Let's start with a banality. Every car has an engine, every engine has a crankcase, covered with a sump, which stores the oil used to lubricate the engine. In fact, it is precisely to protect the oil pan from all kinds of damage that an element is used, usually called crankcase protection.

Most often, this part, which is important for the health of the engine and the car as a whole, is made by stamping from a steel sheet; less often, the crankcase protection is made of aluminum and even less often of composite materials, which include, in particular, carbon fiber. For each car model, an individually configured crankcase protection is produced for its component power plants, because, as a rule, it does not require any modifications during installation due to the correspondence of the mounting holes to the mating elements located on the engine.

Among other things, a well-designed crankcase protection has technological openings necessary for servicing the power unit, made, for example, opposite the oil drain, or opposite the hatch through which access is provided to change the oil filter when the latter is replaced through the oil pan. When purchasing, you need to pay special attention to all these features, since they are made in order to avoid labor-intensive operations of removing/installing protection during maintenance.

Having decided on the need to protect the crankcase, we choose

The market offer of the product in question is actually quite extensive. Numerous manufacturers offer products that have certain advantages over competitors. What should you really pay attention to when purchasing crankcase protection in order to remain completely satisfied with your purchase?

As mentioned above, there are metal and composite products that have their own advantages. They should be discussed in more detail.

Since the main purpose of installing crankcase protection is to protect it from unwanted damage, it becomes clear that the main selection criterion will be the rigidity of the product and its resistance to impacts. And they are determined both by the structural properties of the material from which the protection will be made, and by the features of the structure itself, by the presence of stiffeners in it, for example.

It would be nice if the chosen protection model covers not only the oil pan itself from damage, but also covers the gearbox and even the lower part of the radiator with its plane. After all, they are also at risk of damage from road ledges.

Let's talk about extras. equipment when buying a new car? Part 2. Crankcase protection

Good afternoon, dear friends. Today we will continue the conversation about additional equipment offered at car dealerships. The second most popular after interior mats is engine crankcase protection

. For our roads, which like to “melt” along with the snow in the spring, this is more relevant than ever, because it won’t be difficult to break the engine if it falls into a hole, for example. For your safety, we recommend installing a crankcase protection.

What are they?

Let's get a look. We look at city cars and city driving. In pursuit of price, people often forget about quality and you can hear the phrase “I’ll buy it on the market for 1000” or “it’s a nightmare how much money for a piece of hardware”

Now, in order: Steel

There are two types of protection: sheet iron and stamped steel. Crankcase protection made from sheet iron is usually the most cost-effective, because... they are thinner and have a simple straight shape. As a rule, such protections do not very well follow the shape of the engine boot, thereby leaving significant holes, which entails the entry of dirt and foreign objects into the engine compartment. Here is an example of crankcase protection for Mazda 3, 6, cx-5, cx-9. (pictured Mazda 6 2019)

Judging by the photo, it’s not difficult to select the best option, isn’t it? Further in the photo, I indicated with red lines approximately where this or that protection would end, using the example of the Rival crankcase protection.

By the way, the Sheriff defense also has “wings”, which is good, but again it is a bit short. I’ll tell you a little secret, Rival crankcase protections are supplied as originals for Mazda, but the price from an official dealer is about 5 thousand with installation, or even higher! Prices in stores for the protections presented above are approximately the same, +- 200 rubles. In our store, such protection will cost you only 1,565 rubles, the fasteners are fully included. Installation on average 500 rubles. If, for example, you look at the Kia website, crankcase protection for the Kia Rio will cost 3,452.95, installation varies from 700 to 1,500 rubles. And here is the crankcase protection that we offer:

Manufactured by Rival, Yekaterinburg! The cost of protection is 1664 rubles.

Some protections have technological holes for draining the oil and replacing the filter, but as practice shows, they are not needed, because When carrying out maintenance at a good service station or an authorized dealer, the crankcase protection will still have to be removed to inspect the engine and gearbox for leaks.

In addition to crankcase protection, depending on the type of car, there are protections for the transfer case, separately for the gearbox (if the car is rear-wheel drive), as well as for the rear gearbox. Each of them is important in its own way and is recommended for installation, for example, in the Kia Sportage the rear gearbox actuator is located quite low and can easily be damaged, and this will be a non-warranty repair and will be quite expensive. Protection will certainly protect you from such problems.

The next type of protection is Aluminum!

Here, perhaps, I will talk about the fundamental differences from steel protections: Aluminum protections are thicker

(aluminum is much softer than steel, so the protections are made thicker to obtain the desired effect) They are much

lighter

, which is very convenient when removing/installing, and most importantly, they do not rust, this is in case the paint may “peel off” from the steel protection, or from acids or from damage. Such protections are significantly more expensive than steel ones and the choice is certainly yours. You just need to weigh all the pros and cons and decide whether the overpayment is worth it.

IMPORTANT!

The cheaper the crankcase protection, the lower the quality of both the metal itself, its color, and the fasteners included! You can often find bolts that will rust in the first year and when changing the oil you will have to simply cut them off, which will not save your time and money at all. As they say, the miser pays twice!

Source

Protection and raw materials – metal

Metal protections can be produced:

- made of steel 2 mm thick (in most cases this is quite enough, plus such protection is easy to straighten if it is damaged due to the high ductility of the material);

- made of steel 3 mm thick (such protection is most often required for heavy SUVs, heavier than 2 mm);

- made of stainless steel , which is much more presentable and aesthetically pleasing with significantly greater corrosion resistance, bordering on “eternity,” however, it is less plastic and, if damaged, will require more effort to put in order;

- made of lighter metals - aluminum (with the same mass as a steel structure, the thickness of the protection can reach 5 mm, such protection is significantly stiffer than steel);

- made of titanium - the most expensive material from the list under consideration, combining all the advantages of its predecessors on the list.

It is worth noting that metal crankcase protection with a thickness of less than 2 mm, in principle, is not such and should not even be considered as an option - a waste of money and effort! In addition, the first two versions are the least corrosion-resistant, and despite all sorts of tricks regarding priming/painting (powder or hammer paint is often used), over time such protection will rust, and its protective properties will accordingly decrease. However, the main advantage is relative cheapness and there is no escape from it. Most often, such protection is sufficient for several years of operation, although, of course, much depends on the road conditions in which this operation will be carried out...

Aluminum pallets corrode much less, but it is best to use them on cars with an aluminum body in order to avoid the creation of a galvanic couple, which entails rapid oxidation of the “volatile” metal. For the same reason, steel protection should never be installed on cars with an aluminum body, because it is the second metal that will be subject to oxidation in the iron-aluminum pair due to its chemical properties.

Best crankcase protection: steel, aluminum or carbon?

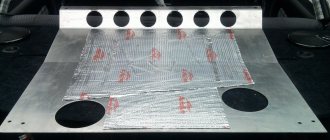

Protection made from structural steel , a relatively cheap material with a thickness of 2–3 mm, is most widespread. The plasticity of steel makes it possible to create stiffening ribs on the product by stamping (photo 4). Such protections can be easily adjusted in case of deformation from an impact.

Sheet steel makes it possible to manufacture protection with stiffeners

Most domestic manufacturers of steel protection coat their products with hot-curing epoxy polyester powder paint. This coating is quite durable with careful driving.

Inexpensive products for domestic cars are painted with ordinary nitro enamel. But even the best-quality coating cannot withstand mechanical impact, for example, when hitting a curb while parking.

Aluminum guards are lighter than steel ones, but are about five times more expensive. Therefore, they are especially often installed on sports cars, where weight plays a decisive role. For the manufacture of protection, both soft aluminum alloys and heat-strengthened (duralumin) D16T or B95 are used. In terms of strength, duralumin is not inferior to steel, but low ductility does not allow stamping of stiffeners. The design of such protections most often consists of a flat sheet 7–10 mm thick with several small transverse bends and holes for fastening and ventilation (photo 5).

Protection made of heat-strengthened aluminum alloy without longitudinal stiffeners

Heat-strengthened protections are much more difficult to straighten after an impact.

Composite protections (photo 6) are made from composite materials consisting of a base - reinforcing fiber and a binder - resin. Fiberglass is most often used as a base, less often carbon fiber, which is more expensive and less technologically advanced. The most durable material for composite protection is Kevlar fabric, developed for body armor, but its high price limits its use.

In terms of specific strength, glass and carbon fiber are 1.5 times superior to steel, and Kevlar is 2.5 times superior, which makes protection easier. However, composites do not withstand concentrated loads well. When hitting a sharp object, the resin crumbles, and the fibers that have lost their support break. Therefore, the thickness of composite protections has to be increased to 8–12 mm, which reduces their weight advantage.

Composite protections simultaneously serve as a boot, as they completely cover the engine compartment from below. Manufacturing technology allows them to be given any shape, but they are more expensive than steel ones.

The high strength of the fibers, increased thickness and trough-shaped shape make them very rigid. If the composite protection has cracks, it cannot be restored.

Protection and raw materials - composite

When choosing composite protection, you can choose from products made from fiberglass (glass fiber core), Kevlar (para-aramid fiber), or carbon fiber reinforced plastic (carbon fiber).

Typically, the required rigidity of composite protection is achieved with its thickness, most often formed by six layers of reinforcing material. The result is a sandwich with very high rigidity and strength, while the weight of the product is significantly lower than that of metal analogues. But the cost is what limits the widespread use of such protective trays on most common automobile brands. Space technologies - astronomical prices... Another drawback is low maintainability, although initially high strength in most cases guarantees against possible expenses on this item.

Note that it is the composite crankcase protection that makes it possible to create the most precise fit to the protected bottom, guaranteeing absolute corrosion resistance, strength and quality.

Here is the main list of advantages of composite crankcase protection:

- high level of strength;

- perfect corrosion resistance;

- absolute freedom in creating the protection configuration in full accordance with the location where it will be installed.

Which crankcase protection should you choose? Difference between steel, aluminum and composite protection.

When buying a car at a car dealership, the buyer often does not purchase such a necessary thing as crankcase protection. But this is an integral part of the car, especially on Russian roads. Everyone knows that if in large cities the roads are even more or less suitable for driving, then in smaller cities their condition is simply deplorable, let alone the roads located outside the city. You can hear a similar question from many: “Why do I need crankcase protection, I only drive around the city?” This is the biggest misconception, because surprises on the roads can await us anywhere. And accordingly, protection is needed not only for off-road use. Troubles can happen even if you are an experienced and very careful driver. In the city, you can easily find an uncovered sewer manhole or a foreign object lying on the road. We all know the problems with a lack of parking spaces when we have to park on a high concrete curb. All this and much more can cause serious damage. But, unfortunately, many manufacturers do not take this into account and additional crankcase protection has to be purchased. Protection along with installation is not that expensive, but repairs in the event of a crankcase breakdown will cost you a pretty penny! Therefore, it is better not to skimp on such an important and necessary part as protection for your car. After all, as you know, the miser pays twice...

Currently, there are many manufacturers of crankcase protection on the Russian market. Everyone, even the most demanding buyer, will be able to find exactly the protection that will meet his requirements and criteria. Our online store offers several protection options: steel, aluminum and composite (carbon plastic).

Let's start with the most popular steel skid plates. Almost all of them are made of 2-3 mm steel. Also, depending on the manufacturer and price, the protection design uses such elements as stiffeners, stamp elements, shock absorbers, sound insulation, and oil drain holes. In our online store you can find Steel crankcase protection from such manufacturers as AlfEco and SHERIFF

Steel protection Sheriff (Sheriff) is powder coated. Has technological holes for blowing the engine. The oil drain hole is closed with a rubber plug, which can be easily removed if necessary. To eliminate vibration and beating, rubber cushions are provided. Sheriff crankcase protection is a reliable, high-tech product that meets all the requirements of modern car protection. We offer you protection for the engine crankcase, gearbox, transfer case and gas tank. All protections are attached to standard holes and do not require additional drilling of the body.

Steel protection AlfEco (Alfeko) is made of cold-rolled steel. Both surfaces of the steel protection are painted, resistant to mechanical stress, with Italian powder enamel from AKZO NOBEL. The design of the protection provides special fasteners for installation in standard places of the car. The modified geometry of the stiffeners complements the vehicle's passive safety. The presence of technological holes for draining oil and normal air circulation in the engine compartment. Additional rubber shock absorbers allow the protection to be mounted as close to the body as possible without reducing ground clearance. A 2mm thick vibration absorber applied to the protection neutralizes the unpleasant hum when driving and engine vibration at low speeds. Such protection certainly protects the car crankcase in almost any operating conditions.

Also, the YUKARS online store offers aluminum crankcase protection. They are mainly made of 5 mm Aluminum sheet. Today, aluminum protection is in great demand for premium cars. They do not have stamped elements, but unlike steel protections, their weight is reduced by 20-30%, which does not weigh down the front of the car much. This protection is not subject to corrosion. Of course, its price is 2 times higher than steel, but the durability of this product justifies the cost. We offer you aluminum crankcase protection from such manufacturers as Novline and ABC-Design

Aluminum protection with a thickness of 5 mm has a more attractive appearance and less weight compared to steel.

Aluminum protections manufactured by ABC-Design and Novline are made from a single sheet of aluminum 5 mm thick, using German reinforced rivets securing the bumper pads. Each protection has a mounting diagram and a complete set of fasteners. The weight of aluminum protection averages from 7 to 9 kg.

Composite crankcase protection (carbon crankcase protection). Nowadays, more and more crankcase protections made of composite materials have begun to appear on the market; this is a very worthy and competitive product. A composite is a material consisting of a polymer matrix with a specified distribution of reinforcing elements in it. In terms of specific strength, fiberglass, from which composite crankcase protection is made, exceeds steel by 1.5 times. Composite protection completely repeats the configuration of the original car boot, thereby providing maximum protection of the engine compartment and transmission components from moisture and dirt; does not interfere with the distribution of air flows under the car's bottom. Clearance losses are minimal. Light weight compared to metal protection. The material is not subject to corrosion, it is neutral to the reagents used to treat roads during icy conditions. When hitting an obstacle, the composite crankcase protection does not receive residual plastic deformation, after which, due to contact and subsequent wear, damage to elements of the vehicle’s engine compartment, such as the crankcase, exhaust pipe or catalytic converter, may occur. After an impact, it returns to its original shape; the design of the protection effectively reduces impact loads and evenly distributes them through the attachment points on the power elements of the car body. In a frontal collision, the composite protection bursts and does not prevent the engine from moving downwards along a pre-calculated trajectory. The operating temperature of the composite protection is from +120C to -60C. The operating temperature of composite protections does not exceed the operating temperatures in traffic jams in the summer. There are no emissions of harmful chemical compounds that are sucked into the vehicle's ventilation system and enter the lungs of the driver and passengers. All materials used in production have sanitary and epidemiological certificates from the State Sanitary and Epidemiological Service of the Russian Federation. The YUKARS online store presents ProROAD composite engine protection from the manufacturer ABC-Design.

The fibrous structure, the presence of rubber shock absorbers, noise-absorbing and vibration-damping pads guarantee an excellent vibration-damping effect and reduces sound emission from various vehicle components. Composite crankcase protection ProROAD (plastic crankcase protection) is the best option for city driving in terms of price-quality ratio.

If you cannot decide which kind of protection is suitable for your car, call us, we are always happy to help you with your choice and answer all your questions!

Go to the selection of composite crankcase protection

“Little things” of protection that should not be neglected

When installing crankcase protection, many people pay attention to its weight, thinking that they will upset the balance of the weight distributed along the axles. Most often, the protective element easily fits into 7-15 kg and therefore does not have any significant effect on the axial weight distribution, to which all control systems of a car of a particular brand or modification are adjusted. However, a similar opinion exists, but there is no point in focusing special attention on this error.

But you should focus more closely on the rigidity indicators, since the influence of the sump mounted under the engine, especially in a head-on collision of the car with an obstacle, can play a bad joke. This is exactly what happened in the case of the Lada Priora, when during a crash test the crankcase protection turned out to be the cause of the underbody tearing. As a result, it is highly desirable to have a document indicating the approval of a particular protective element by the manufacturer.

Another point that requires attention is noise comfort, which can be unexpectedly lost with the installation of the crankcase protection in place. Often, due to poor aerodynamics of the protection or due to an insufficiently well-developed mounting system, it begins to “noise,” which is not prevented even by the factory sound insulation, which in the standard configuration of the car showed its qualities at its best.

HOW TO CHOOSE ENGINE CRANKCASE PROTECTION

Crankcase protection is a device that protects engine components and assemblies from mechanical damage. It is mounted on the bottom of the car directly under the engine.

WHY DO YOU NEED CRANKCASE PROTECTION?

In addition to protecting the engine from mechanical damage, the device often prevents car theft by making it difficult to access the wiring. Sometimes criminals cut through the wire that goes from the battery to the electrical equipment and alarm system and is located quite low. With installed protection this is more problematic.

The protection does not contribute to engine overheating. When the car is moving, air flows through the car's radiator from the front and cools the engine. It will even be useful in winter, because... with it the engine cools down somewhat slower than without it. Also, additional noise insulation is glued onto it so that it rattles less.

To change the oil, the protection has the necessary holes with plastic plugs that are easy to open. There is no need to remove the protection during this procedure. It has to be removed if you need to change the filter, and it can only be accessed from the bottom. Although some products have a hatch for replacing the filter without removing the protection, which will save money on its removal/installation.

The engine protection is easy to install; it does not require drilling holes in the bottom, since it is often attached using standard fasteners. This will be an additional advantage for passive safety. Therefore, try to figure out how it is attached to avoid additional problems during installation.

HOW TO CHOOSE ENGINE CRANKCASE PROTECTION?

There are two types of crankcase protection: composite and metal. Metals are divided into: aluminum, steel and stainless steel

Composite protections have recently appeared on the market, but are already in demand. The term “composite” includes several types of artificial materials, such as fiberglass, carbon or Kevlar. Compared to metal, crankcase protection made of composite materials has a number of advantages: Higher strength and rigidity with the same thickness; Not exposed to moisture and does not rust; Does not affect crash safety; Has low weight; Does not change the vehicle's ground clearance. It has noise absorption properties due to its fibrous structure;

Steel guards are made from ordinary sheet steel and are the cheapest product. Aluminum ones are more expensive, since the material itself is more expensive. These protections have high rigidity and are very durable. Stainless steel protection is similar in functionality to aluminum products, but is more expensive due to its impressive appearance.

Aluminum engine guards are used in motorsports and for other purposes. For example, on sports cars it is not uncommon to see plastic protection, which is lightweight and made of heavy-duty plastic. There is no point in installing such protection on civilian cars - it is too expensive and not practical.

When choosing, you should focus on the rigidity of the product. If the material is not rigid enough, it will bend at the slightest impact. Protection with low rigidity is not effective, so it makes no difference whether it is there or not.

Source

With or without protection? It's up to the owner to decide

Usually, before deciding to install crankcase protection , car owners hesitate a little, however, given the quality of domestic public roads, such hesitation is completely unnecessary. After all, the standard protection is an ordinary thin plastic boot, which at best protects against sand/dust, but not against possible road ledges or stones. Such a boot is especially useless in winter, when the road is dotted with numerous ice growths that strive to pierce such a vulnerable engine crankcase, or in relatively off-road conditions, where you can run into, including a wooden snag.

Here is what is important in choosing the main consumer qualities:

- structural rigidity;

- its weight, the lower it is without compromising the main function - protection, the better;

- high degree of safety in the event of a collision;

- no extraneous noise after installation.

In a word, the decision to use crankcase protection is made exclusively by the owner of the vehicle, which he strives to protect as much as possible from possible damage.

Main selection criteria

The main requirement for protection is rigidity. If the protective pallet is made of flexible material, then even a moderate impact can have catastrophic consequences. The impact through such protection will go into the crankcase, causing its damage. Such protection is simply meaningless.

If you decide to install a metal protective tray, make sure that its thickness is at least 3 millimeters. Otherwise, the sheet will simply not be able to withstand possible impacts.

A very important factor is the weight of the protection. It must be remembered that when designing a designer, they clearly calculate the weight distribution of the body. This means that any load on the suspension can upset the proportions specified by the manufacturer.

SUV with protection

You should not lose attention to such an important factor as safety during a traffic accident. The protective pan should not affect the body deformation model envisaged by the designers.

Another important point worth paying attention to is noiselessness. As a rule, noise occurs when the pan comes into contact with the subframe and all this can be heard very well in the cabin when driving.

When choosing protection for your car, be sure to follow these recommendations and be sure to take into account 4 main parameters:

- high rigidity;

- as little weight as possible;

- safety during a collision;

- silent while driving.

Steel

Steel is the most common material used in the production of oil pans for quite a long time.

pros

The main advantages of steel protection are:

- fairly simple recovery after a strong blow - straightening;

- high rigidity;

- low price.

Steel pallet

Minuses

- However, in addition to the undoubted advantages, there are also several disadvantages, the main one of which is corrosion.

- Poorly made pallets can resonate strongly while driving, creating unpleasant sounds.

- Sometimes the protection touches the crankcase of the power unit, and this can cause holes to appear through which oil begins to flow.

- The weight of the protective sheet is very large, sometimes it can reach up to fifteen kilograms.

- Significantly reduces ground clearance, as a result of which the car, on rough terrain, can, as drivers say, “lie to the bottom.”

- Incorrectly made or incorrectly installed steel protection very often prevents the motor from running away, thereby creating a danger during a collision.

Loading …

Owner reviews

If you have not yet decided which protection is better, perhaps reviews from car owners will help you make the right choice.

Composite protection

| Positive reviews | Negative reviews |

| Very light | High price |

| Easy to install | The holes were slightly shifted |

| Withstands hitting rocks |

Steel protection

| Positive reviews | Negative reviews |

| Low price | Started to rust |

| Takes hits well | Noise appeared after installation |

| Quick installation | Very heavy |