We replace the pads of a Lada Largus car in case of maximum permissible wear of their linings - the minimum thickness of the pad, including its base, must be at least 6 mm. The pads also need to be replaced when the brake disc is replaced, the linings are oily or have deep grooves, cracks and chips on them, as well as when the linings detach from the base of the pads.

We carry out the work on a flat area, inspection ditch or overpass.

Attention! The brake pads of the front wheels must be replaced only as a set - all four pads. Replacing the pads of only one brake mechanism can lead to the car pulling to the side when braking.

If the fluid level in the hydraulic brake reservoir is at the MAX mark, then before installing new pads, use a syringe or rubber bulb to pump out some of the fluid from the reservoir. This operation must be performed so that when the piston is pressed into the wheel cylinder of the brake mechanism while installing new pads, fluid does not flow out from under the reservoir cap.

We remove the front wheel and securely fix the car on a factory-made support stand. Before installing new pads, it is necessary to move the wheel cylinder piston as much as possible inside the cylinder.

2283-14-02-01 (Copy)

To do this, insert a screwdriver with a wide blade through the hole in the caliper between the brake disc and the caliper and rest it on the caliper, move the bracket, recessing the piston into the cylinder.

To do this, insert a screwdriver with a wide blade through the hole in the caliper between the brake disc and the caliper and rest it on the caliper, move the bracket, recessing the piston into the cylinder.

To do this, insert a screwdriver with a wide blade through the hole in the caliper between the brake disc and the caliper and rest it on the caliper, move the bracket, recessing the piston into the cylinder.

Causes of malfunction

Reasons for replacing front brake pads:

- Degree of wear The service instructions state that products must be replaced when the thickness of the friction part is less than 2 mm. But, as practice shows, most motorists begin to change them when the wear level reaches 1.5 mm.

Comparison of the thickness of old and new brake pads

- Break the pads. This creates a sound as if something is entering the block and disturbing it. This malfunction occurs when the quality of the product is poor.

Critical pad wear, begins to “gnaw” the disc

- Another sign that your brake pads need to be replaced is a squealing sound from the front of your tires when braking. This is the critical wear rate.

All these indicators contribute to the fact that the front pads require replacement. Failure to replace this important part will result in brake loss or brake rotor wear.

2283-14-02-02 (Copy)

Using a 13mm spanner, unscrew the bolt securing the bracket to the lower guide pin, holding the pin with a 15mm spanner.

Using a 13mm spanner, unscrew the bolt securing the bracket to the lower guide pin, holding the pin with a 15mm spanner.

Using a 13mm spanner, unscrew the bolt securing the bracket to the lower guide pin, holding the pin with a 15mm spanner.

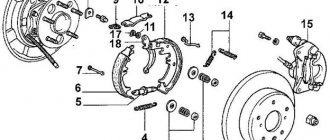

The principle of operation of Largus brakes

Lada Largus is equipped with a modern European brake mechanism, which was developed through various tests and trials. The heir to Renault Logan adopted the quality and reliability of the brakes from its predecessor. The following service brakes are installed on the station wagon.

| Location and type | Characteristics |

| The front ones are disc. | The front ones are ventilated and have a floating bracket. |

| The rear ones are drums. | The rear brake system is a closed drum in which the centering of the pads is carried out independently using mechanisms that regulate the gap between the pads. |

The brake mechanisms are hydraulically actuated, are dual-circuit, arranged diagonally and have a vacuum booster. A huge plus in some trim levels is the presence of an anti-lock braking system (ABS), which has become an indispensable thing in modern cars. It prevents the wheels from locking during braking, in particular emergency braking. The handbrake is actuated mechanically by transmitting drive to the rear axle using a lever.

There are misunderstandings on various forums about whether the same pads are installed on Largus, which has an engine with 16 valves and which has 8 valves. On configurations with separate power units, different brake systems are installed with different calipers and brake disc dimensions. Therefore, its configuration depends on whether your car has 8 valves on the engine or 16 valves. Based on this, one or another mechanism is established.

The Lada's pads with a 16-valve unit are slightly better.

2283-14-02-05 (Copy)

Remove the two spring clamps of the pads.

Remove the two spring clamps of the pads.

Remove the two spring clamps of the pads.

Using a metal brush, we clean the spring brackets and pad seats in their guide from dirt and corrosion.

Before installing new pads, we check the condition of the protective covers of the guide pins. We replace the torn or lost elasticity cover.

How to operate the car after replacing the pads?

After installing new pads in a Lada Lagrus with a 16-valve engine, you should not rush to drive onto roads with heavy traffic. The first presses on the brake pedal can cause inefficiency of the entire system, because consumables require time to grind into the working surfaces of the discs. Contact during this period does not occur over the entire surface, which explains the low performance of the pads. Over time, the situation will normalize. To properly “break in” the LADA Largus pads, we recommend choosing road sections with no heavy traffic. Once the process of grinding the pads to the discs is complete, you can observe the effectiveness of the brakes. At first, we recommend avoiding sudden braking to prevent excessive heating of the new linings. In “quiet” mode you should travel at least 100 km.

2283-14-02-06 (Copy)

To do this, remove the guide pin from the hole in the guide block and replace the cover.

To do this, remove the guide pin from the hole in the guide block and replace the cover.

To do this, remove the guide pin from the hole in the guide block and replace the cover.

To replace the upper guide pin cover, you need to unscrew the bolt securing the bracket to the pin and remove the bracket from the pad guide.

Before installing the pin, put a little grease into the hole in the pad guide.

Let's sum it up

Since the LADA Largus brake system has a significant impact on traffic safety, the elements require increased attention and timely replacement of the front brake pads. It is not recommended to allow excessive wear of the working surfaces. The specified consumables that have become unusable must be replaced immediately. Buy only products of decent quality, which will allow you to gain confidence in the stable operation of the brake unit only in normal mode, but also in emergency situations.

- https://avtonomnaya-gazifikaciya.ru/priora/zamena-perednih-kolodok-na-larguse.html

- https://ZamenaRenault.ru/largus/elektrika-i-tormoza/zadnie-kolodki.html

- https://ZamenaRenault.ru/largus/elektrika-i-tormoza/kolodki-tormoznye-perednie.html

- https://carfrance.ru/zamena-perednix-tormoznyx-kolodok-na-lada-largus-svoimi-rukami-artikuly-s-abs-i-bez/

- https://ladaevolution.ru/zamena-kolodok-lada-largus-svoimi-rukami-poshagovaja-instrukcija/

- https://el-guide.ru/remont/zamena-kolodok-na-larguse-16-klapannom.html

- https://LargusCenter.ru/remont/zamena-tormoznyih-kolodok-largus.html

- https://oootdssk.ru/zamena-zadnih-kolodok-largus/

2283-14-02-08 (Copy)

If the part of the piston protruding from the wheel cylinder prevents the installation of the caliper on the brake pads, then use sliding pliers to recess the piston into the cylinder.

If the part of the piston protruding from the wheel cylinder prevents the installation of the caliper on the brake pads, then use sliding pliers to recess the piston into the cylinder.

If the part of the piston protruding from the wheel cylinder prevents the installation of the caliper on the brake pads, then use sliding pliers to recess the piston into the cylinder.

Similarly, we replace the pads on the other side of the Lada Largus car. After replacing the pads, press the brake pedal several times to set the gaps between the pads and discs. We check the fluid level in the tank and, if necessary, bring it up to normal.

During operation, the surface of the brake disc becomes uneven, as a result of which the contact area of the new, not yet worn-in pads with the disc decreases. Therefore, during the first 100 km after replacing the pads, until the new pads have broken in, be careful, as the car’s braking distance may increase. In this case, the pads may become hotter than usual, up to the appearance of slight smoke and odor, especially in hot weather.

[How to save on maintenance of Lada Largus] [Maintenance of Lada Largus at 15,000/45,000/75,000/105,000 km] [Maintenance of Lada Largus at 30 thousand km] [Maintenance of Lada Largus at 60 thousand km of run] [Maintenance of Lada Largus for 90 thousand km of run] [Maintenance of Lada Largus for 120 thousand km of run] [Independent maintenance - general recommendations] [Safety rules for self-carrying out maintenance] [Tools required for carrying out maintenance Lada Largus maintenance] [Lamps used in the Lada Largus car]

Lada Largus: replacing the brake pads of the front wheels

Selection of front brake pads for Lada Largus

One of the most popular brands on the brake pad market is FERODO.

Lada Largus can be equipped with two types of front brake pads: with and without ABS function.

They have different catalog numbers, so they need to be considered separately.

With ABS

The first ones have the ABS function. There are quite a lot of pads, from low quality to high quality. But we will only consider those that are recommended to be installed on a car.

| Manufacturer's name | Catalog number | Average price in rubles in the Russian Federation |

| Master-sport | 13-0460-2834-2-N-SET-MS | 800 |

| Kraft Automotive | 6005000 | 900 |

| Optimal | 10342 | 900 |

| ABS | 36881 | 1050 |

| Klaxcar France | 24633Z | 1050 |

| Toko cars | CE1-700TOKO | 1050 |

| Bosch | 0 986 467 720 | 1200 |

| Mapco | 6377 | 1200 |

| TRW | GDB 400 | 1400 |

| Febi | 16191 | 1400 |

| Valeo | 301 002 | 1500 |

| Otto Zimmermann | 21463.180.2 | 1500 |

| Febest | 2401-LOGF | 1800 |

| Brembo | P 68 008 | 1800 |

| Fenox | BP43002 | 1800 |

| Automotor France | ABP5071 | 2100 |

| FiT | FP3350E | 2100 |

| Cross | KL05-00162 | 2300 |

| Finwhale | V706 | 2400 |

| Ferodo | FDB 1781 | 2600 |

| SWAG | 60 91 6191 | 3000 |

Analog manufacturers provide a fairly wide selection of analogue brake pads for Largus, but Brembo, Fenox, FIT and Bosch deserve special attention in terms of quality.

Without ABS

The second version of the pads is produced for cars that do not have ABS function. 410608481R is the original catalog number of this product. The average market price in the Russian Federation is 3,000 rubles.

Let's consider what analogues can be installed instead of the original.

| Manufacturer's name | Catalog number | Average price in rubles in the Russian Federation |

| Japan Parts | PA-013AF | 1200 |

| ABS | 37395 | 1200 |

| Starline | BD S331 | 1200 |

| Optimal | 12131 | 1300 |

| Profit | 5000-1617 | 1300 |

| Master-sport | 13-0460-2709-2-N-SET-MS | 1500 |

| Klaxcar France | 24996Z | 1500 |

| Febest | 2401-CLIF | 1500 |

| Pilenga | FD-P 8010 | 1700 |

| Delphi | LP1865 | 1800 |

| TRW | GDB 3332S | 1900 |

| Fenox | BP43018 | 1900 |

| Ferodo | FDB 1617 | 2000 |

| Bosch | 0 986 424 795 | 2100 |

| Delphi | LP1865 | 2100 |

| TRW | GDB 3332S | 2200 |

| Valeo | 301 641 | 2300 |

| Brembo | P 68 033 | 2300 |

| Otto Zimmermann | 23973.175.1 | 2400 |

| FiT | FP1491 | 2600 |

| Automotor France | ABP3332 | 2800 |

As in the first case, analog manufacturers produce a fairly large assortment of brake pads for Largus.

Recommendations and improvements

Some car enthusiasts, in order to improve the use of brake pads, replace calipers and discs with a tuning version. They are more efficient than factory ones. Some modifications may require replacing the hub, since the bolt pattern of the parts may vary.

Since the front brake pads last for a maximum of 20,000 km, some owners are not happy with this.

Brembo extended life front brake pads

Instead of standard pads, you can install a sports kit from Brembo, which costs 1.5 times more, but also has a service life of about 40 thousand km, depending on driving style.

Useful tips

The first thing that worries every motorist during the next technical inspection of the caliper and brake lining is what its maximum wear margin is. Less than 1.5 mm thickness of the friction lining should not be allowed

It is also very important, when changing pads, to also measure the degree of wear of the brake disc.

'); if("undefined"===typeof loaded_blocks_drive){loaded_blocks_drive=[]; function n(){var e=loaded_blocks_drive.shift(); var t=e.adp_id; var r=e.div; var i=document.createElement("script"); i.type=”text/javascript”; i.async=true; i.charset=”utf-8″; i.src=»https://www.drivenetwork.ru/data/»+t+».js?async=1&div=»+r+»&t=»+Math.random(); var s=document.getElementsByTagName("head")||document.getElementsByTagName("body"); s.appendChild(i); var o=setInterval(function(){if(document.getElementById(r).innerHTML&&loaded_blocks_drive.length){n(); clearInterval(o)}},50)} setTimeout(n)}loaded_blocks_drive.push({adp_id:e ,div:t})})(47602)

Brake pads for Lada Largus

Lada Largus brake pads can last up to 50 thousand km. mileage during quiet driving. Aggressive driving style greatly reduces the actual life of the product. Therefore, it is better to monitor the degree of their wear every 10-20 thousand km. mileage

It is important to understand which structural elements are responsible for reliable braking. If the car’s braking distance has noticeably increased and obvious signs of a malfunction cannot be determined, the following possible problems can be identified:

- If the wear of the friction linings is within normal limits, but the brakes are working frankly poorly, check the condition of the brake fluid. Perhaps it absorbed too much moisture and lost its performance characteristics;

- if the brake pads are worn unevenly, this is a clear sign of problems with the caliper, in particular, acidification of the guides and working cylinders. It is also necessary to inspect the caliper;

- Excess oil in the caliper guides can get onto the brake disc, which will also increase the distance required to brake the car.

Signs of wear

Often this information is presented in great detail in the “Operating Manual” of the Lada Largus. This is where all the parameters of the above-mentioned pads that need to be replaced are indicated.

The level of their wear is determined by the remainder of the functional part, that is, the material that is pressed tightly against the “pancakes”. It is he who, like nothing else, is prone to rapid abrasion. It is believed that the brake pad is the most worn part among all other components of the vehicle.

You cannot wait until the mileage exceeds 20,000 or 30,000 km, because the use of such parts can already be dangerous for the lives of people sitting in the car. In addition, their wear directly affects the safety of the discs or cylinders of the same name, which, in all likelihood, will also have to be replaced. Such repairs will be especially expensive if the front brake pads in the Lada Largus are equipped with ABS.

Based on this, it is necessary to take into account the following features of operation during a gradual stop and the appearance of parts:

- a characteristic creaking is observed;

- the car changes its straight course, that is, it drifts first to the left, then to the right;

- the brake pedal vibrates noticeably when pressed;

- the possibility of installation on the “handbrake” is excluded even with the cable fully tensioned;

- the thickness of the disc of the same name should not be less than 21.8 mm;

- the minimum thickness of the friction linings is 2 mm;

- the presence of deep grooves and chips on the pads;

- unstable fixation of the linings with the bases.

To eliminate all of the above braking nuances, you should periodically check the condition of the relevant system. So, replacing brake pads will not be something supernatural, but rather a standard diagnostic procedure.

What types of brakes are there?

Throughout the history of the automotive industry, 3 types of brakes have been installed on cars:

- tape;

- drums;

- disk.

The first cars had a band brake system. The wheel axle was covered with tape. The driver had access to it at any time. If he needed to slow down, he pulled the tape, and this allowed him to reduce the speed.

Through “evolution,” the band brake was replaced by a drum mechanism. The principle of operation is the simultaneous rotation of a hollow drum with a wheel, which is bursting inside with pads. This slows down the car. This type of brake has proven itself well, but it also has disadvantages. With frequent heavy use, the drum overheats, since the ventilation in this closed system is not the same as that of a disk mechanism.

Just like overheating, moisture getting into the mechanism is also harmful to the drum. When individual parts become wet, the effectiveness of the brakes decreases. If any part in the drum wears out or falls off, it remains inside the system. This is both a minus and a plus. Indeed, in this case, the driver will hear a knock, and it will be possible to take measures to replace the part.

The disc brake system is the most reliable mechanism that eliminates the above-mentioned disadvantages of previous systems. Disc brakes work by rotating the disc simultaneously with the wheel, and when you press the brake pedal, the pads jam the rotation of the disc from the outside. Unlike the drum, the disc is ventilated, so it is less susceptible to overheating than the drum. The discs do not retain moisture and damaged parts. The operating principle of this system is based on the ability to work under heavy loads. Therefore, you can stop your car faster with disc brakes.

Such mechanisms are often front-facing and ventilated. Ventilation holes cover the entire radius of the disc. Some modifications have transverse ventilation holes. With their help, excess heat is removed, weight is reduced and worn parts are removed.

Due to the fact that the drum mechanism costs much less than the disk mechanism, today both disks and drums are used.

Replacement procedure

First of all, drivers should know that such pads are replaced in pairs. Experts do not recommend doing this separately, because this can lead to destabilization of the entire car during a gradual or sudden stop. However, only the front elements of the system of the same name require frequent attention, although in many ways everything is justified by a specific malfunction.

Step one

The procedure for replacing the pads is carried out only in a set of 4 parts, 2 pieces on each side. First of all, you should check the brake fluid level in the tank of the corresponding cylinder. If it approaches the maximum, then the fluid needs to be pumped out, because after installing new pads this level rises significantly.

Step two

Next, the wheel bolts are loosened, from which the replacement of the pads begins. The corresponding part of the car is raised with a jack, reliable supports are installed and the wheel itself is removed. Using a screwdriver, the existing pads are removed from the disk, that is, the piston is pressed all the way into the bottom of the working cylinder.