Classic models of the Volzhsky Automobile Plant are highly reliable. The steering mechanism of the VAZ 2107 car has a complex structure and provides reliable control in different road conditions. In the process of modernizing the machine, a safety column with a composite shaft was developed and installed. The size of the steering wheel installed on it allows the driver to easily maneuver. Full rotation of the wheel from lock to lock is 3.5 turns. The steering column transmits force to the drive through a composite shaft.

The steering mechanism of the VAZ 2107 is quite informative, but at the same time it does not tire and does not complicate driving the car. It is somewhat difficult to turn the steering wheel (despite its rather large diameter) when parked, but after starting to move, the resistance weakens significantly. A working steering mechanism has a small amount of play, the limit value of which is determined by the rules of the road and the operating manual. The rod system and the large number of parts in the gearbox cause this phenomenon. In general, the steering on the seven is quite reliable.

The design of the steering mechanism and the principle of operation

The control system on the VAZ 2107 is unified in many details with the first model. The structure and design of the steering have undergone only minor changes; it includes:

- a mechanism that transmits force from the driver to the executive part;

- The steering drive directly rotates the wheels to the required angle.

The steering mechanism, in turn, consists of the following parts and assemblies:

- compound shaft with cardan transmission;

- steering wheel, (diameter 520 mm) or rather a steering wheel with a column;

- worm gearbox.

The system includes the following elements;

- bipod;

- middle and two side rods and ball joints;

- pendulum lever;

- rotary levers.

The outer rods consist of two parts, allowing you to change their size to adjust the toe angle.

Steering diagram

The operation of the system as a whole is as follows: the driver rotates the steering wheel, the size of which allows this action to be performed with little effort. A worm gearbox is driven through a composite shaft, reducing the speed. The steering mechanism of the VAZ 2107 car is lubricated with TAD-17 oil, filled into the gearbox. Rotation of the worm gear causes the double ridge roller to move, which causes the output shaft to rotate.

The bipod mounted on it turns and carries the rod system with it. These parts act on the levers and synchronously rotate the wheels at a given angle. The steering wheel, which is of a convenient size for the driver, has a horn control panel in the middle part. The steering control device of the VAZ 2107 car has a fairly long service life if routine maintenance is performed correctly and in a timely manner.

Maintenance and repair

The VAZ 2107 car has fairly reliable steering, the system has been tested over years of operation. The diameter of the steering wheel is chosen well; its size allows minimizing the load on the driver when driving. The equipment requires periodic inspection and maintenance:

- During maintenance, the mechanism is carefully inspected for increased play and increased wear of ball joints. The steering wheel, the optimal size, turns from side to side. Lack of reaction from the wheels when the wheel deviates from the initial position by more than 5 degrees indicates significant wear.

- The oil in the worm gear housing is changed every 60 thousand kilometers. The device is checked for no leaks of operating fluid through the seals.

- The pendulum steering lever of a VAZ 2107 car is inspected when the steering wheel is slowly turned from side to side. Movements of parts in the vertical plane are not allowed.

Any steering malfunctions must be immediately corrected: the mechanism and drive are partially dismantled. Defects of parts are carried out, the entire steering system is checked with special care. Units with signs of significant wear must be replaced.

Rods, bipod, hinges - where is it all?

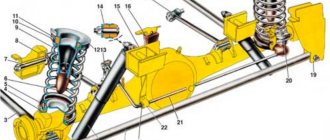

The main parts and steering components of the VAZ-2107 and other rear-wheel drive models are shown in the figure below. To understand what is faulty, let’s remember “who is who”. You also need to remember that breakdowns of steering parts and assemblies are very dangerous and, in most cases, lead to serious accidents! For example, if the steering rod breaks, the front wheels lose contact with the steering wheel and the car flies into a ditch or into oncoming traffic. To prevent this from happening, let's check the condition of the steering of our “classic”.

Steering VAZ-2107

1 – lateral thrust. 2 – bipod. 3 – medium traction. 4 – Pendulum lever. 5 – adjusting clutch. 6- lower ball joint of the front suspension. 7 - right steering knuckle. 8- upper ball joint of the front suspension. 9 - right steering knuckle lever. 10- bracket for the pendulum arm. 11- bearing of the upper steering shaft. 12, 19 - steering shaft mounting bracket. 13- pipe of the steering shaft mounting bracket. 14- Upper steering shaft. 15 - steering gear housing. 16- intermediate shaft. 17- facing casing. 18- steering wheel. 20- fixing plate of the front bracket. Pinch bolt for fastening the universal joint. 22- body spar.

Inspection and testing of the VAZ-2107 steering

You need to check your steering if your car has the following signs: -increased play (free play) of the steering wheel; -knocks in the area of the front wheels; - difficult (tight) rotation of the steering wheel. It is better and more convenient to perform all work in an inspection ditch or on a lift. Be sure to invite an assistant; you can’t handle the check alone. Before work, the car must be thoroughly washed from below. Set the steering wheel to the position for driving in a straight line. Turning the steering wheel left and right, we check one by one: - the play of the steering wheel along the rim is 18 – 20 mm; - there should be no knocking in the hinges and joints; - the fastenings of the steering gear housing and the pendulum lever are not loose; - there is no play in the ball joints of the rods and in the bracket of the pendulum arm, and the bipod does not move in the axial direction; - steering force does not exceed 20 kgf; - the adjusting couplings of the side rods are securely secured with clamps; -all protective caps and rubber covers have no cracks or tears.

Ball joints of steering rods are considered to be in good condition if the axial movement (along the axis of the fingers) is no more than 1.5 mm. When you press the mount on the hinge, you should feel the resistance of the spring.

Trouble-shooting

Loose threaded connections must be tightened, damaged and worn components and parts must be replaced. The most common parts to be replaced are tie rods with joints and a pendulum arm. A stiff steering wheel or knocking noise in the steering mechanism can be eliminated by adjusting the worm gearing . After replacing the rods, you need to adjust the camber and toe angles of the wheels.

Watch the video on steering linkage diagnostics

VAZ cars, which are classic models, are distinguished by pleasant reliability. This also applies to the steering mechanism.

It is quite complex, but its design allows you to maneuver and ensure reliable vehicle control even in the most difficult road conditions.

The modernization process led to the installation of a composite shaft and a safety column. Due to the size of the steering wheel, the driver makes the necessary maneuvers without any problems. From lock to lock, it takes 3.5 turns to turn the steering wheel completely. The force from the steering column is transmitted to the drive via a composite shaft.

The current steering mechanism on the VAZ 2107, a product of the Volga Automobile Company, is quite informative and does not allow the driver to get tired during long trips. There are certain difficulties when turning in a parking lot, but as soon as the car begins to move, the resistance weakens and turning the steering wheel becomes easier.

There is one more nuance - when the steering mechanism is working properly, there is a slight play. But its limit value complies with the traffic rules. This is due to the fact that there are steering rods on the VAZ 2107 and an impressive number of elements in the gearbox.

In general, the steering of the 7 can be considered reliable.

Replacing the steering column or gearbox

Hello again. Thanks everyone for the advice on the steering column.

After reading the information about the repair, I realized that it was not worth the money.

The best option was to purchase a used column in good condition, because... Knowing about the current quality, many will understand me. During the survey, it turned out that Private838

has a normal steering column, which is what I wanted to take.

My grandfather also found out about the problem, and it turned out that a friend of his from the garage had a five-piece gearbox in superb condition. Actually, I got it for myself for seven. For installation I used a steering wheel end puller. The most stressful thing was to unscrew the 3 bolts that secure the gearbox to the body, which was very inconvenient for me personally. In the process, we had to additionally remove the adsorber, the control center, unscrew the locker, remove the wheel and unscrew the cardan from the column shaft

.

the puller is in use, the steering rods are in excellent condition

this is where the oil was flowing, but it was still normal in the gearbox

Oil was also leaking through the side cover.

After comparing the old and new ones, it turned out that my gearbox was a little tight to spin behind the bipod, but with the new one everything was fine. The adjusting screw in my column was recessed flush. The new one stuck out about 4 mm.

old and new

you can see how much the regs are screwed in. screws

place where the cardan is disconnected from the shaft

Then I put everything back in place. In order not to calculate the position of the steering wheel, which was not deployed correctly, I simply removed it and put it in place. I left the old oil in the column because it was yellow. I just topped up a few cubes of Lukoil mineral water.

everything is collected

syringe and oil

Result. After adjusting the steering wheel and driving around, I realized that the controls had changed beyond recognition. If earlier on bumps the steering wheel sat gently in your hands, now it began to be knocked out. On a flat road he stands straight and does not move. Previously, he was wobbling in all directions. In general, I'm pleased.

Among the tips for improving the service life of the speaker, I can say:

1. It does not need to be tightened when adjusting; there should not be much play. 2. Do not turn the steering wheel in a place where it is difficult to turn (asphalt and other surfaces where there is more friction).

Good luck to everyone, may the quality of spare parts be with you!

Mechanism design

To repair the steering column on a VAZ 2107, you first need to understand its structure, as well as the principle of operation.

The seven is in many ways similar to the “penny”. Therefore, the device and design received minor changes. The structure includes:

- A mechanism that transmits the driver’s force to the executive components;

- A steering drive that turns at an angle specified by the driver.

In turn, the steering mechanism consists of:

- Composite shaft with cardan transmission;

- Steering wheel (steering column together with a steering wheel with a diameter of 520 mm);

- Worm gearbox of the VAZ 2107 steering mechanism.

The control system has the following components:

- Bipod;

- Pendulum arm;

- Swivel arms;

- Steering rods for VAZ 2107 (one middle, two side).

The outer rods include two parts, which allows you to change their size by adjusting the toe angle.

Tie rod/end set for VAZ 2107

The operating principle of the steering mechanism looks like this:

- The driver begins to rotate the steering wheel, the wheel size of which ensures that this task can be performed quite simply;

- By means of a composite shaft, a worm gear is activated, which reduces the speed;

- The steering mechanism is lubricated with special oil (TAD 17) poured into the gearbox;

- The worm gears rotate, which causes the double ridge roller to move;

- This, in turn, causes the secondary shaft to rotate;

- The tray mounted on the secondary shaft makes a turn and pulls the rod system behind it;

- These components influence the levers that synchronously rotate the wheels to the required angle specified by the driver.

Steering gear housing parts

1 - crankcase; 2 - bipod; 3 — lower crankcase cover; 4 — adjusting shims; 5 — outer ring of the worm shaft bearing; 6 — separator with balls; 7 — bipod shaft; 8 - adjusting screw; 9 — adjusting plate; 10 — lock washer; 11 - worm shaft; 12 — upper crankcase cover; 13 - sealing gasket; 14 — bipod shaft sleeve; 15 — worm shaft seal; 16 — bipod shaft seal.

Details

1 — steering gear housing; 2 - shaft seal; 3 - intermediate shaft; 4 - upper shaft; 5 — fixing plate of the front part of the bracket; 6 — bracket for fastening the steering shaft; 7 - upper part of the facing casing; 8 — bearing sleeve; 9 — bearing; 10 — steering wheel; 11 — lower part of the facing casing; 12 — bracket fastening parts

What affects the cost?

The cost of a steering column is influenced by the following factors:

- Manufacturer.

- Country of origin (Eurasian compliance standards).

- Type of component.

- Type of equipment.

- State.

- Brand.

- Type of spare part.

- Type of modification (without hydraulic booster).

- Model.

- Serial compatibility.

In addition to such key parameters, the cost is also affected by the type of packaging and internal placement of the product. Original steering columns, which have a clear centering position with a noticeable effort to overcome it, regardless of the direction of rotation, are always equipped with an output shaft mounting bipod. The latter prevents its rotation and axial displacements in the bearing and oil seal. Also, the original AvtoVAZ packaging is different:

- Complete with technical data sheet and warranty card (separate sealed bag).

- Security seal with laser engraving on the top and bottom.

- Since February 2016, compliance with Eurasian standards is indicated on the side of the box, instead of specifications.

Also included in the price is the oil used to fill the steering column. During transportation, the adjusting bolt and gasket are in a free state, which requires compliance with the orientation of the product in space.

Repair and maintenance

Over the years of operation it has been proven that the steering on VAZ 2107 vehicles has impressive reliability. However, this does not take away the fact that the machine requires periodic inspection and repair.

- When performing maintenance, it is important to check for increased play as well as increased wear on the ball joints. To do this, you need to turn the steering wheel from one side to the other. If the wheels do not respond when the steering wheel is turned 5 degrees from its original position, this indicates severe wear. Here you will need to repair the steering column on a VAZ 2107.

- To avoid the need for urgent and rather expensive repairs of the steering gear on a VAZ 2107, it is necessary to change the oil in the worm gear housing. This is done at intervals of 60 thousand kilometers. Leaks may occur through the seals, so they are carefully checked 2-3 times a year. This is one of the weak points of the system.

- The swing arm should be inspected by slowly rotating the steering wheel from side to side. If the parts move in a vertical plane, then surgical intervention is required.

To do this, the drive and steering mechanism are dismantled completely or partially. Everything depends directly on the nature of the breakdown.

Check which parts have defects and what has failed. Inspection is required for each component of the mechanism. If parts are worn out, there is no point in trying to repair them. There is only one way out - a complete replacement of worn-out components of the steering system on a car from a Volga company.

If problems arise with the steering, it is advisable to contact a professional service station.

Photo of the VAZ 2107 steering gearbox

You can replace the gearbox yourself, but the process is complicated and requires at least minimal experience and skills.

The VAZ "Seven" is a true classic of the domestic automotive industry. Unlike modern LADAs, they are more reliable and durable, which is proven by the huge presence of these cars on our roads.

Of course, the VAZ 2107 has long been outdated, it does not have a hydraulic booster, and you have to apply sufficient force to turn and maneuver. But for connoisseurs this is not a problem.

Almost all cars, regardless of brand and class, are equipped with a steering mechanism and the VAZ 2107 is no exception. The safety of driving vehicles directly depends on the condition of this structure, which must be periodically inspected, adjusted, and, if necessary, repaired.

Steering VAZ 2107

The steering mechanism of the VAZ “Seven” consists of several units connected together by means of fasteners. These components and their constituent elements, like any other part of the car, wear out over time and become unusable. The purpose, design, repair and maintenance of the VAZ 2107 steering system should be discussed in more detail.

Purpose

The main function assigned to the steering mechanism is to ensure the vehicle moves in the direction specified by the driver. On most passenger cars, the trajectory of movement is carried out by turning the wheels of the front axle. The steering mechanism of the “seven” is quite complex, but at the same time it provides trouble-free control in different situations on the road. The car is equipped with a safety steering column with a driveshaft that folds upon impact. The steering wheel of the mechanism in question has a diameter of 40 cm and to completely turn the wheels you need to make only 3.5 turns, which allows you to perform maneuvers without much difficulty.

What does it consist of?

The front wheel control mechanism on the VAZ 2107 is made of the following basic elements:

- steering wheel;

- shaft;

- gearbox;

- bipod;

- trapezoid;

- pendulum;

- steering knuckles.

Steering shaft

Through the shaft, rotation from the steering wheel is transmitted to the steering column. The shaft is secured with a bracket to the car body. Structurally, the element is made in the form of a cardan with crosspieces and an upper shaft. In the event of a collision, the mechanism folds, thereby ensuring the safety of the driver.

Gearbox

The VAZ 2107 is equipped with a worm steering column, which converts the rotational movement of the steering wheel into the translational movement of the steering rods. The operating principle of the steering mechanism is as follows:

- The driver turns the steering wheel.

- By means of cardan joints, the worm shaft is driven, thereby reducing the number of revolutions of the steering wheel.

- The worm element rotates, moving the double-ridge roller.

- The secondary shaft rotates, on which the bipod is fixed, driving the steering rods.

- The trapezoid moves the steering knuckles, turning the wheels in the desired direction.

The steering bipod is a part through which the steering linkage is connected to the steering gearbox.

Steering linkage

The radius of the vehicle's trajectory when turning depends on the angle of rotation of the wheels. Since the outer wheel has a larger radius than the inner one, in order to avoid the latter slipping and deteriorating traction with the road surface, the front wheels must deviate at different angles.

This is what the steering linkage is used for. During the maneuver, the transverse thrust of the mechanism shifts under the influence of the bipod. Thanks to the pendulum arm, it pushes and pulls the side rods. Since misalignment occurs, the impact on the tie rod ends is different, which leads to the wheels turning at different angles. The tips of the trapezoid with the rods are connected through adjusting couplings, which allow you to change the angles of rotation of the wheels. The parts of the trapezoid are connected to each other by identical ball joints. This design contributes to the normal operation of the unit even when driving on bad roads.

Pendulum arm

The steering pendulum of the “seven” is necessary for synchronous rotation of the wheels of the front axle without lag. Thus, the car is able to corner safely. If malfunctions occur with the pendulum, the vehicle’s performance during maneuvers deteriorates, which can lead to an emergency.

Rounded fist

The main purpose of the steering knuckle (trunnion) is to ensure that the front wheels turn in the direction desired by the driver. The part is made of durable steel, since high loads are placed on it. Steering rod ends, hubs, and brake system elements are also attached to the knuckles. The axle is fixed to the front suspension arms using ball joints.

REMOVAL OF THE GEARBOX

The design of the gearbox does not allow it to be repaired without removing it from the vehicle. In order to remove it, you must:

- Disconnect the tie rod ends from the gearbox. First, they are uncoiled, then the nuts are unscrewed with a 22 wrench and the tips are pressed out using a special puller.

- Unscrew the clamp securing the steering shaft to the gearbox.

- Remove the three bolts that secure the gearbox to the car body.

The gearbox design should not cause any particular difficulties when repairing it. You just have to take into account that the worn elements, called the worm pair, are both replaced at the same time. After this, adjustments must be made.

Steering problems

The steering mechanism, like any other vehicle component, wears out and requires repair over time. To simplify the troubleshooting, there are certain signs that allow you to find out the nature of the breakdown and fix it in a short time.

Oil leak

On a classic, the problem of a “wet” steering gear is quite common. There can be many reasons for this:

- oil seal wear;

- leakage from under the gasket;

- loosening of the fasteners that secure the mechanism cover;

- Corrosion of the input shaft.

If the oil seal and gaskets can be replaced and the bolts tightened, then if the shaft is damaged, the part will have to be ground.

Tight steering wheel

Sometimes it happens that to turn the steering wheel it is necessary to apply noticeably more effort than usual. Several reasons can lead to this malfunction:

- incorrect wheel alignment;

- failure of one of the elements in the steering mechanism;

- the gap between the worm and the roller is broken;

- The pendulum axis fasteners are too tight.

Steering play

One of the reasons for free play in the steering mechanism is wear on the shaft crosspieces. In addition to them, play appears in the gearbox itself. If the unit has a high mileage, then it is advisable to disassemble it, inspect the condition of all the elements, replace parts with high wear, and then carry out adjustments.

Knock and vibration

If you feel feedback on the steering wheel while driving, there can be many reasons for this phenomenon. Driving a vehicle in such a technical condition leads to rapid fatigue and reduces the level of safety. Therefore, the steering mechanism needs diagnostics.

Table: causes of vibrations and knocking on the steering wheel and ways to eliminate them

| Cause of steering failure | Troubleshooting method |

| Increased clearance in front wheel hub bearings | Adjust the front wheel hub clearance |

| Loosening the tie rod ball pin nuts | Tighten the tie rod ball stud nuts |

| Increased clearance between the pendulum arm axis and the bushings | Replace the swingarm bushings or bracket assembly |

| The adjusting nut of the pendulum arm axis is loose | Adjust the tightness of the swingarm nut |

| The clearance in the engagement of the roller with the worm or in the worm bearings is broken | Adjust the gap |

| Increased clearance in steering rod ball joints | Replace tie rod ends or tie rods |

| Loosening the bolts securing the steering gear housing or the pendulum arm bracket | Tighten the bolt nuts |

| Loosening the swing arm nuts | Tighten the nuts |

↑ Checking the ball joints of the steering rods

- First of all, check the movement of the rod tips along the axis of the fingers. To do this, using the lever and support, move the tip parallel to the axis of the finger.

- The axial movement of the tip relative to the finger should be 1–1.5 mm. This movement indicates that the pin insert is not jammed in the rod tip socket and moves along with the pin, compressing the spring. Replace the hinge with a jammed insert.

- While rocking the steering wheel in both directions, check by touch that there is no free play in the steering rod joints. If you feel free play in the ball joint, replace the tie rod end or tie rod assembly.

- Check the condition of the protective caps of the steering rod ball joints.

- If the protective caps are in good condition and ensure cleanliness inside the hinges, then the service life of the latter is practically unlimited. When moisture, dust, etc. gets into the hinge, premature wear of its parts occurs.

The cap must be replaced if it has cracks, ruptures, and also if lubricant penetrates out when squeezing it with your fingers.

Trouble-shooting

As the vehicle is used, individual components of the steering mechanism gradually wear out. For comfortable and safe driving, as well as to prevent uneven tire wear, any defects in the steering mechanism must be corrected in a timely manner.

Steering gearbox

To identify problems with the steering column, the unit will need to be removed from the car. To do this, you need to prepare the following list of tools:

- a set of keys;

- knob;

- heads;

- steering rod puller.

Dismantling is carried out in the following sequence:

- We drive the car onto an overpass or lift.

- We unscrew the fastening of the cardan to the column shaft.

- We unscrew the nuts that secure the tie rod pins to the bipod, and then use a puller to squeeze out the pins.

Let's disassemble the mechanism for troubleshooting parts:

- Using a 30mm wrench, unscrew the nut holding the bipod.

Inspect the roller and worm for wear or damage. The gap between the bushings and the bipod axle should be no more than 0.1 mm. The rotation of the bearings should be easy and without jamming. Any defects on the internal parts of the bearing are considered unacceptable, as are cracks on the mechanism body. Damaged parts are replaced with serviceable ones. Before assembling the mechanism, lubricate all elements of the gearbox with transmission oil and perform the assembly:

- We hammer the bearing ring into its seat.

Video: disassembling and reassembling the steering column on a “classic”

Backlash adjustment

To carry out adjustment work with the unit in question you will need:

- key to 19;

- wide flat screwdriver.

The procedure boils down to the following steps:

- We set the steering wheel to a position in which the front wheels will stand straight.

- Using a 19mm wrench, unscrew the nut on top of the gearbox.

With a correctly adjusted steering column, play should be minimal, and the steering wheel should rotate without snagging or excessive effort.

Video: eliminating play in the steering gear

Steering shaft

If, when the steering wheel rotates, there is a large play on the hinges of the intermediate shaft or axial movement of the shaft on the bearings, the mechanism needs to be disassembled and repaired. The work is carried out as follows:

- We remove the “-” terminal from the battery, as well as the steering wheel, plastic casing, steering column switches, and connector from the ignition switch.

- Unscrew the cardan mount and remove the bolts.

Pendulum

The pendulum arm itself rarely fails, but the bearings or bushings located inside sometimes have to be replaced. To work, you will need a set of wrenches and a steering rod puller. We dismantle the mechanism in the following order:

- We remove the right front wheel from the car, unscrew the fasteners and use a puller to press out the pins of the steering linkage rods.

- Unscrew the pendulum mount to the right side member.

Replacing bushings

Repair consists of the following steps:

- Unscrew and unscrew the pendulum axle nut.

Trapezoid

A complete replacement of the steering linkage is necessary in the case when all the joints have large wear. We prepare the following set of tools:

- ring wrenches size 13 and 22 mm;

- pliers;

- hammer;

- puller;

- a ruler at least 20 cm long or a tape measure;

- devices for removing the wheel - jack, wheel wrench, wheel chock;

- rags, fabric gloves.

Steering rods on a VAZ 2107 are removed as follows:

- We jack up the front of the car and remove the wheels.

- Unscrew the ball pin and unscrew the nut.

When the work on replacing the trapezoid is completed, it is necessary to check the wheel alignment angles at the service center.

Tie Rod Ends

The extreme rods of the steering linkage fail more often than other hinges. Therefore, if there is a need to replace them, it is not necessary to completely remove all the rods. The tips are changed as follows:

- Repeat steps 1–3 for removing the trapezoid.

- Using a ruler, measure the length of the old part at the centers of the plugs.

STEERING WHEEL PLAY

The appearance of steering play can be caused by two reasons. First, the nut securing the steering wheel to the shaft is loosened. If the nut is not tightened promptly, the splines on the handlebar and shaft will become damaged over time and one of these parts may need to be replaced. The second reason may be wear of the worm gear. To eliminate this malfunction, a special device is provided - an adjusting bolt with a lock nut.

In order to adjust the worm gear, the nut is released, the screw is turned using a screwdriver until the backlash is eliminated, after which the nut is tightened to prevent spontaneous unscrewing. If it is impossible to eliminate the backlash by adjustment, it means that the gearbox needs to be repaired and the worm pair replaced.

To prevent premature wear of gearbox parts, periodic monitoring of the oil level and its replacement is recommended. Level control is carried out as follows:

- Using a 8 key, unscrew the filler plug;

- Use a screwdriver or other object to check the oil level. It should be level with the bottom edge of the filler hole.

- If necessary, add oil using a special supercharger until it begins to flow out of the hole.

To change the oil, unscrew the screws securing the gearbox cover, having previously placed a container under it to collect used oil. Since complete removal of the cap is not required, it is moved to the side and the oil is drained. This operation is best performed on a hot engine. Warm oil has greater fluidity and drains faster. After all the oil has drained out, the cap is screwed into place and new oil is poured into the gearbox using the method described above.