An insufficiently charged battery is a common problem faced by many car enthusiasts. If nothing is done in this situation, soon the only solution will be to replace the battery.

It is a mistake to assume that undercharging is associated solely with the end of the battery’s service life or with its defect. Sometimes the fault lies with the motorist himself, who does not comply with operating rules. In addition, the car's generator is a common culprit. And here you need to figure out why the generator may not charge, and how to act in a given situation.

What indicates a problem

It will be useful for the car owner to know what signs can be used to determine that the car’s generator is not charging the battery. This will allow you to detect the problem in a timely manner and take a number of measures to eliminate it.

In the case of modern cars, which are literally overflowing with all kinds of electronics, it is not surprising that there are problems in the electrical system. Even if we are talking about premium segment models.

If a driver is interested in how to understand that his generator is not charging or is not charging the battery well, then several answers can be given here.

The following characteristic symptoms of such problems are identified:

- a light indicating the battery lights up on the dashboard;

- the electrolyte boils away, traces of it appear on the body;

- even after a long trip, the battery still shows a low charge level;

- During the operation of the car, the intensity of the lighting changes;

- Uncharacteristic sounds are observed from the generator.

If you encounter similar symptoms, there is a high probability that the incorrect operation of the car is due to the undercharging of the battery from the installed generator.

If the battery does not charge from the charger

The most common reason is that the battery is completely dead and cannot “swing” with a small current in normal charging mode. This most often occurs on batteries that have not been used for a long time. Here you can try to increase the charging current and “push” the battery with a more extreme charging method. In most cases, this works, and the battery gradually restores its properties.

If you try to charge a non-working charger, the battery will also not respond at all. Then you should check the device using a multimeter or tester, or simply connect the battery to a working charger. If in this case the battery does not charge, then the reason lies inside it. You should always treat your car battery with care and never leave it unattended while charging. Especially if you charge it with a high current.

Generator performance assessment

If there is a suspicion that the car’s generator is not charging the battery, or is not doing it efficiently enough, then it is recommended to check the unit for functionality. You can do this yourself, without involving third-party specialists in the work.

But here it is quite logical to ask how to independently check the current charging from the generator required for the battery.

It's best to start with indirect signs. Take a look at the dashboard, where there is probably a warning light. If there are no problems in the power supply system, the battery light should not light up. If it is constantly active, then there is a high probability that the battery is not receiving a charge from the generator, or it is very weak.

Of course, such a sign will not give an exact answer. Therefore, it would be more correct to check the generator with a universal multimeter. It will definitely allow you to understand whether the battery is charging or whether there are certain problems in the system.

To do this, you need to connect the probes of the measuring device to the power source, while starting the engine so that the generator runs. If in voltage measurement mode the device shows about 13.6–14.6 V, then everything is fine, the charge is being received. If the device displays about 12 V or even nothing, the battery is not receiving the required charge. You should look for the reasons and eliminate them.

Control of other elements of the charging system

To determine why the alternator is overcharging or not charging the battery at all, you may need a multimeter. Using the tester, you can measure the battery voltage in two modes. With the engine turned off, the charge parameter should be in the range of 12.5-12.7 volts, and with the engine running - 13.5-14 volts. If these indicators are lower when the internal combustion engine is switched on, this may indicate problems in the operation of the diode bridge or brush assembly. By the way, brushes can wear out, so they need to be changed periodically.

If the cause of overcharging or lack of charging is a relay, it can be eliminated by replacing or resoldering the diodes. If the diodes will be soldered, it is necessary to select devices that are closest in technical characteristics. Otherwise they may overheat.

What charge goes from the generator to the battery?

You should also understand the voltage from the generator going to the vehicle battery.

To draw any conclusions regarding performance, you need initial data, indicators that are considered the norm. The primary task is to find out what kind of charge generally should be from the generator to power the battery.

Motorists often make the same common mistake. They replace the battery with a more powerful battery, the parameters of which go beyond those recommended by the automaker. But at the same time, the old generator is left running. The latter, in turn, may simply not cope with the increased load. That is, it does not provide the necessary charging.

Now to the question of how much a standard generator under the hood of a car normally produces to charge the installed battery. The norm is considered to be a voltage of 13.5 to 14.5 V. This is how much the generator transfers to the starter battery so that the latter can replenish its lost charge.

To avoid such undercharging problems, it is better to check the car manufacturer’s recommendations in advance and select components based on these data.

Understanding now what kind of charge the generator should normally provide to the battery, we can give one useful piece of advice. To avoid difficulties starting your car, even in winter, focus on generators capable of delivering a charging current of approximately 10% of the battery capacity. Relatively speaking, if you have a 75 Ah battery under the hood, then the generator should supply 7.5 A. But do not forget that in addition to the battery itself, the generator has a number of consumers that it must also power. And the device should not operate at its maximum capacity. That is, the unit should be purchased with a certain power reserve. The automaker initially calculates this, and therefore the parameters of the factory generator are usually sufficient. It is better to change it if the battery is replaced with a more powerful one, and additional powerful consumers are installed that are not included in the standard configuration of the car.

Insufficient contact

Please note that if the brushes and rings on the rotor become oily or dirty, contact may be lost for a short time or permanently. It is possible that the springs in the brush holder have deteriorated. With their help, the brushes are pressed against the rings on the rotor. Consequently, the total resistance of the excitation winding increases, or the electrical circuit is completely broken. In this case, the generator gives a weak charge or stops working altogether. To get rid of this problem, sometimes you can simply wipe the brushes with a lint-free cloth. It is advisable to moisten it in solvent or gasoline. Of course, if the brushes are very worn, they need to be replaced. In the event that oxidation of the rings has occurred, it is necessary to clean them using glass sandpaper.

How to check voltage

Separately, it is worth considering the question of how you can check the current generator voltage on the vehicle battery. Diagnosis is possible in 2 ways. Directly on the generator itself, or through the battery.

For direct communication between the battery and the generating device, a wire with a thick cross-section is used, which allows you to check the potential difference directly on the battery. Here you can use 3 measuring instruments:

- multimeter;

- voltmeter;

- load fork.

The voltmeter and multimeter are connected with probes to the battery. Moreover, in their case, it is not necessary to observe polarity. If a load fork is used, then plus goes to plus, and minus goes strictly to minus. Violating the polarity is strictly prohibited.

The normal mains voltage is considered to be about 12 V. If you turn on the engine at idle speed, but do not turn on electrical appliances, then the norm will be from 13.5 to 14 V. If the voltage drops to 13.3–13.8 V, this is still considered normal.

Using a tester in the form of an ohmmeter or multimeter in resistance measurement mode, you can check the stator, rotor and diode bridge of the generator. When the resistance on the rotor is about 2.3–5.1 Ohms, the equipment is considered to be in good working order. On the winding, the current consumption should be in the range from 3.0 to 4.5 A, and the resistance should be about 0.2 Ohm.

The diode bridge is tested by determining the presence or absence of resistance. Specific numbers don't really matter. It is only important that the resistance does not turn out to be zero.

Do not forget that for normal recharging of the starter battery, a voltage in the range from 13.5 to 14.5 V must be supplied from the generator.

Theory of the issue

While the car is moving, a dead battery receives a charge voltage of 13.6 to 14.2 V. For the correct and stable operation of all systems in the car, these voltages must be maintained until the engine starts and the crankshaft rotates. Together with the motor, torque is supplied to the generator through the drive belt. At this moment, an amount of energy is generated that will be sufficient for the stable functioning of all systems and to maintain a charge on the battery.

If the generator does not charge, then in most cases the reasons must be sought in the excitation circuits, as well as in the output voltage circuits from the generator to the battery. But this is not always the case. Sometimes problems are related to the generator itself.

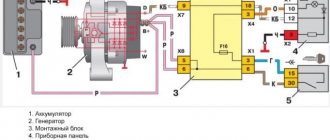

When the driver turns the key in the lock, the relay in the ignition system also starts at the same time. “Plus” flows through the relay and fuse in the mounting block. Next, the voltage passes through the on-board network, reaching the battery charge lamp and charge sensors. It then passes through diodes, relays, elements in the mounting block and finally to the connector in the generator. There, electricity comes to the relay-regulator and, passing through brushes and slip rings, enters the exciting winding.

Number of amperes from the generator to the battery

Also, many are interested in the question of how many amperes a car generator normally produces for a standard battery. It is important to understand here that the current strength is individual for each electrical system of the machine. It is directly related to how many energy consumers are in the car, and how much is needed for full operation. Additionally, the current must be sufficient to charge the battery.

Amps appear only when a load is formed in the electrical system and the battery is being charged. When the engine was started, the current averaged from 6 to 10 Amperes. But gradually this figure will fall as the process of charging the battery takes place, which takes on the main energy consumption. If you turn on the headlights, audio system, heated seats or mirrors, then the charging current parameters will begin to increase.

Some tips for extending battery life

You can keep the battery in working condition without letting it stop charging if you strictly follow the operating rules. Be sure to recharge it on time and keep the device clean. After purchasing a new battery, owners have many questions regarding the charging time and conditions of its use. Sometimes car enthusiasts do not know how to prepare a power source for installation on a car and whether it is worth doing it at all.

Any battery requires careful care and timely maintenance. This will help extend its operational life by at least a couple of years, as well as reduce interruptions in the operation of on-board electronics.

Here are 8 simple steps:

- Keep the battery and its terminals clean. Without proper care, the battery will become covered with a fairly thick layer of dust and dirt within a month. And this is one of the main problems of rapid self-discharge. The body can be washed with an aqueous solution of soda, and then rinsed with clean water. You can clean sulfates or oxidation from the terminals with fine sandpaper.

- Monitor the charge level. This will help you know if it is charging enough from the generator and when it needs to be placed on a stationary charger. You can check it in three ways: by reading the indicator on the battery itself, by measuring the density of the electrolyte, or with a multimeter.

- Charge your battery properly. In most cases, charging from stationary devices is not required; a car generator is sufficient. If for some reason the battery is discharged by 65-70%, feel free to charge it. In addition, it is recommended to charge the battery to 100% at least once a month.

- Monitor current leakage. They can be both useful (alarm operation, DVR, etc.) and harmful (devices left turned on, damaged wiring, incorrect connection, contamination or wetness, etc.). Naturally, they need to be looked for and eliminated immediately.

- Make it easier to start the engine. The harder the engine cranks, the more battery energy is spent on it. Depends on many factors: fuel quality, how the ignition system is set up, the power system, air temperature and much more.

- Conduct preventive training. Very useful, especially if the battery has been operating under harsh conditions. The principle is a forced controlled discharge using a special device, followed by charging it with a high current.

- In cold winters, pre-charge the battery. This is especially important to do if the battery is discharged by more than half during idle time. As a result, the load on it will decrease and the service life will increase.

As you can see, there is nothing new or unusual. These eight points are easy to remember and just as easy to follow. But at the same time, the benefits from them are undeniable - the battery life increases by two or even three times. Perhaps many already follow these rules.

Why problems occur and how to fix them

It is worth considering separately why the generator does not charge the car battery, and what needs to be done in this or that situation.

This problem cannot be ignored. Even if you have a good charger, you can potentially compensate for the insufficient battery charge using a charger. But in parallel, there may be problems with the generating device itself. And its malfunctions directly affect the operation of the entire electrical system of the vehicle, and not just the battery.

There are several reasons why the car battery is potentially not being charged from the alternator. They may be related to:

- terminals;

- generator belt;

- battery condition;

- overload of the generating device;

- contacts;

- winding;

- mechanical problems;

- fuses;

- diode bridge;

- short circuit

Since the reasons are varied, you need to consider them separately and understand why the generator ultimately does not charge the car battery. Accordingly, recommendations will be presented to eliminate this or that problem.

battery

It would be useful to evaluate the current internal state of the battery, since if the battery is severely worn out, the generator may not be able to do its job fully.

Most often, motorists are faced with sulfation and its negative consequences. When device parts are coated with a layer of lead sulfate, charging is disrupted and battery performance decreases.

If sulfation is slight, you can try to restore the battery using a desulfator and special charger modes. But if sulfation has heavily affected the surfaces of the plates, then the most reasonable solution would be to replace the battery.

Terminals

Also look at the condition of the battery terminals connecting the battery to the generator.

If you notice that the battery light on the dashboard suddenly comes on after driving on a bumpy road, it is possible that the terminal has become loose due to shaking and vibration. She needs to be fixed.

Oxidation and mechanical wear can also affect the quality of terminal connections. Check the condition, wipe, remove traces of oxides. Use sandpaper only as a last resort.

Generator belt

To convert mechanical energy into electrical energy, the generator is connected to the crankshaft through a belt. It is the alternator belt that can cause the problem in question of undercharging the battery.

It happens that the belt tension weakens, or it simply wears out over time. Then not only will the battery not receive enough charge, but also general problems in the electrical system will become obvious and visible.

The condition of the alternator belt should only be checked with the engine turned off. Sometimes a simple belt tightening helps. If the profile wears out, the problem can only be solved by replacing the element.

In more rare cases, the belt slips along the pulley due to oil or other liquid getting on the surface. Therefore, it makes sense to try to remove dirt and dry everything.

Overload problem

There are also slightly different situations when charging still occurs from the generator, but the output voltage is not enough. This indicates that the generator is working, but it is not able to fully compensate for the battery charge.

Most likely, these are the last overloads of the generator, which is due to the installation of additional non-standard equipment on the vehicle. New consumers have appeared in the car, and the current electrical system of the car can no longer cope with such a load. Try disabling the newly installed node. If after this the generator begins to charge the battery normally, then the reason has been determined.

There are 2 options here. The first is to install a higher power generator. But this may entail quite complex work to remake the entire electrical system. The second option is based on the refusal of additional freelance equipment.

The decision is up to the car owner. If your dream was to install powerful acoustics, then there is no choice. You will have to make major changes to the car.

Problems with contacts

Most often, specialists and ordinary car enthusiasts discover poor or weak contact in the car, which is why all the previously described symptoms arise.

Contact failure is usually associated with contamination, oxidation, and the ingress of oil and various technical fluids onto their surfaces.

First, you should try to clean all the contacts using a rag soaked in gasoline. Fine-grained sandpaper should be used extremely carefully and only when absolutely necessary.

If there is severe wear on the elements, then there is no choice. You'll have to change contacts.

Winding

We cannot exclude breaks in the winding, which motorists also sometimes have to deal with.

In such a situation, characteristic symptoms can be observed. The generator will not provide the necessary charging, and at the same time its temperature will begin to rise significantly.

To accurately determine the fault, you can disconnect the end of the excitation winding from the brush and connect it to the generator terminal. Then the multimeter is connected via the battery. If there is a break, the multimeter will show zeros. If this is a test light, it will not light up.

To find a faulty coil, a wire from the battery is connected to each of them in turn. If there is an internal break in the coil, you will have to change it. External integrity violations can be eliminated using a soldering iron.

Short circuit problem

A malfunction such as a generator short circuit can manifest itself in several ways. Namely:

- shorts to the rotor housing;

- short circuit on the stator;

- short circuit of the stator to the housing;

- violation of the plus on the body.

A car enthusiast without the appropriate knowledge is unlikely to be able to cope with this malfunction on his own. Therefore, the right decision would be to seek help from specialized specialists.

Mechanical faults

Mechanical failures cannot be ruled out. They often cause a conflict between the generator and the battery.

Mechanical faults include stretching, belt rupture, broken terminals, broken wires and much more, which can be eliminated by repair or replacement.

Fault on the fuse side

And it also happens that the reason lies on the surface, but for some reason the motorist loses sight of it and carries out complex diagnostic work.

In fact, it would be better to start by looking for reasons in the fuse box. After all, if the fuse is blown, then fixing the problem is potentially very easy. To do this, the old element is removed and a new one is installed in its place.

Only here it should be taken into account that the burning of a fuse may be a consequence of an accidental power surge. If there are problems in the wiring, problems with the generator or battery, then replacing the fuse will not solve the situation. Until the cause of the burnout, if any, is eliminated, each new fuse installed will suffer the same fate.

Diode bridge problems

If the diode bridge of a car generator fails, then it will not be able to charge the battery normally.

It is usually possible to diagnose such a problem by changing the intensity of the headlights as the engine speed increases or decreases. Potentially, an experienced auto electrician can restore the operation of the old diode bridge. But the objectively correct decision in such a situation would be to replace it.

There are many reasons why the battery may not be charged from the generator. Consider the symptoms and rely on your capabilities and knowledge. If in doubt, contact a specialist.

Thank you all for your attention! Subscribe, leave comments and tell your friends about us!

Possible causes of malfunctions

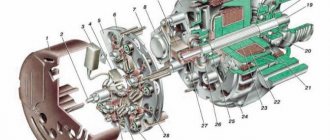

Brush wear

If the generator does not charge the battery, then the first thing that comes to mind on cars with sufficient mileage is wear of the brushes. There are few purely mechanical components in generators that affect its performance - and the brushes, constantly rubbing against the commutator, are worn out.

As the contact wears out, the contact deteriorates, and the current in the rotor winding drops accordingly. At first, the generator gives little charge at low speeds, “waking up” after re-gasping, then it fails completely. The brushes themselves can be either a separate unit or interlocked with a relay regulator.

When removing the brush assembly from the generator, you can easily feel how far it can be extended so that the elasticity of the springs is no longer felt - this will be the remaining working length of the longest brush. Please note that more often the brushes wear unevenly: on the side of the cover, where dirt and brush wear products accumulate, the brush wears out faster. This is also noticeable by the presence of a groove on one of the rings.

The groove itself is not so bad if it is worn evenly. Here it is wavy, with sharp changes in diameter - a direct indication of replacing the slip rings or rotor assembly. On foreign generators there is a monoblock design, when the diode bridge, the relay-regulator, and the brush assembly are one whole. Replacing such a monoblock is not a cheap matter, and it is stupid to do it when only the brushes are worn out. Therefore, they are soldered, selecting suitable ones from domestic generators or power tools.

Break

In the rotor, in addition to wear of the slip rings, there are few probable causes of malfunction - relatively low currents do not allow the winding to burn out, and much more often the wire breaks at the junction with the collector. The rotor is checked with a tester: first, the resistance between the collector rings is measured, then between the rings and the “ground”. In the first case, the resistance is several ohms, in the second - “infinite” (there is no short circuit of the winding to the housing).

Stator and diode bridge

Another reason why the generator does not charge is the most loaded components: the stator and diode bridge. With constant overloads, they overheat, which for the stator is fraught with destruction of the insulation, short circuit to the housing and fire of the winding, and for the diode bridge - failure or breakdown of the diodes. Externally, the symptoms are similar - the power of the generator drops (one or two phases do not work), or the generator fails completely.

The stator is assessed primarily externally - there should be no visible darkening of the insulation and no burning smell. Then, using a tester, the resistance of each phase winding and the absence of short circuits to the housing are checked.

It is better to check the diode bridge using a battery and a test lamp - in testers, the voltage during testing is low, and a broken diode can be missed in this way. A 12-volt 40-60 W light bulb and battery are more reliable in this regard. The test circuit is simple: we connect the “minus” from the battery to the power terminal of the diode bridge, and alternately connect the “plus” through the lamp to each terminal of the bridge to which the stator windings were connected. If the light bulb does not light on one of the phases, the diodes are burnt out. Next, we change the polarity of the connection - in this case, the light bulb does not light up in any phase, otherwise this will indicate a breakdown of the diodes in the bridge. We repeat the procedure, connecting the “ground” to the “horseshoe” of the diode bridge - the lamp does not light up. When connected in reverse, it should light up on all phases. Additional diodes are checked from the stator inputs to the terminal going to the relay regulator.

In this case, malfunctions of the stator and diode bridge are closely related: broken power diodes will lead to overheating of the winding in the corresponding phase, since it is short-circuited.

Problem with the relay regulator

The procedure for checking the relay regulator depends on the design. External ones (like on old Zhiguli cars) in the absence of charging are easy to check by making sure that current flows to the brush assembly after turning on the ignition (by connecting an ammeter to the circuit between terminal 67 of the relay regulator and the brush assembly). There is no current - change the “chocolate”.

If the relay-regulator is combined with a brush assembly, then you can measure the voltage on the brushes after turning on the ignition: it may be less than the on-board one, but it should be. Do not check the relay-regulators without a load: the output voltage in this case may be present, but when a load is applied to the faulty relay-regulator, it will drop sharply, and the working unit will have to be considered defective.

The lack of current in the stator winding will not necessarily be a consequence of a malfunction of the relay regulator itself. Remember what we wrote above about relay power circuits. In generators with additional diodes, it comes from the generator itself, but when the engine is not running, only the current through the control lamp goes to the relay-regulator. Such generators are easy to distinguish - only one low-current terminal from the control lamp is suitable for them. The relay is considered defective if the additional diodes in the bridge are operational.

In generators with external excitation, at least two low-current inputs are required - one from the control lamp, the second from the ignition “plus”. This is a very common scheme on Asian generators, where the pinout of the low-current connector can be easily deciphered by the markings (L - control lamp, IG - ignition). In generators of this type, after turning on the ignition, the voltage at the IG terminal must be present, otherwise the generator will not be excited.

Something else useful for you: