the 7G-Tronic's torque is limited to 735 Nm, while the 5G-Tronic has a torque potential of 1,079 Nm. Additionally, not all all-wheel drive ( AWD)

) are compatible with the 7G-Tronic series gearbox.

In addition to Mercedes-Benz models, cars such as the Jeep Grand Cherokee, Dodge Durango (2011-2012, V6 engines only), Chrysler 300 (2005-2014), Dodge Magnum (2005-2008, AWD, RT and SRT8), Dodge Challenger (2009-2014), Dodge Charger (2006-2014), Jaguar X308 (1998-2002), SsangYong Rexton (2004-), SsangYong Kyron (2006-), Porsche 911 (996 series, 1998-2005 ) and others.