We replace the secondary shaft oil seal if the oil level in the gearbox constantly drops, or if the rear part of the gearbox becomes oily.

We carry out the work on an inspection ditch or a lift.

We disconnect the cardan drive from the gearbox (see Replacing the cardan drive) and move it back.

For ease of operation, use a 13mm head to unscrew the two nuts securing the cross member to the body and lower the back of the box until it stops.

Using two 19mm wrenches, unscrew the three nuts securing the elastic coupling to the flange.

To make it easier to remove and install the clutch, you can put a special clamp on it or wrap it with tape (see Features of repairing a five-speed gearbox).

. remove the elastic coupling

Remove the centering ring seal

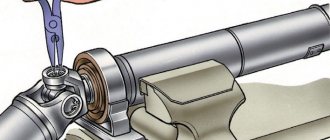

Use a puller to remove the retaining ring from the secondary shaft.

Using the bolt in the elastic coupling flange as a lock, use a 30mm wrench to unscrew the nut securing it a few turns to move the centering ring.

Using two screwdrivers, remove the centering ring of the elastic coupling

Unscrew the nut and remove the spring washer.

. Use a puller to tighten the flange of the elastic coupling.

Using a screwdriver, remove the cuff of the secondary shaft. Before installation, lubricate the cuff with a thin layer of any lubricant.

We press the new cuff through a piece of pipe of a suitable diameter or through the old cuff. Install the removed parts in reverse order

When installing a new cuff, you can slightly underpress it, avoiding distortion (if necessary, placing spacers under it up to 1 mm thick) so that the edge of the cuff works along the unworn part of the shaft. In case of significant damage, replace the shafts and cuffs

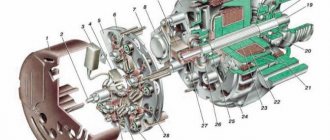

Work diagram for replacing the input shaft oil seal

Let's look at the example of the popular Togliatti model VAZ-2107. VAZ 2107 belongs to the classic models of the plant, the family of which includes the following cars: VAZ 2101 ;02; 03; 04; 05 and 06. The gearboxes on all classic models are identical in terms of replacing the input shaft oil seal and differ only in the number of steps. These are 4 and 5 speed gearboxes, the differences being in the design of the rear cover and a different shape of the box cushion or, as it is also called, traverses.

Gearbox seal VAZ 2107 - description and purpose

An oil seal is a special seal in a vehicle that is necessary to seal gaps and cracks. For example, in a gearbox, the oil seal plays a vital role - it is fixed at the junction between the moving and stationary mechanisms, preventing oil from leaking out of the gearbox.

The oil seals in the VAZ 2107 gearbox are not made of rubber, as most drivers believe. In fact, this product is constantly in the transmission oil, and to keep production to a minimum, manufacturers make oil seals from CSP and NBR composite materials. At the same time, the gasket feels equally “good” at any temperature - from -45 to +130 degrees Celsius.

Box seal dimensions

The gearbox itself on the “seven” is designed for many years of service. However, the service life of the device directly depends on how often (and in a timely manner) the driver changes the seals. Indeed, during the operation of the machine, it is the oil seals and sealing joints that are the first to fail (tear, wear out, squeeze out). Therefore, timely replacement of the oil seal will help prevent expensive repairs of other gearbox mechanisms.

For proper replacement, you need to know the dimensions of the VAZ 2107 gearbox seals:

- The input shaft seals have a weight of 0.020 kg and dimensions of 28.0x47.0x8.0 mm.

- The secondary shaft seals weigh a little more - 0.028 kg and have the following dimensions - 55x55x10 mm.

Which ones are better

The main question for any VAZ 2107 driver when repairing the gearbox is: which oil seal is best to put on the shafts to avoid rapid wear? In fact, there is no universal option.

The standard equipment of the shafts involves the use of Vologda oil seals, but if necessary, you can install any others, even imported ones.

Industry leaders can be considered:

- OJSC "BalakovoRezinoTekhnika" (main materials of manufacture - composites and alloys);

- (the main manufacturing material is thermoplastic elastomers);

- (made from rubber compounds with various additives).

The most affordable oil seal for a box shaft costs 90 rubles; the more modern the manufacturing technology, the more expensive the product will be valued.

Photo gallery: selection of the best oil seals for the VAZ 2107 gearbox

Purpose of oil seals

The main mechanisms in a gearbox are shafts. They are equipped with oil seals, which are necessary to seal the gearbox gaps. Thanks to this, the fuel and lubricant does not leak out of the box. The existing differential seal provides the necessary protection of this mechanism from dirt.

What material are the seals made of? This element is made of composite materials XSP and NBR. Their distinctive feature is that they tolerate temperature loads well, therefore, their minimum output is noted during long-term operation of vehicles.

Signs of oil seal destruction

The seals are located directly on the shafts inside the box, so their wear can be visually determined only when disassembling the gearbox. However, any driver can quickly detect oil seal damage by eye, because there are obvious symptoms:

- Transmission oil leaks under the car.

- Constantly low oil level in the box.

- Problems with shifting gears while driving.

- Crunching and grinding in the gearbox when changing gears.

There are plenty of options. If there is an oil leak at the junction of the clutch bell and the engine, then it could be either the engine crankshaft rear oil seal or the gearbox input shaft oil seal. If there is a leak at the junction of the clutch bell and the gearbox body, the gasket is kaput. If it is wet at the rear end of the box - the gasket or oil seal of the secondary shaft

Electrician

https://www.vaz04.ru/forum/10–4458–1

It would seem how the performance of such a complex unit as a gearbox can depend on a small part. However, loss of tightness for the box is fraught with big problems, because even minor losses of transmission oil will immediately affect the lubrication of moving elements.

It is recommended to change the oil seals in the VAZ 2107 box every 60 - 80 thousand kilometers. The replacement is associated with an oil change, so it will be convenient for the driver to perform these works at the same time. Before this period, it is necessary to change the oil seal only when there are clear signs of its destruction.

Transmission malfunctions

The box on the seventh model Zhiguli is considered a reliable unit. If you maintain it regularly and treat it with care during operation, then repairs will not be needed for a long time. However, all components and parts are subject to wear. There are many reasons for this. In any case, if a malfunction is detected in the gearbox, it is necessary to carry out diagnostics and repairs.

Most malfunctions occur of the following types.

One of the gears does not engage

Without opening the box, we can assume that:

- the hinges and springs are worn out and need to be replaced, or better yet, a complete repair;

- on synchronizers, the rings have become unusable and need to be replaced;

- synchronizer spring burst, replace;

- The teeth on the transmission gears are worn, replace the gear.

Knocks out gear when driving

It happens that when you turn on a gear, it does not turn off randomly. Possible reasons:

- the lever hinge is jammed, inspect and clean;

- the clutch is faulty, it may not engage completely, adjust it, if the disc is worn, replace it;

- The shift lever is broken, replace it with a new one;

- Forks, shift gears are bent, replace with new ones.

Crunching and grinding in the box while driving

This problem appears for the following reasons:

- the bearings are worn out, they should be replaced, and at the same time check the seals;

- the teeth of the gears are worn out, in this case it is better to make a major repair;

- There is not enough or no lubricating fluid in the gearbox, find the leak and fix it, add oil.

Grease leaking from box

The gearbox is designed so that lubricant cannot leak out spontaneously. But if an oil stain has formed under the car, an inspection should be made and the leak eliminated.

The reason may be:

- wear of oil seals and sealing gaskets due to natural aging of rubber must be replaced with new ones;

- the fastenings of the covers on the box have become loose, tighten all the nuts and bolts completely;

- mechanical damage to the body or lids of the box; if the steel lid is damaged, it can be welded. If the crankcase is damaged, it is better to replace it, since it is cast from an aluminum alloy.

Input shaft oil seal

The input shaft oil seal is located directly on part of the input shaft and is in contact with the clutch housing. Therefore, to replace this product, you will need to remove the casing.

To work you will need to prepare:

- nut heads;

- hammer;

- puller;

- flat screwdriver;

- knife (they are most convenient for removing the old gasket);

- new oil seal;

- transmission oil;

- new input shaft seal.

The procedure for replacing the seal can be carried out either on the removed box or directly on the car. However, it is easier and faster to change the product on a dismantled gearbox:

- Disconnect the gear shift fork from the box.

- Remove the release bearing by clamping it with a puller.

- Unscrew the six nuts securing the clutch housing.

- Remove the casing from the box.

- Use the tip of a knife or screwdriver to pry up the old oil seal on the input shaft and remove it.

- It is good to clean the landing area so that there are no traces of the seal, spraying or oil leaks.

- Install a new oil seal, having previously lubricated it with transmission oil.

- Next, assemble the box in reverse order.

Video: replacement instructions

Replacing the rear axle gearbox of VAZ 2106, 2107

DIY crankshaft oil seal replacement: 3 instructions for replacing front and rear oil seals

The main disease of REM is increased noise (hum), and the gearbox can hum for various reasons:

- there is insufficient oil in the bridge, or it is completely missing;

- the gap between the gears of the main pair is not adjusted;

- the gears are worn out, they have chips and other damage;

- the main pair has a manufacturing defect, the gears are not ground in from the factory;

- the shank nut has become unscrewed or loosened;

- bearings are worn out.

The main malfunction of the center differential is the wear of the gears of the axle shafts and satellites, when the surfaces of the parts are heavily worn, play forms between the differential gears, but the rear axle usually does not make noise due to wear of the differential gears.

ZM gearboxes on VAZ classics can be repaired, but only if there is no wear on the gears. If the mechanism can no longer be repaired, it needs to be replaced. We replace the rear axle gearbox of a VAZ 2106 on a “seven” as follows:

- we install the car on a pit or a car lift; changing the gearbox on the ground is extremely inconvenient;

- if the car is installed on a pit, it is necessary to jack up both sides; in any case, the rear wheels must be removed. If the work is not done on a lift, you should install stops under each side of the car (in the rear);

- unscrew the drain plug in the REM, drain the transmission oil, having previously prepared a container for it;

- remove the rear brake drums (two guide bolts on each side), after first removing the car from the handbrake. The drums can be difficult to remove; they are dismantled by tapping them from behind with a hammer through a wooden block. You cannot hit the drum with a metal hammer; the drum may break;

- remove the brake pads;

- unscrew the fastenings of the rear axle axle shafts on each side, each axle shaft is secured with four nuts;

- we press out the axle shafts, for this you will need a special puller, you can also make a homemade device;

- remove the driveshaft by unscrewing the four bolts and nuts. If the same REM is installed, the cardan with the shank must be marked; this is done in order to put the shaft back in the same position. If you install the cardan incorrectly according to the marks, the shaft may begin to vibrate;

- unscrew the eight bolts securing the rear gearbox (key 13), remove the assembly.

At this point, the removal of the gearbox can be considered complete; now all that remains is to either repair the mechanism or install a new one instead.

Secondary shaft oil seal

This gasket is located on the secondary shaft and disconnects it from the box flange. In this regard, replacing the secondary shaft oil seal proceeds according to a different scheme and is very different from working on the primary shaft.

To replace you will need:

- spanners;

- screwdriver with a flat thin blade;

- puller;

- pliers;

- transmission oil.

The work progresses according to the following algorithm on the removed gearbox:

- Firmly fix the box flange so that it does not move.

- Turn the nut securing it with a wrench.

- Using a screwdriver, carefully pry up the metal ring and pull it out from the secondary shaft.

- Place the puller against the end of the shaft.

- Press out the flange together with the fixing washer.

- Use pliers to grab the old oil seal.

- Clean the seating area and install a new oil seal.

- Next, assemble the structure in reverse order.

Video: operating instructions

Thus, replacing oil seals on a VAZ 2107 gearbox does not present any serious difficulties. However, inexperienced drivers are advised to seek help from professionals to avoid problems with the car, since working with the gearbox requires knowledge and experience.

How to change the rear oil seal?

This procedure is quite complicated, since the element is located behind the clutch system. If it is a rear-wheel drive car, the driveshaft is removed. Next, as on front-wheel drive vehicles, there is a gearbox, a clutch assembly with a basket and discs, as well as an engine flywheel. The rear oil seal itself is installed in the housing and secured with eight bolts. After unscrewing them, take out the housing and press in a new element. If you have difficulty installing it, you can use a rubber hammer or a regular steel hammer using a soft spacer. The latter can be made from a piece of an old car camera. Next, all the elements are assembled in reverse order.

Replacing the secondary shaft oil seal of a VAZ 2107 gearbox

The need to replace the secondary shaft oil seal in the gearbox of a VAZ 2107 car arises when oil leakage is detected from the gearbox. The presence of oil drops on the gearbox housing is not allowed, but oil sweating is acceptable, which is not a sign of oil seal damage. To perform the work of replacing the oil seal in the gearbox, you will need a three-jaw puller and fixing glue.

Removing the gearbox seal of a VAZ 2107

1. We install the VAZ 2107 car on an inspection hole or overpass (see “Preparation of the VAZ 2107 car for maintenance and repair”). 2. On VAZ 2107 cars with an injection system, remove the heat shield (see “Drivetrain - removal and installation”). 3. Disconnect the driveshaft from the rear axle gearbox and unscrew the two bolts securing the intermediate support of the driveshaft to the cross member (see “Driveshaft - removal and installation”). 4. Disconnect the elastic coupling of the cardan drive from the flange on the secondary shaft of the gearbox (see “Drivetrain - disassembly and assembly”) and move the cardan drive back. 5. Using pliers, remove the thrust ring.

6. Secure the elastic coupling flange from turning by inserting bolt A into its hole. Using a 30 mm wrench, unscrew the flange fastening nut and move the centering ring B of the elastic coupling along the shaft.

7. After tightening the nut a few turns, use two slotted screwdrivers to pry up the centering ring and remove it from the secondary shaft of the gearbox.

8. Unscrew the nut.

9. Remove the bolt from the flange hole. 10. Place the screw of the three-jaw puller against the end of the secondary shaft and press the flange off the shaft.

11. Remove the flange along with the washer.

12. Using sliding pliers, remove the damaged oil seal from the gearbox.

Installing the VAZ 2107 gearbox oil seal

Attention

Before installing the oil seal, check the condition of the inner cylindrical surface of the flange in contact with the oil seal.

There may be signs of corrosion and wear that should be removed by polishing. Before installation, lubricate the surfaces of the new oil seal with a thin layer of grease. 1. Press in the oil seal with a mandrel of suitable diameter.

For clarity, we show the following operation on a gearbox removed from a VAZ 2107 car. 2. Use a hammer to press the flange onto the shaft. Having installed the washer, apply fixing glue to the threaded surface of the shaft (according to the instructions for use) and tighten the nut.

Oil seal replacement process

Replacing the VAZ 2107 clutch without removing the box

First you will need to arm yourself with the necessary tools. In particular, you need to prepare:

- flat screwdriver;

- calipers;

- a regular mount or some convenient strong metal rod;

- keys for 13 and 24;

- torque wrench;

- dynamometer;

- durable cord.

On a VAZ 2106, the rear axle oil seal is replaced after the oil is drained from the crankcase. In this case, you must not forget about the oil drain cap, which should be screwed into place.

Removing the axle shafts

Let's get started:

both rear axle shafts will need to be removed from the rear axle beam.

To do everything correctly, you need to strictly follow the instructions. So:

- dismantle the wheel;

- remove the brake drum;

- we see four nuts that will need to be unscrewed (to avoid problems, you will need to turn the axle shaft until the large diameter holes coincide with the two brake shield locking nuts):

- unscrew the nuts;

- remove the spring washers;

- turn the axle flange 90 degrees so that the large-diameter holes and the brake shield mounting nuts coincide;

- We secure the brake drum with two wheel bolts (you can tighten them by hand).

Note. These wheel bolts do not need to be tightened, leaving approximately 5 mm to ensure acceleration of the drum. But you need to be extremely careful not to damage the brake drum.

The axle shaft is abruptly removed from the rear axle beam.

Advice. There is a special impact puller that will allow you to remove the axle shaft much faster.

Special impact puller for removing axle shafts

Removing the old cuff

After both axle shafts have come out, you need to do the following:

- holding the cardan from turning with a pry bar (see Repairing the cardan on your own) from turning, unscrew the four nuts securing the hinge flange;

- remove the bolts;

Replacing the rear axle oil seal on a VAZ 2106

- disconnect the flanges using a flat-head screwdriver;

- now you need to wind a strong cord, which was stored in advance, onto the flange of the drive gear (when winding it, you need to make several turns and wind it);

- We use a dynamometer to check the moment of resistance to turning or the RPM of the drive gear (this value must be remembered or written down).

Note. MSP is the product of the dynamometer readings, expressed in kgf, and the force application lever, expressed in cm.

- Now you will need to unscrew the flange mounting nut, holding the drive gear with a special wrench;

- remove the flat washer.

Advice. There is a special wrench to hold the pinion flange. You can even make it yourself from a piece of metal pipe of the required size and two bolts and nuts.

Homemade key for holding the pinion flange

Replacement of the oil seal in the rear axle of the VAZ 2106 continues:

- the drive gear flange is removed;

- we find the drive gear oil seal and remove it from the neck using a screwdriver;

- install a new cuff.

Installation

Note. Before installing a new oil seal, you need to lubricate its working edge with Litol-24.

Light blows with a hammer through a special frame will help to correctly install the oil seal in place.

It is recommended to watch this video, where everything is described in detail.

Note. It must be remembered that the new oil seal should be pressed into the gearbox housing to a depth of 2 mm, counting from the end of the gearbox housing. As a mandrel, you can use some old bearing, or rather its ring, or even a piece of pipe of a suitable size and diameter.

- put the drive gear flange in place;

- put the required washer;

- tighten the flange mounting nut, while holding the drive gear with a special wrench.

Note. The tightening torque of the nut must be equal to a certain value depending on the resistance torque of the drive gear. When tightening the nut, you should start with a smaller torque and periodically check the resistance torque. If, at the moment of tightening the nut, it is discovered that the moment of resistance is too excessive, then this indicates unacceptable deformation. You will have to replace the bushing by disassembling the gearbox and then adjusting the engagement of the main gears. It will be difficult to carry out such work on your own; a highly qualified specialist is needed.

We assemble all the components and parts in reverse order.

The oil seal replacement process is complete. During the process, you should try to compare the methods for dismantling and installing a new oil seal with photos and diagrams. It is not difficult to carry out this operation with your own hands; it will be enough to follow the advice and notes given in the instructions. Replacing it yourself will help you avoid unnecessary expenses and save a lot of time, because at good car services there is now a long queue and the price of services is high.

The meaning of the primary and secondary shaft oil seals

The direct and main purpose of these small parts is to reliably seal the metal parts and connections of the gearbox housing and other parts of the vehicle system to prevent transmission oil from leaking. Oil seals are made of durable polyurethane alloy using special compounds, since they are constantly in an aggressive environment. Oil is constantly present inside the parts, which negatively affects the condition of the part over a long period of time. Externally, these parts can be damaged as a result of mechanical stress due to breakdown or under the influence of an aggressive natural environment. The average resource or lifespan of units largely depends on operating conditions.

The manufacturer does not provide a specific guarantee for these parts; accordingly, it does not limit their service life; planned replacement is not required at certain mileages. However, in most cases, under normal operating conditions, the service life of the parts is sufficient for runs of up to 200 thousand kilometers. When used in harsh natural conditions, reliability decreases accordingly, and with it the service life of up to 100 thousand kilometers.

These parts are located at the junction of the transmission with the clutch in the case of the primary shaft, and the secondary one is located directly inside at the junction of the flange and the gearbox housing. Sealing of pipes and hoses, as well as metal parts, is achieved by tightly connecting two parts directly to the seals, which is a circle with several layers of polyurethane material. It is precisely because of the unsatisfactory condition of these small parts that transmission fluid often leaks outside the box. Therefore, responsible owners, when the first signs of malfunction appear, replace the part with a new one. Due to their simple design and the absence of any moving parts, these units cannot be repaired; they are simply replaced with new ones. However, their failure can cause major consequences in the form of failure of the entire gearbox as a result of oil “starvation”. Therefore, preventing the condition of oil seals is one of the important procedures in the daily maintenance of the VAZ 2107.

Disassembling the box

Increased noise of the gearbox can be caused by wear or failure of its shaft bearings, as well as significant wear of gears and synchronizers. To determine what is causing the increased noise, you will need to disassemble it.

This work is quite complex technologically, and if the car owner is not confident in his abilities, then it is better to contact a specialized service station, otherwise in the future, incorrect assembly can lead to more significant consequences, or to the fact that the gearbox will not work.

But, if you decided to repair the VAZ-2107 gearbox yourself, then this will require a set of keys and sockets, a powerful screwdriver, and pullers for removing bearings.

First of all, unscrew the nuts that secure the shift lever housing and remove the lever from the box.

Then the exhaust pipe mounting bracket is removed. After this, the bolts securing the rear and bottom covers of the box are unscrewed. This will be enough to visually determine the condition of the gears and synchronizers.

If significant wear is noticed, then most likely the reason for the increased noise in them. But it is also worth checking the box shafts for axial displacement. If there is one, then the bearings are also very worn and require replacement.

To carry out work to replace worn parts, a complete disassembly of the gearbox will be required. To do this, first remove the back cover by unscrewing the nut securing it, access to which is possible after removing the bottom cover.

https://www.youtube.com/watch?v=hqcrKAMxH0k

To make it easier to remove, you will need to move the 1st-2nd gear slider down. Then, lightly tapping the lid, remove it from the studs.

POPULAR WITH READERS: Replacing the timing chain of a VAZ 2107

Using a puller, the bearing and the secondary shaft oil seal are carefully removed from the cover housing. If they show signs of noticeable wear, they are replaced with new ones.

Disassembly and reassembly of the gearbox if any malfunction is detected should be performed in the following sequence:

- de-energize the system by removing the negative contact from the battery;

- dismantle the radio panel;

- slightly move the locking sleeve down and remove it from the rod cavity;

- with a sharp movement we pull the rod out of the gear shift lever;

- remove the upper and lower bushings from the lever;

- dismantle the gearbox cover, which is fixed with four screws;

- remove the cover that protects the handbrake from dirt, and then unscrew all the fasteners located on the floor of the car;

- dismantle the hoses through which warm air is supplied to the air filter;

- move the starter forward a little, then unscrew the gearbox housing plug and drain the transmission oil;

- dismantle the muffler and disconnect the universal joint, the reverse switch and the speedometer cable, which connects the part to the gearbox;

- disassemble the clutch housing cover and the cardan drive;

- disconnect the last fastenings of the gearbox, move it back a little and remove it out.

If the user has never encountered the repair of such a complex unit, the procedure should be carefully prepared.

- Disassembly of the mechanism is carried out only after it has been completely cleaned of dirt.

- All the tools required for disassembly are pre-prepared - keys, squeezes, pliers, lock ring pullers. It is also advisable to have a separate container for storing small bolts, nuts, and washers.

- It is necessary to dismantle the mechanism parts by first treating the bolts with an anti-boiling agent.

- When disassembling, the units are folded in the dismantling sequence.

- Human memory is extremely unreliable - a photograph of a disassembled mechanism before its reassembly is the best reminder.

- All gaskets without exception must be replaced. Recycling of seals is strictly prohibited.

- No one has canceled the abundance of the cleaner. When washing the structure, you should not skimp on the cleaning material; the better you wash it, the more fun it will be.

- Assembly of the unit is carried out exclusively in the reverse order.

- If after installation there are excess parts left (which is not uncommon), the entire gearbox is completely rebuilt.

It is also necessary to maintain maximum cleanliness during work. Dust, metal shavings, or foreign objects can cause serious damage to the gears.

Dimensions of oil seals in the VAZ 2107 gearbox

To correctly replace VAZ 2107 gearbox seals, precise geometric dimensions are required, as well as the weight of the product. Otherwise, when installing other parts, the operation of the entire gearbox may be impaired, which may also lead to breakdown. The manufacturer has established clear dimensions for the VAZ 2107 gearbox seals; these parts must fit under them, regardless of the company that will produce them for installation on this model. For the secondary one, the length is 55 mm, the circumference height is also 55 mm, and the width/thickness is 10 mm. The secondary seal weighs 28g, although weight may vary by supplier and is not particularly significant.

Pulling out the internal grenade from the gearbox. Video

Therefore, it is better not to try to tear the grenade out of the box by pulling the brake disc, but to insert a prybar under the grenade and a tube under the prybar, try to squeeze the grenade out of the box if it was squeezed out perfectly. It happens that a grenade cannot be squeezed out, then it is knocked down with hammer blows.

Photo. Removed grenade from the gearbox.

But before squeezing out the grenade, place a container to collect the oil; it can be made from an old canister by cutting a hole. If the oil in the box is normal, then it will definitely flow out of the box.

Diagnostics of VAZ 2107 gearbox seals

A responsible car enthusiast, owning a domestic rear-wheel drive car, is obliged to constantly monitor the condition of many units and components. One of these are oil seals. There are simple but quite labor-intensive means of checking and preventing these parts. To do this, you need to lift the car on a lift or drive it into a pit and conduct a visual inspection of the box body. In the places where the seals meet the parts of the clutch or rod there should be no fogging in the form of oil stains or drips of this substance. Fogging at the place where the part is attached is the first sign of failure; even if there are small spots, it is necessary to replace it, since the leak will only increase in the future.

It is also necessary to wipe and clean the parts from dirt and dust and inspect them for cracks, which may subsequently leak.

The simplest method of prevention without using a lift is to periodically check the oil level in the crankcase using a dipstick.

In addition, one of the signs of failure of parts and the subsequent need to replace the seal of the VAZ 2107 five-speed gearbox is a crunching sound when shifting gears both down and up. Also, this situation may be accompanied by a parasitic hum, which is not inherent in this type of box. At the first signs of malfunctions, it is necessary to urgently carry out a visual inspection, either yourself or go to a specialized service.

The list of works includes the following actions:

- removing the locking sleeve from the plane of the assembly by inserting a screwdriver into the locking hole of the sleeve;

- dismantling the lever rod; dismantling the damper bushing; release the fixing bolts of the cover, which are located on the bottom of the car and remove the lever with the seal;

- disconnect the pipe from the exhaust system;

- dismantling the starter and gradually disconnecting the lamp wire (reverse);

- dismantling the cardan transmission and flexible shaft;

- releasing the clutch housing bolts using a socket wrench;

- disconnecting the clutch from the block;

- Carefully remove the PP box.

Disassembly of the box occurs in a strictly defined sequence.

How to change the oil seal on a VAZ 2107 gearbox

The procedure for replacing the rear oil seal of a VAZ 2107 gearbox differs from that on the front part due to the design features of the fasteners, as well as the very location of the parts and their design. In general, both procedures are divided into several stages.

Replacing the input shaft oil seal in a VAZ 2107 gearbox

Replacing the front oil seal of a VAZ 2107 gearbox occurs in several stages:

- First you need to disconnect the parts of the clutch with which this part interacts by dismantling the clutch fork, housing and release bearing, which are secured with several bolts.

- Then it is necessary to dismantle the casing itself, thereby freeing up space for removing the oil seal itself.

- After this, you should remove the used part by removing it from the seat using a knife. The vacated seat must be carefully processed to remove any remaining waste oil from the part, as well as other contamination.

- A new unit is installed in its original location, lubricated with transmission oil, and the entire system is reassembled in the reverse order.

Replacing the secondary shaft oil seal in a VAZ 2107 gearbox

The secondary oil seal is changed in another way:

- Fix and dismantle the gearbox flange, since it is this part that is fixed to the secondary oil seal.

- After dismantling, it is necessary to press it out using a special puller and gain access to the oil seal itself.

- Next, use a screwdriver or other tool to remove the used part, and also treat the landing site.

- Install the new element and reassemble in reverse order.

Removing and replacing the axle shaft on a VAZ-2107, VAZ-2106 and any classic

Replacing the rear axle gearbox seal of a VAZ 2107

Dear friends, today we will tell you how to remove and replace the axle shaft on a classic on your own.

This procedure may be necessary if the bearing on the axle shaft has failed, or, even worse, its seat has worn out (in the first case, you can limit yourself to replacing the bearing and retaining ring), if the axle shaft seal has leaked, or the axle shaft itself has become eight-dimensional, such happens too. Remember about safety precautions, insure the car, do not rely only on the jack, also protect the car from arbitrary rolling with a shoe. To begin with, we recommend loosening the tension on the handbrake cable; this will make the work easier later; we’ll have time to tighten it after assembly. So, we hang up the required wheel with a jack, remove the wheel itself and proceed to dismantling the brake drum. You need to unscrew two guide pins, these:

- There are times when removing it is problematic, it has become sour or stuck; we read about problems with removing the brake drum on a classic here. For convenience, we hung the rear axle “stocking” itself on the jack, like this:

- The drum is removed, we remove the pads themselves, first we disconnect the springs from the pads like this, prying them with something like a strong screwdriver

- then we clamp the locking pins holding the block and turn the cup to disengage them from each other

We remove the handbrake cable from them, which we previously loosened, and put the pads aside:

Now we need to unscrew the four nuts that secure the axle shaft directly, in the seat itself on the axle shaft there are two holes for this, unscrew the nuts one by one. If the head does not fit into the hole, remove it from the key and first place the head on the nut and only then insert the key itself through the hole and secure it with the head.

- Then we carefully pull the axle shaft out of its seat and see the following picture:

- If we also need to change the axle shaft seal itself, we pull it out from there with this tool:

- then we take a new oil seal, lubricate the working edges with lithol and hammer it into place with a suitable mandrel or head:

- Then we pick up a new or restored axle shaft

- and put everything back together in reverse order:

- We put our drum in place, having previously lubricated the surface of the ring with graphite, with which it comes into contact and is centered with the axle shaft.

That's all, so we learned how to remove and change the rear axle shafts on our VAZ classic ourselves. If you have any questions, ask them in our VAZ classic club on the forum.

Tips and recommendations for replacing the oil seal in a VAZ 2107 box

There are many manufacturers of spare parts for VAZ cars on the market. These are both domestic and foreign enterprises. A lot of these also produce seals. However, the negative side of diversity is the unstable quality of spare parts. There are frequent cases of defects, regardless of the country of origin. Therefore, responsible drivers should carefully examine the unit when purchasing it for quality of workmanship, the presence or absence of cracks.

In general, despite the low cost of the part itself, the installation process takes quite a lot of time, so the best option would be to purchase the part from the car manufacturer itself, which complies with the design dimensions, as well as the production technology of original spare parts.

Also, when installing new parts, it is always necessary to have a drain container on hand to remove excess parts of the transmission fluid, as well as new fluid for subsequent topping up.

Instructions

- Place the car on a lift.

- Disconnect the wire from the terminal.

- Remove the flywheel.

- Remove the rear shield of the clutch housing, which is directed towards the bushings.

- Unscrew the bolts (8 pieces).

- Remove the holder from the part.

- Now you need to knock it out of the gearbox; to do this, use a screw and a hammer.

- Now we take the new element and press it into the holder. Outer diameter - (99±0.5) mm.

- The working edge should be on the inside, if anything, turn it over.

- A gasket that is torn must be removed. It will stay in place thanks to the lubricant on the holder.

- Lubricate the edge with engine oil.

- Also lubricate the crankshaft flange with engine oil.

- Place the working edge onto the flange.

- Tighten the bolts.

- Reinsert the crankcase and bushings.

- Replace the flywheel and clutch.

The process of disassembling the gearbox

is ready, the replacement of the VAZ 2110 gearbox seal has been successfully completed.

Let your machine run for a long time and not leak. A good owner's car is always in excellent condition. So it all depends on you! Monitor and check, take it for diagnostics on time if necessary. And try not to spend a lot of money on service centers, but also don’t try to do everything yourself if you don’t understand this area!

Oil seals

Albert This page showed oil seals by size for VAZ cars and catalog numbers, role and purpose... I welcome all readers to the RtiIvaz.ru blog. The page shows photographs of crankshaft oil seals as a set for the gearbox of a family of classic rear-wheel drive cars, as well as gearboxes of front-wheel drive eights and a dozen VAZs. The cuff of the rear gearbox, also called the rear axle, is installed in rear-wheel drive “Classic” cars.

In fact, there are many of them different in shape, size, and purpose. Some hold oil, antifreeze or antifreeze, others hold air, water pressure, all are designed to protect car parts from dirt, dust and other factors.

For example, the crankshaft seal and the camshaft keep oil from flowing between the joints of the camshaft journal and the seat of the engine block. The same role is played by the cuffs of the gearbox, gearbox, and axle shaft. The hub is protected from dirty water and dust from leaking antifreeze or antifreeze into the pump.

Do-it-yourself replacement of the front crankshaft oil seal

Its internal diameter is 40 and external diameter is 56 mm.

- First, disconnect the protection from the engine. We use an 8 mm key. The screws are removed from the front, back and sides. We remove the protection. If the VAZ 2107 has an injector, there will be an additional shield, but removing it should not cause difficulties.

- We remove the generator belt to facilitate access to the shaft pulley.

We unscrew the nut of the generator, it can move along the axis. We take the mounting bracket and move the generator all the way, the belt is loosened and removed.

- Using a 38 mm open-end wrench, or a special crankshaft wrench, or a gas wrench, unscrew the crankshaft pulley securing nut and carefully remove the pulley.

- The seal is now clearly visible. It may have wear, tears, or a cut mark. Carefully remove it with a wide slotted screwdriver and wipe the seat with gasoline. We carefully and evenly lubricate the new oil seal with oil, carefully place it over the seat, and, using a bearing or an old oil seal instead of a mandrel, lightly tap it with a hammer and press it into the cover.

- The replacement is complete. Next, we put the pulley, generator belt and protection in place.