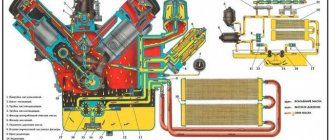

The engine lubrication system involves supplying engine oil to loaded parts and components under a certain pressure, which is created by the oil pump. At the same time, a decrease in lubricant pressure for one reason or another is a critical malfunction that can quickly damage the power unit.

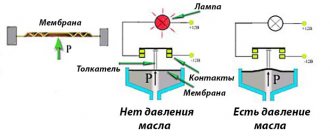

The driver is informed about this decrease in oil pressure by a warning light located on the instrument panel. In some cases, the light may be constantly on, in others the oil light blinks at idle and low speeds, only on a cold or warm engine, etc.

In this article we will talk about why the oil pressure comes on after the engine warms up, what causes and problems in the engine or lubrication system lead to this, and what the driver should do if the oil pressure comes on “hot”.

What to do if the oil pressure sensor lights up on any hot engine: initial diagnosis

Oil emulsion level

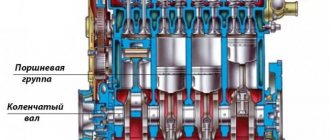

It doesn’t matter whether the oil pressure light is on at idle or at rpm, the first step is to check the oil level in the crankcase. Its deficiency can cause reduced pressure in the oil system, and the sensor records exactly this. This suggests that lubrication starvation is experienced by such important components as:

- Crankshaft bearings.

- Supports for the camshaft and turbocharger rotor.

- Hydraulic compensators.

- Phase regulators.

- Hydraulic belt tensioners.

There is no need to delay refilling. Critical wear and jamming of shafts can occur quickly, and the amount of repair costs will unpleasantly surprise you.

Electrical connections

The level is fine or has been restored, but the oiler is still on - a reason to inspect the functionality of the sensor. But first the wiring. Diagnostics is simple - remove the terminal from the sensor, the lamp on the tidy should go out. If it blinks or lights up, we perform an additional test:

- Select a long piece of single-core wire.

- Remove the supply block of the oil pressure meter.

- Connect the “plus” of the battery and the wire suitable for the sensor.

After the actions have been performed, the icon blinks/is lit, there are definitely questions about the condition of the wiring. It is quite possible that one of the wires has frayed. The indicator goes out - let's move on.

The oil pressure light comes on after warming up: possible causes

If we talk about the situation when the oil pressure light comes on when the engine heats up, in this case you need to take into account that there are several main reasons:

- reduced lubrication level in the engine;

- motor oil is not suitable for the engine;

- the lubricating fluid has lost its properties;

- malfunctions of the lubrication system and internal combustion engine;

First of all, if the oil pressure is on, it is highly not recommended to operate such an engine until the problems are identified and completely eliminated. So, let's start with the simplest reason. We are talking about a banal decrease in the level of lubrication in the engine. Oil can leak out for various reasons, ranging from a broken oil pan to increased fuel consumption, oil leakage in the turbine area, etc.

Also, the unit itself may be worn out, that is, the engine “eats” oil and emits oil smoke due to problems with the CPG or valve stem seals. One way or another, if you do not monitor the lubricant level, if it drops before the power plant warms up, the oil remains thicker and the “cold” light may not light up.

However, after reaching operating temperatures and heating the lubricant, the material naturally liquefies and becomes more fluid. It is also worth remembering that the gaps between the mating parts in the engine are somewhat reduced, and it becomes more difficult for the oil pump to maintain the required pressure while pumping liquid oil through the system.

If we add to this a partial lack of lubrication, then it becomes clear why the pressure lamp begins to light up after the internal combustion engine has warmed up. To solve the problem, you need to add oil to the engine.

Then you can continue to add lubricant to the level for some time or immediately eliminate the leak (replacing oil seals, valve stem seals, piston rings) depending on the specific situation. If the engine is very worn out, then it is better to immediately undertake a comprehensive overhaul.

- Let's move on. In many cases, the cause of low pressure may be the oil itself. For example, if a lubricant is poured into the power unit, which according to SAE does not correspond to that recommended by the car manufacturer according to the manual (for example, the driver filled in 0W20 instead of 5W40), then after warming up the lubricant will be very liquid.

In such a situation, it is quite likely that even serviceable engine oil seals and gaskets will leak, which naturally leads to a decrease in the oil level, and the pressure in the oil system will be lowered. To prevent this from happening, the oil must be selected correctly in terms of viscosity and a number of other important characteristics.

It is also important to consider that the lubricant may lose its properties for other reasons. For example, a significant increase in the planned replacement interval (instead of 10-15 thousand km, the lubricant worked for 20-30 thousand).

Also, loss of properties often occurs after mixing oil with antifreeze. In this case, it is appropriate to talk about a serious breakdown when coolant enters the oil system. This is often caused by cracks in the cylinder block and cylinder head, malfunctions and breakdowns of the head gasket, etc.

The problem can be quickly diagnosed by an increase in the oil level and a decrease in the level of antifreeze in the expansion tank, as well as by the presence of an emulsion under the oil filler cap and on the oil dipstick.

Fuel, which penetrates in excess from the combustion chamber into the crankcase pan, can also change the properties of the lubricant. Often, the problem does not arise on its own, since a violation of the combustion of the mixture in the cylinder leads to engine tripping (the cylinder does not work and the mixture does not burn).

There are many reasons for engine tripping (malfunctions in the power supply system, low compression, lack of spark on the spark plugs, etc.). Also, the injectors can “flow” even when the engine is turned off. In this case, the unit does not move during operation, but fuel still gets into the lubricant. In any case, gasoline in the oil can greatly dilute the lubricant, which will inevitably lead to pressure problems.

It should also be added that adding different types of lubricants, which leads to mixing of engine oil (for example, synthetics and mineral oil), can also lead to the loss of properties of the bulk of the lubricant. The same can be said about the use of various additives and additives (detergents, viscosity agents, stabilizing agents, protective agents, etc.).

Before adding oil or using any additive in the engine, you must take into account all possible risks and effects on the base lubricant.

- Now let's move on to engine and oil system malfunctions. As already mentioned, significant wear on the CPG and an increase in gaps often lead to the oil pressure lamp coming on at idle, on a cold engine, or after the engine has warmed up.

You should also remember that the oil receiver strainer may also be clogged. If a sufficient amount of lubricating fluid does not pass through the filter, then oil starvation of the engine will begin with all the ensuing consequences.

The mesh can become clogged for various reasons. As a rule, the throughput of the mesh is reduced by contaminants that have accumulated in large quantities in the pan. By the way, the detachment of such contaminants from the walls often occurs after the engine was washed before changing the oil with so-called five-minute washes to clean the engine oil system.

The fact is that washing allows such deposits to peel off, but does not dissolve them. As a result, even a working oil pump is not able to pump the lubricant, and the oil pressure burns. To solve the problem, you need to remove the crankcase oil pan, after which the oil receiver mesh is cleaned mechanically or using active solvents. After such an operation, the difficulties in passing oil through the filter mesh will be eliminated.

We also recommend reading the article on how to check engine oil pressure. From this article you will learn what the oil pressure in the lubrication system should be, as well as how measurements are taken.

At the same time, do not forget about the more familiar oil filter, which must be changed along with each lubricant change. If the oil filter is clogged, then this may well be the cause of the pressure problems. It is also important to consider that even a new filter may turn out to be unsuitable for the motor, of poor quality or defective. For this reason, you need to know how to choose the best oil filter for your engine.

Finally, we note that the pressure reducing valve and the oil pump itself deserve special attention. In the case of a valve, this element must remain in the closed position until the oil pressure exceeds the permissible limit. However, if the valve jams in a partially or fully open position, then it is not possible to obtain the required pressure in the lubrication system.

As for the oil pump, its malfunction can be considered a serious breakdown, since the device loses proper performance or completely stops pumping oil. The result is the need to remove the element from the engine. Next, a decision is made to repair the oil pump (if possible) or immediately replace the pump with a new one.

Why the emergency oil pressure lamp is on at idle - significant reasons

Insufficient oil level and incorrect wiring are easily fixable problems. If the icon on the instrument panel is highlighted not due to a malfunction, you should “dig” in the direction of the sensor. Its diagnosis is much more difficult. However, it is not always worth carrying out - it all depends on the circumstances.

Blockage

So, if the oil pressure sensor lights up on a hot engine, you should first perform a simple procedure - clean it. To avoid an embarrassing situation, after unscrewing the touch controller, the mounting hole under it must be plugged with a handy device. An ordinary rag will do just fine for the role of the latter. However, first the control mechanism must be found. By the way, there may even be two of them, as on the VolksWagen T4. Here they are located on the cylinder head and oil filter bracket. Yes, and on the Priora the oil pressure sensor is located on the cylinder head.

How to check the oil pressure in a car

Normal operation of the engine, both at low and high speeds, is ensured by a certain pressure of the lubricating fluid. The required level is indicated in the vehicle operating instructions. For example, the operating parameters for Priora look like this:

- 2 bar (196 kPa) at idle speed on a warm engine;

- 4.5-6.5 bar at 5400 rpm.

On average, for passenger models this value is 2 bar and 4-6 bar, respectively, at idle and at high speeds.

As already mentioned, modern cars are equipped only with a warning light that lights up at idle when the pressure drops. A full-fledged pressure gauge, as a rule, is not available. Because of this, it is often difficult to determine the cause of the indicator signal - either there is a normal lack of oil, or there is a serious problem.

In any case, there is a risk of engine damage when this light is on at idle. How to check the pressure in the absence of a built-in device? A special oil pressure gauge is used for this purpose.

The procedure for working with it is as follows:

- The engine is started, which then warms up to an operating temperature of 90 degrees Celsius.

- After this, the engine is turned off and the hood is opened.

- Find the emergency lubricant pressure sensor and disconnect it. A pressure gauge is connected in its place. Care must be taken as the engine oil is very hot.

- The device is used to determine the current liquid level. If necessary, add oil.

- Then the engine is started again.

- Measure the pressure first at idle, then at high crankshaft speeds.

Repeat the diagnosis 2-3 times and calculate the average value for greater accuracy of the result. Be aware that some fluid may spill out when disconnecting the pressure gauge. Therefore, it is advisable to re-measure the oil level using a dipstick after installing the sensor. If the level is insufficient, add lubricant.

Simple malfunctions - about “lubrication”

The very first and most common reason is – insufficient amount of oil in the engine . Beginners neglect the level and do it in vain. It’s quite simple to determine - we pull out the oil dipstick and see if it’s dry, then we should sound the alarm - we MUST add it to the required level, the engine is experiencing “ oil starvation ”. Fortunately, now the sensor is triggered at a critical but acceptable level.

Second - not timely replacement! Some of us drive on oil for more than 20, or even 30,000 kilometers; it simply turns into mush, after which it is very difficult to wash the inside of the engine! Accordingly, if there is no liquid lubricant, the lamp will signal you about this; such behavior is simply unacceptable. Often the engine cannot be saved, this is especially true on loaded units, for example, on TURBO. So we set ourselves a rule: we MUST change the oil as prescribed by the dealer, and I would even change it even more often, for example, now that my warranty has expired, I change it after 10,000 km, instead of 15,000 recommended by the official dealer.

In 50% of cases, the indicator lights up precisely because of these reasons, so remember them, they are really important, if you follow these rules, then perhaps your sensor will never light up.

Oil light is on: opinions of car enthusiasts

- “We need to check it consistently”

“First determine the current oil pressure in the system at idle speed and only then decide whether it is working properly or not. If the pressure is normal, the sensor is faulty. If it is low, it may be a problem with the earbuds.Pressure problems can be solved by using additives. A friend of mine, having found himself in such a situation, filled it with phenom. The light stopped burning. He drove his car for another year and then sold it without any problems.”

- “Normal oil solved the problem”

“I’ll tell you how it happened for me. There's nothing wrong with the sensor. After changing the oil, the indicator stopped flashing. And it all started when, after Liqui Moly, I poured Toyota grease into my Corolla. I did this twice and topped it up the same number of times after 7000-8000 km. As a result, I noticed that the oil pressure light was constantly on at idle. And it doesn’t just light up, it blinks. I finally decided to fill it with Liqui Moly with SMT 2, and the blinking disappeared. Yes, this is a more expensive option, but as they say, the miser pays twice.” - “I’m not particularly worried.”

“Now I don’t even look at the light bulb. It first started burning at the beginning of 2011, and with the arrival of summer it went out. Not long ago the light came on again. Apparently, the temperature outside has a big effect on it.” - “Allowed only in the first seconds of engine operation”

“A glowing indicator at idle indicates low pressure in the oil system. As the speed increases, the performance of the oil pump increases, and the pressure drops. Maybe the wrong oil was poured in, or it might be a faulty pump.Normally, the light comes on for only a few fractions of a second when the engine starts. A working anti-drainage valve in the oil filter will not allow oil to drain, which should immediately begin to circulate through the system as soon as the engine starts. Accordingly, a certain pressure is established in the oil system immediately at idle. In my car, the light goes out and the pressure reaches the required value immediately after the starter starts rotating.”

About oil pressure

Previously, almost all cars were equipped with a special “screen” where the pressure in the engine was indicated. The scale measured it in units such as - kgf/cm2. The higher the engine speed, the higher the pressure became; if it was not enough, a special lamp would light up, signaling possible malfunctions.

SO:

Normal pressure at idle (from 800 to 1000 rpm), approximately from 0.5 kgf/cm2. I would like to note that for many 16 valve engines it can be a little more, about 0.6 kgf/cm2. This is because they are more revving and their oil is thinner.

This pressure is measured by a special sensor; if the parameters deviate, it lights up a special lamp, which signals that not everything is in order with the engine. As a rule, if the pressure drops to 0.4 kgf/cm2, the lamp begins to blink or burn briefly. Which already signals to you that something is wrong here. But it’s not always a matter of pressure; there are banal reasons, just the driver’s faults.

Complex reasons - that the oil filter

Yes guys, as strange as it may sound, the root cause may be the oil filter, and this manifests itself very often.

1) Oil filter - if you change everything at an official station, then be sure that they will supply you with original spare parts. But there is no guarantee - when you do it yourself! As a rule, you buy non-original spare parts, which can often be counterfeit (assembled in handicraft factories in China), the key factor for you is the price, you can understand! But such filters simply cannot hold pressure, how does this manifest itself? A cold engine or one that has been standing for a long time - you try to start it, it starts and after the first few seconds after starting, maybe from 3 to 10, the pressure lamp comes on, you can hear the knocking of the hydraulic compensators, if you have them. The thing is that the oil filter must have a special valve (check valve) or washer (locking washer) that locks the oil when the engine is turned off, that is, it should not flow into the pan, but be in the system. This is true for normal manufacturers, but for “fake” ones, this is completely far from reality - as a result, the oil drains and the engine needs some time to pump it back into the system! This is very bad, there is increased wear of parts, especially at times of maximum load (in winter)! What to do - just change the filter, you need to find a normal one, otherwise we will simply reduce the resource of the unit.

2) Pump - there is a pump inside the engine, which pumps our lubricant; if it fails or becomes clogged, then the oil supply also stops, or it is “stressed” - we change it - we clean the pump. You need to remove the pan, sometimes you have to disassemble half the engine.

3) High engine wear . If your unit has traveled a huge number of kilometers, for example, about 400 - 500,000 km, then it may have worn out spare parts such as crankshaft liners, oil scraper rings, etc. It’s just time to “capitalize” it, although it will most likely “smoke” blue smoke . The power will also drop, the consumption will increase, and it may be “ ungodly triple ”, even if the spark plugs have been cleaned. These are the causes of wear and tear, nothing can save it - it needs to be repaired.

Complex malfunctions, as a rule, appear even when the engine is running normally, that is, you started it, it works - but the lamp is on (this could also include a malfunction of the pressure sensor itself). You need to go to a service station and measure the pressure in the system, if it is categorically low - 0.2 - 0.3 kgf/cm2, then you need to disassemble the engine and look for the reason, perhaps the pump is simply blocked, or the filter is clogged, and much more.

REMEMBER - you cannot drive, especially over long distances, when your oil pressure light comes on, it is dangerous! Almost always this indicates complex engine malfunctions, so get to the service station quickly!

Now we are watching a short video version.

A fairly common problem during the operation of an internal combustion engine is the oil pressure light on the dashboard coming on. This lamp indicates that the engine oil pressure in the engine lubrication system drops below the permissible level. Low engine oil pressure can occur for various reasons. Among the main malfunctions, experts identify:

- malfunction of the oil pressure sensor;

- low quality motor oil;

- mismatch of engine oil for a specific engine type;

- decrease in oil level as a result of a leak or increased oil consumption (waste, problems with rings or valve stem seals);

- using oil whose characteristics are not suitable for current operating conditions (viscosity index too high or low);

- oil pump malfunctions, decreased performance;

- blockage of the oil filter or oil channels of the engine lubrication system;

Next, we will focus on the problem when the emergency oil pressure reduction light comes on cold and/or hot. In other words, the oil pressure warning light does not go out or blinks/blinks after starting a cold engine, and the oil pressure warning light also lights up on a warm engine that is idling.

Read in this article

Moderate causes - maybe a sensor?

Here it is worth mentioning options from which any driver is not protected, that is, practically not to blame. SO:

1) The pressure sensor has failed , this is a trivial problem with CHEVROLET engines; if the engine is not warmed up, the oil simply “breaks through” the sensor, and it starts to “flow” - it does not show the correct data, even if your level is normal, it will constantly signal you. What to do - just change it! Many cars have this problem, and therefore in winter we warm up the engines at idle - a must! It manifested itself like this, here is the video.

2) Wrong oil ! Rarely, but it happens. Now, however, all manufacturers indicate the tolerance standards that need to be poured into their motor (for example, 5W - 40, 5W - 30), however, there are those who “don’t understand” who can fill in a brand and tolerances that are not designed for your unit (for example, 0W - 20) , what's happening? Such oil is either very liquid, or, on the contrary, very thick, the pressure begins to jump from normal - the pressure lamp lights up! Therefore, we are not being “wise”, we are pouring what the doctor ordered. If you don’t know which one, go to the forums for your model, everything has already been written there a long time ago.

3) Antifreeze or antifreeze gets into the engine crankcase . Unfortunately, this is not uncommon - the gasket between the engine block and the head breaks, and the coolant simply flows into the oil. Accordingly, the lubricant loses its properties, becomes liquid and can no longer withstand the required pressure (that is, it drops below 0.4 kgf/cm2). This malfunction is easy to determine; your coolant level will constantly drop, and there will be no drops under the car anywhere. And the oil level is constantly rising! In general, urgent measures need to be taken, otherwise the engine will “knock” .