Purpose

The purpose of the oil pump is to circulate oil through all engine components to lubricate them evenly and increase their service life. It is driven by an internal combustion engine (internal combustion engine) and is structurally divided into two different types, based on the principle of coupling with the crankshaft. In our case, it connects directly to the crankshaft, that is, it rotates with it. This is the operating scheme of the unit for front-wheel drive VAZ cars. Cars with all-wheel drive, as well as classics, have a more complex system installed. There, the drive contains additional links: an intermediate shaft, a timing chain (gas distribution mechanism), and toothed gears, through which torque is transmitted from the crankshaft to this device.

Common faults

So:

- Most often, the pump of the VAZ 2112 and other VAZ models with front-wheel drive leaks through the seal, which has to be changed.

- The oil receiver also often fails, especially if you use low-quality oil, or missed replacing it in a timely manner, or the oil does not meet specifications (too thick).

- Too liquid simply will not be pumped and the pressure sensor will immediately light up.

- In this case, the oil receiver mesh becomes clogged, the circulation of oil through the engine becomes difficult, causes oil starvation, and as a result, the service life of the engine is significantly reduced.

- This includes a malfunction of the pressure reducing (bypass) valve: either it is stuck in the open position, and then the oil pressure drops. Either it does not bypass, and then the oil will squeeze out through the oil seal

What oil to fill and at what frequency?

The manufacturer recommends changing the engine oil after 10 thousand kilometers, however, it is recommended to shorten this period if possible, and at the same time change the oil filter. You should only buy oil from well-known companies and, when choosing it, beware of counterfeits. The ideal option is to pour oil recommended by the manufacturer and not be fooled by cheapness or high cost (expensive does not mean high quality).

Recommendations for choosing spare parts

So:

- The oil pump usually does not cause car owners much trouble, since it has a service life of at least 120 thousand kilometers. However, no one is immune from breakdowns

- If suddenly you still need to replace the oil pump on a VAZ 2112, it is better to take original spare parts and not save

- Among the well-known suppliers of parts for VAZ cars, the official one is the Tolyatti Automobile Assemblies Plant (TZA for short).

- It also produces oil pumps for the VAZ 2112

- This is one of four varieties of such units in the VAZ line, which fits all front-wheel drive fuel-injected cars

Helpful advice: To avoid serious consequences for the car and major engine repairs, it is important to monitor the indicators on the dashboard. If the oil pressure lamp flashes at idle speed, and replacing it does not solve the problem, the lamp lights up again - this means there is a breakdown

When the warning light suddenly comes on and the performance of your car’s engine is alarming, it is recommended to turn off the ignition and call a tow truck to a repair station. This will save money on subsequent engine repairs (continuing to drive the car under its own power in such a situation, you risk serious damage to the engine).

- Typically, removing the oil pump on any car occurs when disassembling the engine.

- Only if necessary, this work is carried out on the car without removing the engine from it.

- Before starting this procedure, first drive the car into the inspection hole.

- And immediately purchase everything you need to carry out a full replacement, as shown in Photo No. 2.

Designations in the photo:

- 1 - oil pump

- 2—pan gasket

- 3 - pump gasket

- 4 - sealing ring

- 5 - sensor mounting bracket

Attention: The pumps of the VAZ 2108-1011010 and 2111, 2112-1011010 engines are almost the same, with the exception of point No. 5 - the sensor mounting bracket is different, do not miss this point!

Tip: It is recommended to install only a factory-produced gasket under the pump, since a non-standard gasket may have a thickness that does not meet the specifications and cause problems with the operation of the pump.

Necessary tool

- A set of wrenches (open-end - spanner preferably)

- Socket set and ratchet

- Two strong flathead screwdrivers

- Hexagon set

Troubleshooting

Direct connection of the pump to the crankshaft avoids damage associated with its drive. This, however, does not exclude the possibility of other malfunctions.

Pump malfunctions and their symptoms

The main malfunctions of the VAZ 2110–12 oil pump include:

- clogging of the oil receiver mesh;

- damage to the device body;

- wear of gear seats in the housing and cover;

- wear of the drive or driven gear;

- damage to the pressure reducing valve;

- deformation or damage to the valve spring.

A constantly burning warning light in the form of an oil can indicates a drop in pressure in the lubrication system to a critical level

Signs of oil pump failure may include:

- critical oil pressure warning light on the dashboard;

- engine overheating;

- high-frequency knocking (clattering) at the pump location.

The design of the VAZ 2110–12 engine does not provide for the installation of an oil pressure sensor. Like most modern cars, representatives of the tenth family are equipped only with an emergency (critically low) pressure sensor. When the pressure in the system drops, a warning light in the form of a red oil can lights up on the instrument panel. However, this lamp can also light up in the event of other malfunctions (failure of the sensor, break in its electrical circuit, oil leak, etc.).

Engine overheating also cannot be attributed only to symptoms of a faulty oil pump. It usually occurs due to problems in the cooling system.

As for the knocking coming from the oil pump, not everything is clear here either. Sometimes, when gears or housing elements wear out, the device may produce a high-frequency knocking sound. As a rule, it is associated with the formation of play between the gears and the housing (cover) and is most clearly audible at idle. However, similar sounds can also be produced by worn bearings (tension or guide rollers, pumps, crankshafts).

How to determine that the oil pump is faulty

The process of replacing the oil pump on a VAZ 2110-12 is quite simple and does not involve the use of any special tools. However, to do this you need to buy a new pump and spend some time. Therefore, before replacing the device, you should make sure that it is the one that is faulty. This can be done using the following algorithm.

Oil level measurement

First you need to measure the oil level in the engine and check its consistency. This is done with a special probe. It is advisable to remember when the oil and filter were changed. If the car has traveled more than 10 thousand km since the last replacement, it is better to replace them immediately. Then you should apply a drop of oil to your thumb and rub it with your index finger. If the oil turns out to be too dark, liquid and quickly absorbed, it needs to be replaced.

If the lubricant level on the dipstick is below o, add oil and start the engine. Next, you need to see if the warning light on the dashboard comes on. You should also check whether the power unit is overheating. At the same time, the engine is inspected for oil leaks. If you previously heard a knocking sound from the pump, you should listen to see if it disappeared after adding oil.

One of the reasons for the drop in oil pressure in the system may be its low level

Checking the sensor electrical circuit

If the listed symptoms do not disappear, you should do the following:

- Stop the engine and let it cool.

- Disconnect the wire from the emergency oil pressure sensor. On sixteen-valve engines it is located on the left side at the end of the camshaft bearing housing, on eight-valve engines it is located on the right on the rear side of the cylinder head.

- Turn on the ignition without starting the engine.

- In the engine compartment, short the wire going to the sensor to vehicle ground. If the warning light goes out, everything is fine with the sensor circuit.

To check the sensor circuit, it is enough to short-circuit the wire going to it to ground with the ignition on

Sensor diagnostics

To diagnose the sensor, you need to unscrew it with a 21 key and inspect its working part, which goes into the cylinder head. There should be traces of engine oil on it, indicating normal lubricant circulation in the system. If the working part is dry, the oil pump is most likely faulty.

The sensor itself is usually checked by replacing it with a known good one. After this, it is checked whether the warning light is on and how the engine behaves.

Checking oil pressure

If after checking and replacing the sensor the symptoms do not disappear, you need to measure the oil pressure using a special pressure gauge. This pressure gauge has a metal tip with a thread that is screwed into the sensor socket. Then the engine starts and warms up. If the pressure gauge shows a pressure greater than 0.6 bar (60 kPa) at idle, the oil pump is working. If the pressure is lower, the pump should be replaced.

The oil pressure at idle speed must be at least 0.6 bar (60 kPa)

Checking the oil pump on the stand

In a car service center, the oil pump is checked on a special stand. This implies:

- determination of pump performance;

- measuring oil pressure at the pump outlet;

- measuring the pressure at which the pressure reducing valve opens.

In this case, special oil is used, the temperature of which should be exactly 20 0 C. The performance of the VAZ 2110–12 pump at a crankshaft speed of 6000 rpm must be at least 35 l/min, and the pressure reducing valve must open when the pressure inside the pump increases to 0 .55–0.75 MPa.

Common unit breakdowns

- operational wear of the components of the unit: the pump housing or gears fail: during the operating cycle, the gap between the driven and driving gears increases. In normal condition it does not exceed 0.25 mm. Wear leads to the fact that the distance between the parts increases to 0.5 mm: the gears no longer mesh. The described breakdown makes the oil pump unsuitable for routine repairs - it is easier to buy a new part than to install new gears and adjust them;

- leakage: oil begins to leak from under the pump. The reason for this is a leaky oil pump gasket. Replacing the gasket solves the problem;

- Oil receiver clogged: The oil receiver becomes clogged due to a clogged crankcase. In this case, you need to dismantle the oil pan and clean the mechanism.

In most cases, it is necessary to purchase a new oil pump. The price of a new part in online stores is in the range of 1700 - 2500 rubles. The devices are compatible with the first generation Samara.

Signs and causes of oil pump malfunction Lada 2114

There are several markers, the appearance of which will allow you to suspect defects in the pump:

- The corresponding light on the dashboard lights up;

- Oil puddles regularly form under the car;

- Smoke is generated during engine operation.

Causes of unit malfunctions:

- use of motor oil that does not comply with the car manufacturer’s recommendations;

- oil filter clogged;

- permanently low level of lubricating fluid in the crankcase;

- non-working condition of oil level monitoring devices;

- failure of the engine lubrication system valve;

- impurities entering the engine oil (most often coolant is mixed with it).

All the described breakdowns are accompanied by activation of the control lamp, so do not delay repairs; begin service operations after activating the control indicator.

How to check oil pressure?

The actual check is carried out using a special device - a pressure gauge. It is also worth noting that you need to warm up the engine to operating temperature, usually 90 degrees Celsius.

If you measure with a cold engine, especially in winter, the pressure can jump to high values, from 0.5 BAR or even higher, but measuring with a cold engine is WRONG!

In order to check the pressure, you need to find the emergency sensor, which is responsible for the indication on the dashboard. It is worth noting that it is not always located nearby and it is convenient to unscrew it. We unscrew it, and in its place we attach the test output connected to the pressure gauge.

The check can then be divided into two options:

- AT “idle” it is usually from 900 to 1200 rpm.

- Then at “higher” speeds, usually 4000 - 5000 engine speeds.

It is also worth noting that if you unscrew the emergency sensor, the “oil can” will light up on your instrument panel, this is normal.

Now a short video showing how measurements are taken.

Filming

- First you need to disconnect the negative cable from the battery.

- Draining the oil from the engine

- We take out the camshaft drive belt

- We take out the crankshaft toothed pulley, then its key, using two flat-head screwdrivers.

- Then remove the oil sump.

- Unscrew the oil intake mount.

- Using a 10mm socket with a ratchet and an extension, unscrew the six bolts securing the oil pump to the cylinder block.

- Remove the unit from the engine.

Be sure to wash the new oil pump with gasoline to remove grease for preservation. We fill it with oil before installation so that it does not rotate dry when starting. It is also important to turn the drive gear in order to place the pump on the crankshaft: so that the protrusions on the gear coincide with the groove on the crankshaft. Lubricate the seal lip with oil before putting the pump back. Carefully tuck the working edge of the oil seal onto the shaft journal using a wooden stick. Be careful and attentive when tightening the bolts so as not to strip the threads. Proceed in reverse order, install the remaining parts.

As can be seen from the above, this is not such a difficult job. The main thing for her is to approach it correctly and creatively. After all, proper lubrication is the basis for the longevity of a car.

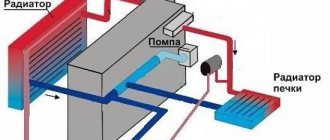

Functions, structure and location of the VAZ 2110–12 oil pump

The engine lubrication system is designed to timely supply engine oil to the moving and hottest elements of the power unit. Oil is supplied from the sump and circulates through special channels inside the block and cylinder head. The oil pump ensures forced circulation of the lubricant.

Location of the oil pump on the VAZ 2110–12

On the VAZ 2110–12, the oil pump is located in the lower right corner of the cylinder block under the crankshaft gear, which drives the gas distribution mechanism.

The oil pump is located in the lower right corner of the engine under the crankshaft gear

This applies to both eight and sixteen valve engines. The pump housing is also the side cover of the power unit.

Oil pump device

The design of the oil pump is very simple and includes the following elements:

- housing with lid;

- driving and driven gears;

- pressure reducing valve with spring;

- oil receiver

The oil pump has a simple design based on two gears

Operating principle of the oil pump

The pump is driven by the crankshaft through the drive gear. The latter rotates the driven gear, creating a reduced pressure at the input of the device and increased pressure at the output. Thus, oil from the crankcase flows through the oil receiver tube into the pump, and from it into the engine oil line. When the pressure inside the pump begins to exceed the permissible value, a spring-loaded pressure relief valve drains excess oil back into the sump.

Step-by-step instructions for repairing and inspecting oil pump parts:

1. For a detailed inspection, it is necessary to remove the oil pump.

2. First, you need to unscrew the bolt (1) and remove the crankshaft position sensor (2), which is only available on engines with a fuel injection mechanism.

3. When disassembling the pump, you need to unscrew the six bolts and remove the pump cover.

4. Using two screwdrivers, you need to lift the pump housing so that the pins on the housing can come out of the holes located in the cover of the VAZ 2110 oil pump. Now remove the housing itself by disconnecting it from the cover.

5. We take the gears out of the cover: first the driving one, and then the driven one.

6. Now you need to unscrew the pressure reducing valve plug. An O-ring must be installed under this plug. Inspect the ring - if it is too compressed, it needs to be replaced.

7. Having unscrewed the plug, we take out the spring of the pressure reducing valve.

8. Now we take out the valve itself, gently tapping the body on a clean wooden stand. If the valve does not come out, it must be removed using a thin pointed object, preferably also wooden, so as not to damage the surface.

9. Now you need to carefully inspect the aluminum cover for visible signs of wear, mechanical damage, deep scratches in the contact areas of the gears. If found, the cover must be replaced with a new one.

11. The size of the maximum permissible diameter of the driven gear socket is 75.1 mm, so we measure the diameter, and if it exceeds the permissible one, we will also have to replace the housing.

12. Now you need to measure the width of the body segment in the middle part. If the measured value is less than 3.4 mm, the VAZ 2110 pump housing must be replaced.

13. Check the gears. The thickness of the drive should not be less than 7.42 mm. We measure: if it is less, we replace the gear.

14. The same applies to the slave. If the thickness is less than 7.35 mm, the gear must be replaced.

15. Then we check the axial clearances of the gears. It is necessary to install the drive gear back into the housing, after which we apply a steel ruler to the housing and use a feeler gauge to measure the gap between the gear and the ruler.

16. In the same way, measure the axial clearance between the attached ruler and the driven gear. For the drive and driven gears, the maximum permissible axial clearance is 0.12 mm and 0.15 mm, respectively. In cases where these values are exceeded, the gears must be replaced with new ones.

17. Through calculation, more accurate values of axial clearances can be obtained. To do this, a micrometer is used to measure the thickness of the oil pump housing along the outer surfaces, as well as the thickness in the area of the sockets for the drive and driven gears along milled surfaces in several places. The axial clearance is calculated based on the difference between the arithmetic mean of the socket depth and the measured thickness of the gears.

18. The next stage of repair is to inspect the pressure reducing valve seat to detect rough scratches and other deep mechanical damage on the inner surface. If found, the cover must be replaced.

19. If burrs and deep mechanical scratches are detected on the pressure reducing valve itself, it must also be replaced with a new one.

20. We also replace a bent, broken/broken or cracked pressure relief valve spring. The height of the spring in its free state is normally 44.72 mm; the same parameter under a load of 4±0.24 kgf is 31.7 mm. If there is a discrepancy, the spring must be replaced.

21. Assembling the oil pump. We install the driven gear with the chamfers on the teeth towards the housing.

22. Then install the drive gear in the same way - with the chamfers on the teeth facing the body. The gears must be lubricated with engine oil before installation.

23. Now you need to install the cover on the body and tighten the fastening bolts.

24. Before installing the pressure reducing valve into the seat with the bottom down, it must be lubricated with engine oil. Then you need to install the spring and tighten the plug with the aluminum O-ring of the oil receiver tube, also pre-lubricated.

25. It is necessary to pour engine oil into the pump through the oil receiver tube.

26. At the end of the repair and complete assembly of the car’s oil pump, turn the gears several turns so that the working surfaces of the gears are well lubricated.

Dismantling

Depending on the situation, the oil pump can be completely replaced, or repair work can be performed - change gears, return the pump pressure reducing valve to functionality.

But let's talk about everything in order. In any case, work begins with dismantling the oil pump:

- Before you remove the pan to gain access to the pump, you will definitely need to drain the oil.

- To do this, warm up the engine to operating temperature, open the drain hole and wait until all the liquid drains out.

- Draining can also be done when it is cold, but due to its high viscosity, the oil can flow for a very long time and most of it will still remain inside the crankcase.

- After draining the oil, remove the three mounting bolts from the crankcase protection using an 8 mm wrench. The protection blocks access to the flywheel near the crankcase.

- Remove the flywheel guard and then remove the bolts from the crankcase. That's it, now the crankcase can be removed.

- In front of you is the crankshaft and the oil sump where the desired pump is located.

- By unscrewing the three mounting bolts, you can remove the intake from the pump.

- Let's move on to the engine compartment. Lift the hood and remove the plastic cover. This is a guard that covers the timing belt.

- Next, you need to remove the front right wheel to remove the pulley fixing washer, and then remove the pulley itself.

- Remove the timing belt and remove the six mounting bolts that hold the oil pump in place. Here you will need an 8 mm wrench.

- Remove the oil pump from the crankshaft.

Disassembly

If you do not want or cannot yet purchase a new pump, you can try to repair it. Perhaps the problem is a malfunctioning valve or worn gears.

- Remove the gasket from the pump;

- Remove the bolt holding the crankshaft position sensor;

- By unscrewing the six mounting bolts, you can remove the cover from the pump;

- Using a pair of screwdrivers, lift the housing so that the pins on it come out of their holes freely;

- Remove the body, disconnect it from the cover;

- Now you need to remove two gears from the cover. The drive gear is removed first, and then the driven gear is removed;

- Next in line is the pressure reducing valve. You need to unscrew the plug under which the o-ring is located;

- Check the condition of this seal. If the ring shows signs of damage or is too squeezed out, be sure to replace it with a new one;

- Remove the valve spring;

- Now you can remove the valve itself. To do this, gently tap the case on a stand made of pure wood;

- The valve may be stuck. Do not worry. Take any thin, sharp object, pry it up and remove the element. It is better not to use metal objects so as not to damage the surface;

- Check the current condition of the aluminum cover. If there are deep scratches or signs of wear, replace it;

- If the pump body shows signs of wear, do not even try to repair anything. The only correct solution would be to completely replace it;

- You also need to make sure that the gears and the diameter of their sockets comply with the standards;

- The maximum diameter of the driven gear socket is 75.1 millimeters. If it is larger, the case must be replaced;

- Measure the width of the body in the middle. If the indicator is less than 3.4 mm, it is worn out and needs to be replaced;

- As for the thickness of the gears, according to the requirements, the thickness of the drive is at least 7.42 mm, and the driven one - 7.35 mm. In case of deviations from the norm, the gears are changed.

Assembly and installation

If you managed to repair the oil pump, then all that remains is to assemble it and install the unit in place. If you decide to completely replace the device, skip the first part of the further instructions.

- Install the driven gear onto the housing with the chamfers on the teeth.

- Also, the new pump drive gear is returned into place using chamfers on the teeth.

- Be sure to remember to lubricate the gears with oil so that they work more reliably and longer.

- Replace the pump cover and screw back all the fasteners.

- Lubricate a new or repaired old relief valve before installing it in its proper place.

- The valve fits into its seat. Make sure installation is done bottom down.

- Now it’s the turn of the spring and the plug, which is wrapped with an o-ring. Again, these elements are pre-lubricated with engine oil.

- Using the oil pickup tube, oil is poured back into the unit.

- Once assembly is complete, rotate the pump gears several full turns. This will ensure effective lubrication of all surfaces inside the pump.

The unit is assembled and can be returned to its place. For this:

- Return the timing belt to its place by pulling it onto the rollers. Don't forget to set according to the labels;

- Return the plastic belt protection to its rightful place, install the wheel;

- Now you need to crawl under the car to install the oil pick-up on the pump;

- Be sure to treat the crankcase with compounds, removing all fat. Treat with sealant;

- We recommend installing a new gasket on the crankcase, after which another layer of sealant is applied;

- The block is degreased, the crankcase is returned to its rightful place;

- To make it easier to attach it, tighten several bolts at different points, and then screw in all the rest;

- Protection is installed on the flywheel, the crankcase protection is returned to its place;

- Pour oil back into the system, start the engine, and allow the oil to distribute throughout the components.

If you carry out all the manipulations correctly and first determine that it is the pump that has failed, the warning light on the dashboard will go out.

The oil pump plays a huge role in the functioning of the engine’s lubrication system, so at the first sign of its breakdown, immediately go to the garage, or entrust the replacement to specialists from trusted service stations.

Didn't find the information you are looking for? on our forum.

We recommend reading:

Turning relay for VAZ 2107 diagram

VAZ 2114 signs of internal CV joint failure, diagnostic methods

VAZ 2107 with a Priora engine

How to remove the gearbox on a VAZ 2107

How to clean the breather on a VAZ 2106

The speedometer on the VAZ 21099 injector does not work

Lada Kalina, what kind of gasoline to fill in a car, 92 or 95

Similar articles

What kind of oil to pour into the VAZ 2115 engine

Choosing oil for VAZ 2110

VAZ color chart, codes, names, description

VAZ error codes - table with a list of all errors

Replacing the oil pump on a VAZ 2110, where it is located, removal and installation, repair Link to main publication

Engine diagram and structure

Many motorists know the structure of the main power unit, but not everyone remembers it. In order to understand how the process itself occurs, let us recall how the engine works.

Engine diagram

1 - channel in the cylinder block for supplying oil to the oil line of the cylinder head; 2 — channel in the cylinder head; 3 — pipe for exhausting crankcase gases into the air filter housing; 4 - oil filler cap; 5 — exhaust hose pipe; 6 — pipe for removing crankcase gases into the throttle space; 7 - oil line in the cylinder head; 8 - camshaft; 9 — oil supply channel to the camshaft bearing; 10 — oil pressure indicator sensor; 11 — pressure reducing valve; 12 — channel for supplying oil from the filter to the main oil line; 13 - oil pump drive gear; 14 — driven gear of the oil pump; 15 — oil supply channel from the pump to the filter; 16 — anti-drainage valve; 17 — cardboard filter element; 18 — oil sump; 19 — oil receiver; 20 - drain plug; 21 - bypass valve; 22 — oil filter; 23 — oil supply channel from the crankshaft main bearing to the connecting rod; 24 — oil supply channel to the crankshaft main bearing; 25 - main oil line

How does engine lubrication occur (diagram and explanation)

Engine lubricant circulation diagram

So, when the issue of engine design has been considered, we can proceed directly to the consideration of lubrication. The system itself is considered combined.

Using pressure, the following are lubricated: main and connecting rod bearings of the crankshaft, camshaft bearings, cylinder walls (using splashing), pistons and oil scraper rings, the camshaft itself, valves and pushers.

The oil pump is located inside the engine, and only the cover cap is visible from above. The oil pump drive is mechanical, forced.

Schematic representation of oil circulation

Replacing lubricant

In order to change the oil, you will need a tool, 5 liters of oil (about choosing oil here) and an oil filter.

Shel Helix oil recommended for filling into the 10 series Lada engine

So, let's look at the sequence of actions:

We remove the lower engine protection (if there is one, of course). Unscrew the oil pan drain plug.

We wait for the oil to drain. While the liquid is leaking out, it is necessary to replace the filter.

To do this, use a special tool to unscrew the filter element. You need to pour a little oil into the new filter and screw it in place of the old one.

It is worth noting that between the motor and the filter there is a copper o-ring, which also needs to be replaced.

We tighten the drain plug. Unscrew the filler plug.

Using a funnel, we pour new oil into the system until the fluid indicator on the dipstick is between the MIN and MAX indicators.

What builds up oil pressure in the system?

Everything is simple here - there is a special oil pump that takes oil from the engine sump and pumps it through the system. It is usually installed in the engine sump and driven by special gears that the engine turns during operation.

Oil through many channels begins to be supplied to the right places under pressure, as I already wrote, this is the crankshaft and its bearings, the camshaft and its “bed”, pistons, and much more.

It is the pump that is responsible for the pressure; if the pump stops, the pressure indicator will drop to zero. THIS CANNOT BE ALLOWED! Because the engine will not be lubricated at all, which will lead to instant breakdown, especially at high speeds.

BUT often the oil pump does not stop, but simply begins to pump worse, this indicates its wear, which is why you need to know the oil pressure in the engine! To respond in time to the nearest oil pump failure.

Rotary

The design of this type of unit is a little more complicated. The device consists of two rotors - driven and driven. Both are enclosed in a housing.

If the pump is unregulated, then the oil that is sucked into the device passes through the rotor blades. If the pressure level in the system is higher than the nominal or calculated pressure, then the pressure reducing valve is activated to relieve excess pressure.

Adjustable devices have a special movable stator equipped with a spring. It regulates and ensures constant oil pressure regardless of the engine speed. The stator is designed to control constant pressure by varying the volume of the cavity between the rotors. To do this, the stator is rotated in the required direction.

The operating principle of modern VAZ rotary pumps

After starting the engine, the car begins to move and gradually accelerates. The crankshaft rotates faster and faster. As the shaft rotation speed increases, the pressure in the engine's lubrication system gradually drops, and the need for new oil increases.

Scheme of pumping oil with a rotary pump on VAZ cars

Article on the topic: What is a torque wrench and how to use it

As the oil pressure decreases, the spring on the movable pump stator expands, the stator attached to it begins to rotate, then moves and engages with the driven rotor. This begins the suction of oil into the pump cavity. The oil is then forced into the engine by the rotor blades and the suction cycle is repeated.

Removal

Begin:

- First of all, disconnect the “-“ (minus) wire from the battery, as with any other repair.

- Drain the oil (through the plug on the oil pan) from the engine

- We take out the camshaft drive belt

- We take out the crankshaft toothed pulley, then its key, using two flat-head screwdrivers.

- Now remove the oil pan

- Unscrew the oil intake fastener

Unscrew the oil intake fasteners and remove it

Using a 10mm socket with an extension and a ratchet, unscrew the six bolts securing the oil pump to the cylinder block.

Unscrew the mounting bolts using a ratchet socket

Remove the unit from the engine.

Be sure to wash the new oil pump with gasoline to wash off the preservation lubricant. We fill it with oil before installation so that it does not rotate dry when starting. It is also important to rotate the drive gear to install the pump on the crankshaft: so that the protrusions on the gear coincide with the groove on the crankshaft. Lubricate the edge of the oil seal before putting the pump back. Carefully tuck the working edge of the oil seal onto the shaft journal using a wooden stick. When tightening the bolts, be careful and careful. so as not to strip the thread. Install the remaining parts in reverse order.

Disassembly

So:

We clamp the pump body in a vice, placing soft pads on the jaws and, using a 8-mm hexagon, unscrew the bypass valve plug.

Unscrew the valve plug

- We remove the piston and spring of the bypass valve.

- We check the seat of the bypass valve - the presence of burrs and scratches is unacceptable

- Using a 5mm hexagon, unscrew the six bolts securing the pump housing to its cover.

Unscrew the bolts securing the housing to the cover

- We take out the pump housing.

- We take out its drive gear from the cover.

- Behind it, we remove the driven gear.

- We wash all pump parts with gasoline, diesel fuel or kerosene, wipe the gears dry, and lubricate them with clean oil before installing them back.

- We carefully inspect the body for cracks, chips, and severe burrs, and if found, replace it.

Permissible seat diameter and permissible partition thickness

- The same goes for pump gears; scuffing, chips, and cracks are not acceptable.

- We check the condition of the pressure reducing valve spring; if it is broken, cracked, or very short (compressed and does not match the dimensions), we replace it.

Acceptable dimensions of the pressure reducing valve spring

Assembly

We assemble the pump in the reverse order of disassembly. The driven gear inside the pump is positioned so that its side with chamfers and a mark is attached to the housing.

The mark with which the driven gear is applied to the housing

The same with the drive gear. That's all. The pump assembly is completed, all that remains is to install it in place, as our instructions say. In addition to the instructions, we recommend watching a video on this issue.

Max

The first problem we encountered after purchasing a used VAZ 2112 car was that the timing belt broke and all the valves were bent. The repair cost more than 15 thousand rubles. After buying a car, be sure to go to a car service center, check everything and repair it, otherwise the repair may cost a pretty penny like it did for me. And so the VAZ car is not whimsical in maintenance. I do everything myself and rarely call for service.

your name

Timing and alternator belts are usually changed immediately upon purchase. The same as liquids (antifreeze, brake fluid, oil).

VAZ 2109: oil pump and its malfunctions When you need to replace the oil pump in a VAZ 2104 Replacing the VAZ oil pump yourself Repair and replacement of the VAZ 2110 oil pump

Complete disassembly of the VAZ oil pump

- The pump removed from the car is clamped in a vice. Using a 12mm socket wrench, unscrew all the fastening bolts of the outlet pipe (there are 3 of them). It should be noted that one of these bolts is shorter than the others. Therefore, when disassembling it is necessary to remember the place from which it was turned out.

One of these mounting bolts is shorter than the others.

- After unscrewing the bolts, the pipe along with the cover is removed from the pump. There is a small washer under the cover. When removing the pipe, hold it with your finger.

When removing the VAZ oil pump pipe, it is important not to lose the washer

- Now the spring that regulates the position of the pressure reducing valve is removed.

The VAZ pressure reducing valve spring can be removed manually

- Next, the valve itself is removed.

To remove the VAZ pressure reducing valve, you will have to apply a little force

- There is a steel cover under the valve. To remove it, you need to pull it upward with force. There should be no scratches or burrs on the removed cover. If they are, it means that the gears are touching the cover and the pump is completely worn out.

There should be no scratches or burrs on the VAZ oil pump cover - Access to the drive and driven gears is provided. They can be easily removed by hand. All parts are thoroughly washed in kerosene and inspected for damage. Reassembling the oil pump is done in the reverse order.

First, the drive gear of the oil pump is removed, then the driven gear

Replacing the oil receiver of a VAZ 2112

In this article we will continue assembling VAZ-2112 engine components.

Lubricate the sealing ring of the oil receiver with engine oil

It is advisable to replace the oil receiver O-ring

We install the oil receiver in place and tighten the bolt securing the oil receiver to the oil pump with a torque of 7.0-8.0 Nm (0.7-0.8 kgf m).

We tighten the two bolts securing the oil receiver to the cover of the second main bearing with a torque of 8-10 Nm (0.8-1.0 kgf m)

Cut off the protruding ends of the oil seal holder gaskets.

Lubricate the plane of the cylinder block with grease

Installing the oil pan gasket

If the pan is slightly deformed, it is better to coat the pan gasket with sealant.

We tighten the oil sump mounting bolts with a torque of 5-8 Nm (0.5-0.8 kgf m).

Install the key into the groove of the crankshaft

Installing the crankshaft timing belt

We put the timing belt on the crankshaft pulley

Install the washer on the belt drive pulley

We put on the generator drive pulley and attach the bolt and washer

We tighten the pulley mounting bolt, holding the flywheel on the other side with a torque of 97.9 - 108.8 Nm (9.90 -11.1 kgf.m)

We install the sealing gasket on the water pump and lubricate the gasket with grease.

Install the water pump into the cylinder block so that the factory marking of the pump is directed towards the mating plane of the cylinder block, since the mounting bolts are located asymmetrically.

Tighten the coolant pump mounting bolts to a torque of 7.64–8.01 Nm (0.78–0.82 kgf.m)

After this, install the cylinder head as indicated in the article - “Removing and installing the cylinder head.”

Running in the engine after assembly

The repaired engine is subjected to bench testing (run-in) without load according to the following cycle: 750–800 min -1. 2 minutes

1000 min -1 . 3 min

1500 min -1 . 4 min

2000 min -1 . 5 minutes

After installing it on the stand and starting the engine, check:

– whether there is a leak of coolant or fuel between mating parts and in pipeline connections; – oil pressure and whether there is any oil leakage through the gaskets;

If any unusual knocking or malfunctions are detected, stop the engine, eliminate them, and then continue testing.

If oil leaks through the gasket between the crankcase and the cylinder block, tighten the fastening bolts to the recommended torque.

If the oil leak continues, check the gasket and replace it if necessary.

If oil leaks through the gasket between the cover and the cylinder head, check the gasket and rubber bushings on the studs securing the cylinder head cover.

If necessary, replace the gasket and bushings, following the recommendations outlined in the article “Engine Assembly”.

After engine repair, a certain period of running-in of the working surfaces of new parts is necessary.

This especially applies to those engines on which the pistons, connecting rod and main bearing shells have been replaced, the crankshaft journals have been ground, and the cylinders have been honed.

Therefore, when running in a repaired engine, do not subject it to maximum loads.

Engine break-in should continue with the vehicle at the recommended speeds for the vehicle's break-in period.

Disassembly and repair

After completing the dismantling work, you can proceed in two ways:

- Replace the old pump with a new one;

- Repair the old oil pump.

Repair allows you to identify worn elements and replace them with new ones, which will restore functionality. If the breakdown is more serious than simple wear and tear of consumables, the optimal solution would be to completely replace the oil pump.

Where does withdrawal begin?

To disassemble the pump, follow the instructions.

Divide the pump into two parts. To do this, we have already unscrewed 6 bolts securing the cover to the body and used a screwdriver to pry off this cover. It came out of the pins on the body. So we remove the element and put it aside. Inside the pump housing there are driven and drive gears, which need to be removed and placed aside for now. Then we will check their condition. Next, the pressure reducing valve is removed. To do this, first unscrew the valve plug and remove the spring from the hole, and then the valve. In some cases, problems may arise with removing the valve. If you encounter this situation, gently tap the oil pump body against a piece of wood or use a wooden cone-shaped pin. It is inserted into the valve hole, the valve is hooked and removed. Having disassembled your oil pump on the VAZ 2109, thoroughly wash all its components using clean kerosene

Don't forget to wipe the parts dry afterwards. Check the condition of the cover and body of your pump for mechanical defects, chips, cracks. Pay special attention to the landing spots of the gears, where there should be no signs of wear or other mechanical defects. If they are, the pump will have to be replaced.

Condition assessment

In many ways, the performance and maintainability of the old oil pump depends on the results of checking the characteristics of the cover and body of the device. It is necessary to take measurements of the gaps.

Check location

Requirements

Driven gear seat diameter

The diameter may increase as the pump operates and friction occurs. The normal diameter of this place for the VAZ 2109 is 75.1 millimeters. If there is a deviation in the direction of increasing diameter, the pump must be replaced.

Thickness of the mating wall

Under normal conditions, this parameter is 3.4 millimeters. If the gap is less than specified, the pump is replaced completely

Drive gear thickness

The normal value is 7.42 millimeters. When the size is reduced, the pump goes to a landfill, and a new one is installed in its place.

Driven gear thickness

For her, the normal parameter is a thickness of 7.35 millimeters. As with the drive gear, deviation from the norm means replacement

Drive gear axial clearance

To measure, take a metal ruler and feelers of 0.12 and 0.15 millimeters. The gap is checked as follows: a gear is placed in the pump housing and a ruler is placed on top with its end. The gap between the end of the ruler and the plane of the feeler gauge is measured. For the drive gear, the gap is 0.12 millimeters

Axial clearance of driven gear

The method for checking the gap is exactly the same. Only for the driven one the normal indicator is 0.15 millimeters

Condition of the pressure reducing valve and socket

Assessing these parameters is very important. If you find mechanical damage on the surface, the element cannot be used further.

If the spring is bent or stretched more than normal, then replace the element. There is no need to completely change the entire pump.

Determining which gear is which is not difficult. The leading one has an external tooth, and the driven one has an internal one, that is, the element is smooth on the outside.

driven gear

Reassembly

Having completed the repair and reassembly of the old oil pump, or having decided to completely replace it, pay attention to several important nuances of reassembly

- Before installation, rotate the pump gear so that the lugs match the flats on the crankshaft.

- Be sure to lubricate the working edge of the oil seal with engine oil. This will allow you to easily slide the oil seal onto the crankshaft journal.

- When installing, be sure to trim the edges of the seal using a thin piece of wood. After this, you can fix the pump and return to their places all the elements dismantled at the stage of preparation for repair.

- After completing assembly of the unit, be sure to adjust the tension of the generator belt and camshaft belt.

«>]

Replacing and repairing an oil pump is quite simple if you have a repair kit and the necessary tools at your disposal. The main objective difficulty lies only in dismantling and reassembling the unit.

Oil pump installation

- 1. Before installing a newly purchased VAZ 2112 or 2110 oil pump, be sure to lubricate its pressure reducing valve and gears. Also, when replacing, use only a new oil seal;

- 2. Install the oil pump, place the timing belt on the tension rollers, and align it according to the marks. Next, the plastic protection is installed.;

- 3. Put on the wheel;

- 4. Install the oil intake on the oil pump VAZ 2112, 2110;

- 5. Thoroughly degrease the crankcase and apply sealant;

- 6. Install a new gasket, then apply sealant again;

- 7. Degrease the block, install the crankcase in its place. The task will be simplified if you first screw a few bolts in different places and then tighten the rest;

- 8. The flywheel protection is installed, followed by the crankcase protection (if available);

- 9. Fill with high-quality oil and start the VAZ 2110, 2112 engine.

Repair of pump VAZ 2112, other models

You can also repair the VAZ 2110 oil pump with your own hands, which consists of disassembling this product, visual inspection to identify worn parts, followed by replacement. But it is the best option only if there are spare parts or another serviceable unit. In all other situations, it would be more practical to purchase a new product for the VAZ 2110, 2112.

Oil pump gasket VAZ 2112 16 valves article number

13 customers chose this product

The engine gasket repair kit is original and fully corresponds to the standard one.

DIY pump repair VAZ 2110/2112

The driver does not always have the opportunity to replace a faulty pump. In some cases, it is possible to repair the device by restoring the operating functions of the pump. If the pump has not yet exhausted its service life (50 thousand kilometers), then you can repair it. However, the pump cannot be repaired without using a special repair kit. This is a set of rubber gaskets and parts that most often fail and need to be replaced.

Repair kits for pumps may vary in composition, depending on which spare parts need to be replaced

In addition, you will have to thoroughly prepare for repairs: the place for disassembling and repairing the pump must be clean and level.

How to disassemble a water pump

Once the pump is removed from the machine, it will need to be disassembled. Only after disassembly and thorough cleaning will it be possible to replace the leaked parts of the pump.

To disassemble the pump, it is recommended to follow the following diagram:

- Wipe the product with a dry cloth.

- Unscrew the pump pulley.

- Pull out the thrust ring.

- Use a hammer to knock out the bearings from the shaft.

- Pull the shaft itself out of the housing.

- Unfasten the impeller.

- If something remains from the oil seal, then remove the remaining rubber from the housing.

The procedure for disassembling the water pump is intuitive: until you remove the pulley, it is impossible to get to the shaft and impeller

After this, the cavity of the pump itself must be thoroughly cleaned of dirt and old deposits - you can wash the pump with the same gasoline that is usually filled into the VAZ 2110/2112 tank.

Replacing the oil pump

As was said, on the VAZ 2109 the oil pump, which is replaced in the cases given above, must first be removed. Let us give again the main reasons why the oil pump needs to be dismantled:

- at idle speed when the engine is warm, there is not enough oil pressure (often this is due to foreign particles getting under the pressure relief valve or the problem is associated with wear of the oil pump gears);

- When the engine is sufficiently warmed up, excessive oil pressure is observed (the pressure relief valve in the pump gets stuck).

We arm ourselves with the necessary tools:

- keys 10 and 13;

- socket heads;

- extension cord;

- cardan joints.

Pump repair

- First, remove the gasket from the device.

- Then unscrew the bolt that secures the crankshaft sensor.

- If you unscrew the fasteners from the pump, you can remove the cover.

- Using screwdrivers, remove the cover, and then the body itself.

- Then the gears are taken out, and one of them is driving, and the second is driven.

- Now you can begin to remove the pressure reducing valve; there is a special plug and a sealing ring on it.

- The sealing ring should not be damaged; if any, replace it with a new one.

- Remove the spring on the valve.

- And after that, you can remove the valve itself, it is not so easy to remove; to do this, you need to have a knife on hand to pry and remove the part.

- Check the condition of the cover; if there is deformation, the cover must be replaced.

- Also, do not forget to check all pump elements; if there are even minor deviations, then it is best to replace the part with a new one.

After replacing all the elements of the parts, it is necessary to lubricate everything thoroughly and, together with the oil pump, the oil seal is immediately changed.