Required Tools

To carry out the work you will need:

- Socket wrench "22". It is the cap type, because the carob can “lick” the edges

- Metal brush. To clean the unit being repaired and its fastenings from dirt

- WD-40 or homemade penetrating liquid so that it can be easily unscrewed

- Socket wrench and socket set to “13”. One conveniently holds the bolts for fixing the supports to the levers, and the second one unscrews their nuts

- Crowbar, hammer, “adjustment” for an accurate blow

- Puller. You can replace the ball joints on a VAZ 2107 without a puller, but you will spend a lot of time and effort. I'll talk about this below.

Knock in the suspension of a VAZ 2107.

If when driving over bumps you are haunted by an unpleasant sound in the front of the car, then there is no need to bring the matter to a critical moment. To find the cause of the knocking, you need to understand the structure of the suspension, both as a whole and its individual parts. In this article I will talk about one of the causes of knocking and how to replace ball joints on a VAZ 2107.

Ball joint device for VAZ 2107.

The ball joint consists of a pin inserted into the body. Between them there is a plastic liner, which wears out over time. A rubber cover placed on the body and fits tightly to the finger protects against dust getting inside the insert. The ball joint housing has a hole for lubrication and checking the condition of the part. But not all manufacturers do this.

Diagnostics of ball joints of VAZ 2107.

If there is a knocking sound on bumps in the front part of the car and a beating in the steering wheel, as well as increased sensitivity of the car to the ruts, you should check the condition of the suspension and one of the points will be checking the ball joint of the VAZ 2107. How to check the ball joint on the VAZ 2107? Very easy! There are several ways to check ball joints.

If you have an inspection hole or overpass, then we go there and begin inspecting the car. First of all, you should pay attention to the condition of the ball joint boots. From them you can determine the first signs of a malfunction of the ball joint of the VAZ 2107. If they are torn, then most likely this was the reason for the abrasive getting into the body and increased wear of the part. If the boot is intact, and you have a ball with a technological hole in the body, as in the diagram above, then cut a piece of thin straight wire, mark 11.8 mm on it and insert it into this hole. If the tag is immersed in the ball, then it’s time to change it.

If you do not have access to the overpass, simply turn the steering wheel and hang the wheels on the jack one by one. Next, we hold one hand at the junction of the body with the finger, and with the other we shake the wheel. To check the upper ball joint, you should rock the wheel while holding its upper part, and to check the lower ball joint, you should apply force to the very bottom part of the wheel. You can also simply rock the upper and lower parts of the wheel toward and away from you, but this may not give accurate results, since in this case the silent blocks of the levers may still make a sound.

Removing old ball joints from the car

Preparatory operations

We take a metal brush and carefully clean the hinge nuts, the threads of the ball pins, the seats and the bolts that secure the supports to the suspension arms.

Soak with WD 40. Spray carefully so that the liquid does not get under the boot. Otherwise, during dismantling, the ball joint pin may rotate along with the nut. This will be a problem, but it can be solved, I’ll tell you about it later. We wait a few minutes for everything to sour. We begin to remove the old ball joint from the VAZ of the seventh model.

Dismantling

Let's start by replacing the lower ball joint. We are developing a nut. To do this, take a spanner wrench set to “22”. If you use a carob, you can “lick” the edges. If you tore it off, then we use an open-end wrench longer, because the cap wrench will not be able to be removed when you unscrew it all the way.

In most cases, this nut gets stuck and rusts. It takes a lot of effort to break it. Having torn it off, we walk it part way, unscrewing it and screwing it back so that part of the thread of the finger goes through, cleaning it.

You won't be able to unscrew it completely. Due to the design features of the steering knuckle on the VAZ 2101-07, it will rest against the bipod. Therefore, when dismantling the lower ball joint, you need to unscrew the nut as much as possible, as much as the design allows.

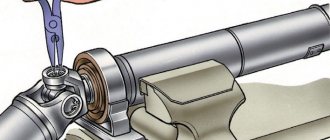

We take a puller and insert it between the fingers of the upper and lower support. We twist it until it rests against them with its edges. We continue to “tighten” it, but not to “useru”, so as not to break the thread on it. If it turns with great difficulty, stop. This force will be enough to press out the lower ball joint.

We have a hammer in our hands, it is advisable to take the adapter in the other hand to increase the accuracy of the blows. We rest one edge of it against the steering knuckle, there is a special protrusion there (shown in the photo below), and “hit” the other with a hammer. After several blows, the finger should “pop out” of the cone.

The rest is a matter of technique. We unscrew the nut completely, now there is enough space for full extension; if it still rests on the bipod, then use a pry bar to lower the lever down.

Important! We do not completely remove the hub from the lower ball pin; we will need it to press out the upper support.

And now the unpleasant moment. Once the finger has come out of the steering knuckle seat, there is nothing holding it. The nut has a fluoroplastic ring that secures it from unscrewing spontaneously. It can pull the finger along with it, and the nut will begin to spin with it.

This is a problem that I have encountered more than once. You can saw the nut or chop it with a chisel, which is what I did at the beginning of my journey as a car mechanic. This is “hemorrhoids”, a big waste of time and effort. With experience, I realized how to unscrew the lower ball joint nut if it rotates with the pin. I want to share this experience with you, but a little later.

We soak the bolts securing the ball to the lever VD-40, having previously cleaned the dirt with a metal brush. We unscrew them with the key “13”. We use two keys, with one we hold the screw from turning, with the second we turn the nuts. We take out the old part from the groove.

Removing the upper support

To replace the upper ball joint, leave the hub on the lower pin. We carry out the preparatory operations mentioned above, “walking” the nut in different directions, gradually running it along the thread.

We unscrew it with the key to “22”. It is recommended to unscrew it completely; nothing will interfere. If this is not done, then after “knocking out” the support, the nut may spin along with the pin.

Place a brick under the lower arm and lower the car until it rests completely on it. Thus, fixing it. We insert the puller, unscrew it all the way and a little more, but not until your teeth creak. We need a “tension” to appear between the supports, sufficient to pull the upper ball out of the fist. We take the tip, a hammer and hit the ebb of the upper fist until it pops out.

We remove the hub from the fingers of both supports and put it aside so that it does not interfere.

Important! Do not damage the brake hoses, otherwise they will have to be changed; I described in detail how to do this in the article on how to change the front brake hoses on a VAZ.

We repeat the operations with fastening the upper hinge in the same way as its lower sister. We spray WD-40, take the keys to “13”, unscrew the bolts securing it to the lever.

Video on how to remove ball joints using a puller:

Parts selection

The main enemies of the upper and lower ball joints are not only water or dirt, but also low-quality materials. It is best to purchase spare parts made of steel, as they are the most durable and wear-resistant. Any auto store will tell you which companies produce such parts. Also, reviews of other VAZ 2107 car owners can help you in your choice. Most of them recommend paying attention to domestic manufacturers, since cheap Chinese analogues can fail at any time.

- pressure plate;

- ball pin cover;

- upper ball pin.

What to do if the lower support nut rotates with the pin

First way. We place a block or brick under the hub. We lower the car on a jack; there should be nothing under the lower arm. The car sits down until the hub is completely seated. When the jack is released lower, at this moment the trunnion warps relative to the lever. The ball pin is clamped like in a vice, this will be enough to unscrew the nut.

Second way. We insert the pry bar between the hub, shown in the photo below, and the edge of the lever, pulling it to the side, creating an artificial distortion. We do not put anything under it; it should hang freely in the air. As in the first case, the force to separate the two parts of the chassis should be enough; the hinge pin will jam in the cone of the steering knuckle. Unscrew the nut completely.

The third method is barbaric. Don’t want to bother with grinders and crowbars? Take a torch and heat the nut until the fluoroplastic ring melts. Once soft, it will not prevent unscrewing.

Tool for unscrewing the support

We will consider another type, which is used not for pressing out the finger, but for removing the support itself.

The fact is that on a number of cars (Peugeot, Citroen) the ball joint is screwed into the lever. Over time, the threaded connection sours, and it is quite difficult to unscrew this suspension element without a special tool.

But you can make the necessary puller yourself, rather than spending money on a factory one.

It is made from a 2" thick-walled pipe 8-9 cm long.

At the end of this pipe it is necessary to make 4 spikes with a width of 5 mm and a height of 7 mm, located at an angle of 90 degrees relative to each other.

That is, you should get 4 protrusions at the end of the pipe, evenly distributed around the circumference. This can be done using a hacksaw and a file, or with a grinder.

From the other end we make slits to a depth of 3 cm, dividing the circumference of the pipe into 8 parts.

Then we bend these petals to the center using a hammer, significantly reducing the diameter.

What to do if the upper ball joint nut rotates with the pin

Remove the hub from the lower pin. We pull it in our direction with our hand until it stops. We wedge the finger in the cone of the fist. It will be clamped, unscrew the nut completely.

Second option. We insert a pry bar between the pin and the edge of the lever. We are trying to move the pin away from the lever. We clamp the finger and unscrew the nut.

Video, if the nuts turn together with the ball pins, how to remove them:

Article number and cost of good analogues of original VAZ 2107 ball joints from third-party manufacturers

The quality of original balls differs from batch to batch. It is possible to purchase both good support and outright rubbish. Therefore, many car owners doubt which one is better to install. They often refuse to buy the original in favor of products from third-party manufacturers. The best analogues of native balls are presented in the tables below.

Table - Good analogues of ball 2101029040828

| Manufacturer | vendor code | Approximate cost, ruble |

| TRW | JBJ250 | 520-600 |

| Lemforder | 3731501 | 590-710 |

| Delphi | TC204 | 370-450 |

| Monroe | L0704 | 440-530 |

| CTR | CBFI4 | 510-630 |

Table - Recommended alternative support options 21010290419286

| Manufacturer | vendor code | Approximate cost, ruble |

| Moog | LABJ0392 | 360-420 |

| Profit | 23010098 | 260-300 |

| Denckermann | D110135 | 250-315 |

| Lemforder | 37320 | 330-425 |

| Delphi | TC203 | 395-450 |

How to replace ball joints without a puller

To press the ball joint pins out of the steering knuckle cones, you need to:

- Jack up the car under the beam, hang the wheel so that it and the lever “hang” in the air.

- Loosen the ball fastening nuts as described above

- We insert a pry bar, when replacing the lower ball joint, between the lever and the knuckle. We press it down, as if squeezing these two parts apart

- With the second hand we hit with a hammer with “bulging” eyes on the ebb of the fist, shown above in the screenshot. After some time, depending on the degree of souring of the ball pin in the cone, the pin will “fly out”

- For the top one we do the same. We insert the pry bar between the upper knuckle and the lever and hit it with a hammer until the ball joint pin pops out

The remaining operations are carried out according to the same scheme as replacement with a puller: preparation, cleaning, lubrication, etc.

Video - replacement without a puller:

What is the purpose of ball joints on a VAZ 2107

A ball joint is a connecting part that makes up the suspension. Due to this small part on the car, the wheel can turn left and right. If you do not monitor the technical condition of the machine, a faulty support can cause an accident. To prevent the development of unpleasant consequences, you need to monitor the technical condition and regularly carry out diagnostics.

Structurally, the SHO ball joint has the shape of a hinge, which is part of the front suspension structure, allowing the wheel to move in the horizontal direction. The service life of the hinges in question is affected by the quality of the product, as well as the nature of driving the car. Judging from practice, on cars of the VAZ family, the SHO is the element that often fails and needs to be replaced.

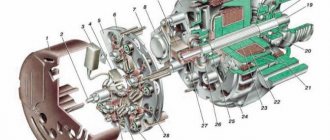

When designing the “seven”, the engineer abandoned the use of kingpins, replacing them with ball joints. Due to the fact that the hinge experiences heavy loads while driving, this leads to the need for regular replacement. Structurally, this mechanism consists of the following parts:

- steel body;

- a ball pin with a thread on the stem;

- plastic liner inside a steel case;

- a protective steel cover or boot that prevents dust and moisture from entering the interior.

The very first ball joints used a spring in their design. It was subsequently removed, and instead of metal liners they began to use plastic ones. A rubber boot was added. As a result, the support became non-removable, and therefore cannot be repaired, but at the same time its service life increased.

This is interesting! It is recommended to apply a layer of Litol 24 lubricant to the inside, under the cover, this will help extend the service life of the hinge.

In addition to the heavy loads that the hinges receive when the car moves, their service life is greatly affected by the ingress of water and moisture into the interior. This is due to the fact that the tightness of the rubber or plastic boot decreases over time. Even if the boot is in good working order, the part may still fail due to the small amount of lubricant inside the boot. It is very difficult to say how long a new support on a car will last, so in order to identify a breakdown, you need to regularly diagnose the VAZ 2107 chassis.

What are the signs of malfunctions and how to diagnose ball joints on the seven

To find out that the ball joints on a VAZ-2107 need to be replaced, you need to check the chassis. Diagnostics of SHO malfunctions on the seven is carried out in the following ways:

- While driving, extraneous sounds occur in the area of the front right or left wheel, depending on which support has failed. Extraneous sound manifests itself in the form of knocking and grinding. The characteristic sound is especially noticeable when cornering and when driving on uneven roads. SHOs fail individually, but if one part fails, then you need to check the integrity of the others.

- The occurrence of wheel sway. If you pick up speed, you will notice that the car begins to drive in different directions. The reason for this is play, which occurs due to a malfunction of the hinge. If the part is not replaced in a timely manner, the car may skid at high speed.

- When turning the steering wheel at low speed, a grinding noise occurs. The cause of the grinding noise is lack of lubrication.

- Detection of uneven tire tread wear. The reason for this may be not only faulty joints, but also other factors, however, if there is a suspicion of a joint malfunction, then identifying tread wear is an additional confirmation.

All of the above factors are indirect evidence that the hinge has failed. After all, grinding noise can also occur due to other factors, so it is strongly recommended that before replacing the ball joint on the seven, you perform diagnostics. How to diagnose and check ball joints on a machine is described in detail in the instructions:

- We determine the breakdown by ear. To do this you will need the help of a second person. One stands near the left, and the second near the right front wheel, and they begin to rock the car. In this case, you need to press on the hood of the car and listen for the corresponding sounds. If a characteristic grinding noise occurs, indicating a lack of lubrication in the ball joint, then we can assume that the part needs to be replaced.

- Presence of play in the hinge. To do this, you need to lift the front of the car on the side where there is suspicion of wear on the steering wheel. After this, one person should depress the brake pedal, and the second, holding the wheel with both hands, swing it left and right, as well as up and down. Setting it to speed will not allow you to carry out this procedure correctly, so you will need the help of a second person. The presence of play indicates that it is time to change the ball joints on the car.

- Inspect the fingers - this method can only be implemented by owners of the latest seven models. For this purpose, the part has an inspection hole, with which the wear of the ball pin is monitored without the need to remove it from the car.

Alternative method

Finally, we note that it is possible to press out the support pin or tip even if it is not possible to make a removable mechanism. But this method should be used only in extreme cases. To remove the finger you will need a pry bar and a hammer.

The pry bar is used as a lever and must be installed in such a way as to create a force to press the support or tip, for example, place it between the steering rod and the rack eye.

After creating force with the mount, it is necessary to apply powerful blows to the body of the eye with a hammer. If everything is done correctly, then after 2-3 hits the finger will pop out.

The disadvantage of this method is that the eye can be damaged due to shock loads, so it is advisable to use pullers rather than knock out the support.

When repairing the steering system and chassis of a car, owners are often faced with the situation of dismantling ball joints and rod ends. These structural parts cannot be removed without a special tool. This is a puller for ball joints. The device can greatly simplify the process of pressing out parts.

Purchasing this tool is not difficult - just go to the nearest auto parts store and select a suitable puller there. You can also make the device yourself. Let's look at the types of pullers, and also talk about choosing these tools.

The modern market for tools for car maintenance and repair offers the widest selection of different pullers, including several types of tools for dismantling ball joints and steering rods.

The first devices are considered a more universal solution. They are suitable for servicing any car.