Cooling system pipes VAZ 2114, 2115

The rubber pipes of the VAZ 2114 cooling system are examined in video and photos at the request of Boris Zverev...

Greetings, Lada VAZ car enthusiast on the RtiIVAZ website!

A YouTube channel subscriber came up with the idea to make a video about the rubber radiator pipes of the VAZ 2114 and the heater pipes of the VAZ 2114, just like his car. This video was filmed at the request of Boris Zverev, and the article was edited on the initiative of Albert Aukhadullin.

Let's start with the steam exhaust hose of the cooling system. This hose serves to remove steam from the radiator to the expansion tank. The length of this product is slightly more than one meter, the diameter of the internal hole is 8 mm.

This hose is installed on VAZ 2108, 2109, 21083, 2113, 2114 and VAZ 2115 models with injection and carburetor engines.

On models of the “ten” family, the same hose is installed as in the photo above, catalog number 2110-1303095.

Next we will consider the hoses installed to heat the throttle assembly.

These are inlet and outlet hoses for coolant. The diameter of the hose when measured with a school ruler is about 10 mm, and the length is 48 cm.

Tap selection

Before making a replacement, you must first select a new high-quality faucet that will serve you reliably.

The same crane is suitable for the VAZ 2108-09 models as for the VAZ-2113, VAZ-2114 and VAZ-2115. As for the factory tap, it is not of very high quality, since the membrane tap is entirely made of plastic. Therefore, VAZ owners begin to argue among themselves about which one to choose - some suggest that a plastic one will do, others say that a ceramic one will last much longer, and others even want to install a tap under the hood so that the problem with leaks no longer bothers them. Next, we will take a closer look at their types.

Types of cranes and their features:

- Factory - the standard type of DAAZ faucet, which equips the VAZ 2108 and 2109 from the factory with a plastic membrane (part code 21080-8101150-00). Its main advantage is its affordable price. If we consider the aspect of reliability and frequency of jamming, then we may encounter some disadvantages. Experts do not advise buying such a faucet unless there are no other faucets in the store.

- Ceramic - it is quite expensive when compared with the factory one, but it has quite high strength, it is also worth noting that its throughput is lower compared to the ball type. The most famous manufacturers of cranes are: Ulyanovsk YAVVA or LUZAR. The number of such a faucet will be 21080-8101150-12.

- Ball - has excellent throughput, also has high reliability and strength, but they are usually the most expensive. They are manufactured by the following companies: Ulyanovsk Simbirsk Foundry Alloy and Chance-Auto. The article number of the ball valve is 21080-8101150-14. The disadvantage of the tap from the Ulyanovsk plant is that it is difficult to open, and this is a negative factor for the stop in the plastic drive mechanism of the valves and the tap at the places where the cables are attached.

If you make a choice between the options presented above, then the most optimal, taking into account all the pros and cons, will be ball or ceramic, but still with minor modifications.

Radiator pipes VAZ 2114

Next comes the upper radiator inlet pipe, connecting the radiator to the engine block head.

This hose goes to injection engines. Its internal diameter is 32mm, see catalog number 21082-1303025.

The next one is the lower radiator outlet pipe, which connects the radiator to the engine cooling system thermostat.

Its catalog number is 21082 – 1303010, internal diameter is 32 mm.

“Angle” pipe for connecting the thermostat to the water pump (pump).

Catalog number – 2109-1303093-01. This pipe fits almost all front-wheel drive VAZ models.

The expansion tank pipe is popularly called the “filler pipe.”

It serves to connect the expansion tank to the thermostat. Through it, antifreeze enters the cooling system when the system is filled or topped up through the expansion barrel. See catalog number 21082-1303080 for its number.

Stove pipes VAZ 2114

The pipe that connects the heater to the block head is often called “big goose” in everyday life because of its resemblance to this bird.

The hose supplies coolant from the block head to the heater radiator. We look at the catalog number 2114 – 8101206.

These considered rubber hoses are reinforced, except for the throttle heating hoses and antifreeze steam exhaust hoses.

The goose curve hose is located under the hood of the car and serves to drain coolant from the heater radiator to the water pump.

Catalog number of the crooked goose 2114- 8101208, factory BRT.

The “short” pipe connects the thermostat to the engine block head.

Shorty catalog number 2108-1303082, BRT plant.

The “small” cabin pipe of the stove supplies coolant to the radiator of the stove, through the tap, from the “crooked goose”.

Its VAZ catalog number is 2114-8101200 from the BRT plant.

The cabin “large” outlet pipe is designed to drain coolant from the heater radiator through the “big goose” hose to the water pump.

Catalog number 2114-8101204 from the BRT plant.

Under the hood, the “big goose” supplies coolant to the heater radiator through a tap. And it takes the liquid to the pump from the radiator of the “goose curve” stove through the “large” cabin hose. For example, thanks to a set of rubber pipes, coolant circulates through the heater radiator.

The rubber pipe, the so-called injection “breather”, serves to connect the valve cover of the block head with the “snail” (2111) for supplying air to the engine.

The upper catalog number of the factory breather is 2111-1014058-10.

All connections presented in the video are located under the hood and in the interior of the VAZ 2114 car, related to the cooling system. In addition to the large breather pipes, small breather pipes and volutes, which serve for the passage of air.

The car also contains well-known gas supply hoses, brake hoses, a vacuum hose, as well as windshield washer fluid supply and others. They will also need to be viewed on video and described in the article.

All rubber hoses in a car need constant replacement, as they are exposed to aggressive liquids and gradually lose their properties. They lose their elasticity, become tanned, crack and sometimes break when used for a long time without replacement.

Therefore, it is recommended to periodically review their condition and replace them if any malfunction is detected.

This video ends the review; I hope that the video will be useful to someone both for information and when servicing their car.

Boris Zverev suggested in the comments the idea of equipping the Lada VAZ 2114 with a set of pipes, for which special thanks. I upload a video about the Renault Logan car on the YouTube channel, since it is my car. You, Boris, have subscribed and write comments about technology. Thanks again for this and respect.

Watch the video

Thank you for watching the video, subscribe to the channel, write comments and ask questions.

Replacing the stove tap

It often happens that a part such as a faucet breaks (it is worth noting that on the 2114 it is not very reliable). When replacing it, you should simultaneously replace the pipes, even if they are in good working order (the location of the pipes of the VAZ 2114 stove was described above).

All faucet replacements are performed in the following order:

- place the car in the pit and secure it;

- unscrew the screw plug and drain the coolant;

- using a screwdriver, loosen the clamps on the pipes located in the engine compartment, and then remove them;

- find the tap in the passenger compartment on the passenger side (located under the panel), loosen the clamps of the pipes suitable for it, and then remove them;

- Using a 10mm wrench, unscrew a pair of nuts screwed onto the studs and securing the valve body;

- from the interior side, pull out the tap and disconnect the control cable from it;

- install a new (similar) faucet in its original place;

- perform assembly in the same sequence, but in reverse order.

Before disconnecting the pipes (especially those located in the passenger compartment), you should place a cloth under them in case of coolant leakage.

Many car enthusiasts who carry out such a replacement are sometimes interested in how to properly connect the pipes to the VAZ 2114 stove? After all, by mistake or forgetfulness, you can connect them incorrectly, which will disrupt the normal circulation of coolant.

In order not to make a mistake, it is worth remembering that the connection diagram for the connection pipes of the VAZ 2114 stove is as follows: the pipes located in the engine compartment are connected: the first - from the tap (inlet) to the hole in the cylinder head, the second - from the tap (outlet) - to "saxophone". The connections in the cabin are connected: the first - from the tap to the thermostat, the second - from the tap to the pump inlet.

Instructions for replacing the cooling system pipes of the VAZ-2114

In cars of domestic manufacturers, engine cooling occurs using a cooling system; in the VAZ-2114, this task is performed by antifreeze. Only with the right choice of antifreeze can you ensure efficient operation of the cooling system:

- Factory antifreeze fluid is worse; due to the smaller amount of additives, the thermal protection of the vehicle suffers significantly. Antifreeze was developed specifically to cool vehicle parts and components, so it is exceptionally useful.

- Factory fluid has one big drawback - it quickly spoils the pipes, which in turn leads to fluid leakage and radiator defects.

Having convinced himself of how important it is to use high-quality antifreeze, the driver of the VAZ-2114 begins to replace the old fluid with a new one. In this case, after a couple of weeks an antifreeze leak is detected, what’s the matter? The owner of the car did not take into account that along with the antifreeze, the pipes through which leaks occur must also be replaced.

Experience shows that old hoses are absolutely unusable; antifreeze corrodes them very quickly. Therefore, it’s time to learn how to replace pipes, and finally close the question of the correct operation of the cooling system. Service station specialists will tell you how to implement your plans.

How to correctly replace pipes in a VAZ-2114

The first question that experts hear from car enthusiasts is which pipes should be purchased for the VAZ-2114? Products made from silicone are considered the most durable and at the same time ideally compatible with the cooling mechanism of the VAZ-2114. The diagram below shows the location of the pipes we are interested in:

- The short ones are mounted on the couplings of the thermostat and the pump pumping water.

- Next comes the conductive hose.

- The pipe located in the lower part is responsible for removing antifreeze from the radiator unit.

Replacing the thermostat

Remove the air filter.

Drain the antifreeze into a prepared container.

Remove the four hoses by lowering the clamps. Keep in mind that a small amount of antifreeze may spill.

Carefully remove the thermostat.

We clean the nest from dust and other residues. We take a new thermostat and apply a layer of sealant to all joints with the hoses, then wait 10 minutes.

To further install the new thermostat, follow these instructions in reverse order:

- install four hoses;

- fill with coolant;

- install the air filter.

Removing the air filter housing

We unscrew the 2 nuts from the front and pull out the plug behind the body.

We remove the connector from the MAF sensor; you need to press the latch from below and pull the connector.

After loosening the clamp, carefully remove the air hose.

Slowly remove the air filter housing, slightly loosening it.

The filter is assembled in the same way, but in reverse order.

Instructions for replacing the cooling system pipes of the VAZ-2114

Step-by-step replacement of cooling system pipes in a VAZ-2114 car looks like this:

- Remove the battery cable that comes out of the negative socket.

- Carefully drain the old coolant, but wait until the engine has cooled completely before doing so. Otherwise, there is a risk of getting burns from the coolant.

- Remove the following components: set aside the upholstery that provides sound insulation, the fan, the trim going to the windshield frame, the facing material.

- Now your goal is to get to the air collector; to do this, unscrew the brackets in the form of springs and the screws responsible for fixing them. A screwdriver is ideal for spring clips; for screws, you need a wrench.

- To loosen the clamps, remove the front housing, and then remove the old hoses from the fittings.

- All that remains is to install new silicone hoses in a specially designated place; it is preferable that the parts are manufactured abroad - they will last longer.

- Reinstall the other components by following the reverse order of this step-by-step instruction.

The process of replacing a heating valve on a VAZ 2113 and VAZ 2115

Before starting work, you should decide on the tools and consumables. Here's what we need:

- working heating tap;

- open-end wrenches;

- socket wrenches;

- six-liter container with new antifreeze;

- container for old coolant (the best option is a small basin);

- flat screwdriver;

- Phillips screwdriver;

- pliers;

- rags.

Sequence of operations

- The machine is placed on an inspection hole or on an overpass. The wheels are securely fixed using wheel chocks. Then the plug under the main radiator is unscrewed, and the antifreeze begins to drain into a previously placed basin or bucket. It should be remembered that completely draining the antifreeze takes from 10 to 20 minutes. It is convenient to drain the antifreeze into a basin placed in advance

- Under the hood you need to find two heating pipes. The pipes have steel clamps. The screws on the clamps are unscrewed using a Phillips screwdriver, the pipes are removed from the tubes manually. The clamps on the external pipes of the VAZ 2113 are loosened with a screwdriver

- In the cabin, on the passenger side, the side panel is removed, under which the heating tap pipes are located. To remove this panel, use a flat screwdriver and a 10-mm open-end wrench. After removing the panel, you will have access to the pipes, which are attached to the faucet with steel clamps. To loosen these clamps you will need a small flat screwdriver. To loosen the internal clamps on the VAZ 2113 tap pipes you will have to remove the side panel

- The other ends of the heating tap pipes are attached to the stove radiator. There are also two clamps there. They are loosened with a Phillips screwdriver and pulled off the radiator pipes by hand.

- As soon as the faucet is completely free from the pipes (both from the passenger compartment and from the engine side), you can proceed to unscrewing its fasteners. The stove faucet is held on two studs with nuts at “10”. It is best to unscrew these nuts using a spanner wrench, since there is little space under the side panel. It is convenient to unscrew the VAZ 2113 furnace pump studs with a spanner wrench

- After unscrewing both nuts, the valve can be removed from the mounting studs. But this must be done more carefully, because a rod is attached to the tap, which will also have to be disconnected.

- The cable rod of the heating tap is held on a steel clamp. To straighten it, you need to use pliers. The rod of the VAZ 2113 stove pump is held on a clamp, which is unbent with pliers

- Now the stove valve is removed from its niche, replaced with a new one, and then the heating system is assembled in the reverse order. The VAZ 2113 stove pump is freed from drafts and pipes and can now be removed

Subtleties of filling new antifreeze

Before you start filling in new coolant, you need to drain the old one, and also thoroughly clean the entire cooling system of contaminants. To do this, it is better to use a special cleaning agent that can be purchased at a car enthusiast store. Make sure that all taps and plugs of the VAZ-2114 are open. You can determine whether the system has been flushed or not based on the color of the antifreeze flowing out.

The plugs and tap are closed only when the product becomes transparent. If the manufacturer describes in the instructions the specifics of using the cleaning mass, follow these rules for effective cleaning. As for the level of antifreeze filling, some drivers prefer to fill to the limit mark, others deliberately do not top up, and later, after a successful test, add more fluid.

After the antifreeze has been replaced, all that remains is to close the expander and start the car engine. The motor should idle until the furnace fan starts running.

Replacing the front brake hose on a "tag" - step-by-step guide

- The first step is to determine the location of the damage and decide which hose you need. In this case, the front brake hose burst. Next, we buy everything we need and get to work. The photo shows the location of the rupture (damage).

- We begin the work by tearing off the wheel bolts while the car is standing on four wheels, then jack up the side we need, unscrew the bolts and remove the wheel.

We treat the bolts with WD-40 and wait until the liquid eats away the rust and allows you to easily unscrew the connection. Next, unscrew the hose connected to the metal brake pipe

Using a wrench set to “15”, hold the tip of the hose, and with another wrench set to “10”, carefully unscrew the brake pipe fitting. Here it is important to be as careful as possible, since it is very easy to rip off or “lick off” the edges. If the nut does not budge, use a special wrench for brake hoses. This wrench allows you to tighten it, making the connection between the wrench and the threaded connection stronger.

- After the connection is unscrewed, the tube should be plugged with something of a suitable diameter, this is necessary in order to avoid leakage of the fuel fluid.

- Now, using a key set to “15”, unscrew the hose fitting connected to the brake cylinder. There is a copper ring installed between the cylinder and the fitting, which it is advisable to replace, but if it is in order, then you can do without it.

Then we reassemble in reverse order. However, it is too early to put an end to this. Before you enjoy the work done, you need to bleed the brake system to remove all the air that has entered the vehicle. I won’t tell you how to bleed the brake system, you can read about this in one of my previous articles - here is a link to this article

After bleeding the brake system, check the tightness of the connections and the level of fuel fluid in the system. Next, let's check how everything works. I warn you, do not rush to accelerate too much to test the brakes, anything can happen, if the brakes fail, you can cause an accident and damage your or someone else’s car. First, check how everything works somewhere in a sparsely populated place at low speed; if everything is ok, check how the car behaves on an empty highway.

Reviews of silicone pipes for the VAZ-2114 cooling system

Drivers of the VAZ-2114, who replaced the usual factory rubber pipes with silicone ones, note the following advantages of the new components:

- Long service life, and all thanks to the increased wall thickness and dense reinforcement, consisting of several layers of material.

- Silicone hoses work successfully and efficiently, regardless of the temperature and weather conditions outside.

- When the silicone pipe is tightened, a force is felt, so overtightening and damaging the hose, like a rubber one, will not work in any case.

- The engine compartment can be painted any color you like.

Among the disadvantages of silicone pipes built into the cooling system of domestically produced VAZ-2114 cars, drivers note:

- high cost of parts, one set is approximately 1.5-2 times more expensive than rubber analogues;

- the manufacturer does not provide any warranty, so if you bought a defective product, it is impossible to replace it and you will again have to spend money on a new set of hoses.

In order not to pay extra, VAZ-2114 owners prefer to order silicone pipes in online stores, where they are found in 2 types:

- with reinforced thread;

- Along with silicone there is a rubber component.

Despite the possible negative nuances of silicone hoses, the owners of the VAZ-2114, who took the time to modernize their car and changed the pipes in the vehicle’s cooling system, note that the modification is worth the money - the engine is cooled like clockwork, no major comments are made.

As for the service life of new hoses, on average it is 2 years longer than that of rubber pipes, but only when it comes to reinforced silicone components.

The following video clearly shows how to change antifreeze and flush the cooling system of a VAZ-2114: https://www.youtube.com/watch?v=CGGDk3F1hNY.

The difference between a rubber hose and a silicone hose is explained in the video:

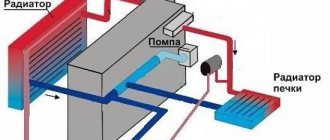

DIAGRAM AND DEVICE OF THE COOLING SYSTEM

The cooling system of the VAZ 2114 is liquid, with forced circulation. Antifreeze or antifreeze is poured into the system as a coolant. In the most extreme case, you can fill it with water, but you can’t drive it for a long time - in winter you can defrost the engine, and during the rest of the season, when the engine is used for a long time on water, the cooling jacket in the block and cylinder head is corroded, and rust accumulates in the radiator.

The VAZ 2114 engine cooling system (SOD) consists of the following elements:

- Radiator. It is the main cooling part in the system and performs the function of transferring heat to the liquid into the surrounding airspace;

- Water pump (pump). The pump creates forced movement of antifreeze in the system, thereby cooling the entire SOD, including the internal combustion engine (ICE). The pump rotates from the timing belt;

- Branch pipes (hoses). Antifreeze circulates through them;

- Thermostat. It regulates the passage of coolant through all pipes or only in a small circle and maintains the required operating temperature of the internal combustion engine;

- Electric fan. The fan is located on the plane of the radiator and, due to the air flow created, cools its surface when turned on. The electric motor turns on only when the temperature set by the sensor is reached (103°C);

- Expansion tank. Liquid is poured into the tank, and when the fan is activated, antifreeze flows into it through the return hose, thereby releasing excess pressure into the SOD;

- Expansion tank plugs. There are valves in the plug that relieve excess air pressure created in the system when antifreeze circulates.

Why the stove does not work or does not heat the air

If the stove fails, it either does not work at all, or it works but does not heat the air. In the first case, first check the fan wiring, starting with fuse F7. If the fuse is blown, replace it. Then they check the relay, which may not turn on the first time or only when the engine is warm. In this case, the relay is replaced with a new one.

Then the serviceability of the electric motor is assessed. To do this, power is directly supplied to its contacts from the battery. If the electric motor starts to operate at maximum speed, then it is in good condition. Otherwise, it will need to be repaired or replaced.

The intensity of the air flow is adjusted using a resistor having two spirals with resistances of 0.82 Ohm and 0.23 Ohm. In the first mode, the current flows through both spirals, in the second - only through a spiral with a resistance of 0.23 Ohms, in the third - bypassing the spirals, that is, without resistance at all. If the resistor is faulty, the fan will only operate in the third mode at maximum speed (handle in the extreme right position). The problem is solved by replacing the resistor, which is located on the driver's side above the accelerator pedal.

If the resistor is faulty, the heater fan will only be able to operate at maximum speed.

If cold air enters the cabin, this may be due to:

- Airlock. It could have formed when replacing the coolant, when the system was depressurized, or because there was insufficient amount of coolant in the system. To remove the plug, remove the heater radiator pipe, use a watering can to add antifreeze to the maximum and put the hose back in place. After starting the engine, coolant under pressure will displace the remaining air from the system.

- Stove tap jammed. This happens if the tap was not initially opened all the way, and during operation, oxide and scale formed on the inner surface, preventing the normal circulation of the liquid. You can try to open the tap using pliers or immediately replace it with a new one.

- The stove radiator is clogged. When using low-quality coolant, the radiator honeycombs may become clogged. The problem is solved by flushing or replacing the heat exchanger. The feasibility of washing is determined by the scale of contamination.

- Installation of a low-quality radiator. In a defective product, the honeycomb may be incorrectly soldered. The radiator should be replaced.

- Low pressure in the cooling system. If heat transfer increases at higher speeds, the pump needs to be replaced.

- Low coolant level. It is necessary to check the level and add antifreeze if necessary.

- Damage to the heater fan impeller. The impeller is carefully inspected and replaced if mechanical damage is detected.

- Cabin filter dirty. If it is heavily polluted, the power of the electric motor will not be enough to pump warm air into the cabin. The filter is replaced with a new one.

- Damage to the cylinder head gasket. If the cylinder head gasket is blown, white smoke will come out of the exhaust pipe. The problem is solved by replacing the gasket and dismantling the cylinder head.

If the stove is clogged, warm air will stop flowing into the cabin.

COOLING SYSTEM PROBLEMS

As a rule, due to malfunctions in the cooling system, the engine overheats, and this leads to engine failure. Any of the elements may be faulty.

- It may leak. Possible leakage through aluminum tubes and plastic tanks. Often the plastic outlet for the return hose of the expansion tank breaks off.

- It may clog, and for this reason the engine will heat up.

Pipes. Because of them, antifreeze leaks due to the fact that the pipe:

- Ragged.

- Old and lost elasticity.

Thermostat. Depending on how incorrectly the valve in the thermostat operates, the internal combustion engine can:

- Overheat (in this case, the antifreeze “throws out” through the expansion tank).

- Do not reach operating temperature. As a result, the car drives poorly, and in cold weather it is cold inside the car.

Water pump (three main problems):

- Noise and play in bearings. It is not worth driving with such a defect for a long time; the pump may jam or fall apart.

- Liquid is leaking through the inspection hole. It also signals the imminent “death” of the part.

- Broken impeller. With such a defect, the engine overheats very quickly.

- A faulty fan also leads to overheating of the internal combustion engine.

The clamps may be faulty or poorly tightened. It happens that thin hoses become clogged with debris (“return”, throttle valve heating).

REPAIR OR REPLACEMENT OF RADIATOR

Let us consider in detail the features of the work.

RINSE

Replacing the cooling radiator is required if the internal combustion engine heats up due to its clogging. But before changing it, you can try flushing the cooling system of the VAZ 2114 engine. Often flushing helps, and the engine stops heating up. We perform washing as follows:

- We park the car on a level surface;

- Unscrew the expansion tank cap;

- Drain the coolant from the radiator by unscrewing the bottom plug;

- We unscrew the water plug from the cylinder block (it is located between the internal combustion engine and the fan in the starter area) and drain the antifreeze from the block;

- We wrap the plugs and fill the system with plain clean water;

- Let the engine run and drain the water. If the water that comes out is dirty, repeat the flushing. We repeat the procedure several times until the draining water becomes clear;

- After flushing, fill in new coolant. It should be noted that the volume of the VAZ 2114 cooling system is 7.8 liters, and if all the antifreeze is not included in the system, most likely an air lock has formed in it. It is necessary to fill the container as much as possible to avoid overheating of the internal combustion engine.

It is often recommended to do the flushing on a cold engine to avoid being scalded by hot antifreeze. On the one hand, it seems to be true, but in cold weather all the dirt will settle on the walls of the SOD, and the washing efficiency will not be so great. And don’t wait every time for the water to cool down. You just need to drain the coolant carefully and work in thick, waterproof clothing and gloves. You also need to remember that the shelf life of antifreeze and antifreeze ranges from 2 to 5 years.

REPLACEMENT

Replacing the cooling radiator on a VAZ is very simple:

- Remove the expansion tank plug;

- Drain the antifreeze from the radiator and cylinder block. It is necessary to prepare a container for liquid in advance;

- We dismantle the air filter housing, it will interfere with removing the radiator;

- Disconnect the electric fan plug, unscrew the two bolts securing it and dismantle the unit;

- We loosen the clamps where it is more convenient and pull off the pipes;

- In the upper part of the radiator, remove the two bolts securing it to the body frame, tilt its body towards the engine and remove the part. Radiator removal is complete;

- We reassemble in the reverse order, then fill in antifreeze and start the engine.

REPAIR

If you wish, you can make minor repairs to the engine cooling yourself, but more often they repair it as a necessary measure:

- If you need to get to some destination;

- In the case when they did not expect a replacement and there is no money yet.

Plastic tanks can be sealed with epoxy resin or soldered; against leakage through the honeycombs, a special chemical composition is used, which is added to the antifreeze and clogs the leaking areas. But it is possible that such chemistry will complicate the passage of coolant throughout the system.

It’s easier not to be tricky with the radiator, but to replace it, especially since it is inexpensive, somewhere from 1,200 rubles.

Therefore, do-it-yourself repairs often become economically unjustified, and a lot of time is spent on useless “treatment.” True, there are more expensive copper radiators, but they are easier to repair - copper can be soldered.

Repairing the thermostat is hardly advisable; it is better to replace such a part immediately. Moreover, it costs about 350-500 rubles.

REPLACEMENT OF PIPE

Replacing the pipes of the VAZ 2114 cooling system is very simple - drain the coolant, loosen the clamp and replace it. In stores, pipes are often sold as a set, and it is also recommended to change them as a set.

Replacing pipes is easy (you can apply sealant to the joints)

Repair and replacement of faulty stove elements

It is completely impractical to change the VAZ 2113–15 stove. First of all, this is quite expensive - buying a new stove without a tap and pipes will cost 4-5 thousand rubles. Moreover, replacing the heater is very labor-intensive - you will need to completely remove and then reinstall the panel. The job may take a full day and will require an assistant. It is much easier to identify the faulty element and replace only it.

Restoring the stove radiator

If a stove radiator is clogged from the inside, you can try to clean it of scale and deposits with various household cleaning products, such as Comet, Krot, Silit, or other chemically active substances. Some car owners use Coca-Cola for this purpose.

It is better to carry out the flushing procedure with the radiator removed, but you can do without dismantling it. To do this, drain the coolant from the system, remove the pipes from the radiator and pour a cleaning agent inside. Then the engine starts, the heater turns on and runs for several hours. After this, the radiator is thoroughly washed by connecting a hose with running water to it and dried with compressed air.

In the event of a leak, restoring the radiator is much more difficult. This can be done by soldering. However, most radiators are made of aluminum, damage in which can only be soldered with a powerful soldering iron using special fluxes and solders. But even in this case, there will be no guarantee that the radiator will be fully operational. It is much easier to replace it - a new product for the VAZ 2113-15 costs about a thousand rubles.

Replacing a stove radiator without removing the panel

The VAZ 2113–15 instruction manual states that access to the radiator can only be achieved after dismantling the panel. However, craftsmen came up with an algorithm for replacing the radiator with only partial disconnection of the panel from the body. To do this you will need:

- crosshead screwdriver;

- keys for 7, 10 and 13;

- a container for draining coolant from the cooling system with a volume of at least 5 l;

- a wide and shallow container for draining liquid from the heater radiator;

- dry rags;

- oilcloth or thick polyethylene film.

The radiator is replaced as follows:

- We drive the car onto an overpass or inspection hole.

- Disconnect the negative terminal from the battery.

- Using a 10mm wrench, unscrew the bolts securing the engine protection and remove the protection.

- Place the container under the drain plug, unscrew it with a 13mm wrench and drain the coolant.

The bolt plug for draining the coolant is unscrewed with a 13 key - Unscrew the cap of the expansion tank. This is necessary to speed up the drainage of antifreeze by equalizing the pressure in the system with atmospheric pressure.

- After draining the coolant, screw the plug back in.

- From the passenger compartment, close the heater tap by moving the control lever to the extreme left position.

- Move the front passenger seat all the way back and fold out its backrest.

- In the center of the panel, use a Phillips screwdriver to unscrew the self-tapping screw covered with a plug.

The self-tapping screw is closed with a plastic plug - From the passenger seat, unscrew the four screws securing the left panel cover.

- Unscrew the four screws securing the instrument panel.

The instrument panel is secured with four self-tapping screws - We unscrew the six fastening screws (three on top and three on the bottom) and remove the steering column casing.

The steering column cover is secured with six self-tapping screws - Disconnect the connectors from the cigarette lighter and radio.

When replacing the radiator, you need to remove the cigarette lighter and radio connectors. - Remove the plastic covers of the stove control levers.

Remove the plastic covers on the damper control levers - Unscrew the two screws securing the upper part of the center console. Disconnect the console.

The upper part of the console is attached to the sides with two self-tapping screws - Unscrew the screws securing the diagnostic connector.

To remove the connector you need to unscrew two screws - We completely dismantle the console.

Before removing the console, you must disconnect all electrical connectors. - We unscrew the screws securing the panel base to the body.

The base of the panel is attached to the floor with two screws - Unscrew the four screws on the side panel fastenings (top and bottom).

On the sides the panel is attached to the body with self-tapping screws at the top and bottom - We unscrew the screws securing the panel to the base according to class=”aligncenter” width=”458″ height=”404″[/img] In the center the panel is attached to the base with self-tapping screws

- We remove the electronic control unit.

All connectors are disconnected from the control unit - We slightly lift the panel on the right side and fix it using improvised means.

The partially dismantled panel is pulled back and fixed - When access to the radiator is open, cover the floor under it with oilcloth, on which we install a container for collecting coolant.

To prevent coolant from spilling on the floor, you will need a shallow, wide container. - Using a Phillips screwdriver or a 7mm wrench, carefully unscrew the clamps securing the pipes;

The pipes should be removed gradually, allowing the coolant to flow into the container without pressure. - Drain the coolant from the pipes and radiator.

- Unscrew the radiator mounting screws.

The radiator is secured with four screws - We remove the old radiator.

- We install a new radiator.

- We put the pipes on the fittings and secure them with clamps.

- We assemble the panel in reverse order.

Video: replacing the VAZ 2113–15 heater radiator without dismantling the panel

https://youtube.com/watch?v=JYC8ijuYJdg

Replacing the heater tap

To replace the stove tap you will need:

- wrenches 10 (preferably socket) and 13;

- crosshead screwdriver;

- dry rags.

The algorithm of actions is as follows:

- We place the car on the inspection hole, unscrew the bolt plug and drain the coolant.

- In the cabin, unscrew the four screws securing the left panel cover.

- In the engine compartment we find pipes going from the engine to the tap. Use a screwdriver to loosen the clamps and remove the pipes.

The pipes are fixed with metal clamps - In the cabin, under the panel on the passenger seat side, we find the heater tap and the pipes coming from it. Use a Phillips screwdriver to loosen the clamps and remove the pipes, having previously laid rags under the tap in case of coolant leakage.

When removing the pipes, you need to cover the floor with dry rags - In the engine compartment, using a 10mm wrench, unscrew the two nuts on the studs connecting the valve body to the body.

To dismantle the tap, you need to unscrew two nuts with a 10mm wrench - We take the faucet out of the cabin and disconnect the drive cable from it.

Before dismantling the tap, you need to disconnect the drive cable from it. - We install a new faucet.

- We reassemble in reverse order.

The process of replacing the VAZ 2113–15 heater tap is described in more detail here.

Replacing stove pipes

When replacing a heater radiator or heater tap, it is advisable to replace the pipes as well. To ensure access to them, you will need to perform the actions provided for in paragraphs 1–25 of the instructions for replacing the radiator. Then you need to loosen the clamps and remove the pipes from the stove tap from the passenger compartment. After this, the pipes going from the engine to the tap are disconnected from the engine compartment. All this is done using a Phillips screwdriver.

After installing new pipes, do not immediately tighten the clamps too much. First you need to assemble everything, add coolant, start and warm up the engine and check the connections for antifreeze leaks. When the rubber of the pipes warms up, the clamps can be tightened a little more.

Replacing the heater resistor

If the stove fan can only operate in one mode, regardless of the switch position, you need to check the resistor. To do this you will need:

- Phillips screwdriver;

- fine-grained sandpaper;

- multimeter

The work order is as follows:

- Disconnect the negative terminal from the battery.

- Using a screwdriver, unscrew the screws securing the right cover of the center console.

To remove the cover you need to unscrew four screws - We find a resistor under the cover on the heater body, disconnect the connector from it and inspect the contacts. If there are traces of oxidation on them, remove them with sandpaper.

The resistor is installed on the heater housing - We connect the connector, the battery and check whether the fan is working in other modes. If not, disconnect the battery and use a screwdriver to unscrew the screw securing the resistor.

- We remove the resistor and use a multimeter to measure the resistance of the additional element and the entire device. It should be 0.2 and 0.8 ohms, respectively. If the resistance is greater or less, change the resistor and reassemble in the reverse order.

To determine the health of the resistor, you need to measure the resistance of its windings

VAZ 2114: cooling system and replacement of pipes

The VAZ-2114 car uses a hidden engine cooling circuit with an injector. It is highly complex and includes 28 elements. Traditionally, the assembly of the cooling system of this car is not of high quality. Therefore, throughout the entire period of operation, it requires constant monitoring, regular maintenance and repair. In this regard, many owners of this car are interested in the nuances associated with independent maintenance, repair and operation of the cooling system, among which the most common questions are:

- 1. How to properly replace the coolant mixture?

- 2. How to flush the cooling system?

- 3. How to remove air from the VAZ-2114 cooling system?

- 4. How to properly replace the cooling system pipes?

Briefly about the car

The VAZ-2114 hatchback is a fairly popular car that can still be found both on domestic roads and on the roads of the entire post-Soviet space. It was produced by AvtoVAZ OJSC from 2003 to 2013 and was one of the variants of the restyled series of the Samara-2 (VAZ-21093) family of cars.

During mass production, various engines with the same type of cooling systems were installed on it, which operate on the principle of internal heat exchange using a special cooling mixture of the “Tosol” type.

Cooling system diagram

Maintenance

Regular maintenance of the cooling system comes down to checking the level of the coolant mixture in the expansion tank and monitoring its color. It is recommended to check before each trip or, in extreme cases, regularly every 500 - 600 km.

The level of the coolant mixture in the tank must constantly exceed the minimum level by 2...3 cm. Checking the level and adding fluid must be carried out only on a cold engine. The mixture intended for topping up must be of the same type as the liquid poured into the system. Mixing different types is not recommended.

IMPORTANT! In the event of an emergency, you can add clean water to the liquid, but the cooling ability of the mixture deteriorates, and the presence of water contributes to corrosion on metal parts. In addition, in winter, the diluted mixture can freeze and damage both the radiator and the engine. Therefore, the coolant mixture diluted with water must be drained as soon as possible and, after repairing and flushing the system, it must be filled with the recommended coolant.

Why is antifreeze leaking from the stove?

A coolant leak in the heating system can occur from:

- stove radiator;

- stove tap;

- stove pipes.

If a coolant leak occurs from the radiator, it is usually replaced with a new one. Repairs to restore tightness are usually complex and labor-intensive. In addition, if the radiator has been in use for a long time, its tubes become clogged with deposits and dirt, and, as a result, heat transfer decreases.

The valve opens and closes the coolant supply to the radiator, thereby regulating the heat in the cabin. Over time, it may begin to leak, as evidenced by the characteristic smell of antifreeze in the cabin, a puddle on the floor on the passenger side and a decrease in the coolant level in the expansion tank. The faucet cannot be repaired and in such cases is replaced entirely.

If the heater radiator starts to leak, it is usually replaced with a new one.

The cause of coolant leakage from the pipes is usually their wear - the rubber ages and cracks over time. When diagnosing a problem, you need to wipe the suspected leak areas with a rag and observe the outlet and inlet pipes on a warm engine. Worn hoses are always replaced with new ones.

The stove makes a hum, whistle, murmur

The cause of uncharacteristic sounds (whistle, hum, murmur, etc.) from the heater is usually a faulty electric motor. Lack of lubrication, contamination, wear of bearings and bushings - all this leads to the fact that the motor begins to whistle. It is removed, disassembled and cleaned, and the rubbing elements are lubricated. If the bearings are heavily worn, the motor will not make a whistle, but a hum. In such a situation, lubricant may not help, and the electric motor will need to be replaced.

Steam is coming from the stove

Sometimes steam starts coming out of the stove. The reason for this is a leak in the heater core. The leaking coolant hits the hot radiator housing and begins to quickly evaporate, and the smell of antifreeze appears in the cabin. To fix the problem, you will need to disassemble the stove and replace the heat exchanger.

Sometimes white steam comes from under the hood and enters the cabin. This happens when antifreeze gets on the hot manifold or exhaust system pants. In this case, you will need to find the location of the leak and fix it. The most common cause is damaged pipes.

Flushing the system and replacing the coolant

Repairs related to replacing the coolant on a VAZ-2114 car are carried out if:

- The color of the mixture in the expansion tank has changed. This usually happens after 20 - 40 thousand kilometers;

- repairs were carried out that required a complete drainage of the mixture.

In general, coolant replacement is carried out in the following order:

- 1. Completely drain the cooling solution. To do this, you need to open all the plugs and taps, and also remove the radiator and expansion tank caps. Drain the mixture only after the engine has cooled down (In a hot engine, the temperature of the solution can be more than 100 degrees Celsius).

- 2. Rinse the cooling system with distilled or clean water. Begin the washing procedure after all the old mixture has drained. It is recommended to flush the engine block and radiator with warm water. Otherwise, it is recommended to fill in cold water, warm up the engine, and then drain the water. The color of the water determines how dirty the system is and repeats the flushing process until the flowing water becomes clean. Only after this they begin to replace the mixture.

- 3. Pour a new cooling solution into the system, having previously closed all plugs and taps. Pour liquid into the tank in a thin stream until the maximum mark is reached. Air pockets are not allowed. Then the expansion tank and radiator caps are closed. In order to prevent the rubber pipes from drying out, they must be lubricated with silicone grease.

- 4. Start the engine and let it idle until the heater radiator fan turns on. After this, you can turn off the engine and, after cooling, check the fluid level in the tank. If the fluid level has not changed, then everything is normal and the work is completed. If the liquid level in the tank has decreased, you need to make sure by visual inspection that there are no leaks. If they are not there, then add fluid, start the engine again and repeat the test.

Changing the coolant strictly according to the maintenance regulations

It is important to change the coolant frequently to prevent engine damage, because over time, it loses its properties and is subject to heating. To carry out work on changing antifreeze or antifreeze, you need to know the important components:

To carry out work on changing antifreeze or antifreeze, you need to know the important components:

Know the period during which you can use cooling liquid, antifreeze for 2 years, antifreeze for 5 years.

Monitor the mileage for fluid changes, usually from 20,000 to 40,000.

Check the condition of the fluid, paying attention to the color; if the color has changed after use, the fluid must be replaced.

Of course, the best choice would be antifreeze as a coolant, because... It has a longer shelf life, unlike antifreeze, and the system wears out less. But the price indicator for antifreeze is much cheaper.

When flushing the cooling system, you must:

- Drain all coolant from the system, tighten the plugs tightly and fill with distilled water to the maximum mark.

- Start the engine and warm up until operating temperature is reached.

- Let it run at about 3000 rpm. Be sure to monitor the movement of the engine temperature scale to avoid overheating.

- Then turn it off and leave it for 7 minutes, after which we pour the water out of the system. In case of water contamination, repeat the procedure until the effect of clean water is achieved.

Replacing cooling system pipes

The cooling system of the VAZ-2114 car uses 4 rubber pipes:

- upper supply pipe - supplies cooled liquid from the radiator to the engine;

- lower outlet pipe - removes the heated liquid below from the engine to the radiator;

- two short pipes that connect the water pump and thermostat to the system.

If the pipes fail, they must be replaced. In this case, it is best to purchase silicone pipes.

To remove old and install new silicone (rubber) pipes, you need a set of wrenches, several screwdrivers and silicone lubricant.

Repairs associated with replacing pipes must be carried out in the following order:

- 1. Disconnect and remove the battery;

- 2. Drain all coolant mixture;

- 3. Remove the fan, soundproofing upholstery, trim and frame trim from the windshield;

- 4. Clear access to the air collector by removing its fastening elements;

- 5. Remove the front housing and release the clamps that hold the pipes;

- 6. Remove the pipes from the fittings and install new ones (silicone or rubber) in their place. Secure the new pipes with clamps. Before installation, it is recommended to lubricate the rubber pipes with silicone grease. It is also advisable to lubricate the clamp screws with silicone grease. Subsequently, this will allow you to easily unscrew them;

- 7. Install all the removed parts in their places, flush the system and fill it with new coolant mixture.

Sequence of repair work

Also need a new head gasket and valve cover gasket. Having all this, you can begin the renovation. The sequence of actions for repairs is as follows:

- The car is placed in the garage, the gearbox is set to neutral, and chocks are placed under the rear wheels. The first thing that is done after setting up the car is to de-energize the on-board network by disconnecting the “-” terminal from the battery.

- The pressure in the fuel system is relieved. For this purpose, there is a control valve on the fuel rail in the form of a regular tire valve. You need to place a container under this valve and clamp the spool. When the pressure is released, gasoline will leak out. You will also need to drain the coolant using drain plugs.

- On the engine, you need to set the piston of the 1st cylinder to the TDC position. To do this, remove the protective cover of the timing belt and rotate the crankshaft until the marks on the pulley, camshaft and flywheel match.

- The next step is to remove the valve covers. To do this, all pipes, the throttle drive rod, the accelerator drive bracket and the valve cover mounting nuts are disconnected from the cover fittings.

- The exhaust pipe of the exhaust gas removal system is disconnected from the exhaust manifold. These works are carried out under the car.

- The wiring is disconnected from the mass flow sensor, the air supply pipe to the throttle assembly is removed, after which it is completely dismantled along with the air filter housing.

- Then you need to disconnect from the head all the elements suitable for the head - pipes of the cooling system of the throttle assembly, vacuum booster, throttle drive linkage, ground wires, bracket for the exhaust manifold supply pipe.

- The intake manifold strut mounts are also loosened, and the struts themselves are removed. Next, the wiring is disconnected from - oil pressure sensors, coolant temperature and throttle position sensors, XX regulator, injectors, high-voltage wires from spark plugs.

- Then the timing belt is removed. Before this, you need to once again check the alignment of the marks on the crankshaft pulley and the timing gear. After this, the belt tension is loosened and it is removed from the timing gear.

- To remove the camshaft gear, you will need to fix it through the technological holes and unscrew the fastening bolt. You need to remove it from the shaft carefully so as not to lose the key. After this, you will need to remove the rear cover, located behind the removed gear, from the head and block.

- The cooling system pipes are removed from the head along with the thermostat from the head, as well as the rest of the wiring. The fuel supply and drain pipes are also disconnected.

- All that remains is to unscrew the head bolts. But to do this, they must first be weakened, and in a strictly defined order. And only after relaxation do they completely unscrew. If disassembly is done correctly, after removing the bolts, you can remove the head and remove the damaged gasket. At this point, the first part of the repair is considered complete.