The vast majority of motorists and ordinary car enthusiasts have clearly encountered the concept of an engine liner. However, not everyone fully understands what this means and how such a procedure is carried out.

The liner, like the boring, affects the cylinder block of the internal combustion engine. Such operations are carried out as part of a major overhaul, that is, a major restoration of the power unit.

If we talk about boring, then this is a method of eliminating existing defects on the cylinder walls. This is done by removing a layer of metal. Boring is done until repair dimensions are obtained, after which new repair pistons and rings are installed there. As for the liner, it is used in situations where the walls have severe and deep damage that does not allow them to be repaired by boring.

Additionally, the liner method is used in situations where the cylinders were previously bored to their maximum repair dimensions. There are some engines where the factory does not provide for boring, since it is not possible to install repair size pistons. Therefore, sleeves or sleeves are immediately used here.

What is a sleeve

This is a small removable element, which can vary in component composition. It is inserted into the cylinder block to ensure its functionality.

The liner plays the role of walls, along which the piston along with the rings is subsequently brought into operation. The working volume of the cylinder directly depends on the size of the liner.

Installation of the element into the cylinder is called lining the cylinder block. The process is complex and requires the skills of a technician, the availability of special equipment and compliance with the requirements of the technological process. Preparatory work in this situation is crucial.

For your information! Some machines can be equipped with dry and wet liners. The first has no contact with the cooled liquid. The second one constantly comes into contact with her. The latter option is equipped with a gasket that prevents liquid from penetrating into the cylinder. The wet sleeve is repairable.

General information

An important component is located on top of the main engine block with cylinders. Inside there is a camshaft that controls the valve timing. Some car models have 2 of them. The body is made in the form of an all-metal structure made of several aluminum alloys.

This allows for high strength. This is also achieved thanks to stiffening ribs that cross the entire surface area. The valve mechanisms are covered from the outside with a light cover equipped with a rubber gasket.

The entire device is represented by several elements:

- intake and exhaust valves;

- guide bushings;

- valve springs;

- breadcrumbs;

- valve stem seals;

- pushers;

- saddles.

In almost any modern engine, the camshaft is located on top and for this reason there is a seat for it, called a bed. The valves themselves perform their own tasks:

- Intake - through them the air-fuel mixture enters the combustion chamber.

- Exhaust - thanks to them, exhaust gases are discharged into the exhaust system.

They are raised and lowered by cams mounted on the camshaft. Their movement is carried out along guides.

Oil seals are needed to seal the connections. They also prevent oil from entering the combustion chamber. There are saddles under the plates, the presence of which should not be underestimated. When the valve is closed, the seat ensures complete sealing in the cylinder head, which does not prevent fuel from burning in the chamber.

Requirements for sleeves

A high-quality sleeve from the manufacturer must meet the following requirements:

- Be resistant to rust formation;

- Do not react or change the original characteristics under mechanical influence and changes in temperature parameters;

- Be made of durable and reliable material.

When selecting a sleeve yourself, it is important to consider the following:

- When selecting a sleeve, an important point is that the element matches the shape (ellipse or cone) and adheres to the wall thickness parameters. The shape should not be more than 0.02 mm, and the difference in wall thickness should not be more than 0.001 mm.

- The accuracy of the work must correspond to grades 8-10.

- In order for an element to be repairable, it is important to select it from the catalog. In this case, the allowance for future boring is important.

If you have no experience in purchasing engine parts and spare parts, it is better to entrust the work to professionals or specialized companies.

Why do bullies appear?

There are several reasons for this phenomenon:

- Natural wear and tear. In this case, scuffing occurs no earlier than after 200 thousand kilometers. There are often cases when defects were absent after 500 or more thousand kilometers.

- Late oil change or driving with a low level. As a result, the elasticity of the film is lost and the engine runs dry. The rings rub against the surface of the walls, causing scoring. Experts recommend changing the oil every 10 thousand kilometers.

- Violation of engine temperature conditions. This can cause not only scratches on the cylinder walls, but also defects in the cylinder head.

- Penetration of foreign objects into the chamber. This could be dust from a dirty air filter. Sometimes - metal shavings from a clogged oil filter. To prevent this, change these consumables every 10 thousand kilometers.

- Using fuel with the wrong octane rating. May lead to detonation, scuffing and burnout of valves.

Lining of the cylinder block

The cylinder block (BC) is lined at the factory or independently. In the first situation, the cylinder block liner involves replacing worn parts. In the second, users select similar repairable elements, with the help of which the bushings in all cylinders, including worn ones, are replaced.

Installation of a dry sleeve

The step-by-step installation of a dry sleeve is as follows:

- The BC is heated until a temperature of 150 degrees Celsius is reached;

- Before installation, the sleeve must be cold; liquid nitrogen is used to achieve optimal temperature conditions;

- The element is treated with a special solution that does not allow the formation of condensation when installing the sleeve in a hot BC;

- The sleeve is inserted into a pre-prepared socket.

Installation is complex and simple at the same time. Considered the best for achieving maximum efficiency. Thanks to optimally selected dimensions, the sleeve is tightly inserted into the socket and comes into contact with the block. The bushing should go in easily, under its own weight.

For your information! If it is impossible to bore a BC made of aluminum, the sleeve is installed using the pressing method. The difference between this method and the previous one is that the socket into which the spare part is installed is treated with sealant and then pressed into place.

If the work is carried out correctly, in compliance with all standards and requirements, the engine can be operated for at least 100-150 thousand km.

Let's sum it up

Taking into account the above, the cylinder block liner is a part of the CPG, which is largely exposed to high temperatures, vibrations and detonation loads. Therefore, the risk of various types of defects, which can lead to expensive engine repairs, is significantly increased.

As a rule, in cases where the owner of a vehicle is faced with the problems described above, it is strongly recommended to refrain from attempting independent or makeshift repairs (sleeving or re-sleeving the block in a garage).

In such a situation, it is optimal to use the help of qualified specialists and carry out troubleshooting, since non-professional repair or replacement of cylinder block liners without using technology can significantly affect the service life and stability of the internal combustion engine.

Pressing in the sleeve

If the sleeve is dry, the installation process becomes several times more complicated. To carry out pressing, boring of the cylinders will be required, as a result of which the specialist must achieve the ideal geometry of the seating shape for the element.

Deviation from the norms will lead to the inoperability of the cylinder and will not allow the normal rotation of the piston and rings.

The step-by-step pressing process is as follows:

- The BC is heated to maximum temperature;

- The sleeve is cooled by exposure to liquid nitrogen;

- The nest is treated with sealant;

- The bushing is pressed in.

How durable the power unit will be depends on the quality of the repair. If the requirements are met, the car owner is guaranteed a distance of many kilometers.

How to profitably exchange a used car

To guarantee the legality of the used car exchange service and its objective cost, the purchase and sale process should be carried out at a trusted auto center. Here the client will be offered:

- Diagnostics of the old model, on the basis of which its cost will be determined;

- Selection of cars for exchange, completely new or with a clean mileage history: all cars undergo forensic examination, therefore the car dealership will never sell a car with a “dark past”;

- Legal support of the transaction: the client enters into a notarized agreement and, if necessary, can use the credit services of the car dealership’s partner bank;

- Efficiency of the service: the client does not need to look for buyers for his vehicle; he does not need to settle issues with the traffic police or the bank. The listed functions are the task of the auto center.

Read here! The gap between the piston and the cylinder. Thus, with minimal documents, it is possible to buy an improved car within one to three days. The used car exchange service makes it possible to regularly change the owner’s vehicle fleet by purchasing its best models.

BC sleeve made of cast iron

Cast iron BCs use alloy liners with increased wear resistance, dry and wet.

- The first ones are installed after boring the BC using a cold or thermal method, which were described earlier.

- The work is done manually. Old elements are replaced with new ones.

- When boring, it is important not to violate the geometry and dimensions of the sleeve hole, otherwise you will then have to remove the excess metal layer, which will negatively affect the strength of the element.

For these reasons, it is worth using new equipment. The tolerance when installing sleeves using the cold method is 0.05 mm.

Honing

Earlier we mentioned a procedure called honing. This operation is designed to reduce the roughness of the cylinder walls. Honing improves the running-in of piston rings and increases the service life of the repaired engine.

- Roughing of cylinders. In this case, the master uses a coarse abrasive.

- Finishing processing. During the operation, fine-grained abrasive is used, which makes it possible to obtain high precision processing. Ceramic or diamond stones are used as an abrasive. The latter are highly reliable and durable. Therefore, processing with ceramic bars is becoming a thing of the past.

- Engine washing. This step removes any remaining polishing paste and metal shavings. Will the metal rust? All internal combustion engine elements are made of highly corrosion-resistant alloys.

- Final cleaning. Not used by all craftsmen, but it allows you to remove old depressions and corners that were formed during the honing process. This ensures high smoothness of the surface of the cylinders.

BC sleeve made of aluminum

The aluminum structure is sleeved similarly to cast iron. If the alloy contains locasil, to restore the BC you will need an aluminum sleeve with a silicon admixture of 28%.

- In modern structures coated with BC nickel, boring is not provided; they are restored using aluminum sleeves. Sometimes, cast iron elements can be used, which will make the repair budget-friendly.

- When carrying out work, it is important that the liner matches the original characteristics of the worn-out part. In another situation, the performance of the power unit will be called into question.

For your information! Cast iron BCs are sleeved in the normal manner. This is a familiar job for specialists and craftsmen. The same cannot be said about aluminum structures. The manufacturer does not recommend sleeving with cast iron sleeves. Practice shows the opposite. Modern “Kulibins”, in order to save money, carry out manipulations with the power unit that defy explanation.

Do-it-yourself crankshaft boring

Boring a crankshaft is a complex procedure that is almost impossible to perform even in a well-equipped garage. Since it requires high precision, and can only be carried out on professional turning equipment. In addition, to obtain a high-quality result, you need extensive experience and appropriate qualifications. You can perform the following procedures yourself:

- Remove the engine and all additional attachments, which include the gearbox, clutch and flywheel.

- Open the power unit sump, unscrew the cover of the main and connecting rod bearings. Then remove it with the liner and remove the crankshaft.

- Clean the crankshaft. For this procedure, you can use special mixtures; their abundance on the market allows you to choose the optimal liquid in any price category.

Photos of examples of engine liners

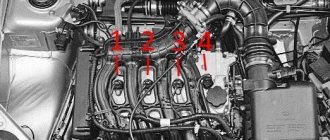

OPTIONS FOR OVERHAUL OF ICE G4KD AND G4NA

Elimination of scoring in cylinders:

Replacing the cylinder-piston group

We replace the cylinder block and pistons with rings with new ones. This solves the problem, but the price of a new unit is high, so such repairs are unprofitable. The cost of spare parts and labor in this option is comparable to the cost of the car.

Replacing the internal combustion engine with a contract one

Buying a contract engine seems optimal, but due to the large number of such malfunctions, it is pointless. Even if you buy a new engine at first glance, there is no guarantee that the same problems will not occur with it.

Block liner and pistons replacement

The best way to solve the problem. Block lining is the production of new cast iron liners that are pressed into the old cylinder block. The liners are made to the nominal size for new pistons and rings, and the block is pre-bored. This repair method is the most cost-effective.

Seizures in G4KD and G4NA cylinders are clearly visible and can be easily diagnosed with an electronic endoscope or by visual inspection after disassembly.

LLC "MotorIntekh"

Repair of engine parts

Tel., Kantemirovskaya St., 59A [direction]

Special offer

New offer.

Grinding a truck crankshaft within 24 hours! Please check with the reception staff for details.

News

Now in our company you can purchase remanufactured engine parts. Information on the availability and cost of parts can be found in the list of refurbished parts.

[Refurbished Parts List]

New equipment.

Ultrasonic bath UZV-2DN for washing parts size:

— Height — 500mm — Width — 450mm — Length — 850mm

Auto parts and components

Service from Auto parts and components for your car in stock and to order. Phones: 8 (495) 325 0131, 8 (495) 785 8137 (multi-channel)

Rules for the provision of services

Rules for the provision of services (performance of work) for the restoration of engine parts and components of MotorIntekh LLC

Questions and answers

Check out our FAQ for answers to frequently asked questions.

Have questions? Ask!

If you have any questions, you can send an email.

Thread restoration

Such a process as restoring a thread or cutting a new one occurs quite often in the process of repairing a car engine, because almost all engine repair operations involve unscrewing bolts, studs and nuts. Over time, even with proper care, any threaded connections can sour, rust, the edges of the bolts become damaged, and then unscrewing the bolt or unscrewing the nut becomes a problem.

Advantages of contacting MotorIntech LLC:

- short deadlines for completing work,

- any sizes and diameters, both metric and inch,

- we restore the thread to its previous diameter, even when there is “not enough meat”,

- the technical parameters of the threaded connection are not violated,

- low cost of work.

Restoring threaded connections, as well as honing cylinders with MotorIntekh LLC is easy. Any reason for damage to a threaded connection, be it corrosion, contamination of the threaded channel, wear, too much torque, is not a problem for our qualified specialists. We will carry out inexpensive and high-quality thread repairs in a short time.

Price examples

The cost varies depending on the region, in the capital from 1800 to 3000 rubles for the entire engine for domestic cars and from 8000 to 15000 for imported ones. In St. Petersburg, prices are almost identical to Moscow. In other areas, the pricing policy is in the following range (the cost of the liner is not taken into account, rubles per cylinder):

- VAZ, Tavria - 1100 per engine.

- Moskvich 407, 408, GAZ-52, Sobol – from 1250.

- UAZ 421 – 1600.

- Regular block (foreign cars) – from 1500.

- Inclined and V-shaped block (foreign cars) – from 2400.

- Aluminum blocks (without warranty) – from 2000.

- Compressor 1-cyl. – 1300 per motor.

- Compressor 2-cyl. – 2000 per motor.

It should be noted that the manufacturing service depends on the material of manufacture and ranges from 1100-2500 rubles per bushing .

Argon welding

Among the optimal options for permanently joining metals, the leading place is occupied by argon-arc welding. It is used in our company to restore various engine parts from simple to complex geometric shapes and is carried out by certified, highly qualified specialists.

Argon-arc welding is capable of completely welding the metal and producing a strong weld.

Advantages of argon welding:

- ensures tightness and strength, has a high level of quality welds

- affordable price

- the ability to weld titanium, stainless steel, aluminum, silumin, copper, cast iron using argon arc welding

Quite often, this type of welding is used to repair cracks in manifolds, build up missing fragments of cylinder blocks, as well as other engine parts.

Welding work at MotorIntech LLC is carried out by qualified specialists using modern equipment for argon-arc welding. Our welders constantly improve their skills in service centers of welding equipment manufacturers. This allows us to guarantee that all work, as well as engine repairs, are carried out efficiently and in a short time. Do you need argon welding? Call us at +7 (495) 325 0131, +7 (495) 785 8137!