Purpose and design

The main function of the oil pressure sensor in Kalina is to inform the driver about the presence of oil pressure in the engine. The sensor is a valve that opens its contacts at a certain pressure.

When you turn on the ignition, you can see a red oil can on the car’s dashboard; it indicates that there is now no oil pressure in the engine, and this is correct, because the internal combustion engine is not running. Once the starter starts rotating and the engine starts, the light should go out within a few seconds. If this does not happen, then there is no oil pressure in the internal combustion engine, which can lead to engine damage.

Required Tools

Replacing the oil pressure sensor on a Lada Kalina will not be possible without the tools presented below.

Table - Tools required to replace the crankshaft sensor

| Name | Note |

| Screwdriver | Flat blade |

| Socket wrench | "at 21" |

| Rags | Non-linting |

Where is

Many people wonder where the oil pressure sensor is on Kalina, but it’s really hard to notice right away. Also, the location of the sensor depends on the type of engine, namely on the number of valves.

- On the 16-valve model, the oil pressure sensor is located to the right of the oil filler neck and is screwed into a special drain.

- On an 8-valve engine, the oil pressure sensor is located on the left side of the engine near the timing case.

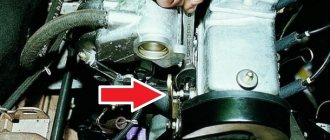

Location of DDM on Lada Kalina

To see where the oil pressure sensor is located on the Lada Kalina, you need to open the hood and remove the decorative cover, under which the 16 or 8 valve power plant is hidden. The DDM is located on the back side of the motor. It is located on the right side of the power plant in the direction of travel. A wire with a terminal block at the end goes to the sensor.

What to do if the oil pressure indicator is on

It happens that the oil pressure indicator on the car lights up, and this indicates serious malfunctions in the engine. If you find such a warning light on your car, you need to stop and turn off the engine as soon as possible.

The reasons why the oil pressure light comes on may be:

- Low oil level;

- Sensor failure;

- Oil pump failure;

- Damage to wiring;

If your car's oil pressure light comes on, check the following after stopping:

- Check the presence of oil in the engine; if the oil level is low, the amount will not be enough to create the necessary pressure for proper operation of the internal combustion engine. Loss of oil can occur due to wear on the CPG, a sump failure, or other leaks in the engine.

- Check the condition of the sensor and its wiring; perhaps a chip (connector) has simply fallen off the sensor. The sensor wiring must be in good working order and must not have any traces of melting or insulation breaks.

- If a visual inspection shows that everything is in order with the car, but the oil pressure lamp is still on, it is necessary to tow the car to a service station for further diagnostics.

What you need to know about DDM?

A modern car has a large amount of electronics installed, based on the readings of which the electronic control unit issues the appropriate commands. One such device is the oil pressure sensor (OPS).

Appearance of DDM

Purpose and location

The purpose of the DDM is to monitor the oil level in the power unit; as soon as the amount of lubricant drops below the permissible level, the corresponding indicator light lights up on the instrument panel.

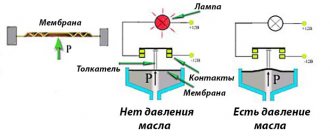

Device operation diagram

The operating principle can be described as follows. Lubricant is supplied to all components of the system under pressure. The system includes a DDM, inside of which there is a membrane indicated by arrow 4. If the pressure is low, then the membrane is not deformed, the contacts numbered 3 are closed and the lamp indicated by arrow 2 is on.

When the engine starts, the pressure increases, the membrane is deformed and acts on the pusher that is installed on it. In this case, the contacts open and the light goes out.

The DDM is located on the cylinder head on the right, when viewed in the direction of travel, on the back side of the engine. It receives power through a wire with a plastic terminal, which makes it easy to detect.

Device location

Diagnostic features

If the indicator on the dashboard is constantly on, you should first check the oil level using a dipstick and the condition of the oil filter. It is also necessary to check for oil stains on the power unit housing. If the level is normal, you should check the device itself. The simplest test option is to install a known-good device instead of the device being tested.

You don’t have to buy a new one, you can ask your neighbor in the garage. True, the sensor should be exactly the same. If, after installing a working device, the indicator stops lighting, then the removed one is faulty.

In addition, using a multimeter, the power supply to the device is checked to see if there is an open circuit. If you have a pressure gauge, you can check the oil pressure. To check, you need to screw the pressure gauge into the DDM seat and start the engine. At idle, the pressure value should be above 0.65 kgf/cm2.

If you don't have a pressure gauge, there is another way to check. To do this, the sensor is unscrewed, and then the starter is cranked without starting the engine. If, when the starter rotates, oil splashes from the seat of the removed device, we can conclude that the device is faulty.

Replacement

You can replace the sensor yourself without much effort. To do this, it is enough to prepare a 21mm key.

You can unscrew the sensor calmly, without fear that oil will escape from there.

- Remove the connector from the oil pressure sensor;

- Unscrew the sensor counterclockwise using a 21mm open-end wrench;

- We take out the sensor and wipe the seat from dirt;

- We install the new sensor in the reverse order, not forgetting to install the O-ring;

Sensor cost

The Lada Kalina uses the original Lada oil pressure sensor 11183829010. Its price is about 180-250 rubles. Third-party manufacturers produce analogues of the native DDM. Among them there are very good options at an attractive price. The table below shows the best sensors from third-party brands that have performed well on the Lada Kalina.

Table - Recommended analogues of the original Lada Kalina crankshaft sensor

| Firm | Catalog number | Approximate cost, ruble |

| AMY | 6022.3829-01 | 80-140 |

| Autodevice | 1118-3829010 | 120-185 |

| Road map | 11183829010 | 75-100 |

| Bautler | BTL1118OPS | 130-150 |

| Baker | 11183829010 | 100-130 |

Features of choosing oil for Kalina

Castrol Edge - the choice of many drivers

We have more or less figured out the additives, but which oil is better to choose for your “swallow”? The choice of lubricant is one of the most difficult issues that should be treated with the utmost seriousness and care.

Some drivers prefer all-season oils; they can be easily refilled throughout the year. But professionals advise doing otherwise. The all-season option, of course, is good for its versatility, but it cannot cope with the loads that a hard-working motor is subjected to every day. Therefore, it is more correct to alternate summer and winter oils: in the warm season, pour in a thicker, more viscous one, and in cold weather, use a special mixture that will eliminate possible problems.

The qualification table will help you make the right choice when purchasing.

| Brand | Temperature |

| 0W | 30-40 degrees below zero |

| 5W | Up to 25 degrees below zero |

| 10W | 15-20 degrees below zero |

| 15W | From 10 degrees below zero |

| 20W | 5-7 degrees below zero |

| 25W | No more than 5 degrees below zero |

Based on the data in the qualification table, you can easily figure out which oil for Kalina you need to purchase.

Exploitation

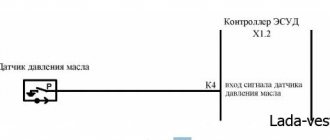

The oil pressure sensor on the viburnum is part of a system that monitors the pressure near the engine pump and filter. For this purpose, the engine block has a socket with a threaded connection through which the sensor is fixed. Electricity meters use a device in the motor block to create a variable resistance that will influence the amount of current through the metering circuit and sensor.

Pressure meters require a power source. The electrical diagram shows that power flows through the meter and back to ground through the sensor. The meter readings as a whole will depend on the resistance of the sensor, which, in turn, is determined by the pressure.

Malfunctions and ways to eliminate them

The indicator can be activated when there is no pressure required to inject oil into the cylinders. Without the lubrication provided by oil, the cylinders may be damaged, requiring a new engine. The warning light may come on for a variety of reasons. First you need to determine whether this is a problem with the meter or something else.

Low pressure

Low pressure is the main reason the dashboard light comes on. The device determines whether oil is supplied in such quantity that it reaches all parts of the engine. If the pressure is insufficient, the friction of the parts rubbing against each other will cause heat and abrasion, damaging the engine. In this case, the device is not necessarily damaged; you should look for the cause of the low oil pressure.

Low level

Low oil level is not a common cause of sensor failure. With a small amount of lubrication, it is possible to circulate oil through the engine at sufficient pressure to activate the sensor. The reasons why the level is low are leaks in the distribution system, improper replacement of the drain plug or oil filter, and debris.

Faulty device

From time to time the unit may become clogged with contaminants, especially if the engine is not properly maintained. A clogged meter gives false readings, causing the warning light to come on.

Replacing the water pump Lada Kalina

On an 8-valve VAZ-21114 engine, the average service life of the water pump is about 70-100 thousand km, and if it starts to make noise or leak, it must be replaced. It should be noted that on all models 2108-15, Lada Priora and Kalina with an 8-valve internal combustion engine, the pump is changed according to the same principle.

The water pump is replaced as follows:

- drain the antifreeze from the cooling system;

- remove the plastic timing belt cover;

- if the timing belt does not need to be changed, then we do not remove the crankshaft pulley; accordingly, there is no need to dismantle the right wheel;

- set a mark on the camshaft - it should coincide with the ebb on the rear timing case;

- loosen the tension roller, remove the belt from the camshaft;

- Unscrew the three pump mounting bolts with a hexagon and remove the pump;

- put the new pump in place, put on the belt, tighten it with a tension roller, check the alignment of the marks, on the crankshaft the mark is located on the flywheel, under the rubber plug of the gearbox housing;

- fill in antifreeze, start the engine, check if the antifreeze is leaking and if the pump is noisy. If everything is in order, put the timing case back in place.