Metelli

This Italian manufacturer produces pumps not only for domestic cars, but also for well-known foreign cars. Many car factories cooperate with him. The products are subject to strict quality control and are practically not counterfeited.

Useful: Do-it-yourself pump replacement on a VAZ 2114 (step-by-step instructions)

Pros:

- High quality;

- Few fakes;

- Reliability;

- Durability;

- Rubber gasket included;

- Affordable price.

Minuses:

- Almost none found.

The cost is about 1300 rubles.

Installing a pump VAZ 2113 VAZ 2114 - step-by-step instructions

The assembly and installation of the VAZ 2113 and VAZ 2114 pumps is carried out in the reverse order. The only thing you should pay attention to is the gaskets - it is recommended to use new ones. In addition, the connections between the pump and the pipes are coated with sealant. When the part is installed, add antifreeze. In order to prevent the formation of air pockets, disconnect the thin hose of the cooling system from the carburetor (on a carburetor engine) and ensure that the antifreeze flows out of the hose and fitting, after which the connection is made.

Start and warm up the engine, inspect the pipes for leaks. If everything is in order, the repair can be considered successfully completed.

Dolz

The company has existed since 1934. It produces water pumps for both cars and trucks. 95% of pumps on European cars are of this brand. Pros:

- Durability;

- Reliability;

- Prevalence;

- Protection against counterfeiting.

Minuses:

- High price.

The cost is about 1000 rubles.

Review of water pumps for Lada

There are currently a variety of brands and manufacturers of water pumps on the market; each manufacturer claims that its products are the best. We will try to impartially figure out what’s what, and consider one of the most popular items - a pump for front-wheel drive eight-valve VAZ cars.

To avoid any confusion, let's clear things up right away. Eight-valve engines on front-wheel drive VAZs were constantly modernized and changed, so the pumps listed below are suitable for all engines equipped with the so-called “eighth” timing belt. If we take it by model, then these are VAZ 2108, 2109, 21099, 2110, 21013, 21014, 21015, as well as Kalinas and Prioras of the first years of production.

We purchased seven samples of pumps from different manufacturers - both domestic and foreign. But before we start introducing the products, I would like to explain some of the terms that are used below.

The impeller is a low impeller, which is located on the reverse side of the main impeller, its purpose is to relieve the shaft-housing seal. Equally important is the presence of holes in the base of the impeller - they also help reduce the load on the mechanical shaft seal with the housing.

A ball roller bearing is a bearing that has balls on one side and rollers on the other. Such a bearing can carry greater loads than a double-row ball bearing.

Double row ball bearing - balls installed on both sides.

Ceramic seal - a friction pair of two rings (moving and stationary) made of various materials (carbon graphites, metals, carbides (tungsten carbide with various bonds, silicon carbide), ceramics (metal oxides), plastics) both of the same material and in combination of various materials (stainless steel - carbon graphite, Al2O3 99% (ceramics) - carbon graphite). To ensure the necessary contact between the rings, a spring, a spring block or an elastic bellows is used.

The distance from the highest point of the impeller to the landing belt - this parameter characterizes the flow: the greater this distance, the better, the smaller the gap between the impeller blade and the mating part of the block - accordingly, suction losses are reduced.

Let's get started.

1.Fenox

Country of origin: Belarus

The pump is packaged in original packaging, a sealing gasket is included with the pump, a 7-blade plastic impeller, without an impeller. There is a product passport.

Warranty - 1 year from the date of sale.

2. TZA

Country of origin: Russia

The pump is packaged in a branded cardboard box, the kit includes a sealing gasket and a product data sheet, and a protective sticker is applied to the box label, which breaks when you try to open the box. On the lid of the box there is an identification number under a washable protective layer to determine the authenticity of the product; for the same purpose, a QR code is applied to the pump pulley. The pump body is used from a VAZ-2112 with a molding for mounting the bracket, this is also evidenced by the markings on the body. The impeller is plastic, 7-blade, with an impeller.

Warranty - 1 year from the date of manufacture.

3. LUZAR

Country of origin: Russia

The pump is packaged in original packaging, the impeller is 7-bladed, made of aluminum alloy, the kit includes not only a sealing gasket, but also fasteners, sealed in a separate bag. Also included is a product passport. The LUZAR marking is applied not only to the body, but also to the pump pulley.

Warranty - 2 years or 125 thousand km from the date of purchase.

4. Oberkraft

Country of manufacture not specified

The pump is packaged in original packaging, the impeller is plastic, 7-bladed, without an impeller, the only marking is the Oberkraft inscription on the body, there are no original or company numbers. The kit includes only a sealing gasket, there is no product data sheet.

We could not find warranty information on the packaging.

5. Bautler

Country of manufacture not specified

The pump is packaged with branded logos, the kit includes a gasket and a warranty card. Bautler markings are applied to the pump body and pulley. Aluminum impeller, 6-blade, powder-coated, without impeller.

Warranty - 2 years, but not specified, from the date of manufacture or from the date of sale.

6. AV Autotechnik

Country of origin: Germany

The pump is packaged in a branded cardboard box and includes a gasket and product data sheet. The impeller is cast iron, 6-blade, there is no marking other than the original number - without packaging it will be impossible to determine the manufacturer.

The warranty indicated in the passport is from 1 year, until how long is unclear.

7. JSC "VolgaPromMarket"

Country of origin: Russia

The pump is packaged in original packaging, a thin gasket is included, no passport was found, the impeller is a plastic 6-bladed purple one. Only the original product number is marked on the case - without packaging it is impossible to determine the manufacturer. The packaging says in red letters: “Attention! The product is protected from counterfeiting!”, on the tongue of the box there is a protective sticker with an individual number.

All comparison results are summarized in a table.

Please note that some manufacturers may have changed the design of the pump, since some pumps are dated 2012.

conclusions

If we consider solely by external data and technical characteristics, the worst pumps in terms of flow will be Bautler , VolgaPromMarket CJSC and AV Autotechnik - they have 6-blade impellers without an impeller, in addition, the Bautler and VolgaPromMarket CJSC pumps have double-row ball bearings installed, They have the largest gap between the blades and the engine mate.

Oberkraft and Fenox - impellers do not have an impeller, which means that the shaft-housing mechanical seal will be more loaded compared to pumps with an impeller.

TZA and LUZAR impellers differ in material (TZA - plastic, LUZAR - aluminum alloy). The LUZAR pump uses more powerful rollers in the bearing compared to all others, but the TZA pump has additional protection against counterfeiting - you can check the authenticity using an individual number.

Skf

Swedish manufacturer, known in many countries around the world. Its production workshops are also located on the territory of the former CIS countries. The product is very durable. It usually lasts at least 130,000 kilometers, which is considered an excellent indicator for water pumps. All products at the factory undergo strict quality control. Therefore, the defect rate is negligible. Spare parts of famous brands are often counterfeited. Therefore, when purchasing, you need to be extremely careful. Original pumps have the workshop mark, and there is always a marking on the box. Even the absence of one of these signs indicates a fake. Pros:

- Excellent quality;

- Durability;

- Availability;

- Acceptable price.

Minuses:

- Lots of fakes.

The cost is about 2800 rubles.

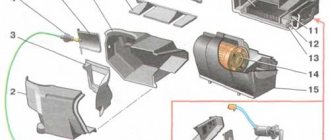

Pump design VAZ 2113 VAZ 2114

On VAZ 2113 and 2114, as on many other domestic passenger cars, the pump has almost the same design. The unit consists of a housing with a central shaft located inside, on which the impeller is fixed. The shaft is secured against axial displacement by means of a bearing, and the tightness of the structure is ensured by an oil seal that prevents coolant leakage.

There is a hole in the pump cover through which the shaft comes out, where the pulley hub and then the pulley itself are attached to it. A belt is put on the latter, which on the “seven” rotates the generator and pump from the crankshaft. On modern cars, the pump rotates via a timing belt.

Hepu

The Hepu water pump is often chosen by owners of the VAZ 2114 and other Zhiguli models. The manufacturer has its own research center. It studies the properties of metals. Therefore, our own developments are used to produce products. The parts of this brand are known for their good quality. They are designed more for moderate loads than active ones. Products often last at least 90,000 kilometers. But sometimes there are defective spare parts on sale. Pros:

- Reliability;

- Own developments;

- Prevalence;

- Affordable price.

Minuses:

- Marriage occurs.

The cost is about 1700 rubles.

Purpose of the pump VAZ 2113 VAZ 2114

The liquid cannot move through the cooling system on its own, so the design of the liquid system includes a water pump, also known as a pump.

Its main task is to ensure the circulation of coolant through the system, which ensures heat intake and removal.

The pump does nothing else, but the normal functioning of the motor depends on its operation. Without it, the power plant will overheat very quickly, since heat removal will not be provided.

The liquid cooling system of the power plant of any car ensures that the optimum temperature is maintained using liquid. Moving through the channels of the engine cooling jacket, the coolant washes the heated elements, taking away some of the heat from them, and then removes it to the environment through heat exchange processes in the radiator.

Valeo

World famous manufacturer. Its water pumps are installed on the assembly line on new cars of many brands. Pumps of this brand often last more than 150,000-180,000 kilometers. This is an excellent indicator. The cost of spare parts of this brand is quite high. In addition, fakes are often found on sale. Pros:

- Durability;

- High quality materials;

- Withstand significant loads.

Minuses:

- High price;

- Lots of fake stuff.

Cost – approximately 3000 rubles.

What is a pump in a car and its purpose?

The liquid cannot move through the cooling system on its own, so the design of the liquid system includes a water pump, also known as a pump. Its main task is to ensure the circulation of coolant through the system, which ensures heat intake and removal.

The pump does nothing else, but the normal functioning of the motor depends on its operation. Without it, the power plant will overheat very quickly, since heat removal will not be provided.

AT

Manufacturer from China. This brand produces not only pumps, but also other spare parts for VAZ and many foreign cars. The products are sold in many auto stores in Russia. Products of this brand are inexpensive. But their quality is appropriate. Water pumps are not recommended for heavy use. Their purchase is justified only with moderate, careful use and a desire to save money. Opinions about the brand among car enthusiasts are contradictory. Pros:

- Low price;

- Availability.

Minuses:

- Small resource;

- Suitable for moderate loads only;

- Marriage occurs;

- Low quality.

Cost – 850 rubles.

How to choose a pump for a VAZ

There are several signs that determine the correct choice of pump for a car. Moreover, each parameter is taken into account individually - there is no universal method.

The pump impeller can be:

- plastic;

- metal.

The first option has the advantage of having no inertial load, which makes it easier to unwind when the motor starts. The downside is the short service life and changes in the geometry of the wings under the influence of high temperatures - this reduces the efficiency of the pump. New foreign cars are equipped with impellers made of expensive materials that can withstand overheating and cavitation abrasion.

The second type is made of metal. Such impellers are heavier, take a long time to spin, but do not change geometry when heated. On the other hand, steel parts quickly become corroded when the wrong antifreeze or water is used in the cooling system, which critically reduces their performance.

According to the design, you should choose impellers with a minimum gap between the housing and the blades. This combination minimizes idle rotation of the mechanism and increases the efficiency of the unit.

The manufacturer recommends using parts of the same brand. If such pumps are not available, you should study reviews of the available company in advance and choose the best one at your own discretion.

Luzar

Russian manufacturer operating on the basis of the Ukrainian Lugansk Automobile Radiator Plant. It produces pumps and other spare parts for the VAZ 2114 and other car models. The products are distinguished by acceptable quality and low prices. It is sold in many physical and online stores. Available in all regions of the country.

The manufacturer claims a guarantee of 125,000 kilometers. But products do not always serve as expected. The percentage of defects is high. Pumps may not be designed for heavy use.

Pros:

- Acceptable quality;

- Prevalence;

- Large declared resource;

- Low prices.

Minuses:

- Not suitable for active use;

- Marriage occurs.

The cost is about 1700 rubles.

How to check the performance of the pump VAZ 2113 VAZ 2114

Checking the correct functioning of the water pump can be done in several ways; we will look at some, in my opinion, the most effective of them using the VAZ 2113 as an example.

- The first method is the simplest; it involves warming up the VAZ 2114 engine to operating temperature (the sensor needle will become vertical). Then you need to clamp the upper radiator pipe; if the water pump is working, you will feel a pulsation of coolant in the squeezed pipe.

- Check the serviceability of the oil seal and whether liquid is leaking through it through the control vent hole of the pump. To do this, remove the timing belt cover, then carefully inspect the above hole. If you find brown deposits, you will need to replace the seal with or without a water pump.

- When a lingering sound is heard from the front of the engine, it can be assumed that the pump shaft bearings have failed. To make sure of this, check the shaft play by shaking the water pump drive sprocket.

- If there are no visual signs of a malfunction, I recommend dismantling the pump and performing a more detailed inspection. Essentially, you need to pay attention to the back of the rotor. The most common problem is blades destroyed by corrosion.

If the water pump on a VAZ 2113 is faulty , repair it or completely replace it.

Dismantling

Before starting work, you need to understand where the part is located. The water pump is located on the left side of the engine compartment, under the camshaft pulley, so when it jams, the timing belt flies off.

The removal process is simple; the engine must cool down before doing this.

In a vehicle with an 8-valve engine, the following actions are required:

- Disconnect the terminal from the battery.

Disconnecting the terminal from the battery

- Remove the timing case (held on by 3 bolts).

Removing the timing case

- Place a mark on the camshaft so that it aligns with the mark on the engine. You need to jack up the car and slowly turn the right front wheel, having previously installed 4th gear.

- Move the timing belt. The product needs to be loosened; the tension roller will need to be removed.

- Unscrew the ignition module mounting bolts without disconnecting the contacts. This is necessary to get to the antifreeze or antifreeze drain plug.

- Prepare a container where the liquid will flow and a hose.

- Unscrew the plug with a key set to “13”. Place the hose, which should be directed into the container.

- When the pressure becomes weak, the lid can be screwed back on. There is no point in draining all the liquid; to make the process easier, you can leave a little.

- Then remove the container.

- Remove the thin pipe. The part is connected to the throttle valve heating unit.

- Remove all heating pipes.

- Wedge the camshaft gear teeth with a screwdriver and unscrew the fastening bolt.

- Remove the pulley.

Pulley removal

- Remove the metal casing (secured with 5 bolts).

- Unscrew the pump. Using a wooden block, tap the device body and dismantle it.

- Clean the sealant from the seating area.

Attention! During the replacement process, it is recommended to check the timing belt and pulley. If the condition of the parts is poor, they must be replaced along with the pump.

Before installing a new pump, you need to check the old one for play. Check the tightness of the oil seal. If there is no play or leaks, the old pump can be reinstalled.