Positive Crankcase Ventilation (PCV) is a positive crankcase ventilation system that controls the pressure in the oil system and removes exhaust gases from the crankcase, first cleaning them of oil particles. The PCV valve, also known as the positive crankcase ventilation valve (PCVV), is an integral part of the above-mentioned system.

This valve plays an important role and yet very often many people are not even aware of its existence. Thanks to it, the performance of the internal combustion engine is increased, and the risk of leakage and excessive oil consumption is reduced. However, if the PCV system malfunctions, it can cause the car owner many different problems. Recognizing the first signs of a faulty engine in a timely manner will allow you to save money and prevent more serious engine problems.

Topical: What happens if you don’t change your engine oil?

History of the occurrence of CVKG

At one time, the large company General Motors (GM) thought about the problem of exhaust gas recirculation. During the engine operating cycle, gases are released, which enter the crankcase, increasing the pressure inside the unit and leading to serious malfunctions.

At that time, the Opel automaker still belonged to the GM concern. Companies have decided to install a PCV crankcase ventilation valve on their cars. This valve has a conical shape and operates under the influence of vacuum in the intake manifold. And the membrane of the KVKG valve opens and closes it. At that time, there was a fierce struggle for the ecological state of our planet.

SVKG device in Lada Priora

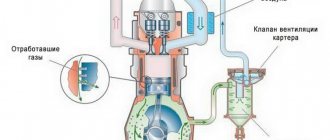

In all brands of cars, the SVKG is built on a similar principle. Only small details differ. On the upper side of the crankcase there is an oil separator, which looks like a hollow plug. An oil deflector is placed under the plug, which is designed to clean the gases from the crankcase as much as possible from oil particles. The oil separator has an outlet for the crankcase ventilation hose.

In order for the gases to return to the cylinder chamber, a ventilation valve is placed along their path. The valve has three modes, which allows you to maintain a certain level of gas rarefaction in the crankcase.

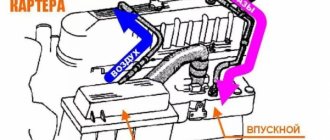

While the engine is idling, gases move through a small circuit hose through a special passage hole in the throttle assembly. At this time, a high vacuum is created in the intake hose, which allows crankcase gases to be effectively sucked out of the throttle block. The passage hole in the throttle regulates the amount of gases that are sucked out.

This allows you to stabilize the engine in idle mode. When the car begins to move, the throttle valve opens, causing gases from the crankcase to enter the cylinder through a large circuit hose for combustion.

What is a crankcase ventilation system

To reduce the negative impact on the engine life, a ventilation system was developed. It reduces pressure by “sucking out” gases through a system of pipes, hoses and valves. It is shown schematically in the figure.

What does it consist of?

- Pipes, hoses.

- Oil separator.

- Control valve.

In classic VAZ models, crankcase ventilation is simplified; there is no valve.

Scheme of work

- Gases enter the oil separator through hoses, where oil vapors are separated from gases;

- Next they enter the ventilation valve. It is connected to the intake manifold. The vacuum in it “sucks” them back into the intake.

Thus, we get rid of excess pressure.

In domestic cars, the breather plays the role of an oil separator. It is directly connected to the power unit. Oil passing through it settles on its walls. It is directly connected to the intake. One hose is connected to the air filter housing; pumping occurs during engine load. The second hose is connected to the carburetor, below the throttle. It is needed for crankcase ventilation at idle speed of the internal combustion engine.

Oil separator

It happens:

- Tangential.

- Labyrinthine.

In the first case, crankcase gases enter the oil separator housing at an angle. They twist and receive tangential acceleration. Due to centrifugal force, the oil emulsion and vapors remain on the walls of the separator and flow back into the engine sump. The gas flow continues into the valve.

The second type has a labyrinth in its design (it is logical to assume from the name). Crankcase gases passing through it, hitting its walls, flow into the sump.

Crankcase ventilation valve

Necessary for adjusting the intensity of the “suction”. A large vacuum can form in the engine intake manifold at different operating modes. A large vacuum can be created in the crankcase through the ventilation system. The higher it is, the more combustion products of the air-fuel mixture will “break through” the compression rings into the engine volume.

When excess pressure is created, the valve opens, gases are “sucked” into the inlet, and the pressure decreases. When a vacuum is formed, it closes, preventing the creation of a large vacuum. Thus, the extraction of fuel combustion residues, gasoline vapors, etc. is adjusted. from internal combustion engine.

Video

Welcome! The crankcase ventilation system is needed so that the atmosphere is not clogged and the exhaust gases are allowed to burn out again, this system was implemented in many cars, starting from the VAZ 2101 and ending with cars such as Lada Priora, Lada Granta, etc., but when the engine is worn out, this system is removed by the people themselves by removing all the hoses of the crankcase ventilation system, usually into a bottle, or just outside, we will analyze this in this article, so if your car has already covered quite a lot of mileage, then this article will be useful to you benefit.

Note! We will only disassemble cleaning the ventilation on 16 valve engines; if you have an 8 valve engine, then go to the article: “Cleaning the crankcase ventilation on a VAZ 2114”, in this article this engine is described; to clean the crankcase ventilation of a 16 valve engine, you will need stock up on: Small pliers, screwdrivers with different heads and all kinds of wrenches; in addition, you will need sealant for the cylinder head cover and a new gasket!

Diagnostic methods

The easiest way to check the PCV valve is by yourself. To do this, just blow into the valve from the side of the valve cover. If the air pressure from the reverse side is weak or does not come out at all, the valve is not working properly. Cleaning the crankcase ventilation system with carburetor cleaner should correct the situation. If the valve is blown in both directions, most likely it is stuck in a half-open state, or the rubber membrane is torn.

The degree of contamination and the overall efficiency of the crankcase ventilation is measured in two main ways:

- The crankcase gas pressure is measured at different engine operating modes.

- The volume of gases that the system can pass through itself is measured.

In order not to encounter the consequences of malfunctions of the VKG system, it is worth periodically changing the PCV valve, filter element, and cleaning the centrifugal/labyrinth oil trap.

What is the purpose of and where is the crankcase ventilation valve (CVVV) located?

The crankcase gas cleaning system is the simplest and lightest thing in the engine. And, meanwhile, it needs increased attention from the driver. We are talking about constant care: inspection, cleaning and testing of the system; you also need to pay special attention to the crankcase ventilation valve (CVG). Preventing the release of gases containing the entire periodic table is the main task of this system.

Its device is designed not only to keep the surrounding area clean, but also to reduce the result of gas pressure on internal combustion engine parts to a minimum value.

The crankcase ventilation valve is needed to pass exhaust gases that accumulate in the engine crankcase back into the combustion chambers of the cylinders through the intake manifold. The KVKG is usually located in the intake manifold. There are two types of crankcase ventilation: forced and non-forced.

Auto parts and service stations

When a car engine operates, vapors and gases are formed not only in the engine block itself, but also in the crankcase or in the pan, which is designed to store oil and is located at the bottom of the engine. These are gases formed from oil, gasoline and water vapors. Also, gases formed during combustion of the fuel-air mixture can enter the crankcase through the gaps. All vapors and gases located in the crankcase are called crankcase gases. The concentration of such gases disrupts the properties of motor oil and has a harmful effect on the metal of engine parts. The crankcase ventilation system is used to remove the resulting gases. It consists of an oil separator, a crankcase gas valve and air exhaust pipes.Types of crankcase ventilation systems

Today, it is customary to distinguish two types of crankcase ventilation systems for automobile engines: open

, or ejection (exhaust gases are discharged directly from the crankcase using a special calibrated ejection tube) and

closed

, or forced ventilation system (

PCV - positive crancase ventilation

).

Open crankcase ventilation system

typical for power units of cars produced in the last century and now discontinued, although many of them still roam the vastness of the universe and domestic off-road. A special feature of this system is that the gases that escape from the cylinders, together with oil mist, are discharged outside the engine, directly into the environment. This method of ventilating the engine crankcase is distinguished by its simplicity and low cost of design, which, however, is “compensated” by significant atmospheric pollution.

Operating principle of the positive crankcase ventilation (PCV) system.

In addition to this disadvantage, open crankcase ventilation has a number of other negative aspects. Such a system is ineffective when driving at low speeds and is absolutely ineffective when the vehicle is stationary with the engine idling, because crankcase gas pressure is minimal. In addition, through an open crankcase ventilation system, when cooling a very hot engine, unfiltered atmospheric air can be sucked into the engine, along with dust and water vapor. There are often cases when, on cars with high mileage, an open-type system became the main cause of wear on the CPG and, as a consequence, loss of compression and oil consumption.

A more modern and effective alternative to open crankcase ventilation is a closed (forced) ventilation system. One of the key parts of such a system is the PCV valve, which removes gases trapped in the engine crankcase into the intake manifold and subsequent combustion in the combustion chambers. Different automakers implement the idea of closed ventilation in different ways, but in most cases, each of the schemes involves the presence of the same elements: a ventilation valve (PCV valve), an oil separator (there may be several, or internal ones - in the valve cover with a labyrinth and drainage holes oil, or external in the form of a separate structure with oil draining directly into the crankcase) and connecting pipes. It is worth noting that crankcase ventilation systems for gasoline and diesel engines have their own characteristics, but in general they have similar designs.

PCV System Operation

The principle of operation of the forced ventilation system is quite simple. When a vacuum occurs in the intake manifold, under its influence, the PCV valve opens and crankcase gases are supplied to the intake, and then, mixed with purified air, into the engine cylinders. To prevent the penetration of oil vapors into the combustion chamber, the system provides for the installation of an oil separator. Modern engines are equipped with a complex oil separator system. Thus, a labyrinth-type oil separator helps slow down the movement of gases from the crankcase. This ensures that oily droplets settle on the walls and then flow into the crankcase or under the valve cover.

In some modern engines, further purification of the oil from crankcase gases occurs using a centrifugal oil separator, which rotates the exhaust gases. Under the influence of centrifugal force, oil particles are retained on the walls and then flow into the crankcase. The final purification of oil from exhaust gases is carried out in the output labyrinth dampers.

PCV valve - design features.

The key role of the PCV valve in a closed crankcase ventilation system is to regulate the pressure of gases in the crankcase by bypassing them into the intake manifold and maintaining a vacuum in the intake manifold. In idling mode and during engine braking, the vacuum in the manifold is maximum (the throttle is only slightly open or completely closed), however, the amount of crankcase gases is not so large, so for complete ventilation a channel with a small flow area is sufficient. In this mode, under the influence of a large vacuum, the valve spool is completely retracted, but at the same time the crankcase gas bypass channel is largely closed, allowing only a small amount of them to pass through. When you press the accelerator pedal and under high loads, the amount of exhaust gases in the crankcase increases significantly. The valve spool is positioned in such a way as to ensure maximum channel throughput. There is also a so-called backfire mode, in which burning gases from the cylinder break into the intake manifold. In this case, the PCV valve is under pressure, not vacuum, and therefore closes completely, eliminating the possibility of igniting fuel and oil vapors in the crankcase.

Operating principle of the crankcase ventilation system

Layout of the crankcase ventilation valve The gases are cleaned from oil droplets, which subsequently flow back into the pan, and the purified gases enter the air supply system into the combustion chambers through the air pipes. The crankcase exhaust valve is responsible for the release of gases into the intake manifold. Cleaning from oil plays an important role, because it not only saves oil, but also combats carbon deposits on working parts. What is a crankcase ventilation valve for? The crankcase exhaust valve regulates the process of releasing accumulated vapors. The principle of its operation is based on the pressure difference in front of the valve and behind it. To understand how the ventilation valve works, let's look at its design. It consists of a plastic body, inlet and outlet fittings, two cavities, a membrane and a spring (forming a kind of piston). If there is a strong vacuum in the intake pipe, then under the action of a spring the valve closes and crankcase gases do not enter the air duct. If the throttle valve is fully open, the intake manifold is set to atmospheric pressure, or even higher in the case of turbocharging, and the valve is closed by external pressure. If a slight vacuum is created, the piston takes a neutral position and gases escape freely. The crankcase ventilation valve has only three operating positions. And because the resulting gases are supplied to the combustion chamber as a component of the working mixture, then the ventilation system is also called the recirculation system, and the valve is recirculation or in the English version - PCV valve, which means the same thing, and stands for Positive Crankcase Ventilation (in Russian - crankcase ventilation system ). Where is the crankcase ventilation valve located?

Where is the crankcase ventilation valve located?

or

An oil separator is located in the upper part of the crankcase. Usually, this is a combination of two types: labyrinth and centrifugal. The gases rise through both types of oil separator and then hit a valve, which is usually located in the intake manifold. How to check the crankcase ventilation valve? Checking the valve is fairly easy. Remove the hose that runs from the crankcase to the PCV valve. Start the engine. Plug the loose valve fitting with your finger. When the valve is operating, you will feel a vacuum being created. You will hear a click when the hole is released. If you do not feel a vacuum, then the crankcase ventilation valve has not passed the test. Malfunctions of the crankcase ventilation valve It is impossible to remove all oil particles when removing gas from the crankcase, so over time, contamination of the components of the ventilation system occurs. If the system is severely clogged, the pressure in the crankcase may increase and oil may escape through the dipstick or through the engine seals. A sign of oil getting into the combustion chamber is the appearance of an unpleasant odor and soot at the engine outlet. If urgent measures are not taken, this can lead to serious malfunctions in the cylinder-piston group. If oil deposits appear on the intake manifold and air filter, this indicates problems with the oil trap.

Signs of a malfunctioning crankcase ventilation system

In the event of a malfunction of the labyrinth system (significant clogging with coked oil), a small but noticeable oil consumption occurs (in the region of 0.1-0.5 liters per 1000 km), traces of burnt oil appear on the spark plugs in the form of grains or “rust”, and in the combustion chamber - carbon deposits, all this is mistakenly mistaken for dead valve stem seals or even rings, although this is not the problem at all. In some cases, especially in the cold season and when driving slowly through traffic jams, oil mist may gradually settle in the form of liquid oil directly in the intake manifold, which leads to cold start problems; when starting, oil from the runners enters the intake and floods everything around, in incl. spark plugs, valves and combustion chamber, interfering with normal mixture formation and ignition of the combustible mixture. And when the start is successful, the trapped oil begins to burn in the form of blue smoke, which is again attributed to dead valve stem seals... but in fact, you need to dig into the crankcase ventilation system. Incorrect operation of the PCV system may be one of the reasons for contamination of the throttle, idle air valve, contamination of the air filter, air line (pipe pipes and intake manifold), oil leakage and squeezing of oil seals and gaskets, more often outward than inward. Clogged ventilation system pipes create excess pressure in the engine crankcase, as a result of which exhaust gases along with oil will seek alternative exit routes. At the initial stages, when the system associated with the PCV valve is clogged (most often the valve itself is clogged, less often the oil separator, labyrinths and pipes are clogged), the ventilation begins to work incorrectly and oil vapors along with gases begin to flow through the ventilation tube, the first sign of this is rapid contamination of the throttle from the inlet side. In some cars, fresh air is taken directly from the air filter box - if the PCV system malfunctions, the filter begins to fill with oil, and in some cases, because crankcase gases are very hot, it is even possible that the filter made of synthetic material will melt and, as a result, the car will be deprived of the air filtration system. In cases where both tubes are already clogged, the consequences are more dire, the dipstick begins to throw out, and the formation of oil smudges in the places of seals and connections (gaskets, oil seals) is also possible. A completely unpleasant option is squeezing out the crankshaft seals or oil filter seals with significant losses in oil volume. Incorrect operation of the PCV valve itself can lead to incorrect metering of incoming air, and the preparation of an over-rich or over-lean mixture, depending on the operating mode. If the valve begins to allow gases to pass in all directions (the pistons or springs are destroyed), a strong air leak into the intake manifold begins, the vacuum in it drops, with all the troubles in the form of increased fuel consumption, unstable or increased idle speed, depletion of the combustible mixture, deterioration operation of the vacuum brake booster. Moreover, the Check Engine may not light up, because There are usually no misfires.

As a rule, a typical malfunction of the KVKG is the wear of the membrane, as in the photo below. It breaks, creating the above problems.

Replacing the KVKG using the example of the M43 BMW engine. Video:

Replacing KVKG BMW G11

Malfunction of the BMW G11 KVKG is a fairly common problem with which people turn to the BMW-E technical center for help. Despite the fact that this car model has only been produced since 2015, some BMW car owners have already managed to repair or replace this unit. And the experienced specialists of our service center happily resolved the malfunction of the crankcase ventilation valve, offering customers the optimal solution to the problem.

The BMW KVKG valve is a small unit that is part of the engine system and ensures timely recirculation of crankcase gases. The latter are a combination of water vapor, gasoline and gas, which are formed during operation of the internal combustion engine and are removed by the valve. Crankcase gases pose a direct danger to the environment and the engine, so you should carefully monitor the serviceability of the CVCG.

If cracked or clogged hoses with combustion products are not repaired in time, or the membrane or valve as a whole is not changed, this will certainly lead to serious engine damage. Pressure is lost when there are too many gases inside the crankcase. In the future, such a seemingly simple breakdown will lead to a leak of crankcase gases and the suction of oil or air mixture.

The BMW-E technical center recommends checking the condition of the unit at least once a year and, if necessary, carrying out a qualified replacement of the BMW KVKG. Our service specializes exclusively in BMW vehicles, and the box is equipped with dealer software. This eliminates any inaccuracies and errors during the repair of new and old cars of the Bavarian company.

How to check KVKG BMW G11 at home

To detect deviations from the norm in the operation of the CVCG, you do not have to go to the service center. The initial inspection and testing of this unit is easy to do at home or in the garage.

- Turn on the G11 engine and open the hood.

- Look for the oil filler neck and unscrew the cap.

- Try to lift the lid slightly, but do not remove it completely.

- If you feel a slight pull of the lid back, then everything is in order with the KVKG.

- However, if you unscrew the lid too quickly or pull it back too strongly, immediately seek the help of a specialist. These are the first signs that the ventilation valve is not working correctly.

Also signs of a breakdown are excessive oil consumption, the appearance of bluish smoke from the exhaust pipe and a smoking engine. If you have one of the listed signs, do not hesitate to go to the BMW-E technical center in order to preserve the integrity of the engine and prevent its destruction due to crankcase gases.

Basic malfunctions of KVKG BMW G11

The cause of malfunction of the BMW KVKG is not so many factors. Conventionally, they can be divided into mechanical and technical factors, however, the procedure for their repair is no different.

Valve failures:

- membrane rupture due to aggressive driving or after an accident;

- cracking or kinking of ventilation/recirculation hoses;

- natural wear of the part;

- hoses become coked by crankcase gases.

At the BMW-E technical center, drivers receive qualified assistance from car mechanics with many years of experience. Our technicians can easily advise the owner of the machine, conduct a quick inspection of the unit and offer optimal replacement units. The service warehouse always has components from the dealer or their durable analogues from reliable suppliers.

Any malfunction of the BMW G11 KVKG is repaired in a sterile box where no dust or dirt gets in. Employees spend no more than a few days on the job and provide a long-term guarantee. The valve will operate without problems after repair or replacement for six months or 10,000 km.

Signs and causes of failure of the BMW M54 KVKG

Failures of the VKV valve manifest themselves not only functionally, but also visually. The main manifestation of a part malfunction is excessive sticking of the cover. This position of the spare part indicates a lack of tightness in the system and deformation of the membrane inside the part. The basic symptoms of a broken VKV valve in BMW M54 cars are:

- Excessively increased consumption of oil fluids and fuel;

- The appearance of uncharacteristic noise in the area where the part is located;

- Reduced engine dynamics and performance;

- Cases of smoke in the engine compartment;

- Uneven operation of the motor;

- Excessive pressure levels.

To check the functionality of the exhaust ventilation valve, it is worth removing the oil filler cap. The lid should fit slightly when opened. If this does not occur and smoke appears, this indicates that the ventilation system is not working properly. Failures in the operation of the VKV valve in BMW M54 cars can occur for the following reasons:

- Complete rupture of the valve membrane element;

- Clogged exhaust gas ventilation hoses;

- Deformation, damage to valve hoses.

Due to these circumstances, the exhaust ventilation valve will absorb oil liquids directly from the engine oil pan. In most cases, this situation can cause the case to become deformed. Air is passed through damaged hoses of the gas ventilation part, which causes a decrease in the performance of the BMW M54.

Clogging of the valve hoses causes the engine oil seals to push through and oil fluids to leak through the valve cover and crankshaft seals.

Cleaning SVKG in Lada Priora

After prolonged use, gas deposits accumulate in the crankcase ventilation system. This deposit makes it difficult for gases to pass into the cylinders. As a result, the gas pressure in the engine increases, which leads to oil leakage. Timely cleaning of the SVKG will help prevent this. The manufacturer of Lada Priora recommends carrying out this procedure after every 60 thousand kilometers. This service manipulation can be performed in a car workshop or independently.

To do this, you need to have tools (narrow pliers, 8mm nut wrench, Phillips screwdriver).

When cleaning the SVKG yourself, you need to perform the following steps:

- Remove the decorative engine cover.

- Remove the air filter.

- Carefully loosen the clamp on the ventilation hose clamp on the engine.

While the engine is running, it is prohibited to break the tightness of the SVKG, as well as to remove the oil filler cap.

This will lead to the release of toxic substances into the environment and disruption of the crankcase.

Design and principle of operation of the crankcase ventilation valve

The ventilation valve has such a simple device that even a novice car enthusiast can easily learn how to disassemble and clean it.

It consists of:

- Plastic case.

- Lids.

- Inlet and outlet fittings.

- Two cavities.

- Membranes.

- Springs.

The principle of operation of the valve in modern cars

Video about the operating principle of the crankcase ventilation system and valve.

The ventilation valve opens in medium mode, when optimal pressure is created on the membrane. In this position, the valve overcomes the spring pressure. After passing through the oil separator, the gases are cleared of oil droplets, pass into the open valve and complete the cycle, returning back to the combustion chambers, where their combustion is completed.

If we are talking about a non-forced crankcase ventilation system, then the valve almost does not open in idle mode and is closed at high speeds. At high speeds, a lot of gases are released, and hot gases often leak into the intake manifold. In this case, the valve is closed, since there is a risk of ignition of crankcase gases in the crankcase itself.

Where do the gases go if the valve is closed?

In any case, crankcase gases must be removed and under no circumstances remain inside the system. There is another iron pipe that leads to another valve. This is the so-called “fungus” or pressure reducing valve. When the main valve is closed (and this happens, let me remind you, at high speeds and at idle), the gases pass through this iron pipe directly into the “fungus”.

It also has two states: closed and open. When it is covered, a small calibrated hole inside it opens slightly, which allows the gas mixture to pass through. In this case, the gases escape through a large hole. That is, a system consisting of two valves ensures uninterrupted and reliable crankcase ventilation.

Design of a crankcase gas purification system in modern cars

Crankcase gases, while passing through a simple system of special valves and tubes, exit back into the combustion chambers, where they are burned out.

Diagram of a crankcase gas cleaning system with a cyclone oil separator (1 – crankcase gas supply pipeline; 2 – air intake pipeline; 3 – membrane; 4 – compression spring; a – open position of the valve; b – closed position of the valve)

First, the gases exit into the oil separator, which is directly attached to this hole. The entire network of gaskets and baffles of the oil separator is designed to separate oil droplets from the gas mixture, which return to the sump. This function is useful because it reduces oil consumption. In different models, the oil separator is either built into the engine, or is placed under the valve cover and forms a separate unit.

What are valve malfunctions?

The presence of a malfunction can be determined by its characteristic symptoms.

- Oil splashing and increased oil consumption.

- Filter dirty.

- The engine does not start at full power or you can hear a slight whine from the engine.

Basic malfunctions.

- The valve and membrane are dirty.

- Exhaust openings and pipes are dirty.

- The membrane has worn out and flattened.

Crankcase gases are usually not completely released from the oil in the oil purifier. All components of the system - membranes, pipes, valves - become dirty and clogged with oil soot. If the driver does not take the time to clean them, the crankcase pressure increases. A strong smell, burning and soot appears when the engine is running. You may notice that oil consumption increases.

When a valve fails, oil pressure increases and is forced past the seals and gaskets. Valve wear is also characterized by a decrease in engine power. In this case, the pressure in the exhaust system increases or even the operation of the internal combustion engine stops completely. If the damaged valve is not completely blocked by the membrane, then oxygen entering the combustion chamber will help the engine fail.

Symptoms of a Stuck PCV

- The engine misfires at idle.

- Lean air-fuel mixture.

- Presence of engine oil in the PCV valve or hose.

- Increased oil consumption.

- Hard engine start.

- Rough, unstable engine operation at idle.

Additionally, a stuck PCV valve can cause a check engine light due to increased air flow. And the diagnostic computer may mistakenly show this error due to the mass air flow sensor or oxygen sensor, making it difficult for you to identify the real source of the problem.

How to check the crankcase ventilation valve

Modern automobile engines use membrane-type CVCV (PCV). The design of such a valve is extremely simple; in the standard version it has:

- a housing on which there are two fittings - for supplying crankcase gases and for removing them;

- cover;

- diaphragm (crankcase ventilation valve membrane);

- return spring.

The operating principle of this mechanism is as follows:

- when the engine is turned off, the valve is closed by a membrane under the force of the spring;

- at idle speed, under the influence of vacuum, the membrane begins to overcome the force of the spring, and part of the CG passes from the internal combustion engine into the intake tract;

- at high speeds, the diaphragm completely clears the channel, and crankcase gases are sucked into the intake manifold in full.

As the valve becomes clogged, it stops working, but before changing the KVKG, you should still check it. A serviceable KVKG removed from the engine should be blown in one direction; in the opposite direction, air passes through it in a small volume. The valve can also be checked with the engine running; to do this, you need to disconnect the hose from the device on the side of the intake tract. On a working CVCG there is a vacuum, and if you put your finger on the fitting, you will feel like your finger is being “sucked”. If the device is faulty, no vacuum is created.

Through the engine ventilation system, you can check how well the piston group of the internal combustion engine “feels”. The check is done as follows - a simple transparent fuel filter is installed between the PCV and the intake manifold. If after a short mileage oil and soot appear in the filter, it means that the piston rings are not in order and the engine needs repair.

PCV valve in the crankcase ventilation system - logbook of the 2014 Lada Granta on DRIVE2

I read about most of the positive reviews, of course, such as adding 10 horses and reducing consumption by almost half, complete nonsense, but still the price is 350 rubles, I decided to take a risk and test it the hard way, so to speak. There is a choice, from China, I refused, there are no reviews , there are two more types General Motors 94580183 and HYUNDAI/KIA 2674021314, I settled on the latter.

I decided to check the removed hose, they say who has a jet there, who doesn’t have it, I had

I couldn’t find a suitable hose, I decided to use a silicone one, since it was the one that fit perfectly, then I’ll change it to an oil-resistant one, if, of course, all this modification is worth it)))

As for the installation, I didn’t install metal clamps, I installed plastic ones, there wasn’t enough pressure to tear it out, the tube was soft, I twisted it so that it didn’t bend, yes, I checked it, it blows in one direction - it’s towards the inlet, but it doesn’t blow into it - to the valve cover.

Bottom line, I didn’t notice the effect of the increase in power as expected))) At first I didn’t notice anything at all, here in the city 1.2 gear is clearly nothing, but on the free road there is an effect, as if the engine works more elastically, and what I immediately noticed was I had twitches when braking with the engine, but now they’re not there, I’ll go for a drive and see how it goes, but so far the system really seems to be justifying itself in some ways.

Crankcase gas measuring device

You can measure pressure with a pressure gauge; normal values should not exceed 60 millimeters of mercury. First, make sure there is no blockage in the breather tube. Also check the engine oil level. The model of the measuring device is selected based on the power and type of engine. It is important to ensure that the device fits the diameter of the calibrated hole.

On vehicles with a closed ventilation system, the breather tube must be disconnected. A plug is placed on the channel inside the intake manifold. A pressure gauge is attached to the tip of the tube. A pressure sensor is connected to the device itself. The engine must be operated at the load and speed at which the rated power is achieved. You need to wait until the pressure gauge readings level out.

After the device has stabilized, the results are recorded. You can then remove the device, pull out the plug and reconnect the tube. It is important to consider that gas consumption may differ on two engines with the same displacement. This situation is possible when the models under consideration are differentiated by performance indicators per unit of time and torque.

Using available materials, you can measure the pressure of crankcase gases, expressed in liters per minute. It is more convenient to perform the operation with an assistant. You will need the following materials:

- Clock with second hand or stopwatch.

- Large bucket or basin.

- Garden hose at least 1.5 meters long.

- Plastic canister for water with a volume of 5-6 liters.

First you need to turn off and plug the purge hoses. Next, you will need to draw some water into the basin. Fill the canister to the top with water and close the lid. Now you need to turn it over, put it in a basin and carefully open the lid.

The engine starts. One end of the hose is connected to the oil filler neck, the other is bent upward and lowered into the canister. When gases begin to escape, it is important to immediately note the time using a stopwatch. If the engine is running normally, the readings should not exceed 20 l/min.

How long does a PCV valve last?

It all depends on operating conditions and many factors. With proper maintenance and regular oil changes, the device “lives” for quite a long time. Otherwise, the accumulation of dirt and various inclusions in the engine oil will significantly reduce the service life of the PCV valve, up to its complete failure.

Pros and cons of a closed crankcase ventilation system

Disadvantages of the crankcase ventilation system:

- oiling of the engine intake tract - regular cleaning is necessary;

- If the engine is in poor condition, the volume of crankcase gases is so large that you can forget about the normal operation of the system and the engine - engine repair is required.

Advantages of the crankcase ventilation system:

- our air is cleaner, since crankcase gases are much more toxic than exhaust gases;

- there is less chance of observing leaks through seals and seals;

- the life of the engine oil increases;

- oxidative processes inside the engine are reduced;

- crankcase gases increase detonation resistance;

- the crankcase does not communicate with the atmosphere, as a result of which dust and moisture are not sucked into it.

Our recommendations

It is good practice to replace the PCV valve with every major service. Changing your engine oil regularly will prevent sludge deposits from forming inside the oil pan, which can cause PCV valve failure.

PCV (Positive Crankcase Ventilation) valve operation diagram

Replacing the PCV (Positive Crankcase Ventilation) Valve

PCV (Positive Crankcase Ventilation) valve after replacement

When is crankcase ventilation diagnostics required?

When the car is in good working order, the check does not need to be carried out. But after a major overhaul of the engine, such a procedure is mandatory. It allows you to verify the exact geometric correspondence of the selected parts. It is recommended to carry out an inspection if there is a suspiciously high oil consumption in machines with open ventilation systems.

If the system is closed, diagnostics are carried out when oil enters the intake manifold. This operation can be performed to detect engine damage. For example, problems are often caused by worn valve stem seals or piston rings. The ventilation can last quite a long time, as it has a simple design. Usually there are only two breakdowns, the first is that the valve cover separators become clogged. The second option is valve failure.

The valve operates in several modes, and its position depends on the condition of the engine. At idle, it opens partially and does not allow gases to pass through completely. As the throttle valve opens, the gap increases. When the engine is turned off, the gap closes completely. If the valve becomes coked or bursts, it begins to work incorrectly. In such a situation, it is always open or, conversely, closed.

How often should cleaning be performed?

If the ventilation system is clogged and its filter is unable to clean the mixture passing through it, then not only unburned gases, but also oil particles and other pollutants will enter the engine. All this will ultimately have a negative impact on both the operation of the engine and its remaining service life.

The frequency with which the crankcase ventilation of the VAZ 2114 should be cleaned directly depends on the condition of the engine. So, if the car just recently came off the assembly line, and its engine has not clocked up 50,000 km, you shouldn’t even think about cleaning it, since the piston rings are still new, and there is practically no leakage of gases through them.

The first cleaning (as recommended by AvtoVAZ itself) should be performed after the car has covered 60,000 km. And all subsequent cleanings should also be performed after every 60,000 km.

Many owners of domestic cars with extensive experience say that 60,000 km is too much, and cleaning should be done at least every 30,000 km - this will help avoid many problems with the engine and extend its life. In this case, the first cleaning should be carried out after the first 60,000 km.

PCV system maintenance

Sometimes, bad valve symptoms are mistakenly reported as coming from a bad sensor. This is why it is important to regularly check the PCV and related components. It takes only a few minutes. If your engine is missing a valve, or you can't get to it without removing one or more components, consult your repair manual for the best way to check your specific system.

Also, check your system's maintenance schedule and replace necessary components at regular intervals, even if it appears to be in good condition. Most PCV valves and related components are inexpensive and will save you money on costly repairs if you replace them at the recommended interval.

In what cases is the presence of oil in the breather not related to the crankcase?

Before diagnosis, it is recommended to make sure that the unpleasant symptoms are actually associated with gases. Oil ingress is also possible in other cases, for example, if more fluid is poured than required according to the standards. It is possible that the breather is not installed correctly and moving it will correct the problem.

Sometimes oil penetrates from the internal elements of the power unit, including injectors. Driving style, as well as the condition of the roadway, also influences. Oil particles may remain when the motor actively moves in the transverse direction.

Cost of the KG ventilation valve

The cost of KVKG can be completely different; the price largely depends on the car model and the engine itself. For example, an original valve for an M54 (BMW) internal combustion engine costs about 2200-2400 rubles; this device is also suitable for M52 series engines and is installed on E39 5-series cars, X3, X5, BMW Compact. For Ford cars (Duratec HE engines), a ventilation valve can be purchased at an average price of 1300-1800 rubles, the cost depends on the seller - custom parts are cheaper if the parts are not needed urgently.

There are original parts that are quite expensive, and besides, they cannot always be found on sale, so it makes sense to buy contract spare parts - they are much cheaper and more accessible. For example, even a contract Mitsubishi KVKG for the 4G94 engine from Vladivostok will cost about 3 thousand rubles; it is difficult to say how much the new mechanism costs. You can also search for more details in car dismantling yards and various advertisements on the Internet.

Sources

- https://repairkit.com.ru/a236179-kak-proverit-membranu.html

- https://akki-carsh.ru/dvigatel/chistka-sistemy-ventilyacii-karternyh-gazov.html

- https://4x4privod.ru/klapan-ventilyacii-karternyh-gazov-princip-raboty/

- https://vibration.su/serii/kvkg-chto-eto.html

- https://VazNeTaz.ru/klapan-ventilyacii-karternyx-gazov

- https://avtotop.info/zabita-ventiljacija-karternyh-gazov-simptomy/

- https://avtoskill.ru/remont-obsluzhivaniye/kak-proverit-ventilyatsiyu-karternyih-gazov.html