Wear of suspension elements is usually characterized by the appearance of a knocking sound in the front of the car when driving over small uneven surfaces. It is difficult for an inexperienced motorist to determine by the sound which part has “gone bad” and requires replacement. But you can diagnose the problem yourself if you figure out how to check the ball joint. After all, it is its breakdown that leads to the wheel coming off and an inevitable accident. The wear of other elements - stabilizer seals, silent blocks and bearings is not so critical and allows you to operate the car for some time.

How does a ball joint work?

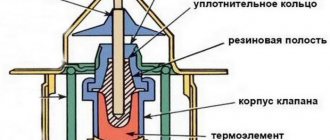

At the base of the constant velocity joint there is a pin with a ball on the edge, tightly rolled into the support body. Between the finger ball and the body there is a Teflon gasket and a special lubricant.

On the top side of the steering rod there is a rolling, the purpose of which is to secure the ball rod in the casing, and on top of it is a boot that prevents lubricant from leaking and prevents grinding components from getting in.

Ball joint diagnostics

The main signs of a failed ball joint are:

- Increased steering effort;

- Clicking sounds in the suspension and the car moving sideways when you press the brakes;

- Violation of camber and toe values. This leads to equal wear on one side of the tire;

- Wheel runout on the side, which initiates tire wear. In this case, the tire wears out unevenly, as if in shreds;

- A peculiar knocking sound that occurs when turning the car. In specific cases, noticeable wobble of the steering column may appear.

Before making repairs, you should first make sure that you need to change the steering rod. This can save a lot of time and money.

When is it worth checking?

It is necessary to check the ball joint when there is a suspicion of a problem.

Let's list the most common ones:

Knock - if a knock is heard from the front wheels while driving off-road.

Wobbling - if there is a kind of “wobbling” of the car when driving on a flat surface.

Creak - if the driver hears strange creaks when turning the steering wheel.

Wear - if it was noticed that the front tires wear unevenly, namely, the wheel with a faulty ball joint is subject to greater wear.

If at least one of these signs of malfunction is detected, we recommend checking the balls. This should be done as quickly as possible, since malfunctions pose a threat to passengers.

Why does the ball start to knock (make noise)

The root of the dysfunction of the ball joint is the development of the polymer insert. Due to rubbing between the insert and the ball, a backlash occurs, which contributes to the rapid and complete breakdown of the polymer.

Moving with loads, the ball slowly distorts the hole in the body, which often ends with the pin being pulled out of its groove. When the impermeability of the plastic boot is broken, this leads to early destruction of the polymer insert.

The penetration of liquids affects the washing away of the lubricant and the coating of the finger with rust. Particles of dust or dirt from the road increase wear, acting like sandpaper.

Unnatural noises heard when driving over road obstacles indicate problems with the steering supports.

Car owners are interested in how to find out the condition of the ball joint without using a lift and overpass? You can do the inspection yourself by doing the following:

- Park and secure the vehicle on an area with a hard surface.

- The car is raised using a jack and the wheel is removed.

- An extension made of wood or metal is placed under the lever located below.

- The car is lowered.

Such procedures are required to compress the suspension spring. By manually moving the axle from the top down, you can easily find out whether or not there is play in the steering rod. It is worth inspecting the boot to find out its integrity.

When the rubber boot is torn, it is recommended to change the support in the kit, because a small penetration of dirt, as well as sand, greatly reduces the service life of the ball bearing.

Signs of ball failure

There are several main signs that will help us suspect problems with support:

- Extraneous knocking in the wheel apron area, which occurs when overcoming road obstacles, especially when speeding.

- The car drifts in different directions when moving in a straight line.

- Creaking sound when turning the steering wheel.

- Increased wear of the tire where the damaged part is located.

If at least one of the problem points is noticed, then checking the suspension parts is mandatory. In addition, it is better to do this in advance to avoid unnecessary expenses for repairs and to protect yourself.

Diagnostics of a ball joint at home (instructions)

It is not difficult to find out the condition of the ball support on a platform or pit. The weight of the vehicle in a compressed state presses on the suspension springs. It is enough to insert the pry bar between the pin and the lever, making several rhythmic movements.

- If play is detected at the finger, then there is a breakdown at the support. It is difficult to see play in the perpendicular plane when the spring is decompressed, especially on massive jeeps, which often accommodate a suspension with many levers.

- When diagnosing on a car lift, you need to press the spring with hydraulics placed under the lever at the bottom and use a crowbar to determine the malfunction of the unit. To identify the state of the ball rod removed from the car, just turn it to the side.

When in this position the apical edge of the finger goes down under its own weight, then the working life of the support is almost exhausted and play will soon arise. It is recommended to replace this support immediately.

Dismountable supports have long ceased to be relevant, even if you received a Moskvich or a VAZ from your relatives, you cannot find spare parts for them to repair the ball joint. It will be easier to install modern units that cannot be disassembled.

Causes of malfunctions in the front suspension

| Cause of malfunction | Remedy |

| Noise (knock) in the suspension when the car is moving | |

| Telescopic suspension struts are faulty | Replace the racks |

| The bolts holding the stabilizer bar to the body are loose. Wear of rubber cushions of guy wires or barbells | Tighten the bolts, replace worn cushions |

| The fastening of the upper support of the suspension strut to the body is loose | Tighten the upper support mounting nuts |

| Settlement, destruction of the rubber element of the strut support | Replace the rubber element of the strut support |

| Wear of rubber-metal hinges of suspension arms, braces or stabilizer bar struts | Replace the hinges |

| Wear of the ball joint of the suspension arm | Replace the ball joint |

| Settlement or breakage of the suspension spring | Replace the spring |

| Destruction of compression progress buffer | Replace buffer |

| Increased wheel imbalance | Balance the wheels |

| Liquid leaking from the strut | |

| Wear or destruction of the rod seal; nicks, scuffs on the rod, damage to the chrome coating; shrinkage or damage to the strut housing O-ring (shock absorber reservoir) | Replace the shock absorber strut |

| Frequent suspension breakdowns | |

| Suspension spring draft | Replace the spring |

| Shock absorber not working | Replace the shock absorber strut |

| Insufficient resistance of the suspension strut during recoil stroke | |

| Leaking recoil valve or bypass valve; insufficient amount of fluid due to leakage; scoring on the cylinder and piston ring; wear or damage to the fluoroplastic layer of the guide bushing; recoil valve spring settlement; the presence of foreign impurities in the liquid | Replace the shock absorber strut |

| Compression valve leaking; insufficient amount of fluid due to leakage; rod wear or damage to the fluoroplastic layer of the guide bushing; the presence of foreign impurities in the liquid; wear, deformation or destruction of compression valve discs | Replace the shock absorber strut |

| Increased ball joint clearance | |

| Wear of the rubbing surfaces of the ball joint parts as a result of contamination caused by leaks or damage to the cover | Replace the ball joint |

| Moving the vehicle away from straight-line motion | |

| Different tire pressures | Set normal pressure |

| Violation of wheel alignment angles | Adjust wheel alignment |

| Destruction of the rubber element of one of the suspension strut supports | Replace the rubber element of the strut support |

| Uneven elasticity of suspension springs | Replace the spring that has lost its elasticity |

| Significant difference in tire wear | Replace worn tires |

| Increased front wheel imbalance | Balance the wheels |

| Increased tire tread wear | |

| Excessive acceleration with wheel slipping | Avoid hard acceleration |

| Frequent use of wheel locking brakes | When braking, do not allow the wheels to lock |

| Wheel alignment angles are incorrect | Adjust wheel alignment |

| Vehicle overload | Do not exceed the permissible loads specified in the instruction manual |

| Uneven tire tread wear | |

| Increased speed when cornering | Reduce speed when turning |

| Extensive wear on ball joints of suspension arms and rubber-to-metal joints | Repair the suspension |

| Wheel imbalance | Balance the wheels |

Have you ever encountered a situation where the suspension rattles (extraneous noises and knocks appear)? Were you able to diagnose the cause yourself?

Let us remind you that we previously told you how to protect the supports (nuts) of the front struts, and also why they install wishbone suspension arms.

Keywords: front suspension Lada Kalina | front suspension of Lada Granta | front suspension of Lada Priora | rear suspension of Lada Kalina | rear suspension of Lada Granta | Lada Priora rear suspension

0 0 0 0 0 0

Share on social networks:

Algorithm of actions from A to Z (master’s recommendation)

To find out the condition of the ball joints, you need to do the procedures in this order:

- The unit is inspected. Violation of the surface of the boot indicates that the element will need to be replaced. To save money, you can stop at replacing the boot. However, such a repair rarely gives good results, because dust that gets into the middle of the hinge will have a bad effect on its integrity. When no superficial symptoms are noticed, then you can move on.

- Using a lift or jack, the car is raised and a previously prepared support is placed under the support body. It is optimal to use a height-adjustable tripod. Then the vehicle gradually lowers down, pressing on the ball bearing. The wheel here ends up in the air and is able to spin without interference.

- Grasping the top and bottom of the wheel, it is allowed to wobble vertically. It’s good when the assistant here begins to turn the steering wheel carefully and smoothly. It will be possible to notice wear only in a separate wheel location. Having seen the backlash, there is no need to come to hasty conclusions. Perhaps it arose due to a breakdown or insufficient screwing of the bearing on the hub, a violation of the silent blocks of the lever, or other errors. The check is ongoing.

- Having installed the flattened edge of the mount into the hole between the pivot pin and the lever, you should press the handle and observe the components of the support. When the part is not broken, there will be no play. Clicks or knocking sounds when pressing on the mount handle also indicate a malfunction of the device.

replacement and diagnostics of Remzon VAZ

In this article we will talk about how to repair the suspension on a VAZ 2114 car, and more specifically, about replacing ball joints.

These are the elements that fail most often, despite the fact that they are practically eternal. Judging by the instructions for use. But the service life of ball joints is affected by the driver’s driving style, the quality of the road surface, and most importantly, the initial quality of the product. Unfortunately, more and more often you can find low-quality products on the market, refurbished ones, which will last very little. There is an opinion that restored ball joints can work for quite a long time. But is there any point in restoring such a simple and fairly cheap mechanism?

The cost of a ball joint for a VAZ 2114 car, as well as for most front-wheel drive models, is no more than 500 rubles. Moreover, for such a price you will get a very high quality product. But let’s get closer to the topic of the article, namely, repairing a car’s suspension.

Diagnosis of ball joint malfunction

Identifying the breakdown is quite simple; to do this, you just need to sit in the front seat of the car. If a peculiar crunch appears from the suspension, we can talk about a malfunction of the VAZ 2114 ball joint. You don’t even need to try to look for any other reasons, the malfunction is in this particular joint. Moreover, a peculiar crunch can be observed when the car is moving slowly. During acceleration it usually disappears, but this depends on the degree of wear of the mechanism.

And the second diagnostic method is to pull the car wheel in a vertical plane with your hands. If there is a breakdown, you will definitely hear a crunch. A similar phenomenon occurs when using a mount. It must be installed between the suspension arm and the wheel hub. If you move the mount sharply, you can still hear the same nasty sound.

To be sure, you can even drive the car onto a viewing hole or overpass. Grasp the suspension arms and pull them down several times. A good knock, as they say, will come out. And if you put your palm on the body of the VAZ 2114 ball joint, you can feel a slight vibration from the inside.

Preparation for replacement and tools

To carry out the repair you will need the following tools:

- Ball joint remover. The price of such a tool is about 350-400 rubles. I advise you to purchase it, as it will definitely be useful to you in the future.

- Standard set of wrenches and screwdrivers.

- Litol type lubricant.

- Jack and reliable supports.

- Wheel chocks, which are placed under the rear wheels to prevent the car from rolling away.

That's all, now you need to prepare the car for repair. To do this, you need to install wheel chocks, loosen the wheel bolts, lift the side being repaired using a jack and install it on a support. Wooden blocks can be used as support, but it is not advisable to use materials such as bricks, cinder blocks, and the like. They are fragile and the car can simply fall during repairs. If necessary, treat all threaded connections with a penetrating lubricant such as WD-40.

Carrying out replacement

Now the crucial moment has come, it is necessary to remove the old ball joint of the VAZ 2114 and install a new one in its place. First, using a 19mm wrench, unscrew the nut that secures the ball joint pin to the front wheel hub. After this, you need to install the puller so that the small ball on its bolt is clearly in the middle of the hinge pin.

Carefully screw in this bolt until the pin comes off the wheel hub. After this, you need to use a key “17” to unscrew the bolts that secure the joint cage to the suspension arm of the VAZ 2114. That’s all, the dismantling is complete. Now all that remains is to install a new hinge, which it is advisable to pre-lubricate with Litol. To be honest, I also used CV joint type lubricant for this purpose.

I haven’t noticed much of a difference; the ball joints have been working without problems for three years now

Please note that when installing a new joint, you may have to install several blocks of wood under the arm and lower the body so that the ball pin fits into the hole in the hub. But this job can be done with a good pry bar.

The repair is complete, good luck on the roads and fewer breakdowns!

Options for determining the condition of the ball joint

It is possible to find out what the condition of the ball is in two ways. You can visually determine the continuity of the boot, and if there are cracks or irregularities in it, replace it with a newer product.

- It is also possible to drive a car onto a platform or pit, and there, due to mechanical manipulations, violations are determined.

- To do this using the mechanical method, you will need to get under the vehicle and pull the wheel with your hands several times to feel the presence of play.

- You can take a crowbar, then put it between the lever and the support, and then try to push it upward.

The use of iron is the most effective way to determine backlash. Another method is to remove the balls, clamp them in a vice, and then check the play of the pin and axle.

When the finger moves with ease, then changing the ball in the kit is really necessary. Experienced drivers can make the replacement, but those new to this business are advised to go to a service station, where all the conditions and experienced specialists are available.

Is it possible to determine the problem yourself?

Of course, it is safer to use the help of service center specialists, but this is not always possible. You can use your hearing and other senses. First, try to properly rock a car standing on a flat surface and try to understand what is knocking and where.

Another method will require a little more effort from you and one assistant. Get behind the wheel and then depress the brake pedal as much as possible. While you hold it in this position, your assistant should rock the front wheel. If at the same time he feels noticeable play, then there are definitely gaps in the ball joints, and therefore they should definitely be changed. And as soon as possible. Of course, to accurately determine the degree of wear, you will not be able to do without more advanced methods and tools.

In the lower ball joint on the classic from AvtoVAZ there is a special diagnostic hole. To accurately determine the condition of the ball, you should accurately measure the distance between its body and the end of the pin. It is important to remember that this is done using a depth gauge or caliper, but only under load. For domestic cars, this figure should be within 11.8 mm. But this only applies to more or less normal, original supports.

And further. You should remember exactly what road you are driving on: if extraneous knocks are heard while driving on smooth asphalt, it definitely won’t hurt you to visit a car service center. If this happens when driving on a gravel road, then the ball joint may not be to blame for the knocking.