The crankcase gas cleaning system is the simplest and lightest thing in the engine. And, meanwhile, it needs increased attention from the driver. We are talking about constant care: inspection, cleaning and testing of the system; you also need to pay special attention to the crankcase ventilation valve (CVG).

Preventing the release of gases containing the entire periodic table is the main task of this system. Its device is designed not only to keep the surrounding area clean, but also to reduce the result of gas pressure on internal combustion engine parts to a minimum value.

What is the purpose of and where is the crankcase ventilation valve (CVVV) located?

The crankcase ventilation valve is needed to pass exhaust gases that accumulate in the engine crankcase back into the combustion chambers of the cylinders through the intake manifold. The KVKG is usually located in the intake manifold. There are two types of crankcase ventilation: forced and non-forced.

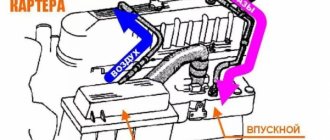

Diagram of the crankcase ventilation system

Diagnostic methods

The easiest way to check the PCV valve is by yourself. To do this, just blow into the valve from the side of the valve cover. If the air pressure from the reverse side is weak or does not come out at all, the valve is not working properly. Cleaning the crankcase ventilation system with carburetor cleaner should correct the situation. If the valve is blown in both directions, most likely it is stuck in a half-open state, or the rubber membrane is torn.

The degree of contamination and the overall efficiency of the crankcase ventilation is measured in two main ways:

- The crankcase gas pressure is measured at different engine operating modes.

- The volume of gases that the system can pass through itself is measured.

In order not to encounter the consequences of malfunctions of the VKG system, it is worth periodically changing the PCV valve, filter element, and cleaning the centrifugal/labyrinth oil trap.

Design of a crankcase gas purification system in modern cars

Crankcase gases, while passing through a simple system of special valves and tubes, exit back into the combustion chambers, where they are burned out.

Diagram of a crankcase gas cleaning system with a cyclone oil separator (1 – crankcase gas supply pipeline; 2 – air intake pipeline; 3 – membrane; 4 – compression spring; a – open position of the valve; b – closed position of the valve)

First, the gases exit into the oil separator, which is directly attached to this hole. The entire network of gaskets and baffles of the oil separator is designed to separate oil droplets from the gas mixture, which return to the sump. This function is useful because it reduces oil consumption. In different models, the oil separator is either built into the engine, or is placed under the valve cover and forms a separate unit.

Design and principle of operation of the crankcase ventilation valve

The ventilation valve has such a simple device that even a novice car enthusiast can easily learn how to disassemble and clean it.

Scheme of gas movement through the ventilation valve

It consists of:

- Plastic case.

- Lids.

- Inlet and outlet fittings.

- Two cavities.

- Membranes.

- Springs.

The principle of operation of the valve in modern cars

Video about the operating principle of the crankcase ventilation system and valve.

The ventilation valve opens in medium mode, when optimal pressure is created on the membrane. In this position, the valve overcomes the spring pressure. After passing through the oil separator, the gases are cleared of oil droplets, pass into the open valve and complete the cycle, returning back to the combustion chambers, where their combustion is completed. If we are talking about a non-forced crankcase ventilation system, then the valve almost does not open in idle mode and is closed at high speeds. At high speeds, a lot of gases are released, and hot gases often leak into the intake manifold. In this case, the valve is closed, since there is a risk of ignition of crankcase gases in the crankcase itself.

Operation of the crankcase ventilation valve in different modes

Where do the gases go if the valve is closed?

In any case, crankcase gases must be removed and under no circumstances remain inside the system. There is another iron pipe that leads to another valve. This is the so-called “fungus” or pressure reducing valve. When the main valve is closed (and this happens, let me remind you, at high speeds and at idle), the gases pass through this iron pipe directly into the “fungus”.

It also has two states: closed and open. When it is covered, a small calibrated hole inside it opens slightly, which allows the gas mixture to pass through. In this case, the gases escape through a large hole. That is, a system consisting of two valves ensures uninterrupted and reliable crankcase ventilation.

How often should cleaning be performed?

If the ventilation system is clogged and its filter is unable to clean the mixture passing through it, then not only unburned gases, but also oil particles and other pollutants will enter the engine. All this will ultimately have a negative impact on both the operation of the engine and its remaining service life.

The frequency with which the crankcase ventilation of the VAZ 2114 should be cleaned directly depends on the condition of the engine. So, if the car just recently came off the assembly line, and its engine has not clocked up 50,000 km, you shouldn’t even think about cleaning it, since the piston rings are still new, and there is practically no leakage of gases through them.

Valve cover of VAZ 2114 engine

The first cleaning (as recommended by AvtoVAZ itself) should be performed after the car has covered 60,000 km. And all subsequent cleanings should also be performed after every 60,000 km.

Many owners of domestic cars with extensive experience say that 60,000 km is too much, and cleaning should be done at least every 30,000 km - this will help avoid many problems with the engine and extend its life. In this case, the first cleaning should be carried out after the first 60,000 km.

What are valve malfunctions?

The presence of a malfunction can be determined by its characteristic symptoms.

- Oil splashing and increased oil consumption.

- Filter dirty.

- The engine does not start at full power or you can hear a slight whine from the engine.

Basic malfunctions.

- The valve and membrane are dirty.

- Exhaust openings and pipes are dirty.

- The membrane has worn out and flattened.

Crankcase gases are usually not completely released from the oil in the oil purifier. All components of the system - membranes, pipes, valves - become dirty and clogged with oil soot. If the driver does not take the time to clean them, the crankcase pressure increases. A strong smell, burning and soot appears when the engine is running. You may notice that oil consumption increases. When a valve fails, oil pressure increases and is forced past the seals and gaskets.

Valve wear is also characterized by a decrease in engine power. In this case, the pressure in the exhaust system increases or even the operation of the internal combustion engine stops completely. If the damaged valve is not completely blocked by the membrane, then oxygen entering the combustion chamber will help the engine fail.

The engine smokes

Usually a small amount of smoke comes out of the exhaust pipe. However, sometimes there come moments when thick smoke can literally pour out of your six

To understand what the problem is, you need to pay attention to its color

Transparent color. Transparent or slightly white smoke that is almost invisible. It's not even smoke, but rather steam. It occurs because the system has not yet warmed up. This is especially noticeable in winter after the car has been sitting in the yard all night. There's nothing wrong with that. After the system warms up, the steam will practically disappear.

Black color. This phenomenon looks quite scary. One of the reasons may be the usual overload of the motor with heavy weight. Try unloading the trunk if you have placed something particularly heavy in it. However, most often this problem does not arise for VAZ 2106 owners due to the small size of the vehicle

Therefore, also pay attention to how the mixture formation process proceeds. Most likely there is too much fuel entering the engine

The result is not only black smoke, but also increased fuel consumption. Try changing the air filter. You also need to measure the compression. Check the condition of the cylinders and whether the engine control sensors are working correctly. Check the spark plugs to see if they have a black coating on them, which may indicate the need to repair the engine.

White color. Unlike the clear smoke described above, this smoke has a thick white tint and does not disappear as the engine warms up. It indicates that there is a malfunction in the cooling system. This is a sure sign that urgent measures need to be taken, because a breakdown can lead to a major overhaul of the engine. Check the candles to see if they have developed a coating similar to what appears on a kettle due to scale. If this happens, it means water is getting into the cylinders.

Bluish color. The reasons for this phenomenon can be various breakdowns. For example, you can check the serviceability of the valve stem seals. If they are damaged, oil may leak and enter the idle engine. You will also have to check the oil rings. Due to their wear, excess oil may flow into the cylinders.

Advantages and disadvantages of the crankcase ventilation system

The crankcase ventilation system was constantly modified with the improvement of mechanical engineering. Modern systems often cause confusion among drivers. It all started with an ordinary pipe that led under the car and ends in modern cars with advanced systems with oil separators and valves of various types. The most modern, closed-type forced system has the following advantages:

- Minimizing the release of harmful substances.

- Oil seals and gaskets are not squeezed out due to the effective reduction of pressure inside the crankcase.

- The service life of the engine oil increases.

- Atmospheric air, dust and moisture do not enter the crankcase.

- Good engine output.