Dependent suspension is a type of suspension in which two wheels located on the same axis have a rigid connection with each other. There are two types:

- on longitudinal springs - a rigid bridge beam is suspended on two longitudinal springs, which are attached to the frame or body. The spring, consisting of several interconnected metal sheets, is fixed with special clamps. Its location along the body helps to cope with forces that act in the lateral, longitudinal and vertical directions, that is, it acts as a guide and elastic element at the same time. Conventional springs cannot boast of such multifunctionality, since they are responsible only for elasticity. If the car is accelerated to high speed, such a dependent suspension will not be able to effectively counteract lateral forces - the bridge will move to the side, worsening handling. Since automakers cannot afford such a risk, longitudinal springs on ordinary passenger cars are almost impossible to find;

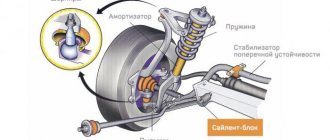

- with guide arms - consists of transverse and longitudinal arms that are attached to the axle beam and the body (or frame) of the car. They must also neutralize forces acting in the longitudinal, lateral and vertical directions, only the roles of the elastic and guiding element are distributed between the coil spring, which is responsible for elasticity, and the shock absorber, which dampens vibrations.

Rice. 1 - coiled spring; 2 — upper trailing arm; 3 — lower trailing arm; 4 - bridge beam; 5 — shock absorber; 6 — wheel hub; 7 — anti-roll bar; 8 — wishbone (Panhard rod).

The most common configuration today is one transverse and four trailing arms. The transverse one restrains the vehicle axle from moving too much sideways, while being characterized by rigidity and uneven operation, and is called the Panhard rod. In addition to it, a composite transverse lever, or Watt mechanism, is used, consisting of two horizontal levers that are attached to a vertical one. The latter is connected to the center of the axle beam and can rotate - this solution improved the performance of the suspension at different points of body roll compared to traction.

The Scott-Russell mechanism, which differs from the Panhard rod by using two levers of different lengths for greater directional stability and better controllability, has also found its application in the dependent suspension. The improvement of these characteristics was facilitated by fixing the long lever to the beam using an elastic connection, in which its movement is limited.

The de Dion system is one of the most progressive types of dependent (or, more precisely, semi-dependent) suspension, characterized by a bending spring-loaded beam, but due to the high cost of materials, this design solution is rarely found.

The dependent suspension is resistant to damage, durable, and does not require special operating conditions, but it is heavy and does not handle so well. The issue of comfort is also important - a car with such a suspension will shake more. It is mainly used for unpretentious SUVs, the main characteristics of which are cross-country ability and endurance, even if for this they have to sacrifice high speed and some precision of maneuvers.

Technical nuances

Now let’s move on to the technical side of the issue and understand the design and structure of the dependent system, as well as its varieties. Similar types of pendants include the following:

- on longitudinal springs (spring);

- with guide arms (dependent spring);

- De Dion pendant.

The first option is one of the oldest. This structure consists of a bridge beam connecting two wheels, as well as two longitudinal springs on which it is attached.

The spring in this embodiment acts as a universal elastic element - it takes on loads in the vertical and transverse planes, and also dampens body vibrations. Of course, you cannot achieve high comfort from the operation of the suspension of such a system, and at high speeds, problems with controllability begin to appear.

A design with guide arms can be called more advanced and modern. There are a lot of design options in terms of the number of levers and their configuration - this includes a suspension with a Panhard rod, and with a Watt or Scott-Russell mechanism. Compared to spring systems, these systems have much better handling and cornering behavior. The main elastic element here is the spring, and the shock absorber helps it.

As for the De Dion pendant, there is one nuance. The fact is that this system cannot be called completely dependent due to the tricky arrangement of the elements, which is due to the fact that it was developed for the rear axle of rear-wheel drive cars. In it, the differential and the beam connecting the wheels are separated.

We recommend: Ignition switch: device, purpose, operation, repair

The differential is rigidly connected to the car body, and rotation from it to the wheels is transmitted through swinging drive shafts. According to experts, the De Dion suspension is superior in many respects to the best examples of independent designs, and its only significant drawback is the price, which is why you can rarely see it, and even then mainly on sports cars.

Device and main purpose

A car suspension is a device whose diagram consists of parts connecting the wheels to the body. Moving along the road, the driver feels unevenness. The purpose of the suspension is to dampen vibrations. With its help, the wheels can rotate smoothly, regardless of the body. In addition, it is considered a mandatory attribute of the “running” of any car.

The suspension has a complex structure from a technical point of view. It includes:

Shock absorbers are devices that are needed to level out the “shaking” of the body.

The guide parts are made in the form of levers. They provide a combination of body and suspension, and also help the wheels move relative to the body.

Elastic parts are a set of elements, including torsion bars, springs and non-metallic parts. Due to their elasticity, they absorb impacts from road bumps and distribute them throughout the body.

SPU is a stabilizer in the form of a metal rod that connects the body to the suspension, while preventing the roll from increasing while the car is moving.

Wheel supports are steering knuckles that take the load from the wheels and distribute it to the suspension.

In addition, the parts include fastening elements, assemblies and suspension units.

As for its purpose, the suspension was originally created to provide comfort while driving. Elastic parts absorb vibration and distribute it. Another “option” of this design is assistance when performing maneuvers. The most complex designs are made just for this purpose. Engineers are constantly improving the part, adding even more controllability and stability to the car.

And the last purpose is an auxiliary function during braking. The suspension is able to absorb forward inertia. Experts can determine its setting by looking at how the driver brakes.

Concept of suspension

Before talking about the pros and cons, as well as the superiority of one suspension over another, if possible, I propose to understand the essence of the concept of suspension.

A suspension is a component of a car that is part of the chassis. This is an intermediate link located between the road surface and the body part of the vehicle chassis. The work of the suspension is to convert into elastic movement all the impacts that the wheels of the car have to face while driving. And these are all kinds of bumps, holes, unevenness, etc. That is, the suspension absorbs energy from impacts and increases the smoothness of the ride.

In this case, a distinction is made between the design of the front and rear suspension. They can be divided into several categories. At the same time, all structures are subject to the same requirements.

The car suspension must keep the car in a horizontal position, regardless of the acting forces, and dampen vibrations. Plus, the structures must be elastic, strong and as durable as possible. Otherwise, expensive repairs will be required.

The current classification provides for the division of pendants into 3 categories.

- Dependent. It comes with longitudinal and transverse springs, it can use guide arms or a thrust pipe. Also distinguished are the torsion-lever design and the De Dion type system;

- Independent. Such systems differ from each other in the use of oblique and double wishbones located transversely, and may have swinging axle shafts. There are options with double and single trailing arms and transverse ones. But still the most popular option is the MacPherson type suspension;

- Active or semi-dependent. Here the rigidity and position change depending on the command given through the control device. Active systems are divided into pneumohydraulic, hydraulic and pneumatic.

But this is objectively not enough to understand what the difference is between them, what differences exist and which type of suspension travel is preferable in terms of comfort. You can also read useful material about checking shock absorbers for performance.

Dependent constructs

First, let's define what it is and what the concept of car suspension dependence means. In simple terms, this is a pair of opposite wheels (left and right), which are rigidly connected to each other using a single beam. This is one of the key ways to distinguish designs from each other. Just take a look at how the left and right wheels connect to each other.

When the impact on one wheel begins, the position of the second changes. The dependence of one wheel on the other explains the name of the design. Such units are more focused on vehicles that are operated in rather difficult operating conditions. Dependent suspension is extremely rare on ordinary passenger cars designed for city driving. Therefore, finding a car is not so easy if you just need a passenger car. But the system is still in demand and is finding its place in the auto market.

Dependent auto suspension components have strengths and weaknesses.

Let's start with the shortcomings. There are several main points worth highlighting here:

- worse sustainability indicators;

- insufficiently clear controllability;

- reduced level of comfort;

- high requirements for road surfaces when driving at high speeds;

- low information content of management.

All this when compared with cars equipped with an independent type of suspension.

The weaknesses are quite significant, and are more pronounced on ordinary roads. But if you drive into ideal conditions for such a suspension, the car will show its maximum.

It is in the element of the dependent structure that its true advantages are revealed. Namely:

- Low cost of maintenance. Maintenance and repair (maintenance and technical work) are quite cheap, which allows you to significantly save on repairs;

- Resistant to damage. This suspension is not afraid of impacts, active driving on bad roads, etc. The design behaves well under heavy loads;

- High strength. Independent suspension is not a competitor in this regard;

- Constant ground clearance. The clearance does not change, which provides a number of advantages;

- Excellent adaptation to off-road and bad roads;

- A small number of design components, which simplifies maintenance and makes repairs more affordable. This also directly affects reliability.

As you can see, in its element, the dependent system allows you to count on a solid list of advantages. But on regular roads everything is not so perfect.

Independent suspension

Unlike the previous design, here the opposite wheels do not have a direct structural connection with each other. Each of the wheels acts and works independently relative to each other.

Such units perform well when driving on highways, in the city, and behave excellently at high speed. Therefore, independent designs are found mainly on passenger cars, crossovers and SUVs.

We recommend: Car rental in Moscow: prices, conditions and advice from professionals

This also has its strengths and weaknesses. Benefits include:

- excellent grip on the road surface;

- excellent level of comfort;

- excellent handling;

- minor deviations along the longitudinal axis.

All this affects comfort, agility and handling. Dependent suspensions are not capable of this.

But don't jump to conclusions about the superiority of the independent system. It also has disadvantages:

- repairs are much more expensive, as is maintenance;

- the lever stroke is short, which may reduce ground clearance;

- the design consists of many components;

- due to the complexity of the layout, the likelihood of breakdowns increases;

- It is almost impossible to carry out repairs in the field.

If we take an initially high-quality independent suspension as a basis, and operate the car in the conditions for which it is intended, all these shortcomings will not be so obvious.

Advantages and disadvantages

The advantages of dependent suspension include:

- simplicity and low cost in production, maintenance and repair;

- high strength, especially in the version with springs; a good spring is difficult to break precisely because it is flexible;

- off-road endurance, first of all, the steel beams of the bridges will come into contact with the road, and not the body, frame and other units;

- stability of ground clearance, since it is determined by unsprung beams.

There are also plenty of negative sides:

- significant unsprung masses, which makes it impossible to ensure a smooth ride with a small body weight;

- inability to obtain acceptable stability and controllability at high speeds;

- blurred reactions to the driver’s actions, which greatly removes his sensations from the actual behavior of the wheels on the road;

- the impossibility of obtaining the effects of useful steering and programmable changes in other wheel alignment angles during suspension travel.

All this imposes restrictions on the use of these types of suspensions.

Dependent suspension

Dependent suspension is the most historically ancient type of suspension: it was used in ancient times on the first chariots and carriages. Simply put, it is simply a rigid connection between the wheels. Today, cars are equipped with two types of dependent suspension: on longitudinal springs and on guide arms. The principle of the spring design is that the axle beam of the vehicle is suspended from the body or frame on two longitudinal springs. The spring itself looks like a set of special metal plates. The connection of the springs to the body is made by a stepladder (this is a special clamp). Springs are located along the body in order to direct and distribute forces acting on the axle in three directions: longitudinal, vertical and lateral.

As a result, the dependent suspension performs the functions of a damping and guiding element, as opposed to springs, which work only for elasticity.

Dependent suspension clamp

A dependent suspension based on levers looks like a structure of levers located longitudinally and transversely. One side is mounted on the axle beam, while the other is mounted on the body or frame of the vehicle. Levers perform the same functions in a suspension as springs. Most often today, cars are equipped with 4 longitudinal and 1 transverse levers, this is the so-called dependent suspension on 5 levers. The wishbone has the function of holding the vehicle's axle when it moves too far along.

There are also more modern composite levers, they look like two horizontal levers that are attached to a third vertical one, which, in turn, is attached to the beam.

A huge advantage of dependent suspension is its high strength and resistance to damage. It is also worth noting the structural simplicity of this type of suspension, that is, maintenance will be inexpensive. The disadvantages can be considered the presence of a certain unsprung mass in any car with a dependent suspension. In addition, such cars handle a little worse and have less directional stability. And, of course, on bad roads such a car shakes more.

In general, the dependent suspension is ideal for an SUV. However, you will have to accept that driving around the city and maneuvering will no longer be so easy. But in off-road conditions, even a heavily damaged car will not lose the ability to move. Even a bent bridge will not stop the car from moving.

Next in our review is the independent suspension.

Swinging wishbone suspension

Check out Ford's Twin I-Beam suspension. On it, the lever of the right wheel is attached to the left cross member of the frame, and the lever of the left - to the right. The result is very long levers - cheap and very unusual. Moreover, it turned out so successfully that a modified version of Twin Traction Beam was used for the drive axle of the Ford Bronco and Ford Explorer, as well as on various off-road sports prototypes that needed enormous suspension travel and strength.

Types of dependent suspensions

There are two types of dependent suspension: suspension with longitudinal springs and suspension with guide arms.

Suspension on longitudinal springs

The chassis consists of a rigid beam (bridge), which is suspended on two longitudinal springs. A spring is an elastic suspension element consisting of bonded metal sheets. The bridge and springs are connected using special clamps. In this type of suspension, the spring also acts as a guiding device, that is, it ensures a given movement of the wheel relative to the body. Despite the fact that dependent leaf spring suspension has been known for quite a long time, it has not lost its relevance and is still successfully used on modern cars.

Suspension with guide arms

A dependent suspension of this type additionally consists of four diagonal or three to four longitudinal rods (levers) and one transverse rod, called the “Panhard rod”. Each lever is attached to the car body and to a rigid beam. These auxiliary elements are designed to prevent lateral and longitudinal movement of the axis. There is also a damping device (shock absorber) and elastic elements, the role of which in this type of dependent suspension is performed by springs. Suspension with guide arms is widely used on modern cars.

Principle of operation

The principle of operation of a dependent suspension

The dependent suspension is a single rigid axle that connects the right and left wheels. The operation of such a suspension is distinguished by a certain pattern: if the left wheel falls into a hole (vertically falls down), then the right one rises up and vice versa. Typically, the beam is connected to the car body using two elastic elements (springs). This design is simple, but it provides a reliable connection. When one side of the car hits a bump, the entire car tilts. While driving, shocks and shaking are strongly felt inside the car, since such a suspension is based on a rigid beam.

Dependency of wheels and dust of decades

What or who does the hero of this article depend on? In fact, dependent suspension got its name because of the rigid connection between the wheels located on the same axis. They are the ones who depend on each other. So, for example, when one wheel hits an obstacle, the second one will also change position - tilt at a certain angle.

Historically, this type of suspension can be considered the first, and it appeared long before the cars themselves, back in those years when horse-drawn carts and carts ruled the roads.

At the beginning of the twentieth century, at the dawn of the era of cars, dependent structures were the dominant type, both as rear and front suspension. Over the decades, their share in the automotive industry has rapidly decreased and today they remain the prerogative of commercial vehicles, heavy-duty vehicles and some SUV models, where they can be found, as a rule, only as rear suspension. We'll talk about why this happened a little later.

Instead of an afterword

In the modern automotive industry, dependent and independent suspension is used. It should not be assumed that one of them is better than the other, since their purpose and scope are different. Under a solid axle, the ground clearance always remains the same, and this is a valuable quality for a car that drives mainly off-road. That is why SUVs use spring or spring rear suspension with a continuous axle. The car’s independent suspension cannot provide this, and the actual ground clearance may be less than stated, but its element is asphalt roads, on which it undoubtedly outperforms the bridge in handling and comfort.

Share with friends on social networks:

Telegram

Similarities and differences

Both pendants serve the same purpose. They are needed to make car travel safer and more comfortable.

In terms of design, what they have in common is that in both cases elastic elements, shock absorbers and guides are used. A striking example is the use of springs. Some actively mount air bags into springs to increase comfort.

But there are much more differences between them:

- The wheels of the dependent system have a rigid connection, making them dependent on each other. The competitor's wheels work independently;

- Independent units have more unsprung masses, which is due to the absence of a bridge;

- Independent is more sensitive to wheels that do not meet the automaker's requirements;

- The likelihood of capsizing during a sharp turn or when falling into a hole on a car with independent auto suspension is less due to the lack of a rigid connection of the wheels.

As you can see, there really is a difference, and it is significant in many ways. What exactly to choose, everyone decides for themselves.

Purpose and suspension device

Unfortunately, the road surface is not always level and smooth, and all vibrations that occur are transmitted to the car body. The suspension is designed to soften these vibrations. In other words, the suspension prevents excessive vibration while driving, providing maximum comfort to passengers. It, along with the wheels, is one of the mandatory elements of the car’s chassis.

Suspension functions:

- Connection of axles and wheels to the car body. Thanks to the presence of suspension, the wheels can turn, setting the direction of movement of the vehicle.

- Transmission of torque from the engine and the main load-bearing force.

- Ensuring a smooth ride and smoothing out the impact of road irregularities. A large load on the chassis occurs when driving on a broken road surface, which can lead to rapid breakdown.

The suspension must be strong and durable to perform its functions efficiently, so all manufacturers are looking for all kinds of solutions in this direction, introducing innovations.

In a modern car, the suspension is a rather complex technical system, which includes:

- Elastic elements. These include metal (torsion bars, springs, springs) and non-metallic (rubber, pneumatic and hydropneumatic) parts that take on the load from vibrations associated with road unevenness and distribute it evenly throughout the body. These parts have elastic characteristics, and therefore belong to this group of elements.

- Guide elements are parts that provide connection between the suspension and the body. These are various levers (transverse or longitudinal) that regulate the interaction of the wheels and the body in relation to each other.

- Shock absorbers are damping devices designed to level out body vibrations received from an elastic element. They have a hydraulic (the operating principle is based on the flow of oil fluid through a system of holes and the creation of hydraulic resistance), pneumatic (the active substance is gas) and hydropneumatic (combined) structure.

- Anti-roll bar. This is a kind of metal rod that prevents the formation of excessive roll while the car is moving.

- Wheel supports are elements on the front axle that absorb and distribute the load coming from the wheels throughout the suspension.

- Fasteners connecting parts together (for example, bolts, bushings, ball joints, etc.)

REFERENCE: the front suspension usually has two ball joints, sometimes four (for example on SUVs), less often three

Independent suspension

Independent suspension diagram

First you need to understand what independent suspension is. Simply put, this is a system in which the wheels of one axle are not connected by any rigid connection to each other. When one wheel changes its position, the other, accordingly, may not change its position. But wheel camber and track size can change during compression and rebound. Independent suspension can be on oblique or trailing arms. Independent suspension is used on various cars. When the suspension is on trailing arms, this is when each wheel of one axle is mounted on a lever, which is movably mounted on the frame or body.

The disadvantage of such a system is that the wheelbase changes greatly, but the track remains unchanged. When the car turns, body roll can be more noticeable than with any other system.

The levers absorb very large forces of torsion and bending, so they have to be made very massive and durable. Another disadvantage is the very low ground clearance, which is not very welcome on our roads.

The trailing arm suspension is not very different. Previously, it was called “independent rear axle suspension.” Accordingly, it was used when the rear axle was always the drive one. The difference with the previous version is that there is one hinge on each axis. The first version of such a suspension: the axis of the lever itself passes through the center of the axle shaft hinges, that is, the lever is located at an angle of 45 degrees to the transverse axis. Because of this, such a suspension is cheaper, but the camber and toe change, so you will have to suffer with this.

Second option: previously widely used and they replaced the old conventional dependent types of suspensions. The damping elements were torsion shafts and various coil springs. With the beginning of the spread of front-wheel drive cars, such a torsion bar suspension began to become obsolete, since it had practically no effect on the front axle.

Application

Now dependent suspensions are used only on those cars that value the above-listed advantages of a rigid connection between the wheels.

These are off-road trucks and cars, designed for constant use on bad roads or in their absence. There, simplicity and strength are much more important than the subtleties of stability and controllability.

There are also compromise options, for example, independent suspension on the front axle with a solid axle at the rear. This is how most modern jeeps are designed. Although the most uncompromising SUVs have retained rigid beams front and rear.

In budget passenger cars, a so-called semi-independent suspension is installed on the rear axle, when there is a connecting beam to the axle, but it is not rigid, but has a certain torsional elasticity. This scheme is cheaper, but its characteristics are quite acceptable.