Steering is present in all cars, regardless of class and year of manufacture. The device must always be in good condition and any changes to it are prohibited. The VAZ 2107 and other classic Zhiguli models are equipped with a worm-type steering column, which requires periodic inspection and sometimes repair.

- Steering gearbox design

Signs of gearbox malfunction - Table: VAZ 2107 steering faults and ways to solve them

- Where is the gearbox located?

- How to remove the gearbox

Video: replacing the steering column using the example of a VAZ 2106

- Video: how to disassemble and reassemble the VAZ steering mechanism

- Video: adjusting the VAZ 2107 steering unit

- Checking the oil level

Video: changing the oil in a classic steering gear

Steering mechanism VAZ 2107 - brief description

The steering mechanism of the VAZ “Seven” has a rather complex design, which ensures reliable vehicle control in different driving situations. The steering wheel is endowed with good information content, which eliminates driver fatigue when traveling long distances. There are some difficulties when turning the steering wheel while the car is stationary. However, as soon as the car starts moving, the steering becomes less rigid and control improves.

The steering mechanism has one nuance - a slight play, which is normal. This is explained by the considerable number of parts in the gearbox and the presence of rods. After modernization, the VAZ 2107 began to be equipped with a safety column, which has a composite shaft. Its design consists of two cardan-type joints, which allow the shaft to fold in the event of an accident. In this way, injury to the driver is avoided.

The steering gearbox is designed to transmit force from the steering wheel to the tie rods to turn the front wheels to a given angle.

↑ What spare parts will be needed?

In case of replacing the entire assembly, the only thing that needs to be purchased is the original part (part number 21050-3400010-00). If this is not possible, you can buy units with other designations, but it is still better to use original components.

↑ Tools and accessories for repairing the steering gear

- set of wrenches;

- beard;

- screwdriver;

- hammer;

- vice;

- mandrel (you can take a piece of pipe of the appropriate size);

- rags.

The repair sequence for the VAZ 2107 steering gear can be divided into two main stages.

Steering gear reducer design

Before you begin repairing the steering column, you need to familiarize yourself with its structure, as well as its operating principle. The design consists of the following main elements:

- a unit designed to transmit force from turning the steering wheel to actuators;

- steering column, which turns the wheels to the desired angle.

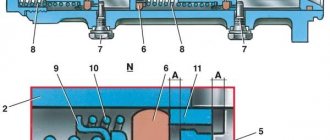

The steering mechanism consists of:

- composite shaft with cardan transmission;

- steering wheel;

- worm type steering gear.

The design has the following components:

- pendulum;

- swing arms;

- steering rods.

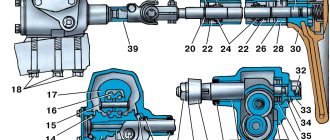

Steering design: 1 - steering gear housing; 2 - shaft seal; 3 - intermediate shaft; 4 - upper shaft; 5 — fixing plate of the front part of the bracket; 6 — bracket for fastening the steering shaft; 7 - upper part of the facing casing; 8 — bearing sleeve; 9 — bearing; 10 — steering wheel; 11 — lower part of the facing casing; 12 — bracket fastening parts

Since the outer rods have two parts, this allows the toe angle to be adjusted. The steering functions as follows:

- The driver operates the steering wheel.

- Through universal joints, the worm shaft is driven, through which the number of revolutions is reduced.

- The worm rotates, which helps move the double-ridge roller.

- The secondary shaft of the gearbox turns.

- A bipod is mounted on the secondary shaft, which rotates and carries the steering rods with it.

- Through these parts, force is applied to the levers, thereby turning the front wheels to the angle desired by the driver.

The bipod is a rod that connects the steering gearbox to the steering linkage.

Signs of a gearbox malfunction

As the vehicle is used, the steering column may develop problems that require repair. The most common of them are:

- oil leak from the gearbox;

- extraneous sounds in the mechanism;

- It takes a lot of effort to turn the steering wheel.

Table: VAZ 2107 steering faults and ways to solve them

| Malfunctions | Elimination method |

| Increased free play of the steering wheel | |

| Loosening the steering gear mounting bolts. | Tighten the nuts. |

| Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| Increased clearance in the ball joints of the steering rods. | Replace tie rod ends or tie rods. |

| Increased clearance in the front wheel hub bearings. | Adjust the gap. |

| Increased clearance in the engagement of the roller with the worm. | Adjust the gap. |

| There is too much clearance between the swingarm shaft and the bushings. | Replace the bushings or bracket assembly. |

| Increased clearance in the worm bearings. | Adjust the gap. |

| Stiff steering wheel rotation | |

| Deformation of steering gear parts. | Replace deformed parts. |

| Incorrect alignment of the front wheel angles. | Check the wheel alignment angles and adjust. |

| The gap in the engagement of the roller with the worm is broken. | Adjust the gap. |

| The adjusting nut of the pendulum arm axis is overtightened. | Adjust the tightening of the nut. |

| Low pressure in the front tires. | Set the pressure to normal. |

| Damage to ball joint parts. | Check and replace damaged parts. |

| There is no oil in the steering gear housing | Check and top up. Replace the oil seal if necessary. |

| Damage to upper steering shaft bearings | Replace bearings. |

| Noise (knocking) in the steering | |

| Increased clearance in the front wheel hub bearings. | Adjust the gap. |

| Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| Increased clearance between the pendulum arm axis and the bushings. | Replace the bushings or bracket assembly. |

| The adjusting nut of the pendulum arm axis is loose. | Adjust the tightening of the nut. |

| The clearance in the engagement of the roller with the worm or in the worm bearings is broken. | Adjust the gap. |

| Increased clearance in the ball joints of the steering rods. | Replace tie rod ends or tie rods. |

| Loosening of the steering gear mounting bolts or the swing arm bracket. | Check and tighten the bolt nuts. |

| Loosening the nuts securing the swing arms. | Tighten the nuts. |

| Loosening the steering intermediate shaft bolts. | Tighten the bolt nuts. |

| Self-excited angular oscillation of the front wheels | |

| Tire pressure is not correct. | Check and set normal pressure. |

| 2. The alignment angles of the front wheels are incorrect. | Check and adjust wheel alignment angles. |

| 3. Increased clearance in the front wheel hub bearings. | Adjust the gap. |

| 4. Wheel imbalance. | Balance the wheels. |

| 5. Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| 6. Loosening the bolts securing the steering mechanism or the pendulum arm bracket. | Check and tighten the bolt nuts. |

| 7. The gap in the engagement of the roller with the worm is broken. | Adjust the gap. |

| Steering the vehicle away from straight-line motion in one direction | |

| Uneven tire pressure. | Check and set normal pressure. |

| The alignment angles of the front wheels are incorrect. | Check and adjust wheel alignment angles. |

| Different draft of front suspension springs. | Replace unsuitable springs. |

| Steering knuckles or suspension arms are deformed. | Check the fists and levers, replace unsuitable parts. |

| Incomplete release of the brakes on one or more wheels. | Check the condition of the brake system. |

| Vehicle instability | |

| The alignment angles of the front wheels are incorrect. | Check and adjust wheel alignment angles. |

| Increased clearance in front wheel bearings. | Adjust the gap. |

| Loosening the tie rod ball pin nuts. | Check and tighten the nuts. |

| There is too much play in the tie rod ball joints. | Replace tie rod ends or tie rods. |

| Loosening of the steering gear mounting bolts or the swing arm bracket. | Check and tighten the bolt nuts. |

| Increased clearance in the engagement of the roller and worm. | Adjust the gap. |

| Steering knuckles or suspension arms are deformed. | Check the knuckles and levers; replace deformed parts. |

| Oil leak from crankcase | |

| Wear of the bipod or worm shaft seal. | Replace the seal. |

| Loosening the bolts securing the steering gear housing covers. | Tighten the bolts. |

| Damage to sealing gaskets. | Replace gaskets. |

Where is the gearbox located?

The steering gearbox on the VAZ 2107 is located in the engine compartment on the left side under the vacuum brake booster. If you have insufficient experience, you may not find it at first glance, since it is usually covered with a layer of dirt.

The steering gearbox on the VAZ 2107 is located under the vacuum brake booster on the left side of the engine compartment

Comments

steering column

The structure, types and principle of operation of the steering mechanism,

guys! That's the problem I have! I rebuilt the steering column myself and apparently I installed the shaft a little wrong. And that’s why my steering wheel turns to the right with a very small radius, and to the left with a large radius. Tell me how to install the shaft correctly, preferably in photographs.

Login to leave comments

And what’s important is mandatory

And what is important, be sure to lubricate the cardboard gasket, which is placed under the cover with the adjusting screw, with sealant.. You may also encounter the problem of worm play after tightening the side cover; the metal plates have different thicknesses

Login to leave comments

Gearbox

The bipod is stuck to the shaft like a dog, the puller flies off, that is, I sewed it with a hammer and a sledgehammer, the effect is 0, only the metal breaks. Do you think it’s possible to cut it down carefully?

Login to leave comments

Specifications

As before, the Nissan GT-R is equipped with a V-shaped six-cylinder turbocharged power unit VR38DETT. Its key features are the presence of two turbochargers, direct fuel supply and an advanced variable valve timing system. After restyling, the engine began to produce 30 horsepower and 9 Nm more. This increase was achieved thanks to an increase in boost pressure, modifications to the ignition system and a new titanium exhaust system. It is worth noting that at the same time, the operating speeds also moved up. The engine now produces 570 horsepower at 6,800 rpm and 637 Nm of torque between 3,300 and 5,800 rpm. Among other things, the six-speed robotic gearbox with two clutches was reconfigured. As a result, the coupe accelerates from zero to the first hundred in just 2.8 seconds and is capable of reaching a maximum speed of 315 km/h.

Elimination

Replacing the steering gear of a VAZ 2107 with your own hands

The fight against backlash should begin by checking and tightening all threaded connections. Often the reason is here

Particular attention should be paid to the nut securing the column to the gearbox. With frequent trips on dirt roads and worn-out asphalt, this fastener regularly becomes loose.

If you do not respond to the problem in a timely manner, you risk getting more serious steering problems. The nut may unscrew entirely, leading to complete failure of the steering. This also leads to increased wear of all parts of the mechanism.

Read more: How much does a Ford Transit weigh?

Adjusting the gearbox also helps combat backlash. To do this you will have to look under the hood. There you will see a gearbox. There is an adjustment screw on it. To get to it, you will have to remove the plug. The screw is protected from turning with a 19mm locknut. It is slightly loosened with an open-end wrench. After this, adjustment is made with a screwdriver. The task is to reduce the backlash. If you can’t do this, then it’s time to change the gearbox. It's easier to do the job with two people.

Column malfunctions and replacement

Six steering wheel repair

The basis of the steering column is a gearbox with two gears, one of which is a worm type. You can feel a steering malfunction at a very early stage, so the main thing is not to miss the first “bell” and carry out repairs on time.

Main signs of failure.

- Creaks directly in the column, caused by excessive wear of various elements, as well as malfunction of the steering column switches.

- The presence of backlashes is the most dangerous sign. Moreover, the backlash can be of two types - axial and longitudinal. The first indicates a malfunction of the gearbox or spline connection, the second indicates excessive wear of the bracket.

The first step is to check the tightness of all threaded connections. If you operate a VAZ 2106 car for a long time with worn splines on the shaft, this will lead to free rotation of the steering wheel. Over time, the slots simply wear out. Moreover, the splines on the steering gear can become unusable, and its price is quite high, and no adjustment of the VAZ steering column can help.

If axial play is present, it can be reduced slightly. A simple adjustment of the VAZ steering column will allow you to do this in a few minutes. To work, you will need a flat-head screwdriver and a 19mm wrench, which you need to loosen the nut on the top cover of the gearbox. You need to take a partner to help you, who will rotate the steering wheel in different directions. The steering wheel should be turned no more than 20-30° in each direction. This will allow you to use a screwdriver to turn the adjusting screw, which will reduce the backlash when tightened. When it reaches the minimum value, you need to tighten the nut.

Repairs associated with replacing the gearbox will be a little more difficult. To do this, you will have to disconnect the battery for safety reasons. Then you need to loosen the bolt on the splined connection of the shaft and gearbox. The left side of the VAZ 2106 is raised on a jack and placed on a reliable support, the wheel is removed. Using a steering tip remover, two rods are removed from the gearbox.

Using 17mm wrenches, unscrew the three nuts from the bolts securing the gearbox to the body. Next, repair or replacement is carried out if adjusting the VAZ steering column is impossible. When installing a new column, it is necessary to securely tighten all threaded connections, and after final assembly, adjust the camber and toe of the wheels of the VAZ 2106.

It is not advisable to remove the lever from the gearbox. Firstly, it is very difficult to dismantle; you will spend a lot of time and effort. Secondly, any adjustable column is sold together with this lever; it comes complete with a gearbox. The tightening is done with a nut that is difficult to unscrew. All this is done to improve security.

It is no secret that not only the controllability and stability of the car, but also the safety of the people in it depends on the serviceability of the steering system. When you first suspect a breakdown, you must quickly diagnose and fix the problem. But what is the right way to proceed? In fact, everything is simple - just know the design features of the unit, possible faults and methods for eliminating them. And in this article we will focus on one of the most important elements of the system - the steering column.

Purpose, device and features

The steering column is the connecting link between the steering wheel in the cabin and the wheels of the car. Its task is to transmit commands from the driver turning the steering wheel to the worm of the steering mechanism. Many car enthusiasts underestimate the importance of this unit. But in vain. Ignoring seemingly insignificant problems can lead to the destruction of mechanical elements and, as a result, loss of vehicle controllability. It's scary to imagine how this could end when driving on the highway.

Among the structural elements of the column, it is worth highlighting the shaft itself (essentially the same steering column), the bracket on which the steering wheel is attached, the bearing, the crosspiece (some models have it) and the steering wheel. Please note that even in classic models of AvtoVAZ products, the design of the steering columns may vary. For example, in the “six” it is a solid shaft made entirely of metal. On top there is a spline connection and a special thread for mounting the steering wheel. On the other side of the column there is an internal connection intended for fastening to the worm gear. In the same “seven” the design of the mechanism is more sophisticated. It includes a pair of small hinges that allow the steering column to fold in the event of a powerful frontal impact. Thanks to this property, this type of design is called “injury-proof”.

Signs and causes of failure

Signs of a faulty steering column are as follows: 1. A knocking sound appears in the rack. If nothing is done, the sound will increase (especially with frequent trips on uneven roads). Over time, strong feedback will appear in the steering wheel, which in itself is very dangerous. The longer you ignore the problem, the worse the controllability will be, and the greater the likelihood of complete failure of the unit. 2. The occurrence of backlash. The appearance of play in the axle is often caused by loose spline connections, and in the plane - by problems with the bracket elements (wear or weakening of the structure is also possible here). 3. Creaking in the steering column is often caused by bending of facing panels or trim, or failure of the steering column switch unit. With high-quality installation and timely care, the steering column can last a very long time. But most car enthusiasts don’t even look under the car. With such operation, after just a few thousand kilometers, nuts and bolts may become loose, play may appear, and the splines may wear out. Over time, the unit becomes completely unusable.

How to remove the parking brake lever of a VAZ 2110

Removing the parking brake lever on a VAZ 2110 car is performed to disassemble it and repair failed elements or replace them with new ones, as well as when carrying out various works in which the presence of the lever will interfere with the progress of their implementation. Prepare a standard set of tools, drive the car into a viewing hole or overpass, turn off the power (disconnecting the minus terminal from the battery) and perform the following sequence of actions:

In the car interior, remove the decorative upper and lower panels of the floor tunnel lining.

- Next, we move under the car and remove the equalizer bar for the handbrake cables by unscrewing the lock nut and the adjusting nut.

- We take out the protective cover from the hole in the floor and remove it from the rod.

We move into the interior again and use a Phillips screwdriver to unscrew the screw securing the parking light switch bracket

Also note that this screw secures the ground wire. Next, unscrew the four bolts securing the parking brake lever

- We put the bracket with the lamp switch aside.

- By removing the rod from the hole in the floor.

- To replace the rod, unbend the antennae of the locking pin and remove it, then the washer and the rod itself. If necessary, if signs of severe wear or damage are detected, replace the plastic bushing.

- Reassemble and install in the reverse order.

Related materials:

- Other

- Engine

- Steering

- Electrical equipment

- Transmission

- Brake system

- Suspension

- Tuning

- VAZ 2110 Other

- Engine

- Steering

- Electrical equipment

- Transmission

- Brake system

- Suspension

- Tuning

VAZ 2114

- Electrical equipment

Engine Brake system Other Steering Transmission Suspension Tuning Lada Priora

- Steering

Engine Suspension Electrical equipment Tuning Brake system Transmission

- Video publications

- VAZ tuning photo stream

- Operation and repair manuals

Purpose and necessary checks of the vehicle control system

The transmission of force to the rotary arms from the steering mechanism is carried out using rods, which are part of the so-called trapezoid. This node consists of:

- gearbox;

- long rod;

- pendulum lever;

- two long tips;

- two short tips;

- two clamping devices with tie clamps.

The main malfunctions of the control system in VAZ models. Controllability, comfort and safety of movement depend on the listed parts. Therefore, increased attention should be paid to monitoring their condition and the schedule of periodic inspections should not be violated. Some people prefer to trust service station technicians, but if you look into it, such an operation is quite doable at home.

For this purpose, the presence of an inspection hole or overpass will be sufficient. Next we examine:

- condition of rubber boots;

- axial movement of fingers;

- presence of cracks;

- hinges for gaps;

- attaching the pendulum to the body.

Next you need to check the steering play. When swaying left and right, free play is allowed no more than 2 cm. Press the brake pedal and experience the ease of movement of the steering wheel - it should rotate relatively easily.

Further repairs will not be a problem.

You only need to follow a few rules:

- the worm pair is changed simultaneously, as a set;

- after assembly/disassembly, adjustments need to be made;

- Do not use old oil, but replace it with new lubricant.

After the repair is completed, the gearbox is assembled and mounted in the reverse order.

The steering gearbox is a rather old mechanical device that is now used mainly on cars of the classic LADA family. Today you will learn what a steering gearbox is - repair, replacement, adjustment with your own hands.

Sounds from the cabin

In modern cars, the steering wheel is not only needed to turn the car. It often houses controls for certain devices, from changing gears to turning on headlights or adjusting the audio system. Therefore, the driver has a natural concern when clicks appear in the steering column when turning the steering wheel. It is typical that the sound comes from inside the cabin from the area of the horn button.

In this case, there is no need to panic. First, you should check the correct installation and condition of the plastic lining of the column. The possibility of plastic deformation cannot be ruled out. A common reason for this phenomenon is a malfunction of individual elements of the steering column switch that produce such sounds. You can check the quality and fastening of the plastic, and replace the faulty switch. Often this is enough so that when you turn the steering wheel you won’t hear a click in the steering column.

Sometimes in the front part of the cabin, when you turn the steering wheel, squeaks are heard, similar to shuffling. Their source is hidden under the beep button on top of the speaker. At the same time, the signal for a problem with the airbag in the steering wheel comes on, and the cruise control buttons do not work.

This means that the steering column cable under the airbag is inoperative. It supplies power to the mechanism of this airbag, the horn and some other devices of the car. It could simply be seriously damaged. Some motorists try to fix such faults on their own. This does not provide any guarantee of reliable operation of the cable. Taking into account the fact that this device affects safety, it is better to replace the steering column cable by experienced car service workers.