Unstable engine operation can lead to major repairs. Many car enthusiasts do not believe the service technicians that the engine misfire needs to be repaired urgently. If at the same time the “check” flashes, it means that a misfire has been detected and the VAZ-2114 engine is tripping for this reason. Be sure to carry out diagnostics so as not to repair the car at random.

What can cause the engine to run unstably?

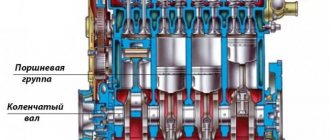

Most often, the “check” can blink and the engine may run unstably when the fourth cylinder of the injector, which has 8 valves, fails. However, this formulation is incorrect, the reasons may be the following:

- problems with the spark plug;

- low compression in cylinders;

- the valves have not been adjusted for a long time (they do not fit tightly);

- the injectors are clogged or overfilled (they will have to be replaced);

- spark plug wire breakdown;

- ignition coil malfunction;

- The crankshaft sensor is not working correctly;

- the electronic control unit has failed;

- the timing belt is misaligned (or it has completely fallen off);

- Air filter contamination.

All these reasons lead to the failure of the cylinder and the appearance of characteristic signs of a malfunction.

In this case, problems can occur simultaneously or after a certain period. Pay special attention to the following signs:

- increased engine vibration during operation - the operation of valves, rotating parts of the power plant and transmission is disrupted;

- an increase in fuel consumption and a change in the nature of exhaust gases (they will contain unburned fuel);

- reduction in engine power and reduction in vehicle maneuverability.

Signs

How do you know if the engine is leaking? With such a malfunction, the check engine light does not always flash. Therefore, it is important to know third-party signs that may indicate a problem:

- Increased engine vibration. It is significantly noticeable at low and idle speeds.

- Spark plug color change. After removal, its head will be dark. Since the mixture does not ignite, the candle becomes covered with soot and soot.

- Increased fuel consumption. This sign is related to the previous one. Since the mixture does not ignite, it simply goes into the exhaust pipe.

- Loss of engine power. Since the engine runs on three cylinders, it does not have enough energy to produce the required torque.

- Exhaust sound. He will be unstable.

- The appearance of black or thick white smoke from the exhaust pipe.

- Intermittent jolts during acceleration and even motion. This symptom also indicates a misfire. This error is often related to the ignition system.

What to do if the engine troits

To determine the exact location of the problem, do the following:

- Start the engine and open the hood.

- Determine the nature of the motor and remember the sound it makes.

- Remove the wires from the spark plugs one by one. If the sound does not change, then the cylinder is faulty. If the nature of the engine operation becomes different, the unit is operational.

Next, diagnostics are carried out based on the condition of the spark plug from the faulty cylinder. It is unscrewed with a special key, which every car enthusiast needs to have on hand. It cannot be replaced with another. To get to the service center, you just need to replace the carbonated spark plug with a new one to temporarily restore engine performance.

- If the electrode on the removed spark plug is clean and the head is dirty, this means dust has appeared in the combustion chamber. In this case, it is necessary to check the air system and, if necessary, replace the filter.

- Burnout of the electrode and contamination of the entire spark plug with fumes indicates a lean fuel mixture and detonation combustion. If the electrode is intact, but there is burning throughout the spark plug, we can talk about an overly enriched mixture and a delay in ignition.

Many car enthusiasts are familiar with the method of checking spark plugs. If it is there, albeit weak, then it is necessary to look for additional reasons for the engine malfunction, and if it is good, you can try to start the engine again, perhaps its operation has been restored. If there is no spark, replace the spark plug with a new one.

Reason one - spark plugs

I wrote in detail about how to determine faults in car systems using spark plugs here .

I recommend reading it - it turned out to be useful, judging by your reviews, thank you.

We unscrew the spark plugs one at a time and look at their insulator.

If it is covered with dense carbon deposits, then it is difficult for a spark to penetrate it. The current seeks the path with the least resistance, so the spark will not be between the electrodes, but will “go” along the insulator to the side. Its energy will not be enough to set fire to the air-fuel mixture. This cylinder will not work.

We inspect the external condition of the spark plug insulator.

If there are microcracks, then part of the current will not be converted into a discharge, but will escape through these damages. You need to look at the internal insulator, which is screwed into the cylinder head, and at the external one, onto which the armor wire cap is placed.

Large or small gap between electrodes.

Many people have heard or know that for certain engines, ignition systems and types of fuel used, spark plugs with a certain gap are required. Usually its value is indicated by the manufacturer of engines and cars.

How to check the spark without special devices on the engine

This is an old, “grandfather” method, some people are afraid of it:

- They unscrewed the spark plug;

- They put an armored wire on her;

- They leaned it with the inner body, the metal part, against the engine;

- Turn on the ignition and turn the starter.

How to carry out repairs if the car has high mileage

If you have been using your car for a long time, then you should do the following:

- Replace the spark plug.

- Install a new set of wires going to the spark plugs. Over time, due to use at different temperatures, microcracks appear on the windings of high-voltage wires, leading to breakdowns.

- Check the compression in the non-firing cylinder. If it is violated, it is necessary to check the valves and rings.

- Set up the valve system. It is recommended to do this every 15 thousand mileage.

- Test the ignition coil and replace it with a new one.

- Replace the air filter.

- Feel the timing belt and inspect its position.

If after these steps the engine continues to stall, and does so even at idle, then it is necessary to check the fuel system and flush it right down to the injectors. As a rule, when starting from a cold engine, the engine stalls due to problems in the fuel supply system or due to the lack of an ignition spark.

Long-term use of the vehicle

If the checkbox starts blinking on a VAZ car with high mileage, then the reasons for the power unit tripping are as follows:

If the above procedures have been completed, and the power unit is still running, then it is recommended:

- Diagnose the ECU. If necessary, it is replaced with a new block.

- Check the injectors and the entire gasoline supply system.

- Check the oxygen sensor for functionality. If the device is faulty or the performance is deteriorated, repair work is carried out.

- The crankshaft position sensor fails - in this case, the ECU generates an error indicating this failure.

Top 10 reasons for the “check” signal

For car owners, it is important what the “check” and error codes on the instrument panel mean, so the causes and methods of troubleshooting should be considered in detail. The check engine light can come on due to hundreds of faults. The list of common reasons why the check may light up or flash includes:

- Poor fuel quality . In Russia, refueling with low-quality fuel is considered the most common reason why the yellow icon of a faulty engine lights up.

- Damage to the lambda probe. (2 – 4) are installed on the exhaust gas emission system . If the lambda probe is faulty or clogged, the “check engine” light comes on.

- Poorly closed fuel tank cap. If the check engine light comes on when leaving a gas station and does not go out, check the gas tank cap.

- Clogged exhaust system catalyst. Fails due to natural resource depletion, clogging, or combustion of honeycombs.

- Malfunction of the mass air flow sensor . If the sensor breaks down, the check light comes on and the power of engine (internal combustion engine) drops.

- Clogged or worn spark plugs . The engine warning icon appears for any ignition failure. In addition to the indicator, failures in engine operation indicate faulty spark plugs.

- Oil level drop. At the same time, the check engine and oiler icons light up, which means that the internal combustion engine is operating in oil starvation mode.

- Clogged injectors . A burning check engine light is accompanied by sneezing and floating engine speed.

- Antifreeze leaks. The check engine icon and the cooling indicator light up, which means the internal combustion engine is overheating and the need to stop immediately.

- Electronic control (EDC) failures. Electronic engine error can be random or systemic. In the second case, computer diagnostics of the error code archive is required. You can fix a random failure yourself.

On the road, situations often arise when the check light is on and the message “ engine power limited ” is displayed. With this signal, the on-board computer responds to a number of breakdowns, which include:

- clogged filters (air, oil, fuel);

- failure of the crankshaft position sensor;

- short circuits, breaks in electrical cables;

- oxidation of contact pads, plugs, connectors;

- depressurization of the exhaust gas recirculation system;

- broken exhaust manifold gasket;

- knock sensor failure.

In these cases, to remove the check engine icon, the vehicle must be diagnosed and repaired at a qualified car service center.

Related material: How to independently diagnose a car using a laptop

Engine malfunction indicator: main causes of fire. Methods of their treatment

There are quite a few reasons why the engine diagnostic light comes on, since the signal comes from the on-board computer, which simultaneously analyzes many vehicle operating systems: ignition, automatic transmission, engine, carburetor, etc. Some faults can be diagnosed independently, but first, let's figure it out in their reasons:

- If the engine light comes on, you need to start by checking the tightness of the fuel system, for example, the gas tank cap is not tightly tightened or it has defects. This engine warning light often comes on for this very reason.

If the “Check” engine malfunction indicator lights up while the car is moving, this may be a signal of low engine oil level. To diagnose this malfunction, it is recommended to stop and listen to the engine in order to identify the presence of extraneous knocks and noises. And also carry out a visual inspection of it - check the oil level, inspect for leaks and damage to the body. In the conditions of our country, the quality of fuel and lubricants products wants to be the best, as a result of which the engine malfunction icon may also light up. To be treated by simply replacing bad fuel. If, despite stable and smooth engine operation, the check engine light still comes on, this may be a sign of a misfire in one of the spark plugs. If you find a “piercing” spark plug or armored wire, then they must be urgently replaced, since they are the main igniters of the fuel system. With a faulty spark plug, you may feel slight jolts when accelerating, which is caused by improper spark supply. The recommended replacement interval for spark plugs is 25 - 30 thousand km

Please note that timely replacement of spark plugs not only improves engine performance, but also reduces fuel consumption. By the way, the gap between the spark plug electrode should not exceed 1.3 mm.

- Ignition coil malfunction. It is necessary to check for the presence of a spark and resistance at the coil terminals.

- Malfunction of the oxygen sensor (lambda probe). This sensor helps monitor your vehicle's fuel consumption, so if it malfunctions, it can have a significant impact on how much power you get and how much power your engine makes. The cause of the breakdown is oil soot, which covers the sensor with a thin layer, which reduces the performance of the gasoline mixture adjustment sensor. In addition, untimely replacement of the sensor can lead to failure of the catalyst. Treated by replacing the sensor.

- Malfunction of the exhaust gas catalyst. The catalyst not only provides more environmentally friendly exhaust gases, but is also responsible for the dynamics of the car. The main cause of catalyst failure is untimely replacement of the oxygen sensor and spark plugs, since the conversion of carbon monoxide in the catalyst into harmless chemical elements depends on them. Otherwise, the catalyst will overheat and may burst. Treat with replacement.

- The injectors are not working properly. As a rule, they require cleaning, but sometimes even replacement.

- Malfunction of the mass air flow sensor.

This sensor is responsible for the leanness of the supplied mixture. A malfunction of this sensor can lead to increased fuel consumption, a decrease in engine power and disruption of the smoothness and dynamics of the vehicle. In addition, the car may have difficulty starting or idling smoothly.

The main reason for sensor failure is untimely or incorrect installation of the air filter.

- Faulty fuel pump or fuel filter. It is necessary to measure the pressure in the ramp (its value should not be less than three atm.). Treat by cleaning the filter and mesh in the gas tank. More drastic measures are replacing the fuel filter or fuel pump.

If the above “treatment” methods did not help and the check light still lights up on the instrument panel, then you must immediately contact a car mechanic, otherwise this may result in serious repairs.

Tips for restoring the performance of the power plant

If cleaning the engine compartment results in the engine being unable to start, the car owner should not panic and immediately call a tow truck. You can correct the situation right on the spot. It is enough to dry the places where liquid accumulates. It is recommended to adhere to the following instructions:

- Open the hood and visually inspect the power plant and other components. Any water found must be carefully removed;

- Remove the terminals from the battery and remove oxides;

- Wipe the high-voltage wires along the entire length;

- Unscrew the spark plugs and let them dry. Make sure there is no water in their planting areas;

- If there is a distributor, it must be dismantled. After this, remove the lid and wipe everything dry;

- Open the air filter housing and make sure there is no liquid in it;

- Check the status of the alarm.

If the above steps did not help, then the malfunction did not arise as a result of the engine being washed, but for other reasons. In this case, it is necessary to begin troubleshooting components and parts. For example, a cracked distributor cap could perform its functions when dry, but the appearance of moisture completely rendered it inoperable.

Check the fuel filler cap

Many drivers, in most cases, when the “check engine” indication appears, will think about serious problems in the car’s engine, but will not even think to check the tightness of the fuel system, which may be compromised due to a defect or an insufficiently tightened fuel tank cap. This is a very common reason for the appearance of the “Check” engine icon.

Reason for the error: Leakage of the fuel system due to the passage of air through the filler cap of the fuel tank will increase the vehicle's fuel consumption, to which the vehicle's diagnostic system will generate an engine error by turning on the "Check engine" indication on the vehicle's instrument panel.

What needs to be done: If, when the “Check” indication appears, your car has not lost power, and there are no audible signs of engine damage (engine knocking, humming, creaking, etc.), then first check the gas tank for leaks. Your gas cap may be cracked or not tightened enough. If the cap was not tightened enough, then after tightening it all the way, continue driving the car for a while to see if the engine error disappears. To prevent a check engine light from appearing for this reason, check your fuel filler cap regularly. Remember that the cover must be replaced with a new one periodically!

How to check spark plugs?

For this we need a special spark plug wrench. All work is performed on a cooled engine. On many cars, access to spark plugs is unlimited. But on some models (for example, Nissan Qashqai), for this you first need to remove not only the decorative cover, but also the plastic intake manifold, as well as the throttle valve. When dismantling these units, you should stock up on new gaskets.

Having taken out the candle, it is worth inspecting its condition. It should not have any plaque. You also need to check the gap with a special feeler gauge. It is different for each car, but often amounts to 0.8 millimeters.

If the gap is too large, a spark simply cannot form, which is why the “check” blinks and the engine stalls. If there is a large gap on the spark plug, this can be easily fixed. To do this, just bend the electrode slightly, and then check the distance with the same probe. If the candle has carbon deposits, it can be cleaned. You can also replace it with a new one. In this case, we will know exactly what the problem is - in the candles or in something else.

How to protect from water when washing

The best remedy is, of course, not to wash the engine. But how to remove oil stains? There are several ways. The most neutral one, which does not lead to consequences, is to buy a grease remover from dishes in a store, spray it on and wait a few minutes until everything drips down. Then use a compressor to thoroughly blow through all engine parts. But no moisture or water.

The second way is to mix a little gasoline with mallow - a product that many car mechanics use to wash their hands, pour this mixture into a spray bottle, spray it on the engine and also air dry.

Diagnostics using special equipment

The diagnostic process using special equipment consists of checking the car using a laptop. To connect to the diagnostic connector you will need a cable with an adapter. Using this cable, we connect the computer to the connector via USB output. For testing you will also need software; the power of the computer used is not important. There are many versions of different testing programs on the Internet.

Diagnostics is performed as follows:

- It is recommended to inspect the vehicle before starting the inspection. Check the volume of consumables - engine oil, brake fluid, coolant.

- Find the diagnostic connector and connect your laptop to it. If you have a special scanner, then that's even better. But since finding a scanner is not so easy, and buying one is not cheap, you can use a laptop. Before testing can begin, the ignition must be activated. There is no need to start the power unit.

- After connection, the testing utility starts. The software interface may vary. When you launch the software, graphs or a list of parameters with numbers may appear. This information will allow you to draw conclusions about the operation of the power unit.

- The scan starts. Fault codes will appear on the laptop screen. To decrypt, use the information provided in this article. We could not describe all the codes, but we deciphered those that occur most often. Usually, when downloading a program to a computer, users are provided with a separate file describing the faults.

- After decryption, the problem is repaired.

Car exhaust catalyst

An automobile catalyst helps a car make engine exhaust gases more environmentally friendly. It converts carbon monoxide and other harmful substances into harmless compounds. If your exhaust catalyst has become unusable, you will notice it not only when the engine icon (check) appears, but also long before that, when the car’s power drops by half. For example, when you press the gas pedal, the car will not have good acceleration dynamics as before.

Replace the mass air flow sensor

The mass air flow sensor regulates how much air needs to be added to the gasoline mixture for optimal ignition of the fuel. The sensor constantly reports data to the car's computer about the amount of oxygen supplied. A faulty mass air flow sensor increases fuel consumption, increases CO2 levels in the exhaust gas, and reduces engine power and smoothness. Also, if the sensor is faulty, poor acceleration dynamics are observed. In cold weather, a car with a faulty sensor has difficulty starting.

What are the reasons for the failure of the mass air flow sensor: Most sensor failures occur due to improper installation of the air filter during its scheduled replacement. Also, if you do not regularly change the air filter, as required by the vehicle maintenance regulations recommended by the manufacturer, the mass air flow sensor may fail.

What you need to do: Theoretically, you can drive for a long time with a broken mass air flow sensor (several weeks or months). But you will notice that the longer you drive, the more your fuel consumption increases. Replacing the sensor in a car service is not that expensive, since the work itself does not take much time and is quite simple. The main costs are related to the cost of the sensor, which for some car models can be 11,000-14,000 rubles if it is an original sensor or up to 6,000 rubles if it is an analogue substitute. Replacing the sensor yourself is very simple. But due to the low cost of replacing the sensor, you can entrust this work to a mechanic at a car service center. Remember that you need to regularly change the air filter, observing the vehicle maintenance regulations!

The injection engine does not pull

Why does the car not pull if the injection systems are equipped with feedback and can self-regulate in a “closed loop”? Unfortunately, the possibilities for self-regulation are not as wide as we would like.

The first enemy of injection systems is insufficient fuel pressure. When fuel consumption is minimal, the correction margin is sufficient for idling. But as soon as you put a load on the engine, the correction will jump to the maximum threshold, but the injectors will still be “underfilled”.

The pressure in the fuel rail is set by three components: the fuel pump itself, the pressure regulator and a set of filters (coarse and fine). The performance of a working fuel pump is several times greater than the engine needs at maximum flow rate - this is done so that pump wear affects the engine’s operation as little as possible. That’s why a fuel pressure regulator is used, which dumps “excess” fuel either immediately at the pump outlet or from the fuel rail after the fine filter.

In the first case, the fuel rail is called drainless (16-valve VAZ engines, modern foreign cars), in the second - drain. The difference between these systems is the location of the regulator and its operation. On drain ramps, pressure regulators are controlled by the vacuum in the intake manifold; the pressure in the ramp changes depending on the load (at 3 bar, normal for a VAZ, at idle it is 2.3-2.4 bar, take this into account when diagnosing!). On drainless ones, the pressure is maintained constant relative to the atmosphere and is 3.5-4 bar, depending on the car model. An exception is direct injection systems, where the operating pressure ranges from 20 to 70 bar.

Something else useful for you:

The resistance of fuel filters has no effect when measuring fuel pressure “in the plug” (the pump is forcibly turned on with the engine off, when there is no fuel flow in the ramp) and minimally at idle. But under load, an excessive increase in filter resistance reduces the fuel supply to the rail, which will lead to a loss of speed. Therefore, measure the pressure at idle and under load (for example, by hanging the drive axle and braking the wheels in gear). In cases where the idle speed is normal, and problems occur while driving, measuring the pressure only at idle speed (idle) is pointless.

Exception stages during verification:

- Remove the coarse filter (“mesh” at the inlet). This is a known problem for a number of cars - for example, on the second generation Focus.

- Replace the fine filter.

- Measure pressure under load.

- On engines with a drain ramp, clamp or otherwise plug the return line to eliminate the influence of the fuel pressure regulator. On engines with a drainless ramp, the RTD is installed in the fuel pump module; here it is easier to temporarily install a plug washer made of polyethylene or other material under it that is not destroyed by gasoline.

- Measure the pressure again: if it has increased, then the RTD needs to be replaced, otherwise the pump needs to be replaced.

The second reason for “underfilling” is clogged nozzles. Even with normal filter operation, the formation of deposits on the nozzles is inevitable over time.

At home, you can only evaluate the shape of the spray pattern by removing the ramp and cranking the engine with the starter (Attention! This procedure is a fire hazard!). A clean nozzle should “dust” evenly, and not give out separate streams or pour to the side

You can evaluate the performance of injectors and compare it with the nominal one only on a bench.

Loss of dynamics is also a consequence of excessively enriched mixture. The fuel pressure regulator cannot be blamed here (the performance of the pump, even when operating without an RTD, is not so high that the correction margin of the injection computer does not cover the enrichment). It is much more likely that the injectors are leaking (again, checked on a bench) or the failure of the sensors that are used to calculate the injection time.

Here the undisputed leader is the mass air flow sensor - an accurate but sensitive device. As the air flow sensor gets dirty and ages, the readings become higher and the car begins to consume significantly more fuel. As a result, the over-enrichment of the mixture can no longer be corrected by the lambda probe. But such a malfunction is immediately visible: the car will begin to smoke, the spark plugs will be covered with black soot. On engines with an absolute pressure sensor, failure of the air temperature sensor is more likely (here it is a separate unit, while in the mass air flow sensor it is built-in).

On cars with an electronic throttle, it is worth checking the operation of the servo drive by removing the pipe from the throttle and allowing it to release gas. The throttle should open evenly, without pauses or wedging, indicating problems with the drive gearbox or critical contamination of the damper (the axle, overgrown with carbon deposits, becomes wedged in the housing).

What does a lit Check Engine light on a Kia Rio mean?

Check Engine on Kia Rio

On Korean Kia Rio cars, a burning CHECK ENGINE light on the dashboard indicates that there is a problem with the operation of the components.

Check came out

When does the check light come on?

- with the ignition on before the power plant starts (normal);

- at the moment of starting the engine;

- in the event of a malfunction of the system that controls the exhaust of the car (in case of problems with the internal combustion engine and gearbox).

The situation is considered normal when, after starting the internal combustion engine, the check goes out and does not light up while driving. If the light on the dashboard is flashing, the catalytic converter may be damaged; driving a car in this condition (without inspection and testing at a service center) is fraught with aggravation of the problem and more serious damage. In the operating manuals for Kia Rio of the second and third generations, the manufacturer indicates that a flashing check indicates a malfunction in the working units that control the process of reducing exhaust gas toxicity. Driving such a car is allowed, but a visit to an official dealer is absolutely necessary.

Unstable operation in cold conditions

From time to time, drivers encounter a problem: the VAZ 2114 engine stalls during a cold start, but as it warms up, the operation evens out. In this case, the reasons may be:

- large valve clearance;

- low compression, wear of compression rings;

- the mass air flow sensor is faulty;

- air leakage under the intake manifold gasket;

- poor quality fuel;

When the car shows signs of shaking, you should contact a service center for diagnostics. Diagnostics are carried out using special equipment, where a specialist can accurately determine the cause of the malfunction. Of course, if you have enough experience, you can figure out the reasons for the unstable operation of the engine yourself.

Why is the Check Light constantly on?

If the Check light comes on on the dashboard of a Kia Rio, you need to determine the cause. The check should be carried out in several stages:

Why is the Check Engine light on?

- You need to see if the cap on the fuel tank is in place correctly. When refueling a car and hastily tightening it, it may happen that it does not fit well (leaks). Constant blinking of the check may also indicate a missing fuel tank cap.

- The warning light comes on when the permissible spark plug gap increases. When measuring with a probe, it becomes clear whether the distance between the electrodes needs to be adjusted.

- At the third stage, the ignition is checked using a tester.

- The check light is also on due to improper operation of the fuel pump. When the filter is clogged, the car operates unevenly; the pump itself should function without any extraneous noise. If there are a lot of them, you need to remove the fuel module, clean or replace the filter.

If a check light is on on the Kia Rio dashboard and the engine is running smoothly, you need to test it. To do this, stop the car and inspect the internal combustion engine, paying attention to what sounds it makes. If there are no defects and the lamp is blinking, it is better to contact the service for a full diagnosis. Without an accurate determination of the cause of the malfunction, it is difficult to eliminate it yourself.

Diagnosing a car

If the CHECK light is blinking on a Kia Rio, and the engine is running steadily, the problem may be hidden in the catalytic converter, which is part of the car's exhaust system. Replacing a failed old catalyst with an original one is expensive, sometimes the part is simply knocked out. Residues of unburned fuel enter the exhaust, causing the catalyst to burn out. The problem may lie in the internal combustion engine cylinders, so the car jerks while driving, and a thorough check at the service center is necessary.

Catalyst

What's the result?

As you can see, if the engine stalls and the check engine light blinks, it is necessary to determine the cause as quickly as possible. A timely call for service or repairs will allow you to avoid subsequent troubles with the catalyst and lambda.

It must be remembered that tripping and misfires do not always indicate a serious breakdown. In some cases, it is enough to replace the spark plugs or explosive wires, while in others the engine still needs to be repaired.

In this case, the spark on the candles will be normal, the injectors will also supply fuel, the compression measurement will not reveal any deviations from the norm, but the “check” in this case will still blink or blink.

The main signs by which you can determine problems with the DPKV crankshaft position sensor. Causes of failures, breakdowns, self-check.

When you sharply press the gas pedal, the engine jerks, jerks and dips appear, the car does not pick up speed: the main causes of the malfunction and diagnostics.

For what reasons may misfire of the fuel-air mixture occur in one or more cylinders? Fault diagnosis, recommendations.

Why does the check light light up on the dashboard? Is it possible to continue driving a car if the check engine light is on? What should you check first?

Why the engine may not pick up speed: gasoline engine, diesel unit, car with LPG. Fault diagnosis, useful tips.

The engine does not start after washing the engine: the main reasons why the power unit cannot be started. What can be done in such a case.

- ordinary user

- Group: Users

- Posts: 863

I really want to understand the logic of the car owner. Why was the decision made to replace the spark plug wires and module? And how do misadjusted valves shake the engine one day and light the check light, but the next day the engine does not shake?

“"Maybe someone has encountered this, where should I dig?" - I have come across the reasons for describing this behavior (the engine sometimes shakes or does not shake and the check wink) this forum is unlikely to be able to handle.

Debugg

You can fix the problems yourself, but the optimal solution is to undergo computer diagnostics of the Kia Rio. Options for the car owner:

- replacement of spark plugs, which are responsible for igniting the air-fuel mixture in the combustion chambers (consumable life is 20-30 thousand km);

- replacing the residual oxygen sensor (lambda probe), if it malfunctions, the on-board computer receives incorrect information about the state of the car (as a result, the performance decreases, the consumption increases, and the Kia Rio’s dashboard displays a burner);

- checking the tank cap and changing the gas station (the quality of the fuel plays a role; sometimes the CHECK light is on because of the fuel)

- checking the ignition coil and wires (resistance and presence of spark are determined).

If the Check light comes on and you have an amateur car scanner at hand, you can arrange a check and then fix the problem yourself. If difficulties arise, it is better to contact the service.

Resetting the error

When the check light is on for a Kia Rio, a check is required and then the problem is fixed.

Don't ignore the flashing light on your dashboard.

After completing the work, you will need to reset the error. In a car service center, the reset is carried out by a diagnostic computer . The service technician will fully diagnose the car, so it is better not to neglect this procedure as part of maintenance. Resetting the device is intuitive; all you need to do is follow the prompts .

Troubleshooting Kia Rio

Meaning and interpretation of error codes

To read the faults, first consider the list with a table of UEr errors that self-diagnosis produces (the author of the video is Ivan Vasilyevich).

These codes can add up; if you see the number 6, this may indicate errors 2 and 4, or if the number 9 is displayed, errors 1 and 8.

In order to immediately read and decipher problems when diagnosing, it is advisable to download and always carry with you a printout with a description. When diagnosing using a computer, codes on engine 21124 may differ depending on the car model. To read the codes, you need to know how they are supposed to be deciphered. Errors must be reset after they have been deleted (the video was filmed and published by the KV Avtoservis channel).

| Number | Decoding |

| p0102, p0103 | An incorrect pulse is supplied from the mass air flow sensor controller. This means you need to check the wiring. |

| p0112, p0113 | 112 or 113 - the incoming air temperature sensor needs to be replaced. |

| p0115-p0118 | Errors from 0115 to 0118 - the antifreeze controller sends an incorrect impulse. There may be problems with the wiring or the sensor itself. |

| p0122, p0123 | TPDZ. The controller is sending an incorrect signal. If the wiring is damaged, interference may occur. |

| p0130, p0131 | The lambda probe requires diagnostics and replacement. |

| p0135-p0138 | Error 0135 and higher - the lambda probe heating regulator needs to be replaced. |

| p0030 | The ECU reports problems in the electrical circuit in the area from the lambda probe heater to the converter. If error p0030 occurs, you need to test the electrical circuit and the sensors themselves. |

| p0036 | P0036 - a break in the wiring of the heating device DK-2 was detected. |

| p0300, p0302 | When codes 300 and 302 appear, the ECU reports a misfire. |

| p0301 | Gaps were detected in the cylinders of the power unit. Compression needs to be checked. |

| p0325 | The knock sensor is not working correctly. In particular, we are talking about a break in the connection wiring. |

| p0335, p0336 | P0036 error VAZ 2114 or 10335 - the DPKV has failed or its connection circuit is damaged. If the wiring is intact, then the sensor is replaced. |

| p0340 | Phase sensor malfunction. |

| p0341 | Error VAZ 2114 0341 means a problem with the camshaft controller. |

| p0342, p0343 | Problems with the phase controller. With such an error, detonation of the car engine is possible. Most likely, only replacement will solve the problem. |

| p0346 | P0346 VAZ error - also a problem with the phase regulator. |

| p0363 | P0363 - misfire of the combustible mixture was detected. In cylinders that refuse to work, the fuel supply is cut off. |

| p0422 | Failure to operate the neutralizing device. |

| p0443, p0444, p0445 | Malfunctions 0443, p0444 and 0445 - adsorber regulator, purge is not carried out. |

| p0480 | The engine cooling fan device has failed. The power unit may overheat if it is not replaced in a timely manner. Before replacing, you need to check the connection contacts to the wiring. |

| p0501-p0504 | Error 0501 VAZ 2114 and error code 0504 - the speed controller refuses to work. The device needs to be replaced. |

| p0505, p0506, p0507 | The idle speed sensor does not work or does not work correctly. Its failure can lead to floating idle speed. Possible engine tripping. The controller itself is tested and the wiring is checked. |

| p0607 | The knock controller operates intermittently. |

| p1135 | Error 1135 VAZ 2114 - you need to test the oxygen controller. |

| p6060 | Processor failure. If the fault remains after resetting the code, then the controller must be replaced. |

| p2020 | It is necessary to test the intake flap position sensor. |

| p1617 | Error 1617 - Rough road controller, wiring damage. |

| p1513 | There is a short circuit in the wiring of the idle speed sensor. It is necessary to test the electrical circuit and check the contacts. |

| p1602 | Failures in the voltage supply to the vehicle's electrical network are detected. |

| p0560 | Incorrect voltage level in the on-board network. This parameter can be overestimated or underestimated. The car battery, as well as the generator unit, are subject to testing. |

| p1514, p0511 | The appearance of these errors indicates a problem with a break or short circuit in the IAC (idle speed regulator) wiring. First of all, diagnose the sensor contacts, and then test the circuit, if possible. The sensor itself may also be damaged. |

| p1303 | P1303 - A detected misfire of the air-fuel mixture in the third cylinder is reported. The malfunction must be corrected as quickly as possible, since it can be critical for the neutralizer. |

| p1578 | Throttle valve malfunction. Literally, the problem stands for “zero adaptation parameter is outside the permissible value.” There are several options to solve the problem. The first thing you need to do is clean the throttle valve. If this does not help, then the throttle is adapted. To do this, you need to activate the ignition, and then start the engine after 40 seconds. Alternatively, you can test and tighten the contact terminals on the throttle. |

| p1621 | Malfunction of the RAM, memory problems in the control unit. Detailed testing of the computer is required. |

| p0650 | Problems in the control circuit of the on-board computer error code indicator State. |

| p2135 | P2135 - malfunction of the throttle assembly. If replacing the sensor and cleaning the damper did not help, then the problem may have to be solved by flashing the on-board computer. |

| p2187 | Lean mixture in internal combustion engine cylinders. You need to do a detailed diagnosis of the problem. |

Error code: Diagnostic connector on Lada Kalina: where is it located?

Why does the check light up? The most common and common malfunctions

So, we figured out the general scheme. Now let's look at what problems lead to the check light coming on and the engine stalling. Often a p0300 error occurs, which indicates that a misfire (misfire) is occurring. There are several reasons for these omissions, and to determine them it is necessary to carry out a step-by-step diagnosis, taking into account certain individual symptoms.

You should start by checking the ignition system. The most common cause of tripping is the failure of spark plugs and armored wires. Candles can wear out their service life, break down, or become heavily contaminated. Armored wires suffer from insulation damage and breakdowns. One way or another, the result is either no spark at all, or there is a spark, but it’s weak.

If everything is in order with the spark plugs and wires, you should pay attention to the ignition module or ignition coils, which may be shorting. In this case, it is better to entrust the check to experienced specialists, since unprofessional actions lead to the fact that you can burn the switch or damage other important elements

It should also be added that you need to carefully inspect the spark plug wells themselves. Quite often, the engine fails if water accumulates in the wells or engine oil gets there. In some cases, lubricant gets into the wells due to problems with the valve cover gasket.

Having dealt with the ignition system, it is necessary to check the power system. As a rule, incorrect operation of injection nozzles or malfunctions in their operation lead to engine tripping. At the same time, the check will light up or flash.

We also recommend reading the article about what misfires in engine cylinders are. In this article, you will learn about the causes of misfires and errors, as well as how to identify and fix the problem.

The best option would be to check the injectors on a special stand. Such diagnostics allows you to determine the need to clean, repair or replace injectors. At the same time, specialists check the power supply to the injectors, the condition of the injector O-rings, etc.

As for compression, a burnt-out valve often leads to an unexpected decrease in the indicator. If the valve burns out, the engine starts to run rough. In this case, tripling is constant and occurs in all modes of engine operation. Engine thrust drops significantly, and significant excess fuel consumption is observed.

Please note that in this case you cannot drive the car, as there is a high risk of damaging the catalyst and oxygen sensor (lybda probe). To confirm the diagnosis, you need to measure the compression, and to solve the problem itself, you need to remove the cylinder head, troubleshoot the head and change the valve.

Vehicle malfunction at idle

If the VAZ 2114 power unit idles at idle, then:

In the first case, the fuel system is flushed and the injectors are cleaned. To carry out the last work, ultrasound is used. In the second case, you will need to replace the spark plugs, high-voltage wires, and diagnose the ignition coils. In the latter case, the valves are replaced or readjusted.

If the power unit stalls while running hot, then auto mechanics advise carrying out similar work as described above. At idle speed with a heated engine, one cylinder may not work due to malfunctions in the fuel mixture supply system or lack of spark. In this case, it is recommended to carry out the same work as in case of failures during cold running.

Before you begin independent repair work, you need to find out what tripling of the power unit is. This concept means the operation of the engine without the participation of one of the cylinders. If such a process is accompanied by a blinking check, then the lambda probe, fuel tank filler cap, catalyst, air mass flow sensor are checked. The motor indicator icon appears without warning, so it is impossible to immediately find out the reason for the blinking check. Before repairing a VAZ, the electrical circuit and design features of the vehicle are studied.

If you lack experience and knowledge in the field of electromechanics, it is recommended to seek help from a specialized service.

Consistently unstable operation of the vehicle's power plant, with evenly repeating interruptions, when approaching the exhaust pipe, audibly perceived as the operation of a “tractor” means that the engine is “troubling.”

Reasons for unstable operation of the VAZ 2114 engine cylinder block

Communities Lada Priora Lada Priora Club Blog Ignition coil

In most cases, we hear as a diagnosis that the cylinder has failed. In fact, this formulation is not correct. The cylinder didn't work, that's it. Alas, you will like a lot about the circumstances of this incident:

- the spark plug is faulty or partially damaged;

- low compression in cylinders;

- the valves have not been adjusted for a long time or they do not fit well;

- the injectors are overfilled or clogged and require replacement;

- the high-voltage spark plug wire is broken;

- the oxygen sensor has failed;

- malfunction in the ignition coil;

- the electrical control unit has failed;

- The crankshaft position sensor (CPS) has failed;

- The timing belt, as it is also called, fell off completely; the timing belt moved several notches;

- The air filter is not working well or is very dirty.

The consequences of stopping the operation of the cylinder can be detected both immediately, that is, specifically when inspecting the machine, and in a delayed mode; these consequences are no longer safe for the machine.

- excessive vibration, which manifests itself due to a rhythm disturbance during the operation of the valves and, accordingly, all rotating parts of the engine and gearbox;

- significantly increased fuel consumption due to irregularities in the injection system and the appearance of a corresponding aroma of exhaust gases due to an increase in the concentration of harmful impurities and unburned fuel here;

- a noticeable drop in the power of the power plant and, accordingly, the maneuverability of the vehicle.

The check is blinking and the VAZ 2114 engine is tripping.

If, after detecting signs of engine “triple”, measures are not taken to identify and eliminate the circumstances of this phenomenon, this leads to wear and tear of the entire unit and its serious repair or replacement. It exists that gasoline is constantly injected into the idle cylinder, which, without burning, mixes with the incoming oil and goes into the crankcase. If this condition continues for a long time, the oil dilutes, loses its lubricating characteristics, and engine parts work in extreme conditions, wearing off and forming chips. The consequences will be felt in a short time and the engine will need to be sent to capital.

Cylinder failure

If the engine operates stable or unstable, it is recommended to check the cylinder. Its malfunction is associated with breakdown of the spark plugs, oxygen sensor and ECU. The cylinder can fail instantly or gradually. In the first case, the VAZ engine suffers, fuel consumption increases, engine power decreases, and vibration increases.

If the vehicle is not repaired in a timely manner, the engine may fail. This is explained by the fact that gasoline is constantly supplied to the broken cylinder, which is mixed with oil and goes into the crankcase. With a long process, the latter substance liquefies, losing its properties. The parts of the power unit begin to work in emergency mode, wearing out and forming chips.

If the check is flashing and the VAZ engine is shaking, then you must follow the following recommendations:

- start the power unit;

- open the hood lid;

- remove the wires from the spark plugs one by one.

The next step is to inspect the spark plugs for condition and performance. To do this, you will need to unscrew the spark plugs with a special key. If there is smoke on the head, and the electrode is clean and intact, then the motor tripping is due to dust getting into the cylinder. In this case, it is recommended to check the air supply system through the filter.

If the burn is on the entire head, and the electrode is completely burnt out, then detonation combustion has occurred and the ignition system has been emptied. If the head is covered with smoke, but the electrode is intact, then the mixture enters the ignition system late. By assessing the condition of the spark plugs, it is possible to determine the exact cause of the failure of the cylinder. To check the performance of spark plugs, it is recommended to use the “spark” method. If it breaks through, then the check continues. If there is no spark, then the spark plugs are replaced with new analogues. A good spark requires starting the VAZ and tracking the dynamics of changes.