Each component and mechanism of the car is important in its own way. There is probably no system without which a car could function normally. One such system is the steering mechanism. This is probably one of the most important parts of the car. Let's look at how this unit works, its purpose, and structural elements. We will also learn how to regulate and repair this system.

Operating principle of rack and pinion steering rod

Rack and pinion steering

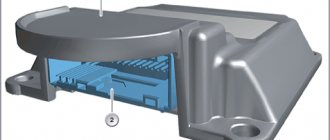

Rack and pinion steering is the most common type of mechanism installed on passenger cars. The main elements of the steering mechanism are the gear and the steering rack. The gear is mounted on the steering wheel shaft and is in constant mesh with the steering (gear) rack. Rack and pinion steering diagram

1 – sliding bearing; 2 – high pressure cuffs; 3 – spool body; 4 – pump; 5 – compensation tank; 6 – steering rod; 7 – steering shaft; 8 – rack; 9 – compression seal; 10 – protective cover. The rack and pinion steering mechanism works as follows. When you rotate the steering wheel, the rack moves left or right. As the rack moves, the steering rods attached to it move and rotate the steered wheels.

The rack and pinion steering mechanism is distinguished by its simplicity of design and, as a result, high efficiency, and also has high rigidity. But this type of steering mechanism is sensitive to shock loads from road unevenness and is prone to vibration. Due to its design features, rack and pinion steering is used on front-wheel drive vehicles

Worm steering gear

Worm gear diagram

This steering mechanism is one of the "obsolete" devices. Almost all models of domestic “classics” are equipped with it. The mechanism is used on off-road vehicles with dependent suspension of the steered wheels, as well as in light trucks and buses.

Structurally, the device consists of the following elements:

- steering shaft

- worm-roller transmission

- crankcase

- bipod

The worm-roller pair is in constant engagement. The globe worm is the lower part of the steering shaft, and the roller is attached to the bipod shaft. When the steering wheel rotates, the roller moves along the teeth of the worm, due to which the steering bipod shaft also rotates. The result of this interaction is the transmission of translational movements to the drive and wheels.

The worm type steering mechanism has the following advantages:

- possibility of turning wheels to a greater angle

- shock absorption from road irregularities

- high force transmission

- ensuring better machine maneuverability

Manufacturing the structure is quite complex and expensive - this is its main disadvantage. Steering with such a mechanism consists of many connections, periodic adjustment of which is simply necessary. Otherwise, you will have to replace damaged elements.

Steering device

Let's consider the steering device of wheeled vehicles with steered wheels. Structurally, the steering consists of:

- steering gear;

- amplifier;

- steering drive.

The steering layout of a truck with steered wheels of the first axle (KAMAZ, MAZ) is shown in the figure. The use of adjustable steering columns allows you to change the tilt angle in steps, usually in steps of 5° within a range of up to 40°. Steering with front steered wheels is used in two- and three-axle vehicles. The layout and design of the steering control are relatively simple and can, in principle, be reduced to the diagrams shown in the figure.

Rice. Steering diagrams for cars with steered wheels on the front axle: a - with a rear continuous trapezoid; b - with a split trapezoid and a pendulum lever; c — with rack and pinion steering mechanism; g - with a split trapezoid and two pendulum arms; d - with dismembered steering shaft; e - with anterior continuous trapezoid; g - with a split trapezoid and two pendulum arms directed backwards; h - with a continuous trapezoid and one pendulum arm; and - with a continuous trapezoid and combined power steering; k - with continuous trapezoid and separate power steering

On four-axle vehicles, steering is most often installed with rotation of the wheels of the first and second axles, the first and fourth, or all axles.

We recommend: How do car window closers work?

For multi-axle (six-axle) heavy-duty chassis, steering is used with rotation of the wheels of the first three axles (in the latest schemes, self-aligning rotary wheels are used on the sixth axis to increase maneuverability). When the car moves in a straight line, the caster wheels, connected to each other by a drive, are blocked by a special device. When driving in a turn with increased trajectory curvature, these wheels are unlocked and turn freely in tracking mode.

Fundamental differences between “left” and “right” drive

There is still controversy surrounding right-hand drive cars. Supporters argue that those cars that were made by Japanese or English engineers “as if for themselves” are higher in quality than similar models, but released for export. It is difficult to say whether this is really the case, but the fact remains: there is a separate category of car enthusiasts who prefer only right-hand drive cars.

The main difference between the steering of right-hand drive cars is the mirror arrangement of the elements. For example, placing the gearbox on the steering rack. And the gearbox itself is designed for the other side of the connection.

Is it possible to convert a right-hand drive car to a left-hand drive car? You can buy a right-hand drive car and then move the steering wheel to the left, and there are even service stations that specialize in such services. But the price of such tuning is quite high, since there will be a lot of “reshaping” to be done. It's not just a steering wheel on the other side; a lot of things are different, from the mirrors to the headlights.

Car steering requirements

According to the standard, the following basic requirements apply to steering:

- Ensuring a given trajectory of movement with the necessary parameters of agility, turning ability and stability.

- The force on the steering wheel to perform the maneuver should not exceed the normalized value.

- The total number of steering wheel revolutions from the middle position to each of the extreme positions should not exceed the established value.

- If the amplifier fails, the ability to drive the vehicle must be maintained.

There is another standard parameter that determines the normal functioning of the steering - this is the total play. This parameter represents the angle of rotation of the steering wheel before the steering wheels begin to turn.

The value of the permissible total play in the steering must be within the limits:

- 10° for cars and minibuses;

- 20° for buses and similar vehicles;

- 25° for trucks.

Advanced Developments

This unit continues to be improved, so the latest achievements are the following systems:

- Active (dynamic) steering. It allows you to change the gear ratio of the mechanism depending on the speed of the car. It also performs an additional function - adjusting the angle of the front wheels when cornering and when braking on slippery roads.

- Adaptive steering (steering by wire). This is the newest and most promising system. There is no direct connection between the steering wheel and the wheels; everything works due to sensors and actuators (servos). The system has not yet become widespread due to psychological and economic factors.

Steering-by-wire system

Some features of the car steering system

Most modern car models have an innovative four-wheel steering system. Thanks to this, the dynamics of vehicle movement in areas with difficult terrain are significantly improved. In addition, the car's steering is adapted to all wheels, allowing for greater maneuverability during high-speed driving. This is possible due to the rotation of each of the wheels.

It is noteworthy that in the steering system, wheel steering can be carried out by the system in passive mode. This is possible due to the presence of special elastic rubber-metal parts in the design of the rear part of the suspension. When body roll occurs, due to changes in the magnitude and direction of the load, the direction of movement is changed. Steering with rear wheel steering function allows you to effectively distribute the force to turn all wheels. In addition, such a system does not allow the wheels to turn when the suspension is active.

The design of the adaptive steering system includes hinges and rods. The hinge has several elements in its composition; for ease of use, its design is presented in the form of a removable tip. It is most convenient to imagine the kinematic diagram of a car’s steering in the idea of a rectangle, on each side of which there are:

- shoulders;

- toe angle;

- camber;

- longitudinal and transverse slope.

The shoulders, longitudinal and lateral inclination ensure movement stabilization, while other parameters are in constant opposition. Therefore, another task of the steering is to stabilize all forces arising during the movement.

Features of the unit and design

Cars use a kinematic method of changing the direction of movement, implying that turning occurs by changing the position of the steered wheels. Usually the front axle is steered, although there are also cars with a so-called steering system. The peculiarity of working in such cars is that the wheels of the rear axle also turn when changing direction, albeit at a smaller angle. But so far this system has not received widespread use.

In addition to the kinematic method, the technique also uses the power method. Its peculiarity is that to make a turn, the wheels on one side slow down, while on the other side they continue to move at the same speed. And although this method of changing direction has not become widespread in passenger cars, it is still used on them, but in a slightly different capacity - as a directional stability system.

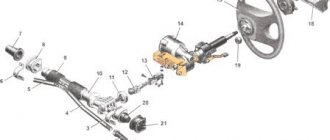

This car assembly consists of three main elements:

- steering column;

- steering gear;

- drive (system of rods and levers);

Steering unit

Each component has its own task.

Main causes of malfunction

The vehicle control system, like all its mechanisms, is susceptible to breakdowns.

We recommend: Types, design and principle of operation of car airbags

In most cases, they can be predicted in advance due to the presence of previous symptoms.

The system can be damaged by adverse events, such as:

- improper operation of the vehicle, expressed in an aggressive driving style;

- poor quality road surface, presence of potholes and uneven surfaces;

- installation of non-original spare parts during the replacement procedure;

- incompetent repair work;

- untimely service;

- Exceeding the service life of the equipment.

Problems that arise with the vehicle control system while the vehicle is moving can cause accidents. Therefore, you should listen to signs that are harbingers of trouble.

Steering rack repair stages

Repairing power steering or power steering racks cannot be carried out without special equipment. In addition, the auto mechanic must be experienced, since restoring the mechanism is not easy. To repair the steering rack, you need to perform several steps in the following sequence:

- We disassemble the mechanism, clean the elements, and find the breakdown.

- If some parts cannot be restored, we install new ones.

- Clean and inspect the gear shaft.

- We install new oil seals, boots, rings.

It is important to carry out repair work in a clean, dust-free room. If contamination gets into the mechanism, the oil seals will fail ahead of schedule, resulting in leaks. The optimal solution is to fix the rail in a vice, or you can put it on a cardboard sheet.

Important! Do not clamp the mechanism in a vice with great force, since the rack is made of brittle aluminum, a crack may form or deformation may occur.

Steering column

Transmits the rotational force that the driver creates to change direction. It consists of a steering wheel located in the cabin (the driver acts on it, rotating it). It is firmly mounted on the column shaft. The design of this part of the steering very often uses a shaft divided into several parts connected to each other by cardan joints.

This design was made for a reason. Firstly, this allows you to change the angle of the steering wheel relative to the mechanism, shifting it in a certain direction, which is often necessary when assembling the components of a car. In addition, this design makes it possible to increase the comfort of the cabin - the driver can change the position of the steering wheel in terms of reach and tilt, ensuring its most comfortable position.

Secondly, the composite steering column tends to “break” in the event of an accident, reducing the likelihood of injury to the driver. The bottom line is this: during a frontal impact, the engine can move back and push the steering mechanism. If the column shaft were solid, changing the position of the mechanism would lead to the shaft with the steering wheel exiting into the cabin. In the case of a composite column, the movement of the mechanism will only be accompanied by a change in the angle of one component of the shaft relative to the second, and the column itself remains stationary.

Helical steering mechanism

The screw steering mechanism combines the following structural elements: a screw on the steering wheel shaft; a nut that moves along the screw; a toothed rack cut into a nut; a gear sector connected to a rack; steering bipod located on the sector shaft.

A special feature of the screw steering mechanism is that the screw and nut are connected using balls, which results in less friction and wear of the pair.

Fundamentally, the operation of a screw steering mechanism is similar to the operation of a worm gear. Turning the steering wheel is accompanied by rotation of the screw, which moves the nut attached to it. In this case, the balls circulate. The nut, through a gear rack, moves the gear sector and with it the steering bipod.

A screw steering mechanism, compared to a worm gear, has greater efficiency and realizes greater forces. This type of steering mechanism is installed on certain luxury cars, heavy trucks and buses.

Drive unit

The drive in the steering design is used to transmit the movement of the rack or bipod to the steered wheels. Moreover, the task of this component is to change the position of the wheels at different angles. This is due to the fact that the wheels move along different radii when turning. Therefore, when changing the trajectory of movement, the wheel on the inside must turn at a larger angle than the outside.

The design of the drive depends on the mechanism used. So, if a car uses a “rack and pinion”, then the drive consists of only two rods connected to the steering knuckle (the role of which is played by the shock absorber strut) via a ball end.

These rods can be attached to the rail in two ways. Less common is their rigid fixation with a bolted connection (in some cases the connection is made through a silent block). For such a connection, a longitudinal window is made in the mechanism body.

A more common method of connecting rods is a rigid but movable connection to the ends of the rail. To ensure such a connection, a ball tip is made at the end of both rods. By means of a nut, this ball is pressed against the rail. When the latter moves, the rod changes its position, which ensures the existing connection.

In drives that use a worm-roller mechanism, the design is much more complex and consists of a whole system of levers and rods, called a steering linkage. So, for example, on the VAZ-2101 the drive consists of two side rods, one middle rod, a pendulum arm and steering knuckles with levers. At the same time, to ensure the possibility of changing the angle of the wheel position, the steering knuckle is attached to the suspension arms using two ball joints (upper and lower).

A large number of component elements, as well as connections between them, makes this type of drive more susceptible to wear and backlash. This fact is another reason for abandoning the worm gear in favor of a rack and pinion mechanism.

Steering purpose

To carry out the movement of a vehicle (V) along a trajectory chosen by the driver, a steering control (RU) is used, the design of which largely determines traffic safety and driver fatigue. There are specific requirements for vehicle steering, the main ones being:

- ensuring high vehicle maneuverability

- ease of control (due to the use of power steering)

- ensuring, as far as possible, clean rolling (without lateral slip) of all wheels of the vehicle when turning (due to the correct design of the drive)

- automatic stabilization of the steered wheels, i.e. returning them to a state of straight-line motion after removing the influence from the driver

- irreversible steering - no transmission of impacts from the steered wheels on road unevenness to the driver's hands

- ensuring a tracking action (any driver input on the steering should cause a corresponding change in direction of movement)

Rice. Steering: 1 — oil cooler; 2, 4 — shafts; 3 — steering column; 5 — steering wheel; 6 — power steering pump; 7 — steering mechanism; 8 — bipod

The steering system is a set of devices used to turn the steering wheels of a car when the driver acts on the steering control element (steering wheel).

We recommend: Popular hubcaps for Citroen

Steering system design

Steering diagram

Structurally, the steering system consists of the following elements:

- Steering wheel (steering wheel) - designed to control the driver in order to indicate the direction of movement of the car. In modern models it is additionally equipped with multimedia system control buttons. The driver's front airbag is also integrated into the steering wheel.

- Steering column - transmits force from the steering wheel to the steering mechanism. It is a shaft with articulated joints. To ensure safety and protection against theft, the speaker can be equipped with electrical or mechanical folding and locking systems. Additionally, the ignition switch, lighting controls and windshield wiper controls are installed on the steering column.

- Steering mechanism - converts the force created by the driver through turning the steering wheel and transmits it to the wheel drive. Structurally, it is a gearbox with a certain gear ratio. The mechanism itself connects the steering driveshaft to the steering column.

- Steering drive - consists of steering rods, tips and levers that transmit force from the steering mechanism to the steering knuckles of the drive wheels.

- Power steering - increases the force that is transmitted from the steering wheel to the drive.

- Additional elements (steering shock absorber or “damper”, electronic systems).

It is also worth noting that the suspension and steering of a car have a close relationship. The stiffness and height of the first determine the degree of response of the car to the rotation of the steering wheel.

Adjustment

In order to increase driving safety and reduce the load on the driver’s arms and back, the vehicle’s steering mechanisms require adjustment.

Adjustment can be mechanical or electronic. Most often, the tilt of the steering wheel is adjusted. The adjustment allows the driver to achieve the most ergonomic and comfortable position.

The most popular option is a mechanical steering wheel angle adjustment mechanism with a lower hinge. It consists of stoppers, bracket and locking bolt.

The stoppers turn. When the lever is in the locked position, the protrusions of the stoppers are opposite each other, an axial force arises, and the column bracket is fixed. When the lever is in the unlocked position, the protrusions of one of the stoppers are in a position exactly opposite the depressions of the other stopper.

The mechanical mechanism for adjusting the height of the steering wheel is also very popular. Adjustment is carried out due to the joint work of the sliding shaft, locking bolt, and locking wedges.

The locking wedges change position when the lever is turned. When the lever is locked, locking wedges secure the sliding shaft in the desired position. When the lever is unlocked, free space appears between the sliding shaft and the locking wedges, creating ideal conditions for moving the shaft along the axis.

As for electrical adjustment, the most advantageous option is combined solutions for simultaneous adjustment of the angle of inclination and height using a servo drive.

For the driver, adjustment is very simple. You just need to press the “Up” and “Down” keys. Therefore, although the solution is not the cheapest, it is very popular.

The role of the amplifier in the steering system

This element, in addition to reducing the force applied by the driver to the steering wheel, can significantly increase the accuracy of driving. Thanks to the presence of an amplifier in the steering design, it became possible to use elements in the system that have a small subordinate number. Control amplifiers are divided into three types:

- Electric.

- Pneumatic.

- Hydraulic.

However, the latter type has become more widespread. Hydraulics are distinguished by their reliable design and smooth operation, but require maintenance to replace the fluid. Electric power steering is less common, but most models of modern automobiles are equipped with it. Reinforcement is provided by an electric drive. Note that electronic control is distinguished by the presence of an expanded range of capabilities, but occasionally requires checking and adjustment.

The importance of good steering

Any vehicle belongs to the category of a source of increased danger, therefore, in order to prevent troubles associated with accidents and their consequences, it is recommended to keep it in good repair and constantly monitor its technical condition.

Since the main purpose of the steering is to provide the driver with the ability to maneuver the car, the proper condition of the system will provide the driver with confidence and safety, which, by the way, is important not only for him, but also for passengers.

Safe steering is also mentioned in the traffic rules, which prohibit the operation of a car if a malfunction of the control system, backlash, oil leakage in the rack from dried out oil seals, as well as the presence of constant noise are detected.

It is worth noting that the serviceability of the vehicle’s control system has an important impact on the condition of the tires, which ideally should wear out evenly in order to avoid subsequently throwing the vehicle along the road and resulting difficulties in driving even after problems in the control system are eliminated.

How to disassemble the mechanism if you decide to repair the steering rack yourself:

- We remove the clamps and tighten the steering rod boots.

- We fix the rack, unscrew the steering rods using an open-end wrench, for which grooves are made on the threaded coupling.

- We unscrew the lock nut, as well as the nut of the adjusting mechanism, remove the washers and the pressure sleeve from the mounting socket.

- Unscrew the housing or drive shaft nut. You will likely need a special wrench to get the job done. And then we pull the shaft out of the housing.

- We take out the gear rod of the rack.

- We remove the sealing collars, bushings, and fluoroplastic rings from the mechanism body.

Recommendation: Before disassembling the rack, it is important to make notes on how the gear rod is positioned, and you also need to measure how far it protrudes from the housing on both sides. If this is not done, problems will arise when assembling the mechanism. Mark the position of the adjusting nut and then count the threads as you unscrew it. Then you can install the clamping sleeve correctly.

Most motorists go to a service center when a breakdown occurs. The fact is that even simply dismantling this element with your own hands can be problematic. However, if the breakdown is not serious, you can try to fix it yourself. To do this, proceed as follows:

- Replace the rubber boot if it is torn. If you immediately detect this breakdown, you can keep the rack and pinion mechanism in good condition. The main thing is to immediately install a new casing on the overpass. Remember that all elements under the boot should be cleaned of dirt.

- We eliminate hydraulic fluid leaks on the pipes: after removing the fluid from the system, we install new hoses.

- We replace the tie rod ends. You will know that the ball pins are worn out if there is play and extraneous sounds.

- We install a new steering shaft crosspiece if it is broken.

- We tighten or replace the belt that rotates the hydraulic pump pulley. If the belt drive slips, the power steering will work worse and you will not be able to rotate the steering wheel.

Thanks to the design features of the rack, the gaps in the transfer unit can be adjusted. If the gears are not very worn, the backlash can be eliminated by tightening the adjusting screws. It is not recommended to do this work on your own, because if you do not leave any gaps, instant wear of the gear will occur.

If the cause of the malfunction is inside the rack and pinion housing, you won’t be able to eliminate the knocking noise yourself, only if you have experience working in a car service center. What are the most common internal failures?

- broken teeth on the rack or steering shaft;

- bearings play;

- the seals are depressurized;

- ring wear of the bushings and cylinders occurred;

- the shaft or rack became deformed due to the car hitting a pothole, resulting in damage to the mechanism.

We recommend

“Knocking in the steering rack: looking for the cause, dealing with the consequences” Read more

A number of malfunctions can be eliminated with the help of repair kits at a service station. It is not recommended to perform separate replacement of failed gear elements. The optimal solution is to replace the rail.