What is a gear ratio? Quite often you can hear the question “what is a gear ratio” from car owners. In this article I will try to briefly cover this topic. So, transmission mechanisms transmit the rotation of one shaft to another, i.e. force the second shaft to rotate through the rotation of the first. This question was explored by Leonardo da Vinci. Some of his inventions are still used today in the designs of bicycles and even cars.

Thus, based on his sketches of gears, globoid worm gears, bevel gears, spiral gears and roller chains, the current vehicle gearbox mechanisms were developed. The gear ratio is the ratio of the angular speeds of the drive to the driven gear (wheels, shafts) or the ratio of the radii of the driven to the drive gear. In particular, gear ratios of a gearbox are determined by the ratio of the number of teeth of the driven gear to the drive gear. If several pairs of gears are involved in the transmission, the total gear ratio is the product of the gear ratios of all pairs of gears participating in the transmission.

General principle of operation of the checkpoint

The gearbox is an integral component of the transmission of a car equipped with an internal combustion engine. It serves to change the rotation speed depending on the speed of movement and the operating mode of the motor. Simultaneously with the variation in the number of revolutions of the output shaft, the torque supplied to the drive wheels increases or decreases. The larger the gear ratio, the more dynamic the acceleration will be, but the top speed will be lower.

The gearbox operates on the principle of transmitting rotation from one gear to another. To match the speed of the vehicle to the optimal engine speed, several pairs with different gear ratios are used. Switching between stages is carried out manually (manual transmission) or using a special mechanism (automatic transmission).

Results

For both manual and automatic transmissions, the gear ratio can be adjusted without any problems or difficulties. The only difference is that with a manual transmission you will still have to change gears yourself; the automatic will do the job for you.

The gear ratio is a good option to customize the car, get the most out of it and tailor it to your requirements. You can do this yourself or seek the help of professionals. In the second case, you must explain as precisely as possible what result you expect to get and the car will be set up for you. When changing the gear ratio yourself, carefully test the result obtained, make sure that everything works correctly and that the engine has enough power.

Undoubtedly, debugging the gear ratio is adjusted individually for each driver. Here it is necessary not only to be guided by the technical characteristics, but also to feel the car very well. The gear ratio allows you to significantly accelerate the acceleration of the car and increase its speed. The most important thing is that the gear ratio is suitable for the power of the car, then it will serve you faithfully for many years.

How to calculate gear ratio

Drivers rarely need to determine the gear ratio (ratio) of a gearbox. The main reason is the modernization of the transmission to obtain better dynamic characteristics. The transmission ratios of the gearbox of different stages are set by the designer when designing the car. They are selected based on the power parameters of the engine and the intended purpose of the vehicle. For the average driver, the transmission ratios of the main and reduction gears are laid down, ensuring the greatest efficiency. Those who want to give their car more dynamics calculate the characteristics themselves.

Calculation without resistance

You can find out the transmission coefficient in the accompanying documentation for the unit (box or rear axle gearbox). When there is no document, the calculation is carried out independently. To do this, compare the number of revolutions on the input and output shafts. Determination of the gear ratio of the main gear pair of the rear axle:

- Raise the drive wheel by lifting the car with a jack.

- Place a mark on the gearbox input shaft or cardan. The second mark is placed on the hanging wheel.

- By rotating the hub, the revolutions of the propeller shaft are counted. When the wheel rotates 360°, evaluate the position of the second mark.

- The gear ratio is determined by dividing the number of revolutions of the input shaft by 1 (wheel rotation). The resulting value is compared with standard values.

For your information!

For a more accurate calculation, the wheel is turned 10 times.

In front-wheel drive cars, the main pair is located in the gearbox. The coefficient is determined according to a similar principle:

- Remove the right front wheel, allowing access to the engine pulley.

- Place marks on the hub and shank of the crankshaft.

- Engage 1st gear and rotate the pulley, counting the revolutions. When the hub rotates 360°, the gear ratio is calculated.

- The procedure is performed for all speeds.

To calculate the final drive gear ratio, it is necessary to compare the technical data with the results obtained. To do this, find reference tables on the Internet where the characteristics of typical gearboxes are indicated and select the matching model.

Gear efficiency

A more accurate calculation of the transmission involves calculating the torque taking into account all resistances. The transmission of rotation from the engine to the wheels occurs with small friction losses in gear pairs, bearings and seals. This interference reduces the output torque and compensates for it by increasing engine power. When calculating, the efficiency of cylindrical and bevel gears is used. In the first case it is 0.98, in the second - 0.97.

General definition

A clear example of changing the number of revolutions is most easily observed on a simple bicycle. A man pedals slowly. The wheel rotates much faster. The change in the number of revolutions occurs due to 2 sprockets connected in a chain. When the large one, which rotates with the pedals, makes one revolution, the small one, standing on the rear hub, rotates several times.

Torque transmissions

The mechanisms use several types of gears that change torque. They have their own characteristics, positive qualities and disadvantages. Most common transmissions:

- belt;

- chain;

- serrated

Belt drive is the simplest to implement. It is used when creating homemade machines, in machine tools to change the speed of rotation of the working unit, in cars.

The belt is tensioned between 2 pulleys and transmits rotation from the driver to the driven. Performance is poor because the belt slides on a smooth surface. Thanks to this, the belt assembly is the safest way to transmit rotation. When overloaded, the belt slips and the driven shaft stops.

The transmitted number of revolutions depends on the diameter of the pulleys and the coefficient of adhesion. The direction of rotation does not change.

The transitional design is a belt gear drive.

There are protrusions on the belt and teeth on the gear. This type of belt is located under the hood of the car and connects the sprockets on the axles of the crankshaft and carburetor. When overloaded, the belt breaks, since it is the cheapest part of the unit.

The chain consists of sprockets and a chain with rollers. The transmitted speed, force and direction of rotation do not change. Chain drives are widely used in transport mechanisms and on conveyors.

Gear Characteristics

In a gear drive, the driving and driven parts interact directly through the meshing of teeth. The basic rule for the operation of such a node is that the modules must be identical. Otherwise, the mechanism will jam. It follows that the diameters increase in direct proportion to the number of teeth. Some values can be replaced by others in calculations.

Modulus is the size between identical points of two adjacent teeth.

For example, between axes or points on an involute along the center line. The module size consists of the width of the tooth and the gap between them. It is better to measure the module at the point of intersection of the base line and the axis of the tooth. The smaller the radius, the more the gap between the teeth along the outer diameter is distorted; it increases towards the top from the nominal size. Ideal involute shapes can practically only be found on a rack. Theoretically, on a wheel with a maximally infinite radius.

The part with fewer teeth is called a gear. Usually it is leading, transmitting torque from the engine.

The gear wheel has a larger diameter and is driven in a pair. It is connected to the working unit. For example, it transmits rotation at the required speed to the wheels of a car or the spindle of a machine tool.

Typically, gearing reduces the number of revolutions and increases power. If in a pair there is a part with a larger diameter, the drive gear, at the output, the gear has a greater number of revolutions and rotates faster, but the power of the mechanism decreases. Such gears are called downshifts.

Why do we need a parasite?

When the gear and wheel interact, several quantities change at once:

- number of revolutions;

- power;

- direction of rotation.

Only in planetary units with teeth cut along the inner diameter of the ring, the direction of rotation is maintained. With external gearing, two identical gears are placed in a row. Their interaction does not change anything except the direction of movement. In this case, both gear parts are called gears, the wheel is not. The second, intermediate, is called “parasitic”, since it does not participate in the calculations and only changes its sign.

Types of gear connections

Gearing can have different tooth shapes on parts. This depends on the initial load and the location of the axes of the mating parts. There are types of gear movable joints:

- straight teeth;

- helical;

- chevron;

- conical;

- screw;

- worm

The most common and easiest to perform is spur gearing. The outer surface of the tooth is cylindrical. The arrangement of the gear and wheel axes is parallel. The tooth is located at right angles to the end of the part.

When it is not possible to increase the width of the wheel, but a large force must be transmitted, the tooth is cut at an angle and thereby increases the contact area. The calculation of the gear ratio does not change. The unit becomes more compact and powerful.

The disadvantage of helical gearing is the additional load on the bearings. The force from the pressure of the leading part acts perpendicular to the contact plane. In addition to the radial force, an axial force appears.

The chevron connection allows you to compensate for the stress along the axis and further increase the power. The wheel and gear have 2 rows of oblique teeth directed in different directions. The transmission number is calculated similarly to a spur gear according to the ratio of the number of teeth and diameters. Chevron gearing is difficult to implement. It is installed only on mechanisms with a very heavy load.

In a bevel gear transmission, the axes are located at an angle. The working element is cut along a conical plane. The gear ratio of such pairs can be equal to 1, when it is only necessary to change the plane of action of the force. To increase power, a semicircular tooth is cut. The transmitted number of revolutions is calculated only by tooth; the diameter is mainly used when calculating the dimensions of the unit.

The helical gear has a tooth cut at an angle of 45⁰. This allows the axes of the working elements to be positioned perpendicularly in different planes.

A worm gear does not have a gear; it is replaced by a worm. The axes of the parts do not intersect. They are located perpendicularly in space, but in different planes. The gear ratio of a pair is determined by the number of thread starts on the worm.

In addition to those listed, other types of gears are also produced, but they are extremely rare and are not standard.

Multi-stage gearboxes

How to choose the right gear ratio. The engine usually produces several thousand revolutions per minute. At the output - the wheels of the car and the spindle of the machine, such a rotation speed will lead to an accident. The power of the actuating mechanism is not enough for the working tool to cut metal and the wheels to move the car. One pair of gears will not be able to provide the required reduction, or the driven part must be of enormous size.

A multi-stage knot with several pairs of gears is created. The gear ratio is calculated as the product of the numbers of each pair.

Uр = U1×U2 × … ×Un;

Where:

Uр – gear ratio;

U1,2,n – each of the pairs.

Before choosing the gear ratio, you need to decide on the number of pairs, the direction of rotation of the output shaft, and do the calculation in reverse order, based on the maximum permissible wheel dimensions.

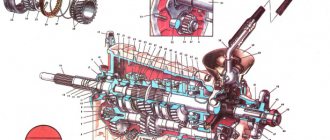

In a multi-stage gearbox, all the gear parts located between the drive gear at the input to the gearbox and the driven ring gear on the output shaft are called intermediate. Each individual pair has its own gear, gear and wheel.

Gearbox and gearbox

Any gearbox with gears is a gearbox, but the reverse is not true.

The gearbox is a gearbox with a movable shaft on which gears of different sizes are located. Shifting along the axis, it includes first one or another pair of parts in the work. The change occurs due to the alternate connection of various gears and wheels. They differ in diameter and transmitted number of revolutions. This makes it possible to change not only the speed, but also the power.

Car transmission

In the machine, the translational movement of the piston is converted into rotational movement of the crankshaft. The transmission is a complex mechanism with a large number of different components interacting with each other. Its purpose is to transmit rotation from the engine to the wheels and regulate the number of revolutions - the speed and power of the car.

The transmission includes several gearboxes. This is, first of all:

- gearbox - speeds;

- differential.

The gearbox in the kinematic diagram is located immediately behind the crankshaft and changes the speed and direction of rotation.

By switching - moving the shaft, the gears on the shaft are connected alternately to different wheels. When the reverse gear is engaged, the direction of rotation changes through the parasite, and as a result the car moves backwards.

The differential is a bevel gear with two output shafts located in the same axis opposite each other. They look in different directions. The gear ratio of the gearbox - differential is small, within 2 units. It changes the position of the axis of rotation and direction. Due to the arrangement of bevel gears opposite each other, when engaged with one gear, they rotate in one direction relative to the position of the vehicle's axle, and transmit torque directly to the wheels. The differential changes the speed and direction of rotation of the driven tips, and behind them the wheels.

What does the gear ratio affect?

The transmission parameter directly affects the traction and speed properties of the car. For production vehicles, the average gear ratio is used. This means that the car will accelerate moderately in the city cycle and on the highway. In this mode, transmission parts wear out evenly, tires wear out less, and fuel is consumed within optimal limits.

Changing the gear ratio directly affects the speed characteristics of the car. By increasing the parameter, we achieve an increase in torque on the drive wheels. This leads to the fact that the car starts faster from a standstill, accelerates faster, and the engine reaches peak power earlier. However, in this case, fuel consumption increases and the maximum speed decreases. Reducing the gear ratio worsens the dynamics of the car: the car becomes “slow” and picks up speed more slowly. However, for lovers of size driving, such transmission tuning will bring benefits in terms of reducing fuel consumption.

Conclusion

Modern cars are quite complex mechanisms, where a large number of elements predominate, the operation and structure of which every motorist should know (at least basic knowledge). If you have this information, you can eliminate the possibility of getting into a difficult situation when there is simply no one to turn to for help, and nowhere. Of course, a car enthusiast will not be able to master all the aspects regarding the gear ratio. However, you should highlight the key aspects for yourself so that you will subsequently be able to make the most of your car’s lifespan, without causing structural elements to become overloaded and subsequently fail.

How can you use the gear ratio?

The gear ratio is the ratio of the pitch diameters of the gears (driven and driven). This criterion is primarily used by transmission designers when developing a car. They select the optimal parameters in conjunction with the power unit, which are suitable for mass production.

For your information! Some models that come off the assembly line may have differences in the transmission, aimed at changing the traction and speed properties of the car.

Drivers of production vehicles can also vary the gear ratio. If the car's dynamics are unsatisfactory and high speed is not needed, the transmission is inspected and the main gear or gearbox is replaced. In this case, an increase in torque on the wheel drive is achieved. This modernization allows the engine to quickly reach the speed at which maximum power output occurs. The car will respond more quickly to pressing the accelerator, and its dynamics will improve significantly.

The gear ratio has a serious impact on the dynamic performance and characteristics of the vehicle. When designing a transmission, engineers separately take into account engine power and the intended purpose of the vehicle, and then select the optimal parameters for all gears. When modernizing, the feasibility of certain modifications is taken into account, as well as the modes in which the machine will be operated.

Why do you need a manual transmission?

The first reason is clear - you need to somehow connect the rotating engine shaft to the wheel drives in order to get moving. There is a second one: the power unit develops operating power (in other words, maximum torque) when it reaches a certain number of crankshaft revolutions. For most gasoline engines, this threshold is 3000 rpm, for diesel engines – 2000 rpm.

For dummies, that is, beginners who want to understand the operation of automotive components, the following explanation is offered:

- During work on site (idling), the crankshaft speed is 800-900 rpm. To start moving, the developed power is not enough and you need to increase it by pressing the gas and increasing the speed to 2-3 thousand per minute. At this moment, you need to connect the wheel drive, which is done using the gearbox.

- Without a manual transmission, the acceleration of the car will be smooth and incredibly long, and if there is an incline, the car will never accelerate. The reason is the same - lack of power. To increase dynamics, you need a force converter that can slow down the rotation but increase the torque.

- To turn and park, the car needs reverse gear, which is also provided by a manual transmission.

If you put a gear train with gears of different sizes between the wheel drive and the crankshaft, the wheels will rotate more slowly. But at the same time, the force on each wheel will increase (in the jargon - traction) and the acceleration of the car will accelerate. And the smooth connection of the rotating elements will be ensured by another manual transmission unit - the clutch.

How to choose a spinning reel

So, here we have looked at the main parameters. Now it’s worth summing up and understanding how to choose the right reel for a spinning rod. This is quite difficult, but what can you do? A reel is an integral part of fishing and fishing equipment. Sometimes both the technical part of this process and the very pleasure that every fisherman receives while fishing depends on its choice.

To begin with, you need to decide where you will fish, how often, and what kind of spinning rod. There are different types of reels and they are all designed for specific bodies of water. Also, if you already have a spinning rod, then choose a reel for it. If you don’t have a spinning rod, then it makes sense to choose it along with a reel. Although they are universal, it is still better when the gear matches each other and is individually selected.

The next step is to determine how often you will go fishing. If you use it regularly, then you should buy a reel that is reliable and unpretentious, and does not require frequent maintenance and repair. If you travel only occasionally, then you should take a reel that won’t hurt your pocket and can pay for itself.

Next, it is important to understand what kind of fish you are going to catch and with what gear. Will it be a large one, or, on the contrary, a small individual?

Study the gear market for a particular reel and type of fishing, choose the fishing line and bait that suits you. There is a lot of information on the Internet, you can compare several manufacturers and decide.

Also, buying a reel also depends on what level of proficiency you have. Whether you are a beginner, an experienced one, or even a professional. If you already have experience in owning a spinning rod, then buying and choosing a reel will be much easier for you.

You can also ask a consultant directly at the tackle store. He will tell you and demonstrate on the spot the difference in coils, show you all the types and their advantages. It is very comfortable.

For those who have not yet decided, you can find out from special experts and knowledgeable people.

Watch this video on YouTube

Transmission gears and the coolness of the car, how are they related?

Knowing the concept of gear ratio, as well as its effect on speed, acceleration dynamics and fuel efficiency, allows you to choose the optimal driving mode. This parameter is of decisive importance for any car, regardless of its price and age. Few people know, but a competent analysis of the technical parameters before purchasing allows you to choose a car that ideally meets the owner’s needs. Let's consider the main aspects that need to be taken into account when choosing.

Tuning

Domestic tuning is a legacy of the Soviet automobile industry, where three types of passenger cars were produced for the largest country in the world. A body kit, LED “BMW eyes” and a leaky straight-through muffler “Maserati sound” allow owners of domestic cars to at least somehow stand out from the faceless stream. “Advanced and handy” car enthusiasts go further and deeper, making design changes to the engine and transmission.

It is believed that “shortening” the box is very cool. Fans of fast driving can purchase instead of standard pairs (rows) of gears, alternative ones that increase the gear ratio. For example, the value for the main pair of VAZ 2107 in the factory gearbox is 3.9, for the VAZ 2108 - 3.8. Change to 4.1 or more, up to 5.1. Yes, this allows the car to “shoot” from a standstill, but it worsens other characteristics. Fuel consumption and engine wear increase, maximum speed decreases, and you have to switch frequently. Excessive gearbox tuning instead of thrills can lead to disappointment.

Source

Types of spinning reels

Technically, the term “spinning reel” applies only to spinning reels—“meat grinders.” Inertial reels, although they can be installed on a spinning rod, are now almost never fished with archaic inertial reels like “Nevsky” ones, and for modern multiplier inertial reels there is a separate class of rods - casting rods, which have a special finger trigger and a special ring design. You can read more about them in this article.

Spinning reels

Most fishermen use the term “spinning reel” to mean spinning reels. Having appeared at the end of the 19th century, spinning reels gained enormous popularity, first in Europe, and then throughout the world, with the exception of the United States, where at that time a long-standing culture of using multipliers had already developed.

Inertia-free casters are easy to maintain and inexpensive, and their most outstanding quality is their long casting range and ease of casting, as well as effective work with small baits and thin tackle. Further in the article we will talk specifically about the choice of inertia-free coils.

You can read about other types of reels that you can install on a spinning rod at the end of the article.

We often hear the same question from people who are just starting to master fishing skills and are thinking about choosing a spinning reel: what gear ratio should the reel mechanism have and what size spool is suitable for certain fishing methods?

The size of the spool, as well as the gear ratio, is a fundamental characteristic of the reel. Different manufacturers have their own standards, but most often on Japanese reels there are markings 1000, 1500, 2500, and on European ones - the last digits of the article or markings 20, 25, 30. The larger the number, the heavier class the reel belongs to. The spool on the skirt also indicates its line capacity.

So, you need to choose a reel in accordance with the fishing method and the class of the rod. For the ultra-light and light class, reels up to size 2000 or size 20 are suitable; for average - 2500, 3000 or 25, 30; for heavy - 4000 or more. When choosing a reel, you should also take into account its weight so that all the gear is balanced. You shouldn’t put a 2000 reel on a heavy class rod, and a 4000 on a light spinning rod.

In my opinion, the more the better. In any case, there is a friction. the main thing is that there are more bearings.. and features in the size of the spool.. depending on what kind of fishing line you have.

if memory serves

The higher the ratio, the “stronger” the reel is, designed for catching large fish. That is, all other things being equal, the ratio 5:1 will be steeper than 5:2. And for herbal plants, almost any ratio will do, as long as it rotates. Moreover, as a rule, as the number of bearings increases, the price becomes more expensive. Therefore, it seems to me that we should be guided by the possibility of a pocket.

on the contrary, the lower, the stronger.

that's right, I remembered it the other way around

In general, everything is simple here, I try to take reels that have 2 spools, because it is convenient. We wind a braided cord on one spool and a monofilament line on the other. And if necessary, we use one or the other on our fishing trips. But this criterion is not strict, so if you find a cool reel, but with one spool, do at your own discretion.

A very important thing, since it affects the operation of the entire gear as a whole. If the reel is poorly laid, then problems may appear during fishing, such as loops, “beards”, etc. This affects casting and line coming off the spool. There are several ways to find out what type of coil is laid:

Diawa + Shimano = perfect fit. Why? I wrote about this in the first paragraph.

The presence of an endless screw in the coil. This is a technology that allows you to lay the line perfectly. You should ask the seller about its presence in the reel.

Search the Internet and read reviews. Moreover, I would relate this point to the entire article as a whole, since now is the 21st century and on thematic forums you can find a lot of information on specific models.

That's all that is important to consider when choosing the right reel for your feeder

I would like to draw your attention to the fact that feeder reels, as a rule, are not marked feeder, although everything is changing. As a rule, manufacturers make coils for specific tasks, but there is a wide variety of coils

Therefore, do not be shy about the various inscriptions on the boxes, look at the coil through the prism of the technical characteristics that we discussed above, read thematic forums, and you will not miss when choosing a feeder coil.

Master of Sports in Feeder

Specifics of operation of the rear axle gearbox

During vehicle operation, gears cling to each other with their teeth, however, even observing high metrological standards of production and adjustment, it is impossible to avoid their wear. Gears are made from high quality hardened steel. The gear housing is filled with special oil. Since the oil, being liquid, periodically tends to leak out of the cracks of the housing, to solve this problem, special gaskets called oil seals are used in the areas where the shafts exit. Unfortunately, the service life of the oil seals is significantly lower than the gears themselves, so when they wear out, the gear housing often contains oil smudges. If the oil completely leaks out (this happens if the seals are not replaced in a timely manner), the life of the gearbox is reduced significantly. In addition, dust and dirt tend to get through worn oil seals. To prevent such phenomena, it is recommended to check the gear housing from time to time using an inspection hole.

Gear ratio

This is the name of a mechanism that uses wheels with teeth in mesh. It is considered the most rational and in demand for mechanical engineering. There are many different options for manufacturing such wheels, differing in the location of the axles, the shape of the teeth, the method of their engagement, etc. As in the case of a chain gear, for a gear gear the gear ratio is determined by dividing the number of gear teeth (z2/z1).

The variety of options for constructing gear drives makes it possible to use them in different conditions, from low-speed gearboxes to high-precision drives.

Gear transmission is characterized by:

- constant gear ratio;

- compactness;

- high efficiency;

- reliability.

One of the types of gear transmission is considered to be a worm gear. It is used in cases where torque is transmitted between crossing shafts, for which an element such as a worm is used, which is a screw of a special design with a thread. To determine the gear ratio of the worm gear, divide the number of teeth of the (worm) wheel z2 by the number of worm thread starts z1.

Planetary gear

This type of gear train contains wheels with geometric axes that can move. What it is can be understood from the figure below. In fact, this is already the design of a kind of planetary gearbox, which includes a certain number of gears that interact with each other. Each of them has its own name - sun, crown, satellite.

For such a planetary gearbox, the change in torque depends on which of its gears is stationary, to which the torque is applied, and from which it is removed.

Whenever a planetary gearbox is used, one of its three elements will be stationary. This planetary option for constructing gears, in relation to a simple gear or belt, has the opportunity to obtain a significant change in torque with a small number of wheels and the dimensions of the device. In a car, such a planetary device has its own scope of application - as part of an automatic transmission, as well as in hybrid vehicles, to ensure the joint operation of the internal combustion engine and the electric motor. Planetary gearboxes are widely used in tracked vehicles.

Belt drive ratio

A belt drive refers to two pulleys that are connected by a belt, as shown in the figure. It is possible that it was one of the first methods used by man. The material used to make the belt changed, its shape changed, but the gear ratio remained unchanged, defined as the frequency of dividing the speed of the drive shaft by the speed of the driven one, or as a result of dividing the number of revolutions of these shafts (n1/n2 or ω1/ω2). For a belt drive, it can be calculated using the diameters (radii) of the pulleys. The gear ratio in this case is also determined as the quotient of the division of revolutions.

If, during energy conversion, the speed decreases, that is, the gear ratio is greater than 1, then the transmission will be reduction, and the device itself is called a gearbox. If the result is less than one, then the device is called a multiplier, although it also functions as a reducer, only a step-down one. The gear ratio of the gearbox allows you to reduce the number of revolutions (angular velocity) coming from the drive shaft to the driven shaft, while increasing the transmitted torque.

This property of the gearbox makes it possible for engineers, when designing various devices, to change the parameters of the transmitted energy, and the gear ratio of the gearbox serves as a powerful tool in solving the problem.

Despite its considerable age, the belt drive is still used on cars; it is used as a drive for a generator, a gas distribution mechanism, and also in some other cases.