Greetings to all readers and guests of my blog!

Nothing interesting is happening with the car at the moment... so I decided to go back in time and remember what interesting things I did last winter... fortunately I have photographic material.

Well, I’ll start with a very useful modernization - the Steering Control of the VAZ 2107 (2105).

I think many owners of classics know that “fives and sevens” have a slightly different steering wheel, namely:

— A steering gear with a long shaft is used — A steering shaft with a cardan mechanism — Another form of steering column, and a plastic cover with it. Convenient location of the emergency gang.

Based on this, I have long noticed this convenient modification for myself, and I have been thinking about the benefits of it in my head:

1) No problems with the alignment of the shaft and gearbox.

More convenient installation and repair and disassembly.

Compared to the old one - easier rotation of the steering wheel (subjective) 2)

Cardan shaft - + for safety. The shaft folds in half during an accident, and does not cause as much damage to the driver as the “spear-shaped” one from 03/01/06.

3)

Modified column casing with a convenient location of the emergency lights. The “seven-five” column cover is convenient - the emergency light is always “under the right hand”, it is aesthetically pleasing - it covers almost the entire shaft up to the pedals, + covers the wiring and technical components of the steering wheel.

So, having “finished off” the old original steering wheel, and unable to bear the huge backlashes and knocks anymore, I decided to replace it with modernization. At the same time I’ll change the trapezoid and pendulum.

Here is a list of what I needed to buy (for me):

— Steering gear 2105-07 (with a long shaft) — Steering shaft 05-07 of two parts (upper and lower half) — Steering column (“binoculars” in popular parlance) — Two needle bearings on a rubber cage — Plastic casing 05-07 — Steering shaft seal (under the pedals)

— Steering linkage assembly — Steering pendulum (on bearings)

VAZ cars, which are classic models, are distinguished by pleasant reliability. This also applies to the steering mechanism.

It is quite complex, but its design allows you to maneuver and ensure reliable vehicle control even in the most difficult road conditions.

The modernization process led to the installation of a composite shaft and a safety column. Due to the size of the steering wheel, the driver makes the necessary maneuvers without any problems. From lock to lock, it takes 3.5 turns to turn the steering wheel completely. The force from the steering column is transmitted to the drive via a composite shaft.

The current steering mechanism on the VAZ 2107, a product of the Volga Automobile Company, is quite informative and does not allow the driver to get tired during long trips. There are certain difficulties when turning in a parking lot, but as soon as the car begins to move, the resistance weakens and turning the steering wheel becomes easier.

There is one more nuance - when the steering mechanism is working properly, there is a slight play. But its limit value complies with the traffic rules. This is due to the fact that there are steering rods on the VAZ 2107 and an impressive number of elements in the gearbox.

In general, the steering of the 7 can be considered reliable.

Mechanism design

To repair the steering column on a VAZ 2107, you first need to understand its structure, as well as the principle of operation.

The seven is in many ways similar to the “penny”. Therefore, the device and design received minor changes. The structure includes:

- A mechanism that transmits the driver’s force to the executive components;

- A steering drive that turns at an angle specified by the driver.

In turn, the steering mechanism consists of:

- Composite shaft with cardan transmission;

- Steering wheel (steering column together with a steering wheel with a diameter of 520 mm);

- Worm gearbox of the VAZ 2107 steering mechanism.

The control system has the following components:

- Bipod;

- Pendulum arm;

- Swivel arms;

- Steering rods for VAZ 2107 (one middle, two side).

The outer rods include two parts, which allows you to change their size by adjusting the toe angle.

Tie rod/end set for VAZ 2107

The operating principle of the steering mechanism looks like this:

- The driver begins to rotate the steering wheel, the wheel size of which ensures that this task can be performed quite simply;

- By means of a composite shaft, a worm gear is activated, which reduces the speed;

- The steering mechanism is lubricated with special oil (TAD 17) poured into the gearbox;

- The worm gears rotate, which causes the double ridge roller to move;

- This, in turn, causes the secondary shaft to rotate;

- The tray mounted on the secondary shaft makes a turn and pulls the rod system behind it;

- These components influence the levers that synchronously rotate the wheels to the required angle specified by the driver.

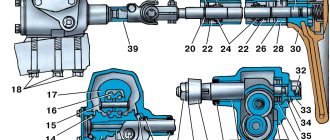

Parts of the steering gear housing

1 - housing; 2 - bipod; 3 — lower crankcase cover; 4 — adjusting shims; 5 — outer ring of the worm shaft bearing; 6 — separator with balls; 7 — bipod shaft; 8 - adjusting screw; 9 — adjusting plate; 10 — lock washer; 11 - worm shaft; 12 — upper crankcase cover; 13 - sealing gasket; 14 — bipod shaft sleeve; 15 — worm shaft seal; 16 — bipod shaft seal.

Details

1 — steering gear housing; 2 - shaft seal; 3 - intermediate shaft; 4 - upper shaft; 5 — fixing plate of the front part of the bracket; 6 — bracket for fastening the steering shaft; 7 - upper part of the facing casing; 8 — bearing sleeve; 9 — bearing; 10 — steering wheel; 11 — lower part of the facing casing; 12 — bracket fastening parts

Gearbox oil

To reduce friction of the internal elements of the steering column, transmission oil GL-4, GL-5 of viscosity class SAE75W90, SAE80W90 or SAE85W90 is poured into the mechanism. In the old fashioned way, many car owners use TAD-17 oil for the unit in question. The filling volume of the gearbox on the VAZ 2107 is 0.215 liters.

Checking the oil level

To avoid premature failure of mechanism parts, it is necessary to periodically check the oil level and replace it. It is worth keeping in mind that the transmission fluid, although slowly, flows out, and the leak occurs regardless of whether the column is new or old. The level check is performed as follows:

- Using a size 8 wrench, unscrew the filler cap.

- The filler cap is unscrewed with an 8 key

- Using a screwdriver or other tool, check the oil level in the crankcase. The normal level should be at the bottom edge of the filler hole.

- A screwdriver or other tool is suitable for checking the oil level in the gearbox.

- If necessary, fill the grease with a syringe until it begins to flow out of the filler hole.

- Tighten the plug and clean the drive mechanism from stains.

How to change the oil in a gearbox

As for changing the oil in the steering mechanism, this procedure should be carried out once every year and a half. If the decision has been made to change the lubricant, you need to know how to perform the procedure. In addition to new lubricant, you will need two syringes of the maximum possible volume (purchased at a pharmacy) and a small piece of flushing hose. The procedure is carried out in the following order:

- The filler cap is unscrewed with a wrench, a piece of tube is put on the syringe, the old oil is sucked out and poured into the prepared container.

- Old grease is removed from the steering column using a syringe

- Using a second syringe, new lubricant is poured into the gearbox to the required level, and it is recommended to rotate the flywheel.

- New lubricant is drawn into the syringe and then poured into the gearbox

- Screw on the lid and wipe off all traces of oil.

Repair and maintenance

Over the years of operation it has been proven that the steering on VAZ 2107 vehicles has impressive reliability. However, this does not take away the fact that the machine requires periodic inspection and repair.

- When performing maintenance, it is important to check for increased play as well as increased wear on the ball joints. To do this, you need to turn the steering wheel from one side to the other. If the wheels do not respond when the steering wheel is turned 5 degrees from its original position, this indicates severe wear. Here you will need to repair the steering column on a VAZ 2107.

- To avoid the need for urgent and rather expensive repairs of the steering gear on a VAZ 2107, it is necessary to change the oil in the worm gear housing. This is done at intervals of 60 thousand kilometers. Leaks may occur through the seals, so they are carefully checked 2-3 times a year. This is one of the weak points of the system.

- The swing arm should be inspected by slowly rotating the steering wheel from side to side. If the parts move in a vertical plane, then surgical intervention is required.

Steering

Steering

The Niva uses a worm-type steering gearbox. It provides reliable vehicle control at any speed and in different road conditions. The worm mechanism is equipped with a globoid type worm (variable shaft diameter) connected to an intermediate shaft and roller. A bipod is installed on the outer part of the roller shaft, which, through rods, activates the rotating mechanism. The rotation of the steering wheel ensures the movement of the bipod through a worm gear; it turns the wheels with rods.

The worm steering mechanism has a low level of sensitivity to shocks and impacts transmitted from the wheels on uneven roads. It has the ability to direct a VAZ vehicle to large turning angles and, accordingly, provides excellent maneuverability of the vehicle. The disadvantage of a worm gear is that it is difficult to manufacture. Worm steering has many connections and therefore requires periodic adjustments and adjustments.

The worm steering mechanism is used on off-road passenger cars with dependent wheel suspension, light trucks and buses. The simplicity of the design has an increased service life and a high degree of maintainability. A slight drawback may seem to be a slightly increased effort on the steering wheel, which occurs for a number of reasons. Having analyzed the design of the steering gear and the loads acting on it, we determine problem areas and ways to solve problems.

The basic one is equipped with a worm pair, which during operation causes steering resistance due to friction between the worm and the worm gear. This is the operating principle of a worm gear; therefore, it is not possible to completely get rid of this factor. The solution is to use high-quality lubricant in the gearbox and monitor the condition of the working surfaces.

The steering gearbox has two rolling bearings (worm shaft), two plain bearings on the bipod shaft (also known as the worm wheel shaft). The bearings themselves, in good and lubricated condition, reduce friction of the main parts (and, accordingly, reduce the force on the steering wheel).

In addition, the pendulum arm, which rotates on two plain bearings and ensures the movement of the steering rack, makes its contribution. The use of high-quality lubricant and periodic monitoring of the condition of boots, connections and rods will reduce the possibility of increased force on the steering wheel.

Thirdly, the six steering fingers must provide a high-quality connection, work correctly in the same planes with the system, and ensure the mobility of the steering mechanism.

Adjusting the Steering Gear VAZ 2101 - VAZ 2107

So, take a look at the photo of Rulevogo Reductor - a; - Do you see the nut (by the way, it is 19-size), and the pin with a slot - coming out through exactly that nut? The nut is a lock nut that locks the one we need and directly performs the adjustment - the stud.

Let's assume that the steering gearbox of your VAZ 2101-2107 is too tight. Then, you should take a wrench or a 19-point socket, loosen the nut (which we mentioned above), remove the locking gasket, and Unscrew the Pin with the Slot. This reduces the load on the steering mechanism of the column. Did you unscrew it? — try the steering wheel now.

Did you unscrew it too much and there was some play? Then you should screw the pin back in.

I think this is all clear. I would like to add that when adjusting the steering gear of a VAZ 2101 and other classics. The play, which did not seem to interfere with turning the wheels in place, and at low speeds, is actually felt at high speeds; - over 80 km per hour.

Therefore, you need to tighten the steering column just enough to just remove the play, or leave it minimal. This way, you won’t ruin your car’s steering mechanism, and you won’t fly off the road when turning.

- What else can cause your steering wheel to not turn?

So; — wheel width, wear of ball joints and steering rods; - this is probably too banal. But, for example, I was surprised when the steering wheel of my Kopeechka, after installing a new column (adjusted) and a new shaft, simply became very tight. The very next day, after a run of 80 - 100 km, it was no longer as light as before, but not as tight as on the previous day of installation. As they told me at the service station, it takes a little time for the new shaft to get used to the bushing, and then it will spin normally. Well, we’ll see, I hope it will be so. But if the situation does not change soon, then I will unsubscribe).

Personally, this is not clear to me; - how, despite the fact that the old bushing was already clearly free for the new shaft; turned out to be too tight for the new one? It’s strange, but time will tell.

One of the main devices of a car responsible for control is the gearbox.

In the VAZ 2107 car it is made in the form of a cardan. The driveshaft is the most reliable for the driver, since as a result of a frontal collision, it folds without causing harm.

Malfunction of the steering gearbox.

The VAZ 2107 gearbox does not require excessive intervention. The main condition for normal operation is the presence of lubrication.

Creaks or extraneous sounds in the structure are common damage. Since in this model the steering wheel is attached to the shaft using splines tightened with a nut, if the fastening is loosened, the splines will be most subject to wear, and the steering wheel will dangle. Squeaks may be heard from the driveshaft crosspieces, which appear as a result of wear of the mechanism parts or lack of lubrication.

Also, damage to the steering wheel play is common.

The driveshaft may come off and, as a result, a gap appears. To adjust the steering column, a bolt with a lock nut is provided. The nut is pulled back and the bolt is screwed in until the play returns to normal. This nut is then tightened and secured in position. After this process, the steering wheel will turn much tighter, but the play will be reduced.

Before you start checking the steering mechanism malfunction, subject to the identified symptoms, you need to adjust the gearing. If the adjustment is unsuccessful (for example, the steering wheel rotates tightly, but the play has not disappeared), then you should disassemble the gearbox to find faulty or non-functional parts of the mechanism.

Repair related work

The steering gear, just like any other unit, is prone to failure. Repairing a steering gearbox is much easier if you understand the cause-and-effect series of problems. Having familiarized yourself with the main problems, their high-quality elimination in the shortest possible time is quite possible.

- The steering gearbox is leaking. This problem occurs frequently and is detected visually by traces of oil under the vehicle. The reasons are varied: from oil seal leakage to corrosion of the input shaft. The first option requires the installation of new oil seals, seals, and gaskets. The second case involves grinding the shaft with subsequent standardization of gas thermal spraying.

- A feeling of “tight” steering, which is observed due to increased effort to turn the steering wheel. To check whether the steering gear needs repair, you should check the steering wheel steering gain with a specially designed torque wrench. After this, the results obtained are compared with factory data. If the indicators do not meet the established standards, they proceed to diagnostics on a specialized stand. This operation is intended to obtain data on the pressure, flow rate of the working fluid, and the presence of its leakage onto the steering gear. Such a development of events requires the help of an experienced craftsman and in no case independent work. The last resort is to repair the steering gear by completely replacing it.

- Play in the steering wheel. The first reason is a breakdown of the steering column crosspiece element, the second is specifically the gearbox play. This will require complete disassembly of the unit, further study of the condition of the parts and replacement of outdated components. The work performed on the device involves bench adjustment.

- Knock in the steering gearbox. A problem of this kind is detected when a certain kickback is felt in the steering wheel. The reason for this is wear of the thrust bearings. This requires replacement of damaged parts with further bench adjustment.

Step-by-step adjustment of the worm gear.

In order to independently adjust the steering gear of a VAZ 2107 car, you need a flat screwdriver, a 19mm wrench, the help of another person and follow the step-by-step work:

- In order for the steering mechanism to be adjusted efficiently, the car must be placed on a flat surface, and the wheels must be in a straight position.

- Next, open the hood and clean the gearbox from dirt. Then you need to find the adjusting screw located in the center of the crankcase cover. This screw is covered mostly by a plastic plug. Before removing it, the plug must be pryed off with a flat screwdriver.

- Then you need to use a 19mm wrench to loosen the nut located on the adjusting screw.

- After loosening the nut, the assistant intensively turns the steering wheel in both directions. At this moment, together with it, it is necessary to start rotating the adjusting screw so that the necessary clearance appears in the meshing of the gears. Free play should be minimized and steering wheel rotation should become much easier.

- After the gap is adjusted, it is necessary to tighten the lock nut tightly, while holding the screw with a screwdriver.

Checking the steering gear.

After adjusting the steering gear of a VAZ 2107 car, axial displacement of the steering wheel is possible. It can be detected if the front wheels are placed in a straight position and at this moment you pull the steering wheel up, in which case the shaft will move.

Increased play in the VAZ 2107 steering wheel is a fairly common problem, characteristic of the entire “classic” family. In most cases, you can fix the problem yourself without resorting to complex, expensive repairs. It is only important to correctly diagnose and localize the causes of play in the steering mechanism.

Checking the steering play of the VAZ 2107

Large play in the VAZ 2107 steering wheel is a vague concept. Meanwhile, the permissible steering play has established standards. For “classics” it is 5 degrees. To check the backlash, a special device is used at the service station - a backlash meter. At home you can do without it. To do this you will need a ruler, chalk (or wire) and the help of a partner. Checking the amount of play is carried out as follows:

- place the machine on a level surface;

- check the tire pressure and inflate them if necessary;

- align the steering wheel so that the wheels are directed parallel to the axis of the car;

Important: if the wheels are level, but the wheel spoke is skewed, then there may be a violation of the wheel alignment angles, and the presence of defects in the suspension and steering. The steering and suspension should be adjusted or repaired.

- place the ruler so that it rests on the dashboard, touches the top of the headlight switch and, with the other end, touches the wheel rim;

- smoothly rotate the steering wheel while your partner monitors the position of the front wheels;

- as soon as the wheels begin to shift, stop turning the steering wheel;

- make a chalk mark on the steering wheel opposite the ruler (or wrap the steering wheel with wire);

- smoothly rotate the steering wheel in the other direction until your partner notices that the wheels have begun to turn;

- make another mark on the steering wheel with chalk or wrap a second piece of wire around it;

- measure the distance between the marks on the wheel rim.

A play of 5 degrees corresponds to a displacement of 17 mm with a steering wheel diameter of 40 centimeters.

The most common problems, their causes and solutions

Any unit is prone to breakdowns and the steering gearbox is, of course, no exception. It will be much easier for car enthusiasts to understand the cause of the problem and fix it as soon as possible if they are familiar with the main problems.

- The most common breakdown is a leaking steering gear. The presence of such a problem can be detected visually by the presence of oil under the car. The reason may be a leaking oil seal or corrosion of the input shaft. In this case, in the first case, during the repair it is necessary to install new oil seals, cuffs, and gaskets. And in the second case, the shaft should be polished, and then it is mandatory to carry out gas thermal spraying to normal dimensions.

- Feeling of a “tight” steering wheel. It appears due to an increase in the effort to turn the steering wheel. At the same time, in order to be sure whether there are reasons for repairing the steering gearbox, it is necessary to measure the level of steering wheel rotation gain with a special torque wrench. Then compare the obtained result with the data provided by the car manufacturer. If the indicators do not correspond to the established standards, it is necessary to carry out diagnostics on a specialized stand. This will help you find out the pressure, flow rate of the working fluid, as well as the presence of leaks in the gearbox. In this case, you should not try to repair the gearbox yourself. It would be much better, easier and more reliable to simply take it to a workshop. Or, if desired, replace it with a new one.

- Play in the steering wheel. This could be part of a faulty steering column crosspiece, or it could also be play in the gearbox itself. This requires not partial, but complete disassembly of the unit, examination of the condition of parts and replacement of worn elements. After the work has been completed, the device should be correctly adjusted on the stand.

- Knock in the steering gearbox. This type of malfunction can be identified by a noticeable “kickback” in the steering wheel. This problem occurs due to wear of the thrust bearings. It is necessary to replace damaged parts and then adjust the unit on the stand.

These four types of breakdowns are the most common, but sometimes there are other faults.

Pivot table for clarity

| Manifestation | Malfunction | Elimination method |

| Flow | Oil seal leak; shaft corrosion; lack of tightness in the cylinder tubes, in the discharge or discharge tube | Complete overhaul of the unit, precise identification of weak points, and their elimination |

| “Tight steering”, poor self-return, creaking | Bent shaft or crankcase; overtightened adjustment of the crayon stop | Replacement or restoration of the shaft or crankcase |

| Knock | Wear of hinges, crackers, right shaft bushing, silent blocks; free play of the steering shaft; crooked shaft or crankcase | Complete overhaul, replacement of worn parts with new ones, possible replacement of the shaft |

| Backlash | Wear of the crankcase, hinges, silent blocks; crooked shaft or crankcase; free play of the propeller bearing | Gearbox overhaul, replacement of worn parts |

| Knocking and play that is felt on the steering wheel when the engine is not running | The spool stops at the limiters, | These manifestations cannot be called a real breakdown, because Steering diagnostics should be carried out with the engine running |

| Weighting of the steering wheel in repeated positions | Steering shaft drive sticking due to corrosion | This is not a serious problem and can be fixed by repairing the driveshaft. |

| Biting the steering wheel in one or both directions | Crankcase wear; cylinder wear in middle position | Complete gearbox overhaul, replacement of worn parts |

Causes of steering play in VAZ 2107

If you notice unacceptable play in the VAZ 2107 steering wheel, the reasons may be as follows:

- The central nut securing the steering wheel to the axle is not tightened;

- the nut securing the steering column to the gearbox is loosened;

- The worm gear of the steering mechanism is not adjusted;

- the steering pendulum bushings are worn out;

- The tie rods are damaged or their ends are worn.

All of these problems require immediate intervention. Otherwise, the steering mechanism may fail and the car will lose control.

Steering mechanism VAZ 2107 - brief description

The steering mechanism of the VAZ “Seven” has a rather complex design, which ensures reliable vehicle control in different driving situations. The steering wheel is endowed with good information content, which eliminates driver fatigue when traveling long distances. There are some difficulties when turning the steering wheel while the car is stationary. However, as soon as the car starts moving, the steering becomes less rigid and control improves.

The steering mechanism has one nuance - a slight play, which is normal. This is explained by the considerable number of parts in the gearbox and the presence of rods. After modernization, the VAZ 2107 began to be equipped with a safety column, which has a composite shaft. Its design consists of two cardan-type joints, which allow the shaft to fold in the event of an accident. In this way, injury to the driver is avoided.

The steering gearbox is designed to transmit force from the steering wheel to the tie rods to turn the front wheels to a given angle.

How to remove steering play on a VAZ 2107

You should begin work by checking the tightness of the threaded connections of the steering mechanism and the condition of the steering rods (tips). Bent rods or worn tie rod joints must be replaced. To do this, you will have to use a puller and a 22mm wrench. You should not try to align the rods or repair the ends. For safety reasons, these parts should always be replaced with new ones. Next, you should check the condition of the pendulum and the adjustment of the worm gear. Worn pendulum bushings must be replaced with new ones. To do this, you need to unscrew the steering rods from it (use a 22mm wrench and a puller) and remove the pendulum from the car by unscrewing the mounting bolts. Clamp the pendulum in a vice, remove the cotter pin and unscrew the adjusting nut. Once the nut is unscrewed, you can disassemble the pendulum and replace the worn bushings with new ones. When assembling the pendulum, it is necessary to tighten the adjusting nut so that its bipod rotates with a force of 1-2 kilograms. If all parts are replaced or in good condition, and the threaded connections are tightened, the VAZ 2107 steering play is adjusted by adjusting the steering gearbox. To do this, you will need a 19 mm wrench and a powerful slotted screwdriver. The adjustment is carried out as follows:

How to repair the steering mechanism of a VAZ-2121 car

We remove the bolt securing the lower cardan joint of the intermediate steering shaft to the steering gear worm shaft (see Removing the steering column).

We hang out and remove the left wheel.

We press the ball pins of the rods out of the bipod holes: middle and side.

We move the rods down.

Using a 17mm socket, unscrew the nut of the bolt securing the steering gear housing to the left side member, holding the bolt from turning with a wrench of the same size.

Similarly, unscrew and remove the other two bolts securing the steering gear housing.

Remove the steering mechanism.

A rubber sealing sleeve is inserted into the hole in the front panel through which the worm shaft passes.

The clearance in the worm bearings is determined by the change in the distance between the end of the steering gear housing and the mark on the worm shaft when the shaft is turned in different directions.

To adjust the clearance in the worm bearings, clamp the crankcase in a vice and use a “13” key to unscrew the four bolts securing the bottom cover.

Remove the cover and shims.

We reduce the gap in the worm bearings by removing the gasket or replacing it with a thinner one

We install the steering mechanism in the reverse order, without fully tightening the nuts of the crankcase mounting bolts.

We secure the steering rods and the intermediate steering shaft.

An assistant turns the steering wheel two or three times to the right and left until it stops. At the same time, we check the installation of steering components in their standard places.

Tighten the nuts of the crankcase mounting bolts completely.

Removing the steering gear bipod

Use a 30mm socket to loosen the bipod mounting nut.

Removing the steering mechanism from the car

Use a puller to press the bipod off the shaft

If there is no puller, we dismantle the bipod using the impact method. We rest the bipod shaft against a wooden block.

We press the bipod on one stop with a sledgehammer, and hit the second with a hammer.

In some cases, you have to cut the bipod with a cutting machine.

The bipod is installed on the conical splines of the shaft in only one position: when the double groove of the bipod coincides with the double spline of the shaft.

Further repairs will not be a problem.

You only need to follow a few rules:

- the worm pair is changed simultaneously, as a set;

- after assembly/disassembly, adjustments need to be made;

- Do not use old oil, but replace it with new lubricant.

After the repair is completed, the gearbox is assembled and mounted in the reverse order.

The steering gearbox is a rather old mechanical device that is now used mainly on cars of the classic LADA family. Today you will learn what a steering gearbox is - repair, replacement, adjustment with your own hands.

The steering gearbox is a small mechanism designed to transfer rotational motion to translational motion. This means that the gearbox converts the rotation of the steering wheel into a force that shifts it in the right directions, causing the wheels to turn and change the direction of movement of the car.

The gear used in the gearbox is a reduction gear and consists of two elements - a worm and a gear. In addition, the mechanism has a special lever that moves the steering rods in the right directions.

The steering gearbox of the VAZ 2107 is sealed and, which significantly increases its service life and simplifies turning the steering wheel, reducing the effort exerted by the driver.

Replacing the gearbox

DIY steering rack repair

https://youtube.com/watch?v=—HYiizjMVo

https://youtube.com/watch?v=—HYiizjMVo

When replacing a unit, the labor intensity is lower than when repairing:

- I removed the fastening of the coupled mechanisms, dismantled the gearbox, there is no need to disassemble it;

- During repairs, parts are reassembled, if necessary, the shaft is welded and ground, then we select the oil to fill, and after assembly we tighten the adjusting screw.

Using the Grand Cherokee as an example, replacing the steering gear consists of the following sequence of actions:

- jacking up the front axle and installing it on temporary supports;

- by removing the front left wheel and the fender liner inside the arch, we gain access from below;

- remove the washer tank;

- unscrewing the bolt that secures the steering cardan to the gearbox;

- dismantling the power steering tubes going to the gearbox;

- The bipod of the steering gear and 4 crankcase mounting bolts are removed.

Removing the steering gearbox

Thus, regardless of the design of the gearbox of the steering system of the machine, most often the gap between the transmission parts is adjusted or the entire unit is replaced. For repairs, sets of gaskets and shaft seals, transmission oil and gear packing are produced. The shafts are restored by folk craftsmen; the manuals do not contain information on the dimensions of the seating surfaces, since the unit is considered non-repairable.

Video - Steering gear repair

In most cases, this unit is not repairable, since it is relatively inexpensive and consists of only two main parts. However, the manufacturer left the option for car technicians to purchase a repair kit.

Before repairing the steering gear, let's determine the malfunctions.

- Firstly, it can be repaired if the steering wheel rotates but the wheels do not. This means that there are defects on the threaded part of its shafts that prevent the two interacting parts from touching.

- The second type of fault is oil seals. If they have reached critical wear, then the oil from the gearbox will certainly leak, which already leads to its accelerated wear. If there are other mechanical damages, the gearbox must be replaced.

First, remove the faulty unit from the car. After this, press the bipod off its shaft using two hammers. Drain the oil from the gearbox through any technological hole. Now unscrew the four bolts that secure the cover and remove it. To access the worm shaft, you need to unscrew a similar cover on the other side of the mechanism. Pull out the remaining parts and replace the faulty ones. These may include oil seals and damaged shafts. After this, reassemble the gearbox in the reverse order. Don't forget to add oil!

Gearbox repair

Drain the oil from the gearbox housing, unscrew the adjusting nut and remove the lock washer.

Using a 13mm wrench, unscrew the four bolts securing the upper gearbox cover.

We remove the head of the adjusting screw from the groove on the bipod shaft and remove the cover.

When replacing the bipod shaft, the axial clearance between the screw head and the shaft groove is set by selecting the thickness of the adjusting plate.

The gap size is allowed no more than 0.05 mm.

The plates have a thickness of 1.95 to 2.20 mm in increments of 0.025 mm.

We remove the bipod shaft with the roller from the crankcase.

Using a 13mm wrench, unscrew the four bolts securing the worm shaft cover

Remove the cover along with the ball bearing adjustment gaskets.

Gaskets are available in thicknesses of 0.1 and 0.15 mm.

AutoNews / Reviews / Tests

Replacing the Steering Gearbox of a VAZ 2107 with Your Own Hands

Replacing the control gearbox on a VAZ 2104, VAZ 2105, VAZ 2107

The control gearbox is also popularly called the control gearbox, thanks to it the wheels of the car spin, it consists in an inexorable order of the housing and the shaft that comes from it, by the way, depending on the length and thickness of this shaft, as well as depending on the size of the parts themselves ( For example, from the worm itself, which is located in the gearbox housing) which are located in the gearbox housing, the control wheel can turn quite easily if all the parts have huge shapes (the larger they are and the longer they are, the easier it will be for the car’s steering wheel to turn), the whole point is that the gearbox simplifies the rotation of the steering wheel and transmits all the torque to turn the wheels of the car, but it, like no matter what other part, wears out over time and, most importantly, after wear it begins to leak, especially if you do not add oil to the gearbox, then over time it becomes so it is difficult to turn the steering wheel, this is especially noticeable when driving not at very high speeds, so the gearbox must be repaired (if it can still be repaired) or, if possible, quickly replaced.

In order to change the control gearbox in a car, you will need tools, namely: A basic set of wrenches, as well as various other types of wrenches, in addition, we recommend that you use socket heads and a wrench because it is not always convenient to unscrew the nuts using wrench, in addition to this (This no longer applies to tools), you will also need to take an assistant with you, since you will have to carry out this operation together, because it is more convenient!

Where is the steering gear located?

It is located in the engine compartment and in the lower part of the car, because of this, removing it from above is not very comfortable, which is why for such work you need a second person who will take the gearbox itself when you unscrew all the nuts that secure it.

If you want to see the gearbox itself, in other words, where it is located, then open the hood of the car and look where on the body (Not on the engine) on the driver’s side, you have a gearbox, which for clarity was shown with a reddish arrow in the photo just below:

When should the steering gear be replaced?

Many people advise immediately going to a car shop and getting a new gearbox and replacing it with a new one, although it, like any other part, can be repaired (Vit, not everyone has the money to buy a new unit), but as they say, the decision here is only for you, but the steering gearbox fails , firstly, oil that is inside it may leak from it (This is either due to the fact that it is rusty and corrosion has corroded it, or the oil seal in it has worn out and requires its own substitution), in addition to this, the steering wheel can also be difficult to turn due to a worn-out control gear (The control mechanism has a huge number of other components that are responsible for steering, so if your steering wheel starts to turn hard, you don’t need to immediately throw all the obstacles at the steering gear , since this could be due to the pendulum arm, as well as due to other parts).

How to change the steering gear on a VAZ 2107

If there is more serious damage, the steering gear must only be replaced. To do this, you need to purchase a new VAZ 2107 gearbox and immediately fill it with transmission oil. Now you need to remove the faulty gearbox from the car.

- Disconnect the tie rod ends from the tie rods. To do this, first unscrew them, and then unscrew the fastening nuts using a 22mm wrench. To pull them out, you need to use a special puller, which is available in any auto parts store.

- Go inside the car and loosen the clamp that secures the steering shaft to the steering gear. Pull the shaft out of engagement with the gearbox.

- All that remains is to unscrew the three bolts that secure the mechanism to the engine compartment of the car.

- Install the new gearbox in reverse order. Before you start operating the car, do not forget to adjust it.

Lubrication

Experienced users often change the lubricant, even in the absence of breakdowns, for the following reasons:

- The standard blue padding is too thick;

- Possible decrease in plasticity in winter;

- it accumulates near the lid and minimally reaches the friction pairs.

Standard gearbox lubrication

Graphite grease with Motul 4100 10W40

Some cars, for example, VAZ 21213 Niva, use transmission oil, as indicated in the official manufacturer's manual for the service station. To do this, the upper crankcase cover has a hole protected by a threaded plug; oil can be added without disassembling the gearbox.

VAZ 21213 gearbox with lubrication hole

Adjusting the VAZ gearbox

Adjustment of the steering gear is carried out to get rid of play in the steering wheel, as well as all kinds of discrepancies when it rotates with the position of the wheels. The car wheels must first be aligned.

To adjust the steering gear, you need to unscrew the lock nut on its cover from above and loosen the special adjusting screw. Ask your partner to sit behind the wheel and rotate the steering wheel in different directions with energetic, but not wide movements, while you gradually tighten the adjusting screw. As soon as the steering wheel begins to rotate tightly and the wheels move with the slightest movement, the locknut is tightened.

This completes the adjustment of the steering gear. As you can see, this procedure is not long at all and can be performed with just a 19-mm wrench and a regular flat-head screwdriver.