Safe driving directly depends on the condition of the car itself, since a serviceable vehicle requires the coordinated operation of all components and mechanisms. In this case, headlights are a source of light that serves to identify a vehicle, as well as to illuminate a large area of the road surface in front of the car while driving in the dark, under different weather conditions, etc.

It is important that the headlights (this applies to low and high beam headlights) not only shine, but are also correctly adjusted. It is through adjustment that you can achieve the most correct illumination of the road surface and the space in front of the car, as well as avoid dazzling oncoming drivers. Next, we will look at how to adjust the headlights and improve their light quality yourself, using the example of a VAZ 2110 car.

When adjustment is needed

Adjustment of the reflector position is required in the following cases:

- the beam of high and low beam is directed too low or high;

- the main spot is directed towards the side of the road or oncoming traffic.

Checking and adjusting the lights will be necessary after replacing light bulbs, a long trip along a broken section of the road, or a minor accident.

Alternative repair method

As for the alternative option for setting up the optics, this method includes the following steps:

- it is necessary to cut threads on the lighting control fasteners;

- then you need to tighten the screws and put washers on the lanterns;

- after this, the plastic clips are removed;

- the strip with low and high beam devices is installed;

- another washer is installed on top of the bar, a spring and another washer are also mounted;

- the entire structure must be secured using a locknut (video author - proVAZ-2110).

Preparatory work

There are several ways to correctly set the VAZ 2110 reflector:

- At a service station using a special device.

- Independently according to the scheme recommended in the VAZ operating instructions.

To adjust the headlights in a car service, you need to pay at least 1000-2000 rubles for the work. If you work independently, you can achieve good results and save money.

First you need to find a flat area and a wall. Suitable surfaces include a garage door, a fence, or a small building. The headlight adjustment diagram is drawn using chalk or a marker. Height data and the distance between points are measured with a tape measure and are the main ones in the process of adjusting VAZ headlights.

To obtain maximum accuracy in angle adjustment, you need to prepare the machine:

- Wash the body in a car wash.

- Inflate the tires according to the instructions on the driver's pillar or door.

- Clear the luggage compartment of excess cargo and stow the spare tire, wheel wrench and jack.

- Fill the tank full with fuel.

- Take with you an assistant or an additional load weighing 50-70 kilograms.

- Prepare the necessary tools.

When placing the VAZ on a flat surface, you should use wheel chocks or special shoes. Installing a handbrake changes the angle of the body and negatively affects the adjustment of optics.

Removal and installation of headlight hydraulic corrector Niva 2121, Niva 2131

What to do if the Renault Logan stove does not work. A little about the air conditioning system of the Renault Logan car - watch the video

We disconnect the hydraulic corrector from the headlights and instrument panel when removing these components. We completely dismantle it for replacement. To disconnect the working cylinder of the Niva 2131 hydraulic corrector from the headlight...

...press the lock, turn it counterclockwise...

...and remove the hydraulic corrector working cylinder from the headlight.

Having removed the rubber plug from the mudguard (see Removing and disassembling a VAZ 2131 headlight, replacing the lamp),…

...we bring the working cylinder into the engine compartment.

Similarly, we remove and remove the working cylinder of the other headlight. To remove the hydraulic corrector master cylinder in the passenger compartment of a VAZ 2121,…

... by pulling it towards you, we remove the control handle.

Using a 21mm socket, unscrew the nut securing the master cylinder to the instrument panel.

We remove the main cylinder of the hydraulic corrector from under the instrument panel.

Having removed the plug from the front panel, we bring both working cylinders into the passenger compartment through the resulting hole. We install the headlight hydraulic corrector Niva 2121 in the reverse order.

Lighting VAZ 2121, Niva 2131

| Headlight diagram and lighting Niva 2121, Niva 2131 |

| Disassembly and assembly of headlights Niva 2121, Niva 2131 |

Adjusting headlights Niva 2121, Niva 2131 |

| Removal and installation of headlight hydraulic corrector Niva 2121, Niva 2131 |

| Brake and reverse lamps, interior and trunk lighting Niva 2121, Niva 2131 |

| Removal and installation of the front lamp Niva 2121, Niva 2131 |

| Removal and installation of the side direction indicator Niva 2121, Niva 2131 |

| Removal and installation of the rear light Niva 2121, Niva 2131 |

| Replacing the reverse light switch Niva 2121, Niva 2131 |

| Removal and installation of license plate lamps Niva 2121, Niva 2131 |

| Removal and installation of lampshades and interior lighting switches Niva 2121, Niva 2131 |

Direction indicator diagram Niva 2121, Niva 2131 |

| Replacing the turn signal and hazard warning switch relay Niva 2121, Niva 2131 |

| Removing and installing the hazard warning switch Niva 2121, Niva 2131 |

Units and diagrams of electrical equipment VAZ 2121, VAZ 2131

Diagnostics of electrical circuits of the Niva 2121 car. Instructions for repairing electrical equipment: generator, starter. Niva 2131 car diagram.

Which headlights for VAZ 2110 are better and easier to adjust?

On VAZ 2110 cars, two types of front optics were installed from the factory:

- domestic production, the so-called Kirzhach headlights;

- imported components made by Bosch.

The diagrams and design of the parts are somewhat different, but the methods for adjusting the angle of inclination are no different. Spare parts are often supplied from Chinese or handicraft products, which are not of high quality. Such headlights often cannot be adjusted to work together within the limits allowed by the standard.

Headlights Kirzhach

The design of products manufactured by Avtosvet JSC (Kirzhach) uses lens optics for low beam lamps. In theory, such a solution should provide a directed and intense beam of light that is easily adjustable. In practice, light is distorted by an external diffuser, as well as by weather phenomena (rain, snow, fog).

The high beam lamps are installed in a standard reflector located closer to the radiator grille. The reflective element is small in size and unreliably mounted. Because of this, the effect of light shaking when moving is observed.

Today, the Avtosvet enterprise is bankrupt, part of the equipment has been transferred. Spare parts sold under the Kirzhach brand are fakes and have nothing to do with the original products.

headlight

German Bosch headlights

German optics are equipped with conventional reflectors, but due to the high quality of components they allow you to obtain an intense and stable beam of light. According to owner reviews, the headlights provide better illumination in any weather than domestic products.

The production of headlights was carried out in Ryazan. Currently, the Automotiv Lighting enterprise, which is a structural division of Magnetti Marelli (Italy), is located there. It is these products that are supplied to the plant and for spare parts. The name “German Bosch” is used by car owners from old memory.

Headlight Bosch for VAZ 2110

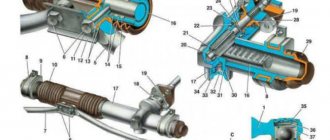

Design of headlight hydraulic correctors

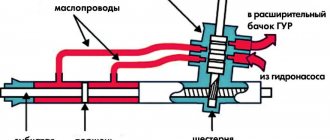

As a rule, the following components are included in the design of a hydraulic corrector:

- master cylinder mounted on the dashboard;

- actuator cylinders mounted on the headlights;

- connecting pipelines that are fixed with clamps;

- working fluid with increased frost resistance.

The manufacturer provides a maximum operating pressure in the normal state of the corrector. To direct the luminous flux of the headlight downwards, the pressure in the system is reduced, as a result of which the actuator cylinder rod is retracted and the optics are rotated downwards. Thus, most of the time the device is under increased pressure.

Quite often, when temperature changes occur, especially in winter, the structure of the seals is damaged due to the poor quality of the rubber, which leads to leakage of the working fluid. In turn, this leads to jamming of the cylinder pistons in one of the positions.

Structurally, all hydraulic correctors that are installed on VAZ vehicles are made according to a similar design, with the exception of some differences in size, layout of cylinder fastenings and pipelines. Today the following modifications of hydraulic correctors are supplied to the market:

- “2105-3718010” - for VAZ 2105-2107;

- “2108-3718010” - for VAZ 2108-21099;

- “2110-3718010” and “2110-3718010-10” - for VAZ 2110-2112;

- “2114-3718010” - for VAZ 2113-2115;

- “21213-3718010” - for 21213 “Niva”.

Why is headlight adjustment important?

The importance of adjusting headlights is explained by the following safety nuances:

- Incorrectly adjusted headlights create a wide beam of light in front of the car, which actually creates a curtain that limits visibility. This effect is especially noticeable in rainy or foggy weather, as well as during snowfall.

- An unregulated beam of light in the low beam mode blinds oncoming drivers, increasing the risk of traffic accidents. When the light is switched to high beam, the trees will be illuminated, but not the road in front of the car.

Features of operation

The new corrector will last a long time and will not need repairs for a long time if the replacement is done correctly. During operation, the corrector must be checked regarding the integrity of the pipeline. If a leak is detected, the entire set must be replaced again.

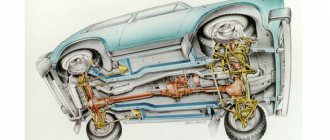

Depending on how loaded the vehicle is, the headlights can be directed higher or lower. To adjust the light flux, special devices are used - hydrocorrectors. If the car is loaded, the headlights should be turned down so that the flow of light is directed not upward, but onto the road. This ensures the necessary illumination of the road surface and prevents the driver of an oncoming car from being dazzled. In the case of a minimal vehicle load, when the rear part of the frame is raised, the headlights should be turned upward.

How to properly adjust headlights without removing them?

Car headlights are adjustable without removing them from the car. For setup, a special stand is used, with individual markings for each model. For self-adjustment, use a portable template made of plywood or drawn on the wall. In a car service center, special adjustable instruments are used that provide increased measurement accuracy.

The adjustment procedure in garage conditions consists of the following steps:

- Applying a marking template on the wall or installing a ready-made one.

- Designation of lamp center points.

- Directly adjust the light.

To adjust the light beam, two regulators installed at the rear of the housing are used. The one closest to the turn signal is responsible for changing the direction vertically, the second - horizontally. Access to the regulators is free and is not blocked by engine compartment units.

Preparatory work before adjustment without disassembly

Requirements before starting adjustment:

- Wash the outer surface of the headlights. There should be no dust deposits, insect residues or oil on the glass.

- Check the operation of the correction device, which can be hydraulically or electrically driven.

- Conduct a visual inspection of the lens glass. If any clouding or scratches are found, polishing is recommended. It is better to carry out the procedure in a specialized service that has tools and materials.

- Check the external condition of the lenses and reflector surfaces. If there are peelings, cracks, or chipping, the part or headlight will have to be replaced.

- It is recommended to replace the low and high beam lamps, especially in cases where the light sources are used for a long time. High-power lamps should not be installed in headlights, as they cause overheating and destruction of the unit.

- Analyze the technical requirements for adjustment. Bring the vehicle load to the required level, set the appropriate tire pressure.

The main difficulty when adjusting the headlights yourself is finding a level area that allows you to freely place the car and the control screen.

Algorithm of actions when setting up

Instructions for adjusting headlights with your own hands:

- Place the VAZ 2110 on a level area at a distance of 5 m from the installed measuring template. There should be a right angle between the machine and the template.

- Load the driver's seat with 75 kg ballast. Often there is an assistant in the driver's seat.

- Rock the car by the front fender to install the shock absorbers and suspension springs in their working position.

- Draw a vertical line on the template or wall corresponding to the axis of the car (indicated as “O” in the diagram).

- Draw parallel lines A and B corresponding to the centers of the lamps. The distance between centers is 1108 mm.

- Hit two horizontal lines. The line marked 1 in the diagram is located at a distance of 600 mm from the floor and corresponds to the center of the headlights. Line 2 is located 75 below and serves to display the center of the headlight's light spot.

- Turn the hydraulic headlight adjustment control to the position corresponding to the minimum load.

- Open the hood.

- Cover one of the headlights with a thick material, such as a piece of cardboard.

- Rotate the adjusting rods to set the beam of light on the open headlight. The upper limit of the light spot should lie on line 2. The connection point of the horizontal and inclined segment of the light spot coincides with point E.

- Carry out a similar procedure with the other headlight.

Visualization of the adjustment process

If, during the process of adjusting the headlights on a VAZ 2110, it is not possible to bring the beam into the specified parameters, then it is necessary to dismantle the lighting device for repair or replacement.

Let's sum it up

When operating a car, it is important to understand that properly adjusted headlights are the key to the safety of not only the driver and his passengers, but also the safety of other road users. For this reason, it is necessary to monitor the condition of the optics, as well as the quality of the car headlight adjustment.

We also recommend reading the article on how to choose fog lights for a VAZ 2110. From this you will learn about the features of selecting fog lights for a VAZ, as well as nuances that must be taken into account separately when selecting.

In turn, adjusting the headlights of the VAZ 2110 can be done either independently or at a service station (using a special stand-screen). If the work is carried out independently, it is necessary to take into account that in general the procedure for carrying out adjustment work is not complicated, but requires accurate measurements.

One way or another, by reading the above instructions, you can achieve correct adjustment of the VAZ 2110 headlights. This will improve the quality of road lighting, reduce eye strain when driving at night, and also increase overall safety, etc.

How to remove the headlights yourself and adjust them if the device has defects?

In some cases, the VAZ 2110 headlights cannot be adjusted. This is due to damage to the hydraulic corrector or defects on the reflectors or glass. In this case, you can try to disassemble the unit and replace unusable parts.

How to disassemble the headlight?

Sequence of disassembling the VAZ 2110 headlight:

- Remove the part from the car, remove all lamps from the housing.

- Heat the glass evenly with a hair dryer, melting the sealant layer. Separate the lens from the headlight housing using a flat object. When disassembling a Bosch headlight, you need to unfasten the glass mounting brackets.

- Unscrew the three reflector mounting points.

- Remove the corrector spring through the hole for installing the actuator.

- Remove the reflector from the housing by turning the angle adjusters.

- Wash the headlight components, replace faulty parts and reassemble the assembly. The sealant used is a silicone compound used for installing car windows.

Removed headlight Cleaned reflector Assembly components Reflector guide Headlight assembly Sealant applied

Features of removing and adjusting the headlight

Headlight removal procedure:

- Disconnect the battery terminal.

- Remove the upper decorative radiator grille, which is mounted on two bolts.

- Remove the power supply plugs for the headlight.

- Remove the actuators of the correctors. The part is secured with a latch and a rotary lock.

- Unscrew the three bolts securing the headlight and recess it a little deeper.

- Slide the decorative strip (“eyelash”) and remove it from its seat on the bumper. To facilitate dismantling, loosen the upper bumper mount located between the headlights.

- Unscrew the fourth mounting point of the headlight and remove it from the socket.

- Install a new part (the procedure is performed in reverse order).

A removed VAZ 2110 headlight can be cleaned of dirt and repaired; the design does not provide for any adjustments.

Replacement

Many car enthusiasts struggle with replacing and installing a hydraulic corrector. But in reality this work is not difficult. And if everything is done correctly, then no problems should arise. Replacement consists of the following steps:

- First the preparation is done. All clamps securing the tube to the body are removed. It is also advisable to remove the radiator expansion tank. This will make access to the headlight easier. In the cabin, the control knob is removed; to do this, you simply pull it towards you;

- Next you need to get the cylinder. To do this, grab the switch on the panel and pull it off. In most cases it can be easily removed. After this, the cylinder is unscrewed from the switch. This is done using a 22mm head. Afterwards the cylinder is pulled out by the tube under the torpedo. As a result, he should hang on the hoses;

- The actuator cylinders are disconnected from the headlamp. They are dragged into the salon. This completes the dismantling of the corrector.

Reassembly is done in reverse order

In this case, pay attention to the seals. They must stand straight

Otherwise, you will have a noisy interior, and in winter it will blow from there. Don't forget to check the operation of the new hydraulic corrector. If it turns out that it does not work, you will have to repeat the procedure.

What to do if the headlight unit is faulty?

A common defect of “Kirzhach” parts is the failure of the hydraulic corrector. Because of this, the headlight cannot be adjusted or the beam of light changes direction when trying to adjust it with the corrector. The cause of the defect is a leak in the seal or jamming of the actuator. To monitor the serviceability of the unit, the stroke of the actuating rods is measured, which should be in the range of 6.5-7.5 mm. In the event of a breakdown, the unit must be replaced; repair of parts is impossible, since the device is non-separable.

The easiest repair method is to install a mechanical regulator. To do this, a suitable bolt with a lock nut is screwed into the actuator housing. The disadvantage of this design is the need to manually adjust each headlight. Therefore, installing a manual regulator is not recommended.

Installation of hydraulic corrector

To replace a standard hydraulic corrector with an original unit, you must:

- Remove all points attaching the corrector pipelines to the body.

- Remove the regulator located in the instrument panel.

- Remove the protective frill of the trapezium wipers.

- Remove from the mountings and move the expansion tank to the side.

- Remove the old tubes from the seats protected by rubber seals. Many owners cut the lines and take them out piece by piece.

- Remove the old system master cylinder.

- Clean out debris from under the frill. Insert the new tube into the standard hole. To simplify the procedure, it is recommended to use copper wire to pull the tube.

- Reinstall the rubber channel seals. This is important because the hole is located directly above the relay and fuse mounting block.

- Route the lines along standard routes through the engine compartment.

- Check the system operation.

- Adjust the headlights using the method described above.

Some of the replacement steps are shown below.

General view of the new corrector Approximate volume of dirt under the frill Pulling the wire through the hole Tubes leading into the engine compartment Routing lines Installing the regulator

The procedure for installing a new hydraulic corrector is shown in the video tutorial from the author “Aleks B”.

Installation of electrical corrector

A number of owners install an electric drive from the GAZ 3110 Volga on the VAZ 2110:

- Install the corrector motors in the standard place. The installation location does not require any modifications.

- To control the installation angle, a button from the standard electric window, installed in the housing of the hydraulic corrector control handle, is used.

- Connect power to the electric drive from the ignition switch. A 5 A protective fuse is installed in the circuit.

- Route the wiring into the engine compartment. It is recommended to use protective corrugated sleeves to protect the wires from chafing the insulation.

- Crimp the ends with plugs that will ensure reliable contact with the motors. On motors, only two of the available four contacts are used.

- Protect the connection point of the wires to the motors with electrical tape.

- Cross the wiring onto the plug that will connect to the control key.

- Connect button.

A schematic diagram of connecting wires to the key plug.

A photo gallery of installing an electric corrector on a VAZ 2110 is shown below.

Installation kit Electric motors for GAZ 3110 corrector Power supply to the button Upgraded standard regulator Wiring pulling Laying wires in sleeves Connecting motors Insulated unit

Trembling of light

Another common defect is the shaking of the light beam, which is observed when the car is moving. The defect occurs on Kirzhach headlights; German products have a durable design.

The causes of the defect are:

- reflector exits from mounting points;

- corrector failure;

- poor condition of lamps;

- weakening of the adjusting springs.

To install the reflector in its original place, the headlight must be disassembled using the method described above. You can compensate for spring fatigue by lengthening the working rod of the corrector using a cap. A part of a plastic dowel is used as an extension, which is put on and fixed on the rod.

Electromechanical types of correctors

This type of device is high-tech, it is the most popular and widespread. Its design is simple, consisting of several elements:

- Geared motors for each headlight.

- 4 position switch.

- Wiring.

- Fuse.

If you use such a device, you will need to do the following:

- Remove (if installed) the hydraulic corrector drive.

- If you plan to install the switch in another location, then the first step is not necessary. The most suitable place to mount the switch is to the left of the steering wheel.

- Lay the electrical wiring to each headlight. It is advisable to connect the wires to the harnesses with special plastic ties.

- Install new stepper motors in place of the adjusting rods of the old hydraulic corrector.

- Connect the wires to the stepper motors.

- Since this device consumes, albeit a small current, it is necessary to install a 7.5 Ampere fuse in the positive gap of the power supply. This device will save you from a short circuit. But it is best to calculate the maximum current consumed by the entire system. Based on this value, select a suitable fuse with a margin of 25%.

It is best to connect the VAZ-2109 headlight electric corrector to the wiring that comes from the ignition switch. This will completely de-energize the circuit when the ignition is turned off, and this will increase the reliability of the device and safety.

Preparing to adjust the light output

In order to improve visibility on the night road, without dazzling drivers of oncoming cars, it is necessary to adjust the headlights. You can do this in a service center, or with your own hands. Knowledge of the basic rules for adjusting headlights will help improve the luminous flux on a VAZ.

So let's get started:

- Serviceability. Make sure that your hydraulic corrector or electric headlight corrector is working correctly (depending on the configuration). Please note that the corrector plays an important role, therefore, before the adjustment takes place, you need to be sure that this mechanism is working properly;

- Position. Having chosen a completely flat area, install the car. The area must be checked with a level to prevent distortion, otherwise it will not be possible to adjust the headlights correctly;

- Build a kind of vertical shield screen at a distance of 5 meters from the car on which you can draw;

- It’s not bad if you have a flat area in front of the garage door. They are also unlikely to be particularly harmed by chalk;

- Loading. A car that is being adjusted must be “fully equipped” - fueled, with normal tire pressure, and a load of the driver’s weight (or a person of approximately the same weight) placed on the driver’s seat;

- Vertical markings. On the screen, wall or garage door, draw three vertical lines and mark them: “O” - there will be a line in the middle of the car (this place is usually indicated by the sign of the car, in our case it is the usual VAZ sign); “L” means right;

- Horizontal marking. Draw a horizontal line through the centers of the headlights, marking it N, and 65 mm below it, draw another line, which is marked “P”. Now it becomes possible to adjust the light with your own hands.

Making an element by hand

The main advantage of the method is that if the hydraulic corrector becomes deformed, you do not need to repair it - you just need to manually adjust the headlights.

For one optical element you will need:

- lock-nut;

- a pair of nuts with turned ends to secure the bolt in the body of the product;

- M8 bolt 6-10 cm long;

- The corrector housing from the device is in working condition.

On the back side of the correction housing, drill a hole for normal movement of the bolt in it. The structure will sit smoothly thanks to the nuts with ground edges. For extra confidence, you can seal the nuts with epoxy glue.

To make driving safer, your headlights must be properly adjusted. In particular, in this article we will talk about domestic “tens”. How to adjust the headlights on the VAZ 2110 model, how to adjust the optics without disassembling them? You can find out more about this below.

Adjustment algorithm

We sequentially perform the following:

- Cover the right headlight with cardboard or other material that does not transmit light;

- Turn the hydraulic corrector to the first position (I);

- Open the hood, find the screws used for adjustment, and turn them. At the same time, if the left headlight is adjusted, then it will be correct if its light at the top reaches the line N, and at the bottom – P;

- Having adjusted one, the adjustment of the other begins, closing the previous one.

Remember, if the headlights shine too low, they need to be raised, otherwise you may not notice the pedestrian in time, especially if there is slush on the street and he is wearing black clothes. If the light is set high, that is, you deign to raise them high, oncoming drivers will not thank you because you will blind them. Therefore, do-it-yourself adjustment on the VAZ must be done very carefully.

Hydrocorrector malfunctions

Among the most likely causes of a non-working headlight hydrocorrector is depressurization of the joints of tubes and sealing cuffs. The consequence of loose connections is loss of working fluid and air being sucked into the system. For the working pistons to move properly, the system must be completely filled with liquid. The manufacturer does not suggest repairing the hydraulic corrector, so if the system fails, the assembly is replaced. Nevertheless, the article “Repairing a hydraulic corrector” shows that the system can be troubleshooted and restored.

This is interesting: Ways to check a car battery: how to determine the health of the battery using a multimeter

Where is the lamp hydraulic corrector located? Each headlight unit has an actuator that acts on a reflector, from which 2 tubes go into the cabin. Through a technological hole in the engine shield, the tubes go to the master cylinder and the switch on the dashboard.

Reasons for failure of the hydraulic regulator

If, when turning the headlight adjustment knob, the light beam does not change direction, this indicates a failure of the hydraulic corrector. There are several reasons for the malfunction:

- One of the working cylinders is jammed. In this case, the corresponding reflector will not rotate.

- The connecting tubes were damaged and the system depressurized.

- Failure of sealing due to damage or wear of seals.

If the system is depressurized, it is impossible to regulate both lamps. Most often, they lower and take a lower position, as a result, the headlights only illuminate the road next to the car. At night, this increases the risk of an emergency. You can try adjusting the hydraulic device rod.

Manufacturers of hydraulic correctors did not provide for the repair of the closed system as a whole and individual elements. Therefore, if the device fails, it is necessary to either install a new hydraulic regulator or replace the hydraulic device with an electric one.

Some car enthusiasts try to repair the regulator, but this does not bring long-term results. For example, they replace the working rod with a self-tapping screw of a suitable diameter with the sharp end removed. This makes it possible to fix the reflectors in a certain position. It will be impossible to make adjustments from the interior.

If, during a visual inspection of the hydraulic regulator, cracks are found in the connecting tubes, the repair will consist of eliminating them. The cause of cracks is temperature changes in the engine compartment of the car. If the crack is close to the main or working cylinder, cut off the cracked end. The tube damaged in the middle is completely replaced by pumping with antifreeze.

Modernization

With a little modification, you can significantly improve the Kirzhach headlights with your own hands and make their glow brighter.

First, the headlight must be removed, then disassembled in the following sequence:

- To remove glass from Kirzhach, use a hairdryer - you need to heat the sealant, then use a sharp knife to separate the glass;

- Remove the reflective pad;

- The modernization will only affect the low beam units, so unscrew them;

- And then you have a choice: with Kirzhach you can either move the lens towards the reflector by 10 millimeters, or grind off the modular ring, making it shorter. This will help improve the luminous flux of the Kirzhach headlights, raise it and make it wider.

Electric corrector

By assembling the circuit shown in the figure, you can check the smooth operation of the servo drive. If the gear motor does not respond to power supply, you can safely proceed to replacing or disassembling it. In most cases, the housing is secured with plastic latches. If the latches cannot be snapped off, they can be carefully cut off, and when installing part of the body, they can be joined with dichloroethane (special glue for plastic). The electric motors themselves fail extremely rarely, but they are also sold separately.

Read news about the new Niva

- Home> Popular> Auto and motorcycle products>»Niva LED headlights»3,813 products found

- Replacing headlights on Niva 2121: tips and tricks

- Chevrolet Niva electrical circuit diagram and its description

- The best headlights for the Niva - Auto magazine Inkam Auto

- Adjusting headlights VAZ 2114 and 2115: tips and tricks

- Tuning headlights for Niva 21213(4) - options for high-quality lighting

- Chevrolet Niva fuse box with description (up to 2009 release)

- Why do headlights sweat from the inside and what to do about it?

Also interesting: Do-it-yourself power bumper for NIVU

Alternative to mechanics

Even if you adjusted it yourself according to all the rules, if the VAZ load changes, you also need to change the angle of the light beam. A hydraulic corrector was invented for this purpose. Moreover, the corrector is designed non-separable, it is also not adjustable.

Accordingly, if it fails, the corrector is simply replaced with a new one. And the most common reason that the hydraulic corrector fails is a “wedge” of the pistons or a fluid leak.

If the need arises, it would be advisable to replace this corrector with a more modern and high-tech electrical corrector. The kit, which provides for an electric corrector to be installed on the car, consists of a headlight range control, the mechanism itself with rings - seals and wires.

Video “Polishing optics with toothpaste”

How to polish the headlights on a “ten” with your own hands using toothpaste, see the video below (the author of the video is Dima Artist).

As practice shows, road accidents most often occur at night. And this is not strange, because after sunset, the visibility of the motorist is significantly reduced. And in the case when the headlights do not work at all, the likelihood of an accident is extremely high. According to statistics, the main reason for this trend is improper adjustment of lighting fixtures, which leads to dazzling other road users.

Every motorist knows first-hand how much strain the eyesight experiences in a direct beam of light.

The view is not just reduced, it practically disappears, resulting in unpleasant or even tragic consequences.

In our realities, uneven road surfaces always stimulate vibration of the car, which disrupts the glow geometry of the head optics. Therefore, headlight adjustments should be carried out regularly, including when installing new lights.

Eliminating headlight shake

Many owners of the VAZ 2110 find that the light flickers when the car is moving. Such a breakdown most often occurs in Kirzhach headlights, but in Bosch parts such a breakdown rarely occurs. There is only one reason: reflector rattling. To eliminate light flicker, check:

- Is the reflector in place in the latch;

- The presence of an adjusting bolt rod;

- The emphasis is on the seating recess of the hydraulic corrector rod;

- We check the sagging of the thread (swap the high beam and low beam bulbs);

- Integrity of the tube in the hydraulic corrector (it may fray).

Lighting problems

If the illumination of the road with headlights has deteriorated, then you should first determine the cause of this malfunction. You may not need to adjust your headlights. First you need to carefully wash the lens of the device. It may well be that the reason is simple - pollution. To avoid having to constantly wash the lighting fixtures, it is recommended to install a washer. Installation of the device does not cause problems, and the working fluid is supplied to it from the windshield washer.

Next, you should check the integrity of the lens. If small cracks, damage from small stones or other defects are found, this may lead to scattering of the light flux. The lens needs to be replaced. Abnormal operation of headlights can also be caused by defects on the surface of the reflector.

Perhaps, for various reasons (for example, defects), the reflective material began to deteriorate, which does not allow creating the desired concentration of the light beam. This reflector needs to be replaced urgently. Finally, the light element itself no longer satisfied the driver’s wishes.

Installing a halogen light bulb instead of a regular one will significantly enhance the lighting.

We repair the light fixture without disassembling it

You can snap the ball into place without removing the glass, through the holes of the light bulbs on the back side of the illuminator:

- We drill a hole exactly opposite the latch at the top of the headlight;

- Insert a screwdriver into the hole;

- Attach the collet to the corrector ball;

- We seal the hole we drilled;

- We attach a hinged loop from a furniture cabinet (hinges 5-6 centimeters long, with mounting holes and a cutout on top on which it is attached) to each broken corrector unit;

- We insert the canopy into the slot of the adjustment screw;

- We move the screw so that the slot is in a narrow place of the canopy;

- Holding the canopy, unscrew the screw until it stops with force. This is how the canopy is fixed, which needs to be placed in a horizontal position;

- Using an electric drill, using a 3 mm drill, we make a hole in the base of the light where there is a hole on the canopy;

- We screw a shortened screw into the hole so that it does not reach the high beam reflector. This slot secures the adjustment screw securely; it can be broken again.

How to use concealer

The corrector has knob A on the dashboard of the VAZ 2107 to the right of the steering wheel, next to knob B for adjusting the brightness of the dashboard lighting. If you rotate knob B counterclockwise, the brightness of the light decreases.

As they say, the control knob of the device has an “intuitive interface.” To change the direction of the light flow, with the trunk loaded and the headlights on low beam, you need to align the mark shown on the regulator with one of the marks marked on the unit body so that the beam of light does not blind oncoming drivers.

The VAZ 2107 hydraulic corrector has four switching options (in order from large point to small point):

If not

I can adjust the headlights

on

NIVA

2121,21213,21214 then watch this video to the end.

I - minimum load, the front of the car is slightly lowered: one driver, or there is a passenger in front;

II - driver and four passengers, the body sags evenly downwards;

III - the same as II, with an additional load of up to 75 kg in the trunk:

IV - driver and maximum trunk load: the “nose up” the most.

In order to see how the angle of inclination of the light beam changes during operation of the corrector, it is better to place the car perpendicular to the wall. Let us recall the standard requirements for the location of the low beam.