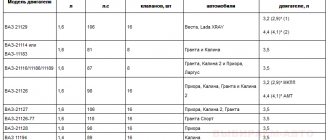

| № | Name | Rating | Nomination |

| 1 | LUZAR VAZ 2170-72 Priora | 4.85 | Most popular pump |

| 2 | TZA POWERFULL | 4.80 | Better performance |

| 3 | FINWHALE WP126 | 4.75 | The most affordable pump |

| 4 | LADA 21126-1307010-82 | 4.70 | The best balance of price and quality |

| 5 | DOLZ 2170 | 4.67 | The most enduring |

Experienced owners and car service technicians recommend replacing the timing belts on the Lada Priora after 50-60 thousand kilometers. A new water pump is usually installed in parallel with the belts. The pump also needs to be changed if you notice leakage, jamming, noise or play - these are symptoms of damage.

The best brands of water pumps for Lada Priora

Among manufacturers of pumps for Priora, car owners give preference to the TZA and LUZAR brands. The first one produces original parts for the Lada, and many buyers want to see exactly these on their car. And the second brand is considered one of the most reliable. The choice of manufacturers is quite large, and each has advantages.

TZA plant

Since its founding, it has been supplying parts to the AvtoVAZ assembly line. For Priora, he offers models with an 8-blade impeller, which increases the efficiency of heat removal.

Spanish pumps DOLZ

, which correspond to the original in all respects, cope with their tasks perfectly and are not capricious in relation to antifreeze.

Water pumps LUZAR

capable of operating at high speed for a long time. And the manufacturer gives them a 2-year warranty.

Pumps produced under the LADA brand –

original parts demonstrating optimal compatibility with vehicle components and high performance.

And the German brand FINWHALE

famous for the performance and extended life of the pumps.

Purchase rules

When purchasing a spare part, visually inspect it, evaluate the condition of the metal and connections. Visually compare several options from different manufacturers for the quality of rotation of the blades and the clearly set angle on the side where the pump is attached to the engine block. Because an unevenly located pump will lead to belt wear. Below, we have selected the most popular models of water pumps, which are characterized by stable and long-lasting operation.

Choosing a pump (which is better for VAZ-2114)

- Gates.

- Luzar.

- TZA.

- HEPU.

Pump from TZA

Pump from Luzar

Pump from HEPU series R 620-625

Pay attention to how to determine the originality of a product.

It is very difficult to definitively answer the question of which manufacturer or company is better, because a large number of devices have both negative and positive reviews. Therefore, you should make your choice from the most popular models among car enthusiasts.

Tips for choosing pumps for Lada Priora

In the line of any brand there are pumps for different car models, differing in dimensions and design features. When choosing a water pump, you need to take into account the mounting dimensions and materials from which the part is made.

The pump body for cars is made of aluminum. The metal does not corrode and is easy to shape into any shape. Manufacturers most often choose steel for the shaft so that it can cope with the load from bearings, seals and impellers.

Impeller.

One of the most important elements of a water pump, on which the performance of the pump depends. It comes in cast iron, other metal and plastic. The cast iron part is durable, but heavy and has thick blades, so its efficiency is inferior to others. Metal is lighter and more efficient, but is susceptible to corrosion. Plastic is the lightest material. Such an impeller is productive, but over time, due to contrasting temperatures, it becomes fragile and begins to slip.

Impeller

on the back side of the impeller relieves the shaft-housing seal. Not available on all models, but it helps to increase the efficiency of the pump and increase its service life.

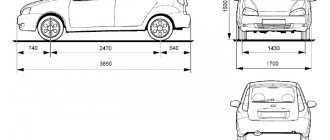

Water pump LUZAR TURBO VAZ 16V Kalina, Priora, Granta, Vesta, X-Ray, Largus

Water pump “LUZAR” TURBO.

APPLICABILITY: VAZ 1117, 1118, 1119 (Lada Kalina with VAZ 11194 1.4L 16V or VAZ 21126 1.6L 16V engine), VAZ 2170, 2171, 2172 (Lada Priora 1.6L 16V), VAZ 2190, 2191 ( Lada-Granta 1.6L 16V), VAZ 2192, 2194 (Lada Kalina 2 1.6L 16V), LADA Vesta (LADA Vesta 1.6/1.8L 16V), LADA X-Ray (LADA X-Ray 1.6/1.8L 16V), LADA Largus ( LADA Largus with VAZ 21129 1.6L 16V engine).

Flaw in the design of VAZ engines.

Many owners of front-wheel drive

VAZ are aware of this problem, especially when stuck in traffic jams.

A sudden boil usually occurs according to the following scenario - the car is driving at speed, then suddenly stops during a traffic jam, it is at this moment that the engine usually begins to boil. Why is this happening? When driving, the engine is heat-loaded - the pump operates at high speeds and provides a decent flow of coolant through the engine block head. During a sudden stop, the pump speed drops sharply, and along with it, the fluid flow rate drops sharply, while the engine still has thermal inertia - its parts are still hot. Therefore, the liquid simply boils in the block head. Development of the TURBO water pump.

While testing various materials used in the production of water pumps, we discovered a new, more advanced, more technologically advanced material called “ceramic plastic”

and which has the prospect of being used

as a material for impellers

.

Polyphenylene Sulfide PPS (PPS)

- a semicrystalline material consisting of alternating units of sulfur atoms and phenylene rings.

It is a high-tech material from the category of so-called superstructural thermoplastics

.

This material was used specifically in the TURBO project, within the framework of which a new impeller for VAZ water pumps was developed

.

The efficiency of the TURBO impeller.

The process of preparing the production of water pumps "LUZAR" TURBO

was not easy.

During development - taking into account existing technological capabilities - it was decided to simplify the design of the impeller. Despite these simplifications caused by the imperfections of today's technologies, we were able to achieve enormous advantages compared to the “standard”

pump and compared

to the pump (model 1)

.

Thus, the “LUZAR” TURBO

“LUZAR” impeller at idle speed by more than 50%

with a gradual reduction as the speed increases and the flow level is equal to 3000 engine revolutions.

Thus, the problem of increasing fluid circulation in the most difficult conditions is solved - in traffic jams and during a sudden release of gas

.

"LUZAR" "Lugansk Automobile Radiator Plant"

produces a variety of water pumps (pumps) for both passenger cars and commercial vehicles and trucks.

The LUZAR

product range includes more than 100 pump models for both domestic and imported cars. There is a continuous development of new water pumps for everyone for popular cars.

Water pumps circulate coolant in automobile engines, ensure the removal of excessive heat from the cylinder block and the supply of hot fluid to the interior heater radiator. Suitable for all automobile engines with a water cooling system. Water pumps are not used in air-cooled engines.

The performance of the water pump is proportional to the speed of rotation of the crankshaft. This is due to the fact that the water pump is driven directly from the crankshaft - thus, as engine speed increases, the circulation of coolant also increases.

The water pump must solve several problems:

— ensure a more uniform temperature in different parts of the cooling system;

— smooth out sharp temperature fluctuations (eliminates the “thermal shock effect” with a sharp change in engine speed;

— deliver the coolant to the heater radiator, ensuring heating of the interior.

Design of LUZAR water pumps.

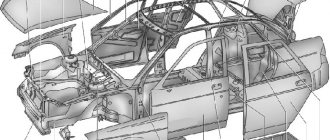

The water pump (pump) consists of a housing in which a bearing with a shaft is located. A drive pulley is pressed into place at one end of the shaft, and an impeller (impeller) at the other. On the impeller side of the shaft there is a sealing element (oil seal) that protects the bearing from liquid ingress.

Frame

. Two types of materials are widely used - cast iron and aluminum. Aluminum is a more modern material and allows you to create housings of complex shapes with strict adherence to dimensions, which makes it possible to install a bearing under tension. Cast iron pump casings are used, as a rule, on heavy-duty vehicles - where the engine speed is low, but a long service life of the part is required.

Bearing. Typically, two radial bearings are used, between which grease is placed. Outdated design - two open-type ball bearings are located separately on one shaft and are secured against rotation with screws. It is possible to additionally press grease between the bearings; for this purpose, a grease nipple is located on the pump body. Modern design used in LUZAR

– double-row ball or ball-roller bearing of a closed type, rigidly pressed into the pump body. This bearing uses high-temperature grease, which does not require replacement for the entire service life of the bearing and pump.

Pulley. Made from steel. The pump can be equipped with either a toothed or a V-pulley. In some cases, the pulley is not included in the water pump and is attached additionally. The transmission of torque and the service life of the drive belt depend on the accuracy of the pulley dimensions.

Impeller. It is the main “actuator” of the water pump, responsible for its performance. Read more about the impeller on the last page of the brochure.

Sealing element (oil seal). Designed to seal the bearing and protect it from liquid ingress. It is the most important part of a water pump - due to the “dynamic nature” of the pump’s operation, the sealing element is constantly under heavy load.

Advantages of LUZAR water pumps:

Double row ball roller bearing.

In LUZAR

the best bearing of all possible options is installed.

A double-row radial ball-roller bearing of a one-piece (closed) type is used, which does not require maintenance throughout the entire period of operation. This bearing is high-speed, highly loaded and provides maximum operating conditions. On some pumps, due to the insufficient height of the housing, ball roller bearings cannot be used. In this case, double-row radial ball bearings of the one-piece type are used. Metal-ceramic sealing element.

To seal the moving housing-shaft connection, a double mechanical seal is used, in which the moving and stationary rings are made of ceramic. Due to the special properties of ceramics, friction between the rings is minimal, there is practically no air gap - thereby guaranteeing high tightness and long service life.

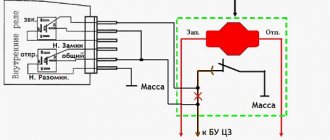

The patented method for installing the oil seal is additional sealing of the oil seal-shaft and oil seal-housing interfaces.

According to the results of numerous studies

(the data set contains more than 5,000 observations) it turned out that about 20% of pump bearing failures occur due to the penetration of coolant bypassing the oil seal at the oil seal-shaft and oil seal-housing interfaces.

This phenomenon occurs due to microscopic pores in the casting of the pump body and “loosening” of the sealing element during operation. The solution is adhesive sealing of the sealing element of LUZAR

, which led to a significant increase in the service life of the products.

100% ultrasonic body inspection.

Microscopic defects in the pump body casting can lead to loss of operational (resource) characteristics of the water pump. In this regard, we carry out quality control of the casting of pump housings, guaranteeing excellent mating of parts.

100% control of impeller overhang.

It is known from the hydraulics course that the closer the impeller is to the response part of the water pump, the greater the pump performance (in an inverse cubic relationship - as the distance to the response part decreases, the flow rate increases in cube). LUZAR water pumps

have a guaranteed gap

of 0.9-1.3 mm

, controlled during production. Note: There are often cases of deposits on the pump body. Such deposits may prevent installation of the pump. In this case, it is necessary to either carefully clean out these deposits, or use an additional gasket when installing the pump.

Complete with installation fasteners.

The water pump is operated in an aggressive environment. In this case, the pump fasteners become covered with salt corrosive deposits and become unusable. That's why all LUZAR

are additionally equipped with installation fasteners, which must be used when replacing the pump.

Warranty 2 years or 125,000 km.

All products are certified according to the international quality management system ISO 9001 TUV and have GOST-R certificates of conformity.

Includes: water pump, gasket, 3 bolts and 3 washers.

Top 5. DOLZ 2170

Rating (2021): 4.67

The most durable Pump easily withstands intense loads and operates stably no matter what coolant is used.

- Characteristics

Average price, rub.: 1750

- Country: Spain

- Impeller: plastic

Spanish water pumps are distinguished by their unpretentiousness in relation to the coolant and the intensity of vehicle use. This pump can be installed on any Lada with a VAZ-21126 engine with 16 valves. It is reliable and durable. At the same time, it demonstrates high performance, which allows it to effectively protect the engine from overheating. This model is installed on a gasket, which is included in the kit. There is no need to additionally use sealants, since the connection is quite tight - a correctly installed pump will definitely not leak during the warranty period. Among the disadvantages that few buyers highlight is the high price of the pump.

Advantages and disadvantages

- Withstands intense loads

- Durable

- Undemanding on coolant

- No sealants needed

- Prices are a bit high

Signs of pump failure

You can talk about a pump malfunction if you have the following malfunctions:

- The coolant level in the reservoir drops to a minimum. This reason is the most common, since this is how you can understand that the coolant is constantly leaving due to leaks. They can be in the tank itself, the pipes, or at their connections, as well as directly in the radiator. Only by checking the entire system can you be sure that this is not the reason.

Coolant level is at minimum.

- There is liquid on the vent . The presence of traces of liquid in this place indicates the presence of leaks from the pump seal. This happens in cases where the service life is long, or its previous installation was carried out incorrectly. This is characterized by either loss of fluid (indicated in paragraph - 1 - note), or the presence of smudges.

- Broken rotor bladesA. This malfunction can only be diagnosed by completely dismantling the pump. And if at least part of them is broken, then the operation of the entire unit is completely disrupted.

A clear example of a new and old pump.

- A hum is heard while the engine is running . The hum occurs when the pump bearings are worn out; in the presence of such breakdowns, increased wear on the timing belt may occur. This happens because the pump axis weakens and the tension that was there before disappears. Remember that a broken timing belt can have not very pleasant consequences.

- Plaque on the pump seal . This symptom is not the cause of the malfunction, but can cause rapid wear and further leakage.

Note! Remember that with a stably functioning, working pump, the arrow on the dashboard very rarely climbs to the red mark. This can only happen in the summer, in the heat, when the car is idling or at high speeds.

Remember that the coolant temperature should not be higher than 97 degrees Celsius.

Examination

It’s easy to check the operation of the pump on the go; you need to move the control levers to blow warm air into the cabin and wait to see what the effect will be. If the air is cold, this means that there is no coolant circulation and the pump is faulty.

Above, all the reasons were described, if they occur, you will, one way or another, need to replace the water pump. And you may have a reasonable question about which one is better to choose and how to protect yourself from buying a obviously low-quality, and sometimes counterfeit, product.

Top 4. LADA 21126-1307010-82

Rating (2021): 4.70

The best balance of price and quality A productive and reliable water pump under the LADA logo is in the middle price range. At the same time, the quality of the part is not satisfactory.

- Characteristics

Average price, rub.: 1503

- Country Russia

- Impeller: plastic

Original spare part intended for Lada Priora with a 16-valve engine. Provides stable circulation of coolant and protects the engine from overheating. Due to the plastic 7-blade impeller, the part is lightweight, which makes life easier for the engine. But under the influence of high temperatures of antifreeze, the blades can become deformed and begin to scroll. However, this pump is productive and durable. Those who install this water pump on their car say that it is of high quality and lasts for at least 50,000 km. At the same time, the price for the part is affordable.

Advantages and disadvantages

- Original pump

- High performance

- Light weight

- Durability

- Plastic impeller

Top 3. FINWHALE WP126

Rating (2021): 4.75

The most affordable pump The average price for this water pump is the lowest among the participants in our rating. At the same time, the part has an increased resource.

- Characteristics

Average price, rub.: 1122

- Country: Germany

- Impeller: aluminum

The water pump with a toothed pulley is suitable for LADA Priora 2170 after 2008. The manufacturer focused on the wear resistance and durability of the part. Drive shafts are hardened to increase hardness. Polymer-ceramic seals minimize friction of the moving components of the pump and help maintain tightness for the entire life of its operation. In addition, the bearing housing has been enlarged. This allowed the use of a modernized double-row bearing capable of withstanding heavy loads. The service life of the water pump is 80,000 km. At the same time, the price tag for it is one of the lowest among analogues. In this case, you can find a fake. The red hologram with a whale and packaging with the same image help to recognize the original German pump.

Advantages and disadvantages

- Low price

- Increased resource

- Good performance

- You can find a fake

See also:

- 10 best power banks for cars

Top 2. TZA POWERFULL

Rating (2021): 4.80

Best Performance This model is equipped with an 8-blade thermoplastic impeller. The increased height of the blades creates a larger area for heat removal from the motor.

- Characteristics

Average price, rub.: 1252

- Country Russia

- Impeller: thermoplastic material

This model was produced at the Tolyatti plant, which since its founding has been supplying the needs of the AvtoVAZ conveyor. The design features and imported components of the water pump made it possible to increase its service life and productivity. There is a Slovak bearing with improved load-carrying characteristics and an Italian cassette seal. The upgraded 8-blade impeller is made of thermoplastic and has increased blade height. This made it possible to expand the working area and more efficiently remove heat from the engine. The pump shows high wear resistance, but may still begin to play towards the end of its life.

Advantages and disadvantages

- High performance

- Wear resistance

- High quality build

- May loosen over time

See also:

- 12 best batteries for VAZ