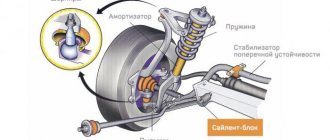

The double-wishbone suspension with short upper and long lower arms ensures minimal lateral movement of the wheel (harmful to the lateral stability of the car and causing rapid tire wear), as well as minor angular movements during up and down travel. The wishbone configuration allows each wheel to independently absorb bumps and remain more upright on the road surface. And this means better grip.

MacPherson suspension, named after the engineer Earl MacPherson who developed it in 1960, is a wheel suspension consisting of a single link, an anti-roll bar and a unit of spring element and telescopic shock absorber, called a swaying plug, due to the fact that it It is fixed in the upper part to the body using an elastic hinge and can swing when the wheel moves up and down.

Kinematically, the scheme is less perfect than a suspension on two transverse or longitudinal arms: that with a large suspension stroke, the camber (the angle of inclination of the wheel to the vertical plane) will change, and the more, the greater the suspension stroke. But due to its manufacturability and low cost, this type of suspension has become very widespread in the modern automotive industry.

Multi-link suspension is somewhat reminiscent of double-wishbone suspension and has all its positive qualities.

These suspensions are more complex and more expensive, but provide a smoother ride and better vehicle handling. A large number of elements - silent blocks and ball joints - absorb shocks well when hitting obstacles sharply. All elements are mounted on the subframe through powerful silent blocks, which increases the noise insulation of the car from the wheels.

The use of multi-link independent suspension, which is mainly used on luxury cars, gives the suspension stable contact of the wheels with any surface on the road and precise control of the vehicle when changing direction.

The main advantages of a multi-link suspension:

-Independence of the wheels from each other, -Low unsprung weight, -Independent longitudinal and lateral adjustment, -Good understeer, -Good option for use in a 4x4 configuration. The main disadvantage of the modern scheme is complexity and, accordingly, price. Until recently, it was used only on expensive cars. Now it “holds” the rear wheels of even some golf cars.

Installation of pneumatic elements On all suspensions described above, the pneumatic element is installed according to a similar scheme. It fits onto the shock absorber rod through seals that ensure the tightness of the system. The place where the pneumatic element is attached to the rack body is also reliably sealed.

Rear dependent suspension

A typical representative of this design is a rear suspension with coil springs as elastic elements. As an example, we can cite the design of the rear suspensions of classic Zhiguli cars. In this case, the rear axle beam is “suspended” on two coil springs and additionally attached to the body using four trailing arms. In addition, to improve handling, reduce body roll in corners and improve ride smoothness, a transverse reaction bar is installed.

The main disadvantage of this type of suspension is the significant mass of the rear axle beam. This figure especially increases when the axle is driven: you have to “load” the beam with the weight of the main gear housing, gearbox, etc. And all this leads to an increase in the so-called unsprung masses, which causes the smoothness of the ride to deteriorate significantly and vibrations to appear.

Pendant type "De Dion"

In an effort to “lighten” the rear axle as much as possible, engineers at many automobile companies began to use the “De Dion” type suspension, named after its inventor, the Frenchman Albert De Dion. Its main difference is that the main gear housing is now separated from the axle beam and attached directly to the body. Now the torque is transmitted from the car engine to the drive wheels through axle shafts swinging on constant velocity joints. This type of suspension can be either dependent or independent. Something similar is used on off-road vehicles, in the design of the independent type front suspension.

But despite the improvement of the design, all dependent suspensions have one very significant drawback: the car exhibits unbalanced behavior when starting and braking. The car begins to “squat” during intense acceleration and “nod off” during braking. To eliminate this effect, additional guide elements began to be used.

Semi-independent rear suspension

Structurally, it is made in the form of two longitudinal arms, which are connected in the middle by a cross member. This type of suspension is used only in the rear, but on almost all front-wheel drive cars. Among the advantages of this design are ease of installation, compactness and low weight, as a result - a reduction in “unsprung masses”, and its most significant advantage is the most optimal kinematics of the wheel. There is only one drawback: such a suspension can only be used on a non-driving rear axle.

Installation of pneumatic elements If the spring and shock absorber are structurally installed separately from each other, the spring is simply replaced with a pneumatic element with spacers of the required thickness. Spacers are used to determine the minimum and maximum ground clearance of the vehicle. If the springs with shock absorbers are assembled into a single unit, like a front strut, then the pneumatic element is installed in the same way as on the front suspension - it is put on the shock absorber rod.

McPherson type suspension

This type of suspension was developed back in 1960 by engineer Earl McPherson, in whose honor it received its name. It has several main parts:

- Anti-roll bar;

- Lever arm;

- Block (consists of a telescopic shock absorber and a spring element).

A telescopic shock absorber is also called a “swinging candle”, because it is attached to the body via a hinge and can swing when the wheel moves up and down. If interested, you can read how to check shock absorbers.

This type of suspension has its drawbacks (a significant change in the wheel camber angle), but it is extremely popular due to its affordable price, low complexity and reliability.

Types of pendants. Advantages and disadvantages

Dependent suspension

This type is distinguished from others by the presence of a rigid beam that connects the wheels. The functional principle involves the influence of the work of one wheel on another. Simple design, low maintenance, and as a result, low cost. Most often used on economy class cars, trucks and SUVs.

During the operation of such a suspension, if one wheel hits an uneven surface (rises or falls), then the second wheel, as if on a lever, takes the opposite position. In its standard form, the beam is connected to the body by springs. This type of connection is considered the most reliable. When driving on a bumpy surface, the entire body of the car tilts. In the cabin, you can feel all the unevenness of the road surface that the car's wheels hit.

Maneuverability, controllability, and smoothness are average with the dependent type of suspension.

Suspension subtypes

The rigid axle is suspended on longitudinal springs. The beam (bridge) is connected to the springs with strong clamp fastenings. The spring is a “softening” element that is the first to take impacts and smooth out their force. This is the very first type of device that was used in Egyptian chariots, but has not lost its relevance in modern automotive industry.

This subtype involves the use of a transverse (reaction) rod and diagonal or trailing arms. The car body is connected by each of the levers to the beam. The levers perform the function of softly fixing the axis. Shock absorbers and springs soften shocks in this type of suspension.

For trailers and domestic trucks, dependent spring-balance suspension is often used. Not only springs, but also balancers act as shock neutralizers, redistributing the load along the axles.

- Base (bridge). A rigid beam that connects the wheels.

- Spring. The number n of spring leaves on each side (longitudinal elements) or transverse ones located along the beam is set. Springs take part in damping. The number of sheets depends on the make/model of the car and its purpose.

- Bracket. Attaching springs to the body. The brackets can be installed fixedly or not fixedly. Non-fixed brackets are called earrings.

- Clamps.

- Shock absorbers.

- Ladder.

- Spring supports.

- Hubs.

- Springs.

- Levers.

- Panhard thrust.

- Stabilizers.

- Additional shaft (De Dion suspension).

- Differential.

- Clutch.

- Brake disk.

- Balancers.

Depending on the type and subtype, the component elements differ and not every element is present in a certain subtype of pendant. Pneumatic elements are used less frequently.

Independent suspension

This type of suspension is used most often. Unlike the dependent one, here the wheels do not have a rigid connection and do not fully influence each other. There are many subtypes within the independent system, the following are most often used:

- Double lever. Two levers, upper and lower, serve as fasteners. One end of the lever is mounted on the hub, and the other is mounted on the body. For more than half a century, this type has been used in various types of cars, most often for passenger cars. In Formula 1, it was the double-lever system that was used. Most representatives of the Zhiguli family are equipped with such a suspension.

Structurally, the lower arm from the hub is directed to a beam or subframe, and the upper arm, at the other end, is attached to the body. Silent blocks act as the basis for the hinge mounts. Shock neutralizers of this type can use springs, pneumatic cylinders, semi-elliptical springs, and torsion bars.

- Pneumatic. Essentially, this is equipment for the shock-absorbing part of the pneumatic suspension. Consequently, the type of suspension can be different (one, two and four circuits, dependent, independent, semi-dependent, etc.).

Pneumatic equipment allows you to change the ground clearance and adjust the stiffness of the suspension. Automatic mode allows the suspension to adapt to the nature of the road surface and traffic intensity.

- Dubonnet. In pre-war times, this system was popular due to improved driving performance at an inexpensive cost. Technically, the device was a lever resting on a spring, which was enclosed together with a shock absorber in a common housing. The lever represented the appearance of a knee. There was shock-absorbing fluid in the housing. This method did not find widespread use, since liquid was constantly oozing from the casing with a shock absorber and spring at the exit point of the lever. But there is an interesting fact: such a system was used in the Leopard 1 suspension and the shock absorber leak on the tank suspension was eliminated, which did not affect the automobile pneumatic elements.

- Hydraulic. The operating principle of such systems is similar to pneumatics. The difference is in the elastic element and the special liquid. Hydraulic systems are designed to last longer.

- McPherson. Created in 1960 by engineer McPherson. It consists of a lever, a spring block with a “swinging plug” shock absorber, which acts as a pivot and stability stabilizer. A less effective system compared to a double-lever transverse or longitudinal, but widely used due to its low cost and manufacturability.

Double wishbone suspension

This is one of the most advanced schemes. It is a suspension with 2 arms of different lengths (long lower and short upper), which guarantees the car excellent lateral stability on the road and minimal tire wear (lateral movements of the entire wheel are insignificant).

This means that each individual wheel perceives holes and bumps independently of the others, which allows you to maintain the most vertical attitude to the road surface and optimal grip of the tire on the road surface.

Multi-link suspension

This type of suspension is a little similar to a double wishbone design, but it is much more complex and advanced. It is not surprising that all the advantages of the previous type migrated to it. This is a set of levers, silent blocks and hinges that are attached to a special subframe. A large number of ball joints and “silents” provide not only an enviable smooth ride, but also perfectly absorb impacts in the event of a sudden collision with any obstacle, and they also reduce the noise level in the cabin from the wheels.

With this scheme, the best adhesion of the tire to the road (any type of surface), refined handling and a smooth ride are achieved.

- small unsprung masses;

- optimal wheel steering;

- independence of each individual wheel from the others;

- separate transverse and longitudinal adjustments;

- good potential with all-wheel drive.

However, the multi-link suspension has one significant drawback - its high cost. Although recently there has been a turning point: if previously this type of suspension was used only on executive cars, now even golf-class cars are equipped with it.

Adaptive suspension

This pendant is fundamentally different from other types. Strictly speaking, the creation of an adaptive scheme was not a real revolution, since the hydropneumatic suspension implemented on Citroen and Mercedes-Benz cars was taken as the basis.

But in those days it was quite primitive, heavy and took up too much space. Today, designers have been able to get rid of all these shortcomings. The only disadvantage of this approach is its complexity.

As for the advantages, there are a lot of them:

- adaptation to a specific driver;

- minimal body roll and wave buildup at high speeds;

- high security;

- excellent straight line stability;

- forced variable damping;

- automatic adaptation to any road surface.

Pendant type "De Dion"

This type, as well as the McPherson suspension, was named after the inventor. It was the Frenchman Albert De Dion. The purpose of this type of suspension is to minimize the load on the rear axle of the car by separating the final drive housing. If previously it was attached to the bridge beam itself, in this case the crankcase is held directly on the body.

This allows you to transmit torque through axle shafts mounted on CV joints, and make the suspension both independent and dependent.

But the De Dion type could not get rid of the main disadvantages of all dependent suspension options. For example, it is almost impossible to brake without “pecking”, and with a sharp start the car simply “squats” on the rear wheels.

Despite attempts to eliminate these shortcomings by installing additional elements (guides), the unbalanced behavior of the car remains the main problem.

Semi-dependent and semi-independent

In our country, controversy over this term began with the advent of front-wheel drive VAZ-2108 cars. Before this everything was simple. The Zaporozhets had an independent suspension all around, while the Volga, Zhiguli and Moskvich had an independent suspension at the front and a dependent suspension at the rear.

Independent suspension is when the movement of one wheel of the axle does not affect the other, and dependent - when it does.

Rear dependent suspension

This type is a characteristic feature of the “classic” Lada. A special feature of this design are cylindrical helical springs, which act as elastic elements. In fact, the rear axle beam not only “hangs” on these 2 springs, but is also fixed to the body by means of 4 trailing arms. This set is complemented by a reactive crossbar, which is supposed to dampen body roll and improve handling performance.

Comfort and smoothness leave much to be desired, due to the large weight of the rear axle itself and unsprung masses. This is especially true in cases where the rear axle is the drive one, since the gearbox, final drive housing and other components are attached to the beam.

Rear dependent, independent and semi-independent suspension, which is better?

Cross-country ability, smoothness, and controllability are affected by a number of characteristics. One of the main influencing factors is the suspension.

The automotive industry produces three different types of suspensions:

Within each type there are subtypes - multi-link, double-link, leaf spring, spring and others. There is also an adaptive suspension based on hydropneumatics.

Semi-independent rear suspension

This scheme has become widespread and is used in the design of most modern all-wheel drive vehicles. It consists of two longitudinal arms, which are attached to the cross member in the center. This type of suspension has many advantages:

- Small sizes;

- Light weight;

- Ease of maintenance and repair;

- The best kinematics of the wheels;

- Significant reduction in unsprung masses.

There is only one disadvantage of this design - it cannot be used on rear-wheel drive vehicles.

Independent suspension

Independent suspension diagram

First you need to understand what an independent suspension is. To put it simply, this is a system in which the wheels of one axle are not connected by any rigid connection to each other. When one wheel changes its position, the other, accordingly, may not change its position. But wheel camber and track size can change during compression and rebound. Independent suspension can be on oblique or trailing arms. Independent suspension is used on various cars. When the suspension is on trailing arms, this is when each wheel of one axle is mounted on a lever, which is movably mounted on the frame or body.

The disadvantage of such a system is that the wheelbase changes greatly, but the track remains unchanged. When the car turns, body roll can be more noticeable than with any other system.

The levers take very large forces of torsion and bending, so they have to be made very massive and durable. Another disadvantage is the very low ground clearance, which is not very welcome on our roads.

The trailing arm suspension is not very different. Previously, it was called “independent rear axle suspension.” Accordingly, it was used when the rear axle was always the drive one. The difference with the previous version is that there is one hinge on each axis. The first version of such a suspension: the axis of the lever itself passes through the center of the axle shaft hinges, that is, the lever is located at an angle of 45 degrees to the transverse axis. Because of this, such a suspension is cheaper, but the camber and toe change, so you will have to suffer with this.

Second option: previously widely used and they replaced the old conventional dependent types of suspensions. The damping elements were torsion shafts and various coil springs. With the beginning of the spread of front-wheel drive cars, such a torsion bar suspension began to become obsolete, since it had practically no effect on the front axle.

Suspensions for pickup trucks and SUVs

In different jeep models, designers take different paths. It depends on the weight and purpose of the SUV. There are three possible options for used pendants:

- Dependent rear and independent front circuits;

- Fully dependent suspension;

- Fully independent suspension.

As a rule, the rear axle is equipped with either leaf spring or spring suspension, which are combined with rigid continuous axles. Springs are used when creating pickup trucks or heavy jeeps, as they are reliable, unpretentious and able to withstand serious loads. In addition, this scheme is quite cheap, which is the reason why some budget cars are equipped with springs. Detailed information about the advantages and disadvantages of leaf spring suspension.

The spring circuit is soft and long-stroke. It is more focused on comfort and is installed on light jeeps. Regarding the complexity of the design, it is only slightly more complex than a spring one.

As for the front axle, here, in most cases, torsion bar or dependent spring circuits are used. Of course, it is also common to equip jeeps with rigid continuous axles, but such a solution is quite rare these days.

Truck suspensions

As a rule, trucks use a dependent suspension design with transverse or longitudinal springs, as well as hydraulic shock absorbers. Due to its simplicity, such a suspension is still widely used in production.

In addition, this option is the simplest. This means that the longitudinal springs are fixed in the body brackets, and the axle is suspended from them. As for the shock absorbers, they are attached directly to the rear axle beam. With this design, the main role is given to the springs, which not only support the bridge, but also connect the body and the wheel, and also act as guide elements.

However, such simplicity is decisive only in production, while the driver has to contend with poor vehicle handling at high speeds. The fact is that springs are far from ideal as guide elements. Consequently, wheel grip on the road is significantly reduced.

To summarize , we note that the types of car suspensions considered are not an exhaustive list, but these days they are the most popular, both in the domestic and global automotive industries.

- Semi-independent suspension - how does it work?

- 1. Operating principle of semi-independent suspension

- 2. Pros and cons of semi-independent suspension

What does semi-independent suspension mean?

In a modern vehicle there are many components and mechanisms, the serviceability of which directly determines the functional state and operating capabilities of any vehicle. One of the most important of them is the suspension, which performs many different functions. So, it is this element that affects the smoothness of the car, its stability and controllability.

In addition, thanks to the suspension, the body and wheels of the vehicle are connected together. The design of this unit provides for the presence of three main components: damping, elastic and guiding elements. As a rule, the role of the first one is played by shock absorbers - elastic parts presented in the form of springs, springs, rubber, torsion bars and pneumatics. They act as a buffer between the body and the suspension, smoothing out all the bumps and shocks encountered when the car moves over potholes. The guiding device is often suspension arms, which not only connect the car body to the wheels, but also determine the kinematics, that is, the trajectory of the wheel, and therefore the controllability of the car on the road. Taking into account the type of guide element, experts distinguish two main types of suspensions - dependent and independent structures. In the first version, the wheels are located on the same axis and are rigidly connected to each other by means of a beam or bridge, and in the second, they are capable of moving separately from each other. However, the named types are not the only possible designs of the described unit. With the development of technology, intermediate versions have become widespread, such as, for example, semi-independent and semi-independent suspensions.

The latter is presented in the form of longitudinal arms connected to each other by a transverse, elastic beam. This scheme is simple and reliable, providing good controllability and smooth running. In this article, we would like to pay attention to the working principles of semi-independent suspension and its advantages compared to the use of other similar designs, and since nothing is perfect in our world, we cannot fail to mention the existing disadvantages.

Operating principle of semi-independent suspension

As we just noticed, the semi-independent suspension consists of two trailing arms, which are connected to each other using a transverse beam, that is, the entire structure has the shape of the letter “P”. The trailing arms are located on both sides of the vehicle (one on each) and are attached at one end to the body (or frame of the vehicle) and the other to the wheel hub. Since the beam is able to resist bending well and twist easily, the operating principle of the entire structure is based on the shape of the elastic element. Thanks to this, the wheels were able to move in a vertical plane, regardless of each other. When the car is in motion, the suspension structure is subject to torsional forces that occur during acceleration or braking, and the cross member (beam) strives to return the wheels to their place. Sometimes, an additional electric motor is installed on the shaft (beam) and the driver has the opportunity to change the suspension stiffness manually.

The torsional force appears on the axle and from there is transmitted to the suspension. This phenomenon is compensated by strengthening the rear part of the suspension and its elastic elements. This operating principle can be called similar to the operating principle of a sprung and spring suspension. Semi-independent suspension is an intermediate link between dependent and independent suspensions, which is why it got its name. This type of design has found its application on many cars, ranging from “A” class to vehicles belonging to “C” class. Among domestic cars, the described type of suspension is installed on VAZ cars from 2108 to 2115, and among foreign cars, prominent representatives are Renault, some HONDA models and many others. A feature of the semi-independent suspension is that it can only be used on the rear, non-driving axle of front-wheel drive vehicles, however, it is installed on almost all such vehicles.

Pros and cons of semi-independent suspension

The design features that determine the type of rear suspension provide not only the advantages of its use, but also some disadvantages. It is clear that, like any other automotive component, semi-independent suspension has its own characteristic pros and cons. Among the main positive aspects of using a design of this kind, it is worth noting the comparative ease of installation, a high level of rigidity in the transverse direction, the possibility of changing the characteristics of the suspension using the geometry of the cross section of the “U”-shaped tank, compact dimensions and low weight, which helps to reduce “unsprung masses” “, but the most important and significant advantage of a semi-independent suspension is optimal wheel kinematics.

In addition, a positive point, but this time for the developers of the mechanism, is the low cost of manufacturing a semi-independent suspension and simplifying the process of assembling a car at the manufacturing plant: the entire structure of this type (including the cross member, levers and struts) is usually assembled at a separate conveyor and installed in one step. The key disadvantages , many experts say, are the possibility of installation only on the rear, non-driving axle and the presence of separate requirements for the geometry of the underbody. In general, this is the simplest version of the suspension design, suitable for ordinary cars.