29.04.2020

| (Votes: 3, Rating: 5) |

Issues discussed in the material:

- Functions of the alternator belt in the car

- Why does the alternator belt break?

- Is it possible to drive if the alternator belt is broken?

- What to do first if the alternator belt breaks on the road

- Signs that the alternator belt is about to break

- What do drivers think about the situation when the alternator belt breaks?

Any car enthusiast may find himself in a situation where the alternator belt breaks while on the road. Of course, many are interested in the reasons for the breakup, but in this case they are not the main thing. It’s much better to figure out what to do and how to move on.

In this material, we will analyze in detail why the alternator belt breaks, what to do immediately after discovering a problem, how to get to the nearest workshop, and whether it is generally possible to drive a car if the drive belt has broken.

Extending the life of the alternator belt

So, in order for the alternator belt to last a long time, you need to take care of it. Carefully check for debris and dirt in the belt tracks. Check the tension of the alternator belt promptly and carefully. A properly tensioned alternator belt should rotate 90 degrees. A too-tightened alternator belt will quickly become unusable and lead to a series of breakdowns. The consequences of a tightened belt can be sad. This is mainly the failure of the bearings of the generator, pump, air conditioning clutch and power steering. If the alternator belt is not tightened, the belt may squeak when the headlights or air conditioning are turned on, that is, when a load appears on the belt, it will slip along the pulley, which will quickly render it unusable. It is advisable to buy belts from trusted manufacturers and only ones suitable for a car of a specific brand. It is not recommended to install used belts.

Preventive measures

Preventative measures that will allow you to quickly identify or prevent wear:

- On most cars, according to the service documentation, the alternator belt must be replaced once every 30 thousand kilometers. This interval must be observed or the instructions in the technical manual must be followed.

- It is necessary to periodically check the tension of the drive belt. The product should not be too tight or loose.

- Once every 5 thousand kilometers you need to check the condition of the transmission product, or more often if there are signs of wear. Cracks indicate wear on the product.

- Do not allow oil or other liquids to come into contact with the belt structure.

Reasons why the alternator belt breaks

There are a huge number of reasons why the alternator belt breaks. It is not always possible to predict a broken alternator belt. Therefore, you should carefully monitor the technical condition of the car.

Aging

The main reason for a broken alternator belt is aging. During its service life, the belt experiences enormous loads, from mechanical to thermal. Over time, the elasticity of the belt is lost; it becomes rougher and more fragile; cracks appear, resulting in breakage.

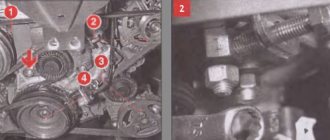

Old belt with cracks

Seized bearings

Another very common problem with a broken generator belt is jamming of the bearings of the mechanisms that drive the generator belt. For example, such as a generator, pump, air conditioning compressor, power steering, etc. To prevent the belt from breaking for this reason, you should listen to the operation of the engine and, if noise appears, eliminate the cause of the noise.

Broken alternator belt

Foreign objects getting under the belt

While driving on the roads, you can often notice various debris or something similar on the road. All this can cause the generator belt to break. Quite often there are cases when stones or sticks get under the generator belt, as a result of which the belt experiences overvoltage and breaks. The same can happen if the car is driven through deep snow, water or mud. In order to avoid such a set of circumstances, it is not recommended to drive without protective boots and generator casings.

Causes

Let's look at the reasons why a strap on a Solaris, Priora or other vehicle may burst and break.

Pulleys and Alignment

Incorrect installation of the pulley is one of the main reasons why the belt may break. If there is no alignment, this contributes to incorrect rotation of the elements. The pulleys touch other components and mechanisms, causing the belt to wear out faster. The shaft on the power steering pump unit is installed backwards - the alignment is broken. Experts advise periodically diagnosing the condition of the crank pulley for runout. The appearance of uncharacteristic sounds is often caused by a violation of alignment. A dial indicator is used for diagnostics.

The presence of runout should be checked directly on the unit, on its tension roller. Proper testing will reveal the presence of misalignment. Open the hood and look at the strap. If the product is tensioned evenly, this indicates that the pulleys are installed in the same plane. In the case of V-straps, slight wear is allowed, but not more than 1 mm per 10 cm . Please note that misalignment is caused by incorrect installation of the components themselves, and not the pulleys. For example, if a non-original pump is installed on Logan or Kalina, the alignment is disrupted. Diagnostics will show a large difference from the hub directly to the base.

Vehicles may use prefabricated pulleys made of two parts and joined by spot welding. When the strap is tightened, the weld often cannot withstand the high load and falls off. Due to the tension, parts of the pulley move apart, as a result of which the product falls into the resulting gap and breaks. If a non-original pulley with a smaller diameter is used, the load on the generator device will be higher. This will cause the strap to slip, which ultimately contributes to accelerated wear on the sidewalls. Some car owners, to save money, do not change such pulleys, but place washers and other materials under them to compensate for the sizes. This way you can achieve optimal alignment, but it is better to simply change the shaft.

How a generator set with a jammed pulley works, watch the video (author - STO Kovsh channel).

A problem in the operation of the pulley can arise when burrs form on the plane. When its surface wears out, small, barely noticeable scuffs appear, causing damage to the rubber material of the strap structure. Hangnails are a serious problem. Because of them, the belt can wear out in less than one week.

As for the pulley itself, sometimes the reason for the break lies in its high rigidity. On some older Russian-made cars, new straps are not designed for hard metal. Such machines use pulleys made of Soviet steel, and the design of the device itself is non-separable and stamped. It is better to replace such a pulley, since belts for hard metal shafts are difficult to find. It is advisable to use a light alloy product.

If there are burrs on the pulley, the surface of the device should be filed and sanded. This will increase the service life of the belt. If the vehicle is actively used, it will last at least one year. Due to incorrect alignment, the strap twists, as a result of which the battery cannot hold a charge for a long time. This is due to the inability of the generator device to produce the required voltage level.

Bearings have failed

The belt may break due to bearing devices. These parts have a certain service life, after which they must be replaced. If the bearings wear out, the strap will emit a whistling noise that is uncharacteristic of its operation. The devices themselves are designed to soften the friction of the elements. And if they fail, they cannot perform their assigned functions. And this leads to increased friction. In the absence of a strap, the bearing elements should rotate easily; if this is difficult for them, then in the future they will jam.

They should not jam, noise in the operation of the bearings is also not allowed. Regardless of the type of component failure, the problem can be corrected by dismantling and disassembling them. But it is best to replace the worn bearing with a new one, this will save financial resources for repairs.

Detailed instructions on the topic of replacing bearing devices are given below (material filmed and published by the Autoelectrics HF channel)

Incorrect selection and installation of the strap

The belt may break due to over-tightening. Because of this, the crank shaft damper bends; high loads kill it. The mistake often lies in the incorrect installation of the strap, if the product is placed backwards. In particular, when an upper pulling branch is installed under the roller. Therefore, the correct installation should be checked with the instructions. The belt must be chosen correctly, since its quality determines a lot. When choosing, consider two main nuances:

- Low quality products stretch much faster. Because of this, they slip, which leads to accelerated wear of the belt and a decrease in the car's battery charge.

- Cheap straps emit a squeaking sound when operating, this is especially evident when starting the power unit.

What to do when the alternator belt breaks on the road

The first thing you should do is not panic, because there is a way out of any situation. If you are in the city or not far from an auto parts store. You can get to the store without an alternator belt, but you first need to assess the situation.

Some vehicles use an alternator belt drive to rotate the coolant circulation pump. Therefore, if on your car the coolant circulation pump is driven by the alternator belt drive, then driving without an alternator belt on such a car is strictly PROHIBITED . If you start driving such a car, the engine will inevitably overheat and fail.

The engine on which the alternator belt rotates the coolant pump

If the pump on the car is rotated by the timing belt drive, then you can safely continue driving on the battery. For a longer trip, you must turn off all electrical equipment of the car, i.e. turn off the headlights (if you are driving at night, you can turn off one right headlight and continue driving with one headlight, this will save battery power), the interior heater, music, etc. On a well-charged battery, you can travel up to 50 km.

Signs of a weakening and imminent belt break

The owner of a car, be it a Ford Focus, Volvo XC70, Renault, or Mazda, needs to be aware of signs of wear. In order to change a torn or defective strap in time, you should understand the symptoms that allow you to determine whether it is stretched or damaged. What are the signs to determine if a car belt is broken?

- Formation of cracks across the ribs. The product shows minor damage in the form of cracks. They are located across or along one or more ribs.

- Product chipping. Small pieces or crumbs of material come off on the inside of the belt. If there is spalling, the situation is critical, since breakage can occur at any time.

- Seals on the structure. If the alternator belt breaks, it is often due to material abrading from the ribs and accumulating in the grooves.

- Abrasive wear of the structure. The front of the product is shiny, but subsequently shows signs of wear. The fabric layer is exposed, resulting in damage to the strap.

- Detachment of one or more ribs. Over time, the edge of the product moves to the side and begins to separate from the base of the structure.

- Uneven wear of one or more ribs. If one rib wears more than the others, the belt will soon break. With such a problem, a friction sound that is uncharacteristic of the normal operation of the generator may appear, such as knocks.

- Wear and damage to the outer ribs. The sides of the belt become glossy, and its outer threads wear out. In this case, the ribs look torn. As a result, loud noise appears when the generator set operates. This problem is rare, but can cause the timing belt to become too tight. This will lead to serious damage to the power unit and costly repairs.

- The surface on the edges of the strap became swollen, scaly and sticky. This occurs as a result of motor fluid entering the structure.

- The battery charge indicator on the dashboard came on. Its appearance is associated with malfunctions in the battery or generator set.

- Uncharacteristic noise and extraneous sounds. Clicking, grinding, knocking, squeaking and even chirping noises may occur. This indicates that the product is not working correctly.

- Formation of cracks on the outside of the belt. This indicates accelerated wear on a VAZ 2107, 2110, 2114 or other car model. Soon the product will begin to whistle and break off.

- Incorrect operation of optics. When you release the gas pedal, the headlights will become dimmer. When the driver presses on the gas, the illumination of the lights is restored. This is due to the fact that when you press the pedal, the rotation speed of the strap increases.

What to do when the tension weakens?

The first thing to do when the alternator belt is loose is to tighten it. There are several rollers on the generator device, one of them is used for tension. When loosening the strap, take a wrench of the appropriate size and tighten the tension element of the device. But it is also not recommended to tighten it too much, as this contributes to its wear.

What happens when a belt breaks?

If the alternator belt breaks on the road or when starting the engine in a diesel or gasoline car, the consequences for the driver will be unpleasant. What will happen:

- The generator set will not be able to power the vehicle's electrical network.

- All energy consumers will be powered from the battery.

- If the car is equipped with power steering and air conditioning, these devices will not work.

Consequences of driving without a belt

Many car owners are interested in the dangers and whether it is dangerous to rupture the belt of the generator unit in the vehicle. If the belt falls off, then in general this will not affect the operation of the main systems and components of the power unit. Due to the fact that it is coupled with a hydraulic booster system, you will have to apply more effort to turn the steering wheel.

Using the machine with a broken strap can quickly drain the battery.

Watch the video (by Roman Romanov) to see how the generator belt whistles and makes noise before it breaks.

Tools at hand instead of a belt

The alternator belt can be replaced with improvised means that are found in every car and used as a belt.

Handy tools that can be used to replace the alternator belt:

- nylon tights

- tape or tape

- rope

- lumbar belt

Rope instead of generator belt

In order to replace the alternator belt with improvised means, you do not need any special skills in car repair.

Nylon tights and tape are wound on the pulleys where the generator belt should be and tied into a knot; you can drive on such a belt of tights or tape for up to 100 km, after which a break is inevitable. All these items can be used to get to the nearest auto parts store or service station where your car will be restored to good condition.

Video “Instructions for replacing the alternator belt yourself”

Using the example of VAZ Samara cars from the 2110 family, we suggest that you familiarize yourself with a detailed guide on how to replace the alternator belt with your own hands (the material was filmed and made public by the channel In Sandro’s Garage).

Often in our work we are faced with the following situation: a call comes in asking to send a mechanic to replace the alternator belt. People do not always understand which belt has broken and what needs to be done in such a situation. In order to decide what to do, you need to understand which belt has broken: the timing belt or the alternator belt. Next, we will consider both situations and propose methods for solving them.

Video “The timing belt broke: causes and consequences”

In this video, an experienced auto mechanic will tell and show in detail what can happen to the engine if the belt is not replaced in time.

During everyday trips, drivers begin to forget about such things as checking oil, antifreeze and belts. The result is constant breakdowns. If we talk about belts, they simply break.

What function does the alternator belt play?

The newer the car, the more different electronics it contains. In older cars, the only electrical equipment was the ignition system and lighting. Nowadays, almost all elements and accessories in a car consume electricity. The biggest consumers are air conditioning, on-board computer, radio, alarm system. If many accessories are turned on, then the load on the network increases and more energy is consumed. They are all powered by a battery and a generator, which restores the battery charge. The generator is driven from the crankshaft using a belt.

Why does the belt break?

As practice shows, the belt breaks only due to severe wear. During engine operation, the belt experiences heavy loads. Despite the modern manufacturing technology of the accessory, cracks and abrasions may appear on it. It is also very common for the edges to become frayed and teeth to wear away.

If it so happens that you looked under the hood to check the condition of the belts and found at least one of the signs there, then you should think about replacing the belt. Soon he will make himself known. If there is something wrong with the belt, it may “whistle”. Also, a characteristic squeal can be heard in wet weather. Sometimes the whistle disappears, but this only means that the tension has weakened. You can tighten the belt tighter, but you shouldn't. Better to replace it. Replacing the alternator belt yourself is not a difficult task. But you can also contact the station.