The fact is that the red lamp number 15 is on, it shows that I have problems charging the battery. I changed the relay, checked the belt tension, cleaned all the contacts, but it still lights up. Could it be the generator? Who can tell me what to do?

This lights up correctly and warns the driver that the battery is not charging. If you ignore this, the battery will discharge quite quickly and acid batteries do not like deep discharges.

Therefore, you need to check the entire battery charging network (circuit). In the description of the car, there are very detailed instructions for this case and everything is very clearly described there. Therefore, I see no point in adding anything there. It can be from a banal wire break, oxidation of battery contacts, to a malfunction of the generator itself and the relay regulator.

Everything is very simple, just like a light bulb glows constantly, as I understand it. You begin to measure the voltage with the engine running on the generator itself and subsequently further in accordance with the electrical circuit diagram. Where the voltage ceases to correspond to the norm in that area there is a malfunction.

By the way, this could also be due to the battery.

Basically there is contact, there is no contact.

I had much worse. When the engine is running in a parking lot, everything is hurt. When driving, sometimes this light was on, or even half-lit. I had no time, I had a backup battery and that was enough for me to ride all day. How things worked out. I started to figure it out, and how to figure it out, I checked all the contacts, everything was normal, I measured the voltage, everything was within normal limits. As a result, the generator began to blame, although the brushes were normal and so on. Replaced the generator and everything was back to normal. The story with the generator did not end there; after traveling for two years, the same chaos began again. Then I went to a specialist and he and I discovered soldering on the armature winding (it’s mind boggling. They sell such substandard stuff!). He and I replaced the anchor, fortunately the control unit was found and all the problems were over.

So open the description of the car, the electrical diagram of the car and especially carefully check the ways of recharging the battery. And you will be happy!

There may be several reasons why the VAZ 2106 battery light is on. Initially, it is necessary to check the integrity of fuses No. 9 and No. 10, as well as the reliability of their installation in the sockets. If the fuse links are visually intact, then you need to simultaneously check the tops of the fuses, where they can rub against their socket. This can be easily determined by the belt that appears there, which breaks the contact in the charge circuit.

Next, you should check the integrity of the alternator belt and its tension. If the belt is intact and its tension is normal, then you should check the pulleys for wear on their internal parts. The generator belt has a wedge shape, due to which it expands between the “cheeks” of the pulley. When the pulley wears out, the generator belt falls down the pulley and begins to slip. This is easy to determine by the shiny inside of the pulley, which has been polished by the belt. If the belt slips, either the battery will be incompletely charged or there will be no charge at all. This may be one of the reasons why the battery light on the VAZ 2106 is on. In such cases, the pulley must be replaced together with the generator belt.

The burning of the light bulb may also be due to oxidized terminals of the battery wires, which prevent the passage of charging current from the vehicle's generator set.

| The first step in solving battery charging light problems on any car is to strip the battery terminals and associated wires. |

Oxidized terminals can be easily cleaned with a solution of soda and water, which removes the oxide.

The terminals must be completely cleaned of oxide, wiped dry and coated with some kind of lubricant, for example Litol 24. The battery terminals themselves must also be cleaned, and also wipe the surface of the battery with a piece of rag or a brush with a soda solution. You should not clean the terminals with sandpaper, especially coarse sandpaper, since the lead from which the terminals are made can be easily removed with sandpaper. The terminals become smaller in diameter and when installing the terminals, it is no longer possible to achieve reliable contact.

It is also necessary to check the condition of the connection of the terminals on the generator, where the terminals may also be oxidized or there may be poor contact between the generator output and the terminals. In addition, the generator needs to be checked for reliability of its contact with the vehicle ground. Usually this is a wire in the form of a “snake”.

If the generator provides charging, but the light continues to light, then it is necessary to check the reliability of the wire connection and its integrity from the generator to the battery.

The malfunction may also be in the generator itself. This may be a failure of one or more diodes in the diode bridge (horseshoe), a malfunction of the stator winding, an open or short circuit of the rotor, as well as wear of the slip rings in the rotor excitation circuit.

The burning of the light bulb can also be associated with the brush assembly. Here there may be extreme wear of the brushes or their jamming in the brush holder.

The malfunction may be in the regulator relay or charging relay or in the circuit connecting them.

- Battery for VAZ 2105

There may be several reasons why the VAZ 2106 battery light is on. Initially, it is necessary to check the integrity of fuses No. 9 and No. 10, as well as the reliability of their installation in the sockets. If the fuse links are visually intact, then you need to simultaneously check the tops of the fuses, where they can rub against their socket. This can be easily determined by the belt that appears there, which breaks the contact in the charge circuit.

Next, you should check the integrity of the alternator belt and its tension. If the belt is intact and its tension is normal, then you should check the pulleys for wear on their internal parts. The generator belt has a wedge shape, due to which it expands between the “cheeks” of the pulley. When the pulley wears out, the generator belt falls down the pulley and begins to slip. This is easy to determine by the shiny inside of the pulley, which has been polished by the belt. If the belt slips, either the battery will be incompletely charged or there will be no charge at all. This may be one of the reasons why the battery light on the VAZ 2106 is on. In such cases, the pulley must be replaced together with the generator belt.

The burning of the light bulb may also be due to oxidized terminals of the battery wires, which prevent the passage of charging current from the vehicle's generator set.

| The first step in solving battery charging light problems on any car is to strip the battery terminals and associated wires. |

Oxidized terminals can be easily cleaned with a solution of soda and water, which removes the oxide.

The terminals must be completely cleaned of oxide, wiped dry and coated with some kind of lubricant, for example Litol 24. The battery terminals themselves must also be cleaned, and also wipe the surface of the battery with a piece of rag or a brush with a soda solution. You should not clean the terminals with sandpaper, especially coarse sandpaper, since the lead from which the terminals are made can be easily removed with sandpaper. The terminals become smaller in diameter and when installing the terminals, it is no longer possible to achieve reliable contact.

It is also necessary to check the condition of the connection of the terminals on the generator, where the terminals may also be oxidized or there may be poor contact between the generator output and the terminals. In addition, the generator needs to be checked for reliability of its contact with the vehicle ground. Usually this is a wire in the form of a “snake”.

If the generator provides charging, but the light continues to light, then it is necessary to check the reliability of the wire connection and its integrity from the generator to the battery.

The malfunction may also be in the generator itself. This may be a failure of one or more diodes in the diode bridge (horseshoe), a malfunction of the stator winding, an open or short circuit of the rotor, as well as wear of the slip rings in the rotor excitation circuit.

The burning of the light bulb can also be associated with the brush assembly. Here there may be extreme wear of the brushes or their jamming in the brush holder.

The malfunction may be in the regulator relay or charging relay or in the circuit connecting them.

- Battery for VAZ 2105

There is one of the indicators on the dashboard of cars that informs the driver about a decrease in oil pressure in the engine unit. The so-called oil pressure light in the form of an oil can signals a critical condition of the engine - insufficient amount of lubricant. On the panels of VAZ “classic” cars (six, seven, nine) there is also such an indicator. And if it suddenly lights up while driving or at low speeds while parked, this is a signal that there is a malfunction in the engine.

Why does the oil pressure light come on in a VAZ classic?

The first step is to distinguish cases when an icon in the form of an oil can is suddenly displayed. It is completely safe for the icon to light up for just a few moments in the following cases:

when there is a strong roll of the car on a sharp turn;

when starting in winter;

after a long period of parking on uneven ground.

As a rule, in such situations, oil flows from one part of the engine to another, which is why the oil pressure sensor is triggered. However, after some time, the working fluid is evenly distributed, and the signal about a drop in pressure in the system stops. The situation is similar when starting the engine unit in the cold season: at low temperatures, the working fluid thickens, accordingly, it is necessary to warm up the engine properly in order to create the necessary pressure in the system.

In all other cases, the appearance of an oil can on the instrument panel indicates the presence of failures or malfunctions. So for what reasons can the oil pressure light come on in classic VAZ models?

First of all, due to a lack of oil in the engine.

Due to an exhausted oil filter.

The oil pressure sensor or its wiring is to blame.

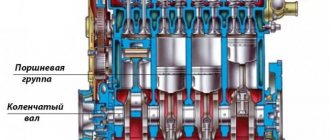

Wear of the liner on the crankshaft.

The oil pump has failed.

Any of these reasons can affect the oil pressure level in the engine unit. Therefore, the car owner will first have to find the source of the problem and only then begin troubleshooting.

The oil level control device is located separately

Dashboard faults

The instrument panel of the VAZ Six consists of a small number of devices that may stop functioning over time. The causes of breakdowns may be different, but any of them will require dismantling and partial disassembly of the shield. If one of the devices malfunctions or fails altogether, driving the vehicle becomes uncomfortable because it is impossible to control one or another vehicle system. Therefore, it is necessary to monitor the serviceability of the indicators and promptly correct any problems that arise.

Removing the dashboard

To dismantle the dashboard you will need a pair of flathead screwdrivers and pliers. The procedure is performed in the following sequence:

- Unscrew the fastener and remove the steering shaft housing.

- We pry up the shield first on one side and then on the other.

When reassembling, first install the top part of the panel, and then press on the bottom to snap the brackets into place.

Replacing backlight bulbs

If it was noticed that one of the indicators on the tidy stopped lighting up when the lights were turned on, then the most likely reason is the failure of the light bulb. To replace it, you will need a pair of slotted screwdrivers, and the procedure itself consists of the following steps:

- Repeat steps 1–2 to remove the dashboard.

- We find the device on which the light bulb has burned out and, with a simple movement of the hand, remove the socket from the pointer.

Checking and replacing the instrument panel light switch

Sometimes a situation arises when the instrument panel lighting switch stops functioning. In this case, the panel is simply not illuminated and driving a car in the dark becomes problematic. Breakdowns of the switch in most cases are caused by damage to the internal mechanism. To remove and check the part you will need a flathead screwdriver and a multimeter. The process works as follows:

- By pulling the button, we remove the switch from the instrument panel.

Checking and replacing individual devices

The breakdown of any of the VAZ 2106 indicators causes inconvenience. Problems are caused both by the age of the car and the attitude of the owner towards it. Therefore, it is worth considering possible device malfunctions and ways to eliminate them.

Fuel level indicator

Two elements are responsible for the fuel level readings on the sixth Zhiguli model: an indicator installed in the dashboard and the sensor itself, located in the gas tank. Through the latter, the light in the indicator is also activated, which indicates a low fuel level. The main problems with the device in question boil down to sensor problems, in which the arrow constantly shows a full or empty tank. We check the mechanism as follows:

- With the tank constantly full, disconnect the pink wire from the sensor by turning on the ignition. If the arrow moves to the beginning of the scale, the sensor is considered to be working. If this is not the case, then the problem lies either in the pointer indicator or in the wiring shorted to ground.

- To check the indicator, dismantle the tidy and disconnect the gray wire with a red stripe, then turn on the ignition. When the arrow returns to the extreme left position, the pointer is considered working and the wire is damaged.

If the fuel sensor fails, to replace it you will need a 7-mm open-end wrench and a Phillips screwdriver. The essence of the procedure is to remove a pair of terminals and unscrew the fasteners. A new one is installed in place of the faulty part.

Table: checking the fuel sensor

Video: installing a digital fuel gauge

Tachometer

The instrument panel tachometer displays engine speed readings. The TX-193 device is installed on the VAZ 2106. The following problems are possible with the mechanism:

- lack of evidence;

- twitching of the arrow in any mode of operation of the power unit;

- overestimated or underestimated readings.

The first malfunction is caused by wiring problems and poor contact. Therefore, you should check the condition of all connecting elements and connectors, starting with the brown wire with the terminal on the ignition coil: there should be no oxides or other damage on it. Otherwise, clean the contact with fine sandpaper and tighten the nut. You should also check the reliability of the connection between the tachometer and ground and, if necessary, restore it. In addition, with the ignition on, use a multimeter to check whether power is supplied to the device. If there is no voltage, inspect the integrity of fuse F9. Also, a digital device is used to check the reliability of the contacts in the tachometer wiring harness.

If the arrow twitches, then the problem lies in poor wiring contact or in the distributor (wear of the shaft bearing, slider or contacts on the cover). Such a malfunction can be eliminated by restoring contact or replacing failed parts. If the tachometer readings are incorrect, you will need to disassemble the distributor, clean the contacts and set the correct gap between them. If this does not help, one of the elements of the tachometer board may have failed. In this case, the device is dismantled, the board is disassembled and repaired. However, disassembly is only appropriate if you understand electrical engineering.

To replace the device you will need pliers and a screwdriver. The sequence of actions is as follows:

- We pry up the tidy and move it to the side.

- We disconnect the corresponding pads from the tachometer.

temperature sensor

The engine coolant temperature is measured using a sensor located in the cylinder head and an indicator on the dashboard.

Despite the high reliability of the sensor, malfunctions can sometimes occur with it, which are indicated by non-standard readings, for example, the absence of needle deviations. To check the sensor, you will need to remove it from the engine, lower it into water and gradually heat it up, and measure the resistance using a multimeter.

What to do when the oil pressure light comes on on Zhiguli cars

Service center specialists advise drivers of any cars, both domestic and imported, to stop driving and turn off the engine at the first signal of a drop in engine oil. When the oil pressure sensor is triggered, it is clear that there is some problem with the engine.

First action

The first thing to do after stopping is to measure the oil level. It is likely that it is below the minimum mark and you just need to add the required amount of liquid. After adding, it is necessary to take another measurement - if the level is between the Max and Min marks, then we can conclude that the sensor was triggered precisely because of a lack of oil in the engine. Try to start the engine, if the oil can icon disappears, then the problem is solved.

In VAZ-2106, VAZ-2107, VAZ-2109 cars special oil pressure sensors were installed. Modern models have not used this type of device for a long time. The oil pressure sensor on all cars of the Zhiguli family performs the same function - it measures the amount of lubricant in the engine unit. If there is not enough oil, the friction force between the moving parts of the engine increases, and this leads to rapid breakdown of both the valves, the camshaft or crankshaft, and cylinders.

The oil pressure sensor on classic VAZ models is mounted directly on the engine itself. And in the cabin, on the left side of the steering wheel, there is a dial-type indicator that shows the driver the current state of oil pressure. However, the oil can itself lights up only in one case - when there is completely no pressure in the system. The sensor cannot show any intermediate positions: either the pressure in the system is normal or there is no pressure at all.

What's next

Therefore, if you have checked the oil level and it is normal, you will need to take other measures. Maybe you recently changed the engine oil to new one? In this case, the likely cause of a sharp drop in oil pressure while driving is a defective filter. Alas, this is not uncommon these days. You will have to carry out the procedure of changing the oil and oil filter again.

Checking the sensor

Do not exclude the possibility that the oil pressure sensor is to blame. It is likely that the engine is not in any danger at all, but the sensor wiring is shorted or its life has expired, which is why it is sending incorrect signals.

To make sure that the fault lies in the sensor, you need to start the engine and at idle speed press the gas pedal to 1000–1100 rpm. If the oil can icon immediately disappears, it means that the oil pressure in the engine is actually normal and your car does not require repair. But the sensor will need to be replaced, since for various reasons it does not work.

Oil quality control

In cases where the oil filter and pressure sensor are in working condition, and the light continues to light, it is necessary to once again check the oil level in the engine, or rather, carefully inspect the oil dipstick itself. In some cases, antifreeze or gasoline may enter the engine, causing the oil level to rise. It is enough to lower the dipstick into the water; if bright stains characteristic of oil remain on the surface, it means that gasoline or coolant has actually entered the engine.

There should be only traces of oil on the oil dipstick, without the smell of any impurities

In this case, a minimum of engine flushing will be required, but most likely a major overhaul - service station specialists will determine the reason why foreign liquids are entering the unit.

The final stage

It is also likely that during the operation of the vehicle, the wires from the sensor to the light bulb were damaged or the oil paths became clogged. If you do not have the skills to work with electronics, it is best to turn to professionals at a service station.

There is a light on on the instrument panel of the VAZ 2106, what should I do?

The fact is that the red lamp number 15 is on, it shows that I have problems charging the battery. I changed the relay, checked the belt tension, cleaned all the contacts, but it still lights up. Could it be the generator? Who can tell me what to do?

This lights up correctly and warns the driver that the battery is not charging. If you ignore this, the battery will discharge quite quickly and acid batteries do not like deep discharges.

Therefore, you need to check the entire battery charging network (circuit). In the description of the car, there are very detailed instructions for this case and everything is very clearly described there. Therefore, I see no point in adding anything there. It can be from a banal wire break, oxidation of battery contacts, to a malfunction of the generator itself and the relay regulator.

Everything is very simple, just like a light bulb glows constantly, as I understand it. You begin to measure the voltage with the engine running on the generator itself and subsequently further in accordance with the electrical circuit diagram. Where the voltage ceases to correspond to the norm in that area there is a malfunction.

By the way, this could also be due to the battery.

Basically there is contact, there is no contact.

I had much worse. When the engine is running in a parking lot, everything is hurt. When driving, sometimes this light was on, or even half-lit. I had no time, I had a backup battery and that was enough for me to ride all day. How things worked out. I started to figure it out, and how to figure it out, I checked all the contacts, everything was normal, I measured the voltage, everything was within normal limits. As a result, the generator began to blame, although the brushes were normal and so on. Replaced the generator and everything was back to normal. The story with the generator did not end there; after traveling for two years, the same chaos began again. Then I went to a specialist and he and I discovered soldering on the armature winding (it’s mind boggling. They sell such substandard stuff!). He and I replaced the anchor, fortunately the control unit was found and all the problems were over.

So open the description of the car, the electrical diagram of the car and especially carefully check the ways of recharging the battery. And you will be happy!

Why does the oil pressure light come on at idle when the engine is warm?

Most Zhiguli owners are faced with the problem of indicating a drop in oil pressure at idle speed. There may be several reasons for this:

malfunction in the oil pressure sensor;

the oil pump is clogged or faulty;

low-quality oil is poured;

severe wear of the splines;

a faulty oil filter is used.

Video: reasons for the oil pressure sensor to operate and troubleshooting methods

Thus, the pressure sensor signals the presence of problems in the engine unit. If the owner does not have the necessary experience in diagnostics and repair, then it is better to entrust the identification of the true cause of the problem to a specialist. In addition, when the oil can icon lights up, it is not recommended to drive the car - there is a high probability that the rubbing parts of the engine will jam. In this case, the motor will practically not be restored.

VAZ cars of classic models are equipped with outdated, but fully functional mechanisms. The same oil pressure sensor, which signals the driver about problems with the lubrication of engine elements, performs its functions quite successfully: at the right moment the device is activated, which allows the driver to take timely measures. The most important concern of the car owner should not be repair work, but preventive procedures. Only vigilant monitoring of the condition of the engine unit and the selection of proven working fluids and filters will allow you to delay costly major repairs as much as possible.

The dashboards of classic domestic cars are not highly informative. There is nothing superfluous on them, except for indicators of the operation of the main engine systems, but they are quite enough so that the driver is informed in time about possible malfunctions of the car. However, it happens that some device fails, and then it becomes impossible to determine the failure at its initial stage.

In this article we will talk about the case when the battery charging light is constantly on, using the example of the popular classic cars VAZ 2106 and 2107. We will look at the main reasons for this phenomenon, and also try to diagnose and eliminate possible faults.

Low beam lamp VAZ-2106

- The incandescent light bulb is an outdated model, burns out quickly, is characterized by low energy efficiency, and is practically not used by modern manufacturers.

- Halogen. The most popular. They have a good service life and sufficient brightness and other lighting parameters for road conditions.

- Xenon. They are distinguished by a good bright white glow that is 3 times stronger than that of their halogen counterparts. Disadvantages - they require additional installation of an ignition unit, and can also blind oncoming road users.

- LEDs. They have the best characteristics - durability up to 100 thousand hours, high brightness, low energy consumption, no overheating. However, they are expensive and require a special reflector design for full operation.

Why do you need a battery charging warning light?

In order for the driver to monitor the charging status of the battery, there is a voltmeter with a scale on the instrument panel, as well as a small red window under which a warning light is installed. When we insert the ignition key and turn it in the lock one turn, this lamp turns on and lights up red. The voltmeter needle is in the zero position. This means that the generator is at rest and does not charge the battery. When the engine starts, the lamp should go out and the instrument needle should move to the right, indicating the amount of voltage supplied to the battery. This happens when the machine’s power supply system is fully operational. But if the VAZ 2107 or 2106 battery charging light is on even after the engine is started, most likely there is a failure somewhere. And our task is to find its cause and eliminate it.

1.8. Instruments and warning lamps

Shows driving speed in kilometers per hour (km/h) or miles/hour.

Trip meter

Records the total number of kilometers traveled.

The figure on the far right shows a run of 100 meters.

Daily trip counter with reset button

The reset button for the trip meter is located at the bottom right of the speedometer panel.

Coolant temperature indicator

If the needle is in the middle of the large field while driving, this indicates normal operating temperature.

If the gauge indicates overheating, stop the vehicle and let the engine idle until the coolant temperature drops to normal levels.

Fuel indicator

When the ignition is on, the indicator shows the amount of fuel in the tank.

If the needle does not deflect or deflects unevenly, stop the engine immediately and check the oil level.

If the level is normal, have the engine lubrication system checked by your nearest technician.

The tachometer shows the engine speed in revolutions per minute.

The red zone indicates a dangerously high speed.

When the turn signal is on, the lamps flicker to indicate the turn direction is in effect.

When the hazard warning lights are on, the lamp flickers to indicate that the alarm is active.

The warning light comes on when the remaining fuel reserve is about 7 liters. Warning

The fuel warning light comes on when the ignition is turned on.

When this light comes on, it indicates that the high beams are on.

This warning light indicates that the transfer case lever is in the 4H or 4L position.

The warning light lights up when the ignition is on and goes out after the engine starts.

If it lights up while driving, contact a specialist.

The warning light lights up when the ignition is on and goes out when the engine starts.

If it flashes while driving, the oil pressure is very low.

Stop the engine immediately and check the oil level.

If it is normal, have the lubrication system checked by your nearest service center.

Under no circumstances should the engine be operated with the warning light on.

When the ignition is on, this indicator light illuminates if the handbrake is applied.

It does not show braking effect.

If this warning light comes on with the ignition on and the handbrake applied, the brake fluid level is below the specified level.

If it comes on while driving, stop immediately and check the brake fluid level.

If it is very low, contact the workshop immediately.

If this warning light comes on, the fluid reserve has dropped to a critical point or the brake booster line is faulty.

To achieve sufficient braking in this situation, greater pedal pressure is required.

Repeated activation of the service brake system may cause a short-term drop in pressure, which cannot be regarded as a malfunction.

When the water accumulated in the water separator reaches too high a level, this warning light comes on.

If it lights up while the engine is running and does not go out, the water separator must be drained.

This indicator light may remain on for a short time or go out immediately.

The effect depends on the temperature of the engine and coolant.

If the glow plugs are warm enough to start a cold engine, the warning light goes out and the engine can be started.

The warning light comes on when the ignition is turned on and goes out when the engine is started.

If the warning light comes on during operation, the timing belt must be replaced.

The timing belt needs to be changed every 75,000 km.

If you continue to drive while the warning light is flashing, you may damage the engine.

Replace the belt as soon as possible.

The indicator light comes on when the ignition key is turned to the “ON” position.

If the light comes on while driving, it indicates a malfunction in the electronic injection system.

You need to contact a specialist and fix the problem.

This signal indicates that the oil temperature in both gearboxes is too high.

If the light comes on while driving, you need to slow down and stop the car in a suitable place.

Switch the lever to "P" and let the engine idle until the signal goes out.

When the signal goes out, you can continue driving.

If the signal does not go out, you need to have the automatic transmission lubrication system checked by a specialist.

If at high speed with all-wheel drive (4H) this signal comes on, you need to switch to 2H and move the freewheel hubs to the “FREE” position.

What can a constantly burning battery charging lamp indicate?

If the battery charging light is on in a VAZ 2107 or VAZ 2106, there can be only one reason - the battery is not receiving voltage from the generator, or is receiving it, but its value is insufficient. There may be several malfunctions that lead to this:

- violation of normal contact at the battery terminals;

- loose tension or damage to the alternator belt;

- lack of contact of its “negative” terminal with “ground”;

- break in the rotor excitation circuit or wear of the generator brushes;

- diode bridge malfunction.

- defective fuse;

- failure of the relay regulator.

Before starting diagnostics

An important point in deciding why the VAZ 2107 or 2106 battery charging light is on is the very fact that voltage is supplied to the battery from the generator. In other words, if it does not reach the battery at all, there is nothing to be surprised about. The lamp must light in such a situation. But if the battery charging light is on, but there is charging, it will be a little more difficult to solve this problem.

Our first priority is to determine whether voltage is supplied to the battery. This is not at all difficult to do, especially since this requires only one device - a voltmeter or multimeter turned on in its mode. We start the car engine, raise the hood and measure the voltage at the battery terminals with the generator running. If all elements of the system are working properly, the voltmeter should produce 13.6-14.2 V, and no less. This is a working indicator for normal battery charging. If the voltage is below these values, then there is some kind of malfunction.

Instrument panel VAZ-2103

- Glove box cover,

- storage shelf,

- Gear shift lever.

12 Parking brake lever,

- Alarm,

- Instrument lighting switch,

- Indicator lamp for insufficient fluid level in the hydraulic brakes, 16. Accelerator pedal,

- Brake pedal,

- Clutch pedal,

- Ignition switch

- Instrument cluster.

Loose or damaged alternator belt

During diagnostics, it is imperative to check the condition of the alternator belt. Sometimes it happens that due to its long-term operation or under the influence of other factors, it becomes deformed, as a result of which the generator drive misfires. Pay attention to the belt tension. Its weakening leads to the same effect.

If the belt is not deformed and has no visible damage, it can simply be tightened. Otherwise, it must be replaced. The normal belt tension is such that it can be rotated around the horizontal axis by 85-90 degrees.

Generator faults

If the battery charging light is on, but there is charging (VAZ 2106, 2107), the generator must be checked. The most common problems in terms of our malfunction are a break in the rotor excitation circuit or wear (damage) of the brushes.

First of all, the generator must be dismantled and disassembled. To check the rotor winding, we use the same multimeter turned on in ohmmeter mode. We connect its probes to the terminals of the winding and measure its resistance. For a working rotor it should not be less than 4.5 ohms. If the resistance does not reach this value, most likely an interturn short circuit has occurred somewhere. If it is not detected at all, the winding may break.

Let's move on to the brushes. We take them out of their seats and inspect them for wear. If the length of the brushes does not exceed 7 millimeters or they show signs of damage, we change them. Pay attention also to the condition of the brush commutator. If defects are detected in its copper plates, we change the rotor.

Diagnostics and repair

When the battery charging indicator light is on, it is necessary to carry out diagnostics and determine the reason for its lighting. Initially, you need to make sure that the battery is charging or the light is signaling due to some other problem, i.e. determine whether the generator is working or not.

There are a couple of simple ways to check. If trouble occurs on the road, you need to pay attention to lighting devices (headlights, panel lights, interior lights); when there is no charging, the battery runs out and the brightness of the glow decreases. Can be used at night when the headlights are on (more noticeable).

During the day, you can use the “old” effective method, which does not require any instruments and equipment, which will certainly answer whether the generator is working or not. The diagnostic sequence is as follows:

- open the hood;

- start the internal combustion engine;

- turn on consumers, providing load on the network (headlights, heated rear window, etc.);

- remove the negative terminal from the ABK;

- if the engine continues to run and the headlights are on, then the generator is successfully generating electricity that can power all systems and charge the battery;

- If the engine stalls after removing the negative terminal, then the electromechanical power source is broken.

After making sure that the generator does not produce electricity, it must be carefully examined, installed and repaired. It is better to carry out the procedure in a garage and have the minimum necessary tools.

Generator belt

You need to start with the simplest action, i.e. Check the integrity of the drive belt and its tension.

The tension is checked by pressing the belt with a finger, at an equal distance from the pulleys, with a force of about 8 kg. The deflection rate of an old belt is up to 5 mm, a new one is up to 2 mm. If it falls within these parameters, then it’s fine; if not, then it needs to be tightened up. A too-tight belt won't do any good either. It will act on the bending of the shafts of the generator, water pump and other attachments, if any.

The integrity of the belt, if there is no obvious damage, is checked after its removal. Having loosened the tensioning device (it can be on the generator or installed separately in the form of rollers), remove the belt, turn it inside out and bend it. We carefully examine the inside; if there are cracks, the belt must be replaced.

Current collection brushes

Having finished with the belt, we move on to the brushes. On most vehicles, the location of the generator on the engine allows the brush block to be removed without removing it. The brush holder and the relay regulator are manufactured as a single unit.

To remove the brushes, you need to de-energize the power system by disconnecting the terminal with the minus sign. Next, remove the wire of the voltage regulator relay from the generator connector and unscrew the two screws securing the “chocolate”. After this, remove the relay and inspect the brushes. Both the contact planes and the brushes as a whole must be smooth, of a regular rectangular shape without chips. The length of the protruding part of the brushes must be at least 40 mm. If one of the requirements does not meet, they must be replaced. The installation process is in reverse order.

Voltage regulator

After diagnosing the brushes, you can immediately check the voltage regulator, you just need to put it in place. The check is not difficult, you can do it yourself. To do this, you need to have a multimeter with you.

The point of the test is to measure the voltage at the output from the generator at different engine speeds. Procedure:

- start the engine;

- in idle mode, measure the voltage, the limit should not go beyond 13.2 to 14 V;

- increase the crankshaft speed to 2000 - 2500 rpm, the voltage values should be in the range from 13.6 to 14.2 V;

- from 3500 rpm of the crankshaft and above, the voltage on the generator should not exceed 14.5 V.

If, during measurement, the parameters coincide with the above limits, then the regulator is normal and works perfectly in tandem with the electrical machine; if there are discrepancies, then you should think about changing the regulator.

It should be remembered that the voltage supplied from the generator under load (high beam headlights, heater or air conditioner, heated windows, etc.) should not be lower than 13.2 V, and without load at maximum speed no higher than 14.8 V.

There is an option to check the voltage regulator relay for operability in a dismantled state. To do this, you need to have a power supply with adjustable voltage and a 12-volt light bulb. The circuit is simple, shown in the figure.

If the relay is working properly, the light will glow in the range from 12 to 14.5 Volts. Before and beyond these values, it should not light up, otherwise the relay-regulator does not work.

Diode bridge

The diode bridge is designed to rectify the current supplied from the generator to the vehicle's power supply system, and its breakdown significantly affects the quality and quantity of electricity generated.

Before you start checking the rectifier in detail, you need to make sure that the bridge circuit is not short-circuited.

To do this, attach the ohmmeter probe to the generator terminal marked 30, and install the second probe on the housing. With a normal working diode rectifier, the reading on the device should tend to zero.

After making sure that there is no short circuit, check the diodes for breakdown. It is better to remove the diode bridge from the generator when carrying out this procedure, otherwise the readings may not correspond to reality, and it is more convenient to manipulate. The semiconductors in the rectifier are conventionally divided into “positive” with a red housing and “negative” with a black housing. Each diode needs to be checked.

Procedure:

- Set the multimeter to measure resistance in the range from 1 to 2 kOhm.

- Separately, each diode is checked with probes, touching the outputs of the semiconductors.

- First, the diode is checked in one direction, then the probes are swapped and checked in the other direction.

- Serviceable diodes in one direction should show a resistance from 400 Ohms to 800 Ohms, in the other “infinity”.

- If the measuring device shows resistance in both directions or “infinity,” then the diode is damaged.

The damaged bridge is replaced with a new one.

Bearing

A bearing malfunction is a purely mechanical failure, leading to unpleasant consequences, including mechanical damage to the rotor and stator of an electrical machine. Bearing failure occurs due to a highly tensioned belt, poor lubrication, and lack of protection against dirt. This malfunction cannot be ignored; it will make itself known as soon as it appears. In the initial stage, the generator pulley will wear out the belt intensively, then the generator may simply jam. To prevent this, you need to do an inspection more often - check the play in the generator bearing.

It’s easy to check, first inspect the belt to see if there is obvious wear, then with the belt removed, move the generator pulley up, down and from side to side, checking the play. If so, the bearing needs to be replaced. To do this, the front cover of the generator is removed, the bearing is pressed out, a new one is pressed in and the cover is put in place.

There is no contact at the generator terminals

To be even more convincing, once we are ready to fully examine the generator, it is necessary to check the positive contact of the generator output. This may also cause the battery charging indicator light to light up. This happens because under the influence of an aggressive environment and vibration, this contact oxidizes and corrosion appears on it, preventing the normal flow of current from the electromechanical power source to the network. Therefore, in any case, it is better to do prevention after examination. Clean, if possible tin the ends of the wires and secure firmly.

In parallel with the preventive maintenance on the generator, it would not hurt to completely inspect all the wires coming from it. Inspect the terminals, insulation and, if necessary, repair or replace.

Do the same with the wires to ground.

Open circuit of the generator

There are cases of generator phase failure, most often this happens at the points where the end of the winding with the diode bridge is attached. Therefore, after fixing the problem, it is worth checking the remaining bolted and soldered connections. If there are any violations, then it is necessary to clean the bolted connections from corrosion and tighten them well; the soldering should be well tinned and soldered.

It wouldn’t hurt to check the stator winding for insulation resistance and interturn short circuit. All measurements are made with an ohmmeter or multimeter.

If during measurement the parameters do not correspond to the norm, then the generator must be rewinded, or it can also be replaced with a working unit. The insulation resistance should tend to infinity, and the resistance of the turns is indicated in the passport of the electrical machine and should not deviate.

Alternator belt tension

The belt is tensioned by special tension rollers or a belt tensioner on the generator, depending on the engine design.

The photographs show a pair of belt tension adjustment devices, and the degree of tension and testing are described above.

Diode bridge

The diode bridge is used to convert alternating voltage to direct voltage. If at least one of the diodes breaks down, the device stops coping with its tasks, which is why a voltage that does not correspond to its parameters begins to flow into the on-board circuit of the machine. That is why the rectifying bridge must be checked in the case when the battery charging light is on, but there is charging (VAZ 2107, 2106).

You can also determine the health of the diodes using a multimeter in the appropriate mode. Turn on the tester and connect the red probe to the positive terminal of the bridge, and the black probe to one of the contacts marked “AC”. The threshold (pass) voltage for silicon diodes ranges from 400 to 1000 mV. If the device shows you a value that does not fit within the specified range, the bridge must be replaced. It is impossible to repair it.

Fuse failure

The electrical charging circuit of the battery, like any other, is protected by a fuse. It is located in the mounting block under the hood of the car. In “sixes” and “sevens” this fuse is usually designated as F10, but, in any case, it is better to look through the user manual before checking. Most often, when it malfunctions, no voltage is supplied to the battery at all, but it also happens that it is the reason why the battery charging light is on, but there is charging.

The fuse is checked with a tester after it is removed from the socket. If the device shows that the part has become unusable, simply replace it.

Instrument cluster VAZ-2103

- Fuel level indicator,

- Coolant temperature gauge,

- Oil pressure gauge,

- Tachometer,

- Daily mileage counter,

- Speedometer,

- Odometer,

- Indicator lamp for turning on the high beam headlights,

- Turn signal indicator lamp,

- Indicator lamp for turning on side lights,

- Trip counter reset button,

- Battery charge indicator lamp,

- Indicator lamp for the carburetor choke control handle,

- Parking brake indicator lamp,

- Heated rear window switch,

- Insufficient oil pressure warning lamp,

- Rear fog lamp switch,

- External lighting switch,

- Fuel reserve warning lamp.

Malfunction of the relay regulator

Another reason that the battery charging light is on, but there is charging, may be a failure of the relay regulator. It, in fact, is responsible for the timely switching on and off of this lamp. In VAZ 2106, 2107 cars, the relay is installed in the engine compartment on the upper part of the wheel mudguard on the right side. The principle of its operation is as follows. When the ignition is turned on (with the engine off), current from the battery flows through its closed contacts and powers the warning lamp.

When we start the engine, the generator turns on, supplying the relay with already rectified voltage. Under its influence, the armature of the device is attracted to the core, opening the contacts. The lamp should go out.

It is not difficult to check the relay yourself. To do this, just disconnect both wires from it and short them together. We start the engine and look at the warning light. If it does not light, we replace the relay.

Description of the torpedo on the VAZ 2106

The front panel is installed in the front part of the car's interior and is a non-separable structure made in the form of a metal frame treated with polymer foam and enriched with finishing material. The panel houses the instrument panel, lighting controls, heater controls, air ducts, radio and glove compartment.

What kind of torpedo can be installed instead of the standard one?

The front panel of the sixth model Zhiguli, in comparison with modern products, does not look very attractive both in appearance and in terms of instrumentation. Therefore, many owners of “classics” are puzzled by the issue of making changes to the torpedo or replacing it. The most preferred options for front panels are products from old foreign cars. On the VAZ 2106 you can install parts from the following cars:

- VAZ 2105–07;

- VAZ 2108–09;

- VAZ 2110;

- BMW 325;

- Ford Sierra;

- Opel Kadett E;

- Opel Vectra A.

Regardless of the chosen option, it is important to understand that modifications and adjustments to the selected torpedo are inevitable.

How to remove the panel

The torpedo can be dismantled for repairs, replacement or modifications. Tools you need to prepare:

- flat and Phillips screwdriver;

- knob;

- extension;

- socket head for 10.

Dismantling is carried out in the following order:

- We remove the tidy.

- Remove the stove body.

- Unscrew the screws at the bottom of the panel.