Hydropneumatic suspension is an automobile unit that consists of elastic elements that interact with each other through hydraulic and pneumatic force. The modern system of this design is known as Hydractive. The third generation provides automatic adjustment of characteristics, which makes the unit active, depending on the road and other traffic conditions. Let's look at the features and characteristics of this block.

History of creation

Citroen's hydropneumatic suspension first appeared in 1954. It was on this brand of car that a more modern system, compared to its analogues, was tested. Over the past period, designers have been actively refining this unit and making fundamental changes to it.

Nowadays, the third generation of this type of active suspension is used. The design allows us to minimize the impact of the human factor. A similar system is also used by Mercedes under license.

Advantages

The main advantage of hydropneumatic suspension is smooth operation and minimal shock transfer to the car body. In addition, it is possible to adjust the ground clearance. The latest generation of the system in question is able to adapt to driving style. High efficiency dampens vibrations even when driving fast on uneven roads or making sharp turns.

Manufacturers who have the official right to produce the system in question often combine it with analogues of the McPherson type. The complexity of the design and high price mean that this unit is used mainly on expensive cars.

For example, the hydropneumatic suspension of the Citroen C5 is combined with a multi-link unit at the rear, and is combined with a MacPherson strut at the front. This combination makes it cheaper and easier to maintain. The main development of the node goes in two directions: expanding functionality and increasing reliability.

Device

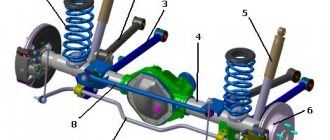

The latest generation hydropneumatic suspension consists of the following elements:

- front suspension struts;

- hydropneumatic cylinders on the rear axle;

- hydraulic and electronic unit;

- reservoir for working fluid.

Each part performs its own function, but, in some cases, a hydraulic power steering circuit may still be present.

The combined hydroelectronic unit (CHB) ensures stable system pressure and fluid level. Additional devices include:

- electric motor;

- pump;

- piston;

- electronic control;

- shut-off and safety valve.

A container with liquid is placed above the BBB. The front strut combines hydropneumatics and a cylinder, and between them there is a damping valve, which is responsible for reducing vibrations of the car body.

Hydraulic car suspension: why is it so convenient?

Greetings, dear car enthusiasts!

I’ll immediately name the main character of our article - the hydro suspension of the car. Question: what, in your opinion, are the “tricks” of business and premium class cars? Surely, for some it is the decoration and equipment of the interior, others are more attracted by the quality of materials and workmanship, but in any case, many of you will name the comfort that cars of the highest price category can give to their owners.

Comfort is expressed in the way the car handles and behaves, as well as in the fact that the car rides smoothly, absorbing almost all the bumps for which our roads are famous.

What should the happy owners of these cars be grateful for for their convenience? Answer: a special type of suspension plays a role in ensuring proper comfort, the heroine of our article is the hydropneumatic suspension of a car.

Working element and cylinder

The hydropneumatic suspension is equipped with a part that is a metal sphere, inside of which there is a multilayer membrane. The space above it is filled with liquefied nitrogen, and in the lower part there is a special liquid. Consequently, the liquid provides pressure, and the gas serves as the main elastic element.

The latest modification of the unit in question is equipped with one elastic part for each wheel and a pair of spheres on the car axle. Additional elastic elements significantly increase the range of stiffness adjustment, and the gray spheres used in the system have a working life of at least 200 thousand kilometers.

The hydraulic cylinder serves to accumulate fluid intended for elastic elements. In addition, it serves as a body height regulator relative to the track. The part consists of a rod, a piston connected to a suspension arm. The front and rear cylinders are identical in design, but the rear ones are placed at an angle.

see also

- Hydrolastic is a type of automotive suspension used in many passenger cars manufactured by British Leyland and its subsidiaries.

- Hydragas are an improved form of Hydrolastic that use compressed nitrogen springs rather than rubber.

- Oleo strut is a suspension for the largest aircraft, using the same physical properties of air and hydraulic fluid.

- Active Body Control - ABC is the Mercedes Benz brand name used to fully describe the hydraulically active suspension, which allows control of vehicle body movements and therefore virtually eliminates body roll in many driving situations, including cornering, acceleration, and braking.

- Air suspension is a type of vehicle suspension that is powered by an electric or engine-driven air pump or compressor. This compressor forces air into a flexible bellows, usually made of textile-reinforced rubber. Air pressure inflates the bellows and lifts the chassis off the axle.

- Electronic Air Suspension (EAS) is an air suspension system installed on the second version of the car. Range Rover. This system offers five suspension height options.

Hardness regulator

This part is designed to change the stiffness of the suspension. The regulator consists of a shock-absorbing and solenoid valve, a spool and an additional sphere. To achieve maximum softness, the unit allows the maximum internal volume of gas to be pumped. In this case, the solenoid valve is disconnected from the power supply.

When the solenoid valve is activated, the hydropneumatic suspension goes into hard mode. In this case, the rear cylinders, additional spheres and struts are isolated from each other.

Additional input devices of the system include sensors and mode switches. The Hydractive 3 type unit has sensors for measuring body height and steering angle. Another indicator monitors the speed and rotation of the steering wheel. The mode switch forcibly sets the height of the car and the stiffness of the suspension.

Electronic control unit

The computer is used to receive and process signals from input devices. It then outputs a signal to the suspension devices. The electronic control unit usually functions in tandem with the engine control system and anti-lock brakes.

The actuators of the Citroen hydropneumatic suspension include an electric pump motor, headlight range control, and valves. The electric motor controls rotation speed, system pressure and pump performance. The latest generation of the unit in question uses four solenoid valves, two of which regulate the rear axle, and the remaining pair regulate the front analogue. Mostly these elements are placed in liquid level regulators.

Operating principle of hydropneumatic suspension

The unit in question serves to automatically control ground clearance, adjust rigidity and force changes in these indicators. The clearance is adjusted taking into account the speed of movement, driving style and road surface. For example, at a speed of more than 110 km/h, the ground clearance is automatically reduced by 15 millimeters. On bad roads and low speeds (60 km/h or less), this parameter increases by 20 mm. It is worth noting that the height is maintained regardless of the load.

This possibility exists thanks to a special liquid circulating in the system circuit. This makes it possible to maintain a given level of the car body when driving on uneven roads.

The operation of the hydropneumatic suspension of the “+” category is distinguished by the fact that it automatically adjusts the stiffness depending on acceleration when cornering, during sharp braking and driving straight. The control unit takes into account vehicle speed, steering parameters and other aspects that change while driving.

The system automatically controls the solenoid stiffness valve, increasing or decreasing this indicator. Stiffness can change on a specific wheel or on all elements. The designers also provided for manual control of changes in ground clearance.

Receiver

Thanks to the selection of compressed air from the receiver, rapid lifting of the car body is ensured with a minimum noise level. The receiver is filled only when the car is moving, so the noise of the compressor is practically inaudible. If the pressure in the receiver is high enough, the body level can be raised without a compressor. Sufficient pressure means a level at which a pressure difference between the receiver and pneumatic elastic elements is ensured of at least 3 kgf/cm2. At vehicle speeds of up to 35 km/h, air is supplied to the system primarily from the receiver (as long as the pressure in it is high enough). At speeds above 35 km/h, air is supplied directly to the system by the compressor. This compressed air supply system helps reduce noise during operation and protects the battery from excessive discharge.

Repair and service

Hydropneumatic suspension, the design of which is discussed above, is quite an expensive pleasure. Consequently, its repair will also cost a pretty penny. Below are the approximate prices for repairs of certain elements of the system:

- Repairing a hydraulic shock absorber - from two thousand rubles.

- Replacement of the stiffness regulator - from 4.5 thousand.

- A similar procedure for the anterior sphere costs 700 rubles and more.

- The cost of the liquid used in the third generation is at least 600 rubles.

The final cost depends on the configuration of the unit and the year of manufacture of the machine. It is worth noting that the failure of one of the parts often leads to the failure of other elements. As you can see, you will have to spend money on maintenance, but it is worth it.

Recommendations

- Heissing, Bernd; Ersoy, Metin: Fahrwerkhandbuch - Grundlagen, Fahrdynamik, Komponenten, Systeme, Mechatronik, Perspektiven. Wiesbaden: Vieweg/Teubner, 2008

- https://www.linguee.com/french-english/translation/suspension+oléopneumatique.html

- ^ a b c d e

Reynolds, John: Daring to be Different p.75. Haynes, 2004 - "Archival copy." Archived from the original on 2015-02-06. Retrieved 2015-01-29.CS1 maint: zipped copy as title (link)

- "Hydropneumatic shock absorber US 1967641 A."

- "Shock-absorbing device US 1918697 A."

- ^ a b

"Two-stage oleopneumatic shock absorber."

google.com

. - ^ a b

"Project Report" (PDF).

www.wpi.edu

. - ^ a b

"Archival copy". Archived from the original on 2015-01-29. Retrieved 2015-01-29.CS1 maint: zipped copy as title (link) - "Data" (PDF). www.hydragas.co.uk

. - "Archival copy." Archived from the original on 2015-01-29. Retrieved 2015-01-29.CS1 maint: zipped copy as title (link)

- "1971 Citroen DS." nbc.com

. January 12, 2015. - "Archival copy." Archived from the original on 2015-01-29. Retrieved 2015-01-29.CS1 maint: zipped copy as title (link)

- "Lexus LX 470 suspension." activesuspensionsystems.com

. - Popular Science

. Bonnier Corporation. 1991. pp. Retrieved June 12, 2022. - REINE, Les RENDEZ-VOUS de La. “TRACTION AVANT 15cv, 6 cylinders, hydraulic suspension! LA REINE DE LA ROUTE - LES RENDEZ VOUS DE LA REINE.” lesrendezvousdelareine.com

. - "1955 Citroën DS 19 - Citroën - SuperCars.net." supercars.net

. March 31, 2016 - "Citroën Faces - the people behind Citroën." Source: Citroën

. Archived from the original on 2009-08-03. Retrieved 2014-04-01. Majes was the originator of the DS hydropneumatic suspension. His ideas were discovered by chance by Pierre Boulanger, and Boulanger was fascinated by them, although Citroën technicians considered them hopeless. Boulanger hired Mages in the development department. A decision he would never regret. Paul Majes was a curious person and studied all the literature concerning wheel suspension, suspension in general and braking systems. - "Hydraulics information" (PDF). www.mycitroen.dk/library

. - “Project Car Hell, video for the budget edition: Silver Cloud or Silver Shadow?” autoweek.com

. - Jackson, Tony; Bardenwerper, Mark L. (March 2016). "Updated description of Citroën hydraulic fluids." citroen.cappyfabrics.com

. - ^ a b

"LDS Fluid Technical Data Sheet" (PDF).

lubadmin.com

. - "Technical characteristics of the Citroën XM." Citroenet.org.uk. 2000-06-10. Retrieved 2018-06-29.

Hydropneumatic suspension "Citroen C5": reviews

As the owners confirm, the main advantage of the Citroen C5 car is precisely the presence of the described suspension. And, no matter how its competitors criticize it, it allows you to keep the car confidently and levelly on almost any road surface. The unit in question allows you to adjust the ground clearance from 15 to 20 millimeters towards decreasing or increasing. And this happens automatically.

Among other advantages, users note the smoothness of the ride, ease of dismantling the wheels and the durability of the unit. Consumers consider the high cost of repairs to be a negative feature. In addition, when moving, pits and potholes are practically unnoticed, which leads to more intensive wear of the suspension

Which cars have hydraulic suspension?

Mobile

Many have seen extremely low-slung cars passing by, and probably each of us has wondered how this is even possible. Today we want to talk about such a miracle of the automotive world as air and hydraulic suspension.

Their main purpose is to provide higher comfort and safety while driving.

Car air suspension

- This is a type of suspension with which it is possible to change the vehicle's ground clearance. Until recently, this type of suspension was most often used on trucks and trailers, minibuses, as well as SUVs and business class cars. Today such joy can be installed on almost any car.

The main difference between air suspension is the presence of an air cushion, thanks to which it is possible to ensure constant ground clearance at different vehicle loads. The air suspension is based on the designs of existing suspensions. Adjustment of the clearance, as well as softness, occurs under the control of the computer or manually. Depending on the speed of movement and intensity of acceleration, the system adjusts the ground clearance for the best aerodynamics of the car. Let us omit the principle of its operation, noting only its positive and weak sides.

Pros of air suspension:

The disadvantages include:

It is quite easy to identify air suspension problems.

A clear sign is that the car began to sag. This is due to air loss through the connection elements and wear of the air spring. Corrosion of the air spring fitting is common. The wear and service life of air suspension is directly affected by the quality of roads, climatic conditions and driving style.

Rating of the best cars with air suspension.

As practice shows, the most reliable cars with air suspension, in our opinion, are cars from the VAG concern (Audi Q7, VW Touareg, Porsche Cayenne).

These car models have a lot of positives, but there are also disadvantages. The weak point in these cars is the pressure valve coming out of the air tank. Cylinders, on the contrary, are very “tenacious”, since they are protected from the external environment by a metal shell.

The air suspensions in the Audi A8 and VW Phaeton

. The service life of air struts is quite long (up to 160 thousand km), but it all depends on driving style and road surface. Only the assembled racks are replaced, which is quite expensive.