Adjusting the parking brake drive

Lada Largus

We adjust the parking brake drive after replacing the rear wheel brake pads, cables or parking brake lever. We hang the rear wheels and securely fix the car on factory-made stands. Lift the parking brake lever.

Remove the lever trim cap that covers the adjusting nut

parking brake drive (for clarity, shown with the floor tunnel lining removed).

To adjust the position of the brake pads, press the brake pedal several times. We hold it down and then repeatedly raise and lower the parking brake lever (while moving the lever, you must keep the parking brake release button on the lever depressed at all times so that the ratchet mechanism does not work). In this case, clicks will be heard in the brake mechanisms of the rear wheels from the operation of the mechanism for automatically adjusting the gaps between the pads and brake drums. If you do not hear clicks when moving the parking brake lever, then increase the tension of the cables by tightening the nut on the threaded end of the front cable. We raise the parking brake lever and lower it until the clicking in the brake mechanisms stops. After this, we check the stroke of the lever, which should be 7-8 clicks (teeth along the sector of the ratcheting device of the lever). If the number of clicks does not correspond to the specified one, then.

. Using a wrench or a high socket “10”, rotate the nut on the threaded end of the front cable (increasing or decreasing its tension), thereby adjusting the travel of the parking brake lever (for clarity, shown with the floor tunnel lining removed). When the parking brake lever is fully lowered, the suspended rear wheels should rotate freely, and when the lever is raised, they should be locked. A properly adjusted parking brake should hold the vehicle on a slope of up to 23% inclusive.

Pull the handbrake on the grant

Adjusting the hand brake on Lada Largus

The first step is to unscrew the bolt securing the plastic casing under the handbrake lever, which is clearly shown in the photo below:

Then remove this cover completely so that it does not interfere.

Then, under the lever itself, we bend the so-called cover to the side, and there we see a nut on the rod. You need to tighten it clockwise if you want to tighten the handbrake. After several revolutions, it is advisable to check the operation of the handbrake so that it is not overtightened.

It is most convenient to tighten using not a regular open-end wrench, but a socket wrench or a deep socket with a crank.

When the adjustment is completed, you can put all the removed interior parts back in place.

Typically, adjustment is required very rarely and it is possible that during the first 50,000 km you will never even do this once, since it will not be necessary.

While I was fiddling with the armrest, I decided to tighten the handbrake, since access to it opened after removing the panel...

The rubber boot easily rises to the top. It is secured at the top with two latches. There is an adjusting nut under the boot (10mm wrench). You need to turn it with a socket wrench.

Well, so, in joy, I twist and twist, twist and twist. I lift the handbrake lever periodically. And he has 6 clicks both before and after the tightening. As it was, so it remains.

I start it, drive off, don’t even pull the lever and realize that I’ve overtightened the nut.

Then he put the machine on an incline and, loosening HALF of what was TWISTED EARLIER, ensured that after the 4th click Largus stopped dead in his tracks. Please note that if you just stand and pull the lever, there are still 6 clicks! I already have the sad experience of tightening the handbrake on Kalina. Alas, not a pleasant memory. ...I did it by 2 clicks. To turn around like a tank in icy conditions... After 70 km, the rear right wheel began to smoke... It turned out that there were no clicks at all on the handbrake handle (?!) In an unfamiliar city, I waited for 2 hours for the service station to open. (Early morning. Frost -28) We loosened the cable slightly and... we moved on...

Tools:

- Electrohydraulic lift type P-3.2G

- Medium flat screwdriver

- Driver for socket attachment

- Extension for the end attachment on the wrench

- Torx wrench attachment T-20

- 10mm wrench attachment

- 13mm wrench attachment

- Torque wrench

- 10mm curved box spanner

- Calipers

- Wheel key

Removal

1. Place the vehicle in the work station, apply the parking brake and turn off the ignition.

2. Remove the floor tunnel lining by unscrewing the screws that secure it using a socket wrench and a screwdriver.

3. Move the boot under the handbrake lever and loosen the adjusting nut of the handbrake lever equalizer cable using a socket wrench.

4. Disconnect both cables from the equalizer.

5. Remove the two nuts securing the arm to the floor tunnel studs using a socket wrench.

6. Then disconnect the wiring harness connector 1 from the handbrake lever warning light switch.

Handbrake warning switch:

1 – block of the instrument panel wiring harness.

7. Remove the handbrake lever.

Installation

1. Connect the wiring harness block to the warning light switch of the manual brake lever, install the lever on the mounting studs and secure with two nuts using a socket wrench. Ensure the tightening torque of the nuts is 8 N·m (0.8 kgf·m) using a torque wrench.

2. Install the handbrake cables into the equalizer holes.

3. Screw the adjusting nut of the manual drive lever so that dimension X from the upper end of the adjusting nut to the end of the threaded part of the equalizer cable is 16 ± 0.3 mm.

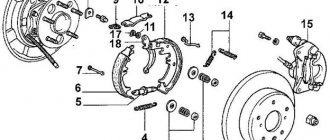

Hand brake parts:

1 – manual brake lever;

2 – equalizer cable for the manual brake lever;

3 – adjusting nut of the equalizer cable;

4 – equalizer for manual brake cables;

5 – manual brake cables;

X – adjustment dimension for tensioning the cables, X = 16 ± 0.3 mm.

Adjusting the hand brake

1. Place the vehicle on a two-post lift, apply the parking brake, and turn off the ignition.

2. Tighten and release the manual brake lever five times to the original position to bring the drive cables into working condition.

3. Make sure the rear wheels rotate. If not, check the following items and repair or replace them as necessary:

– manual brake cables;

– wheel cylinder piston;

– automatic gap adjustment mechanism.

4. Remove the rear wheels using a wheel wrench.

5. Loosen the cable tension adjusting nut using a bent spanner.

6. Place the handbrake lever on the second cutout of the gear sector (a second click will be heard when the lever is lifted).

7. Tighten the adjusting nut with a wrench until the brake drum stops rotating by hand.

8. Tighten and release the handbrake lever 2-3 times and check the rotation of the brake drum. If the drum does not rotate, gradually loosen the adjusting nut using a spanner until the drum rotates freely.

9. Install the rear wheels using a wheel wrench, tightening the mounting bolts with a wheel wrench in the sequence shown in the photo below.

10. Reinstall the floor tunnel lining using a socket wrench and a screwdriver.

11. Check the effectiveness of the service brake system.

The first step is to unscrew the bolt securing the plastic casing under the handbrake lever, which is clearly shown in the photo below:

Then remove this cover completely so that it does not interfere.

Then, under the lever itself, we bend the so-called cover to the side, and there we see a nut on the rod. You need to tighten it clockwise if you want to tighten the handbrake. After several revolutions, it is advisable to check the operation of the handbrake so that it is not overtightened.

It is most convenient to tighten using not a regular open-end wrench, but a socket wrench or a deep socket with a crank.

When the adjustment is completed, you can put all the removed interior parts back in place.

Typically, adjustment is required very rarely and it is possible that during the first 50,000 km you will never even do this once, since it will not be necessary.

When to tighten and when to change?

During operation of the machine, the steel cable gradually stretches and begins to sag. Then part of the lever stroke is used to remove this slack (the first 2-3 clicks), and only then the force is transferred to the brake pads of the rear wheels. As a result, they are weakly pressed against the surface of the discs or drums and the car does not brake reliably.

The first sign of a malfunction is that the handbrake stops working on the first two clicks of the handle and is raised by hand without any effort. In this case, it is definitely necessary to tighten the hand brake, or rather the cable drive.

But the operation of the mechanism also depends on other factors:

- on the degree of wear of the brake pads;

- from the depth of excavation on the surface of the steel disk or drum.

Abrasion of the linings does not have much effect on the operation of the main system, since the stroke of the hydraulic pistons is quite large. But the effect of the mechanical “handbrake” gradually weakens. To return it to working condition, it is necessary to compensate for the wear of the elements by tensioning the drive. If the cable itself is in satisfactory condition, the extension of the tension pin will be enough to ensure the operation of the parking brake at any degree of wear on the linings.

The cable is replaced in the following situations:

- The element has stretched to such an extent that at maximum tension the pads do not grip the discs and the car rolls away on any slope.

- Due to the constant ingress of water under the cable casing, it rusted and became tightly jammed. This happens when a motorist rarely uses the handbrake.

Cable jamming also occurs in winter, when water trapped under the casing freezes inside. In this situation, do not rush to change it; first warm up the car in the garage, and then drive out the moisture using WD-40 aerosol lubricant.

When adjustment is required

Experienced motorists are advised to diagnose the current condition of the handbrake once a month, or after every 30 thousand kilometers traveled.

If there is a suspicion of a malfunction, under no circumstances should the inspection be postponed. Moreover, diagnostics are quite easy. There is no need to go to the service center.

The proposed instructions provide 2 methods for diagnosing the handbrake, which is done by hand.

- First method. Drive your car onto a fairly steep slope and do not press the handbrake all the way. If the car is stationary and does not roll, the system works normally. If the car starts to move, tighten the cable all the way and observe the behavior. If the car still drives, the handbrake needs to be adjusted or even changed;

- Second method. Pull the handbrake fully, engage 1st gear, carefully and slowly release the clutch pedal. Here it would be logical to remember the principle of operation of the clutch on a car. If everything is fine with the handbrake, the engine should stall. If there is a problem with the handbrake, the car will move. Here you need to repair or adjust the unit.

Most often, the parking brake stops performing its tasks normally due to weakened tension, wear of the brake pads, or due to an increase in the gap between the pad and the drum.

Need to adjust the handbrake

I would like to focus on several situations when it is strongly recommended to adjust the parking brake yourself or even with the help of specialists. This is also done in the following cases:

This is also done in the following cases:

What kind of UAZ Patriot tuning can you do yourself?

- brake pads were changed;

- brake discs or drums were changed;

- brake pads were adjusted;

- the cable was repaired;

- the handbrake cable was changed;

- an adjusting unit was installed;

- the lever stroke has increased;

- diagnostics showed a malfunction.

Anyone can adjust a mechanical parking brake. This is much easier than doing a wheel alignment yourself, and is also noticeably easier compared to adjusting the low beam headlights on a car.

Largus hand brake cable

Dear customers, in order to avoid mistakes when sending a parking brake cable for a LADA LARGUS car, please indicate your car model and year of manufacture in the “Comment” line.

The parking brake (also known as the handbrake, or in common parlance “handbrake”) is an integral part of the car’s braking control. Unlike the main braking system used by the driver while driving, the parking brake system serves primarily to hold the vehicle in place when parked on sloped surfaces, and can also be used as an emergency emergency braking system in the event of failure of the main one.

1 — parking brake mechanism (360106743R), 1 — parking brake mechanism (360109167R), 2 — self-locking hex nut with collar (7703034256), 3 — parking brake cable (6001549112), 4 — double mounting bracket (7703179103), 5 — fastening bracket 1 (7703079254).

The parking brake cables (6001549112) are replaced if they are broken, pulled out or jammed inside the sheaths (rear cables), when adjusting the parking brake fails to keep the LADA LARGUS vehicle stationary on a slope of up to 23% inclusive.

The main purpose of the parking brake (or handbrake) is to hold the car in place during long periods of parking. It is also used in case of failure of the main brake system during emergency or emergency braking. In the latter case, the handbrake is used as a braking device.

The handbrake is also used when making sharp turns on sports cars.

The parking brake consists of a brake drive (usually mechanical) and brake mechanisms.

The mechanism is activated by moving the lever to a vertical position until the latch clicks. As a result, the cables that press the brake pads of the rear wheels to the drums are stretched. The rear wheels are blocked and braking occurs.

To remove the LADA LARGUS from the handbrake, you need to hold the locking button and lower the lever down to its original position.

The original cable 6001549112 for the parking brake drive, which is supplied to the AvtoVAZ conveyor, is intended to replace the failed standard one.

Why do you need a parking brake light?

Most of the indicators found on the machine's console are alarm indicators. They show that the car has some kind of breakdown or something is faulty. In such a situation, you need to use the services of a car service center, where they will give your vehicle computer diagnostics and offer the necessary repairs.

Initially, if the handbrake light is on, this is not an indication of malfunctions or errors. Just a car on the handbrake, the indicator lights up when the handbrake is raised. If the lever is lowered, the light stops lighting. It is easy to understand that the indicator on the dashboard is connected to the brake mechanism.

In principle, you can see that the handbrake light comes on even with a slight change in the position of the lever. Lift it just a little, without reaching the first click. And now the contact has already closed, and the indicator lights up.

There is no light signal provided that the lever has reached its extreme horizontal position. And if the car starts moving, but the indicator is still on, it means that you did not lower the handbrake all the way. This circumstance confuses most motorists.

However, the glow of the indicator may also indicate some damage to the braking functions of the vehicle. In reality, the role of the light bulb is not only to signal the position of the lever. It also informs the driver about various malfunctions: the mechanism cable has stretched or the volume of “brake fluid” in the hydraulic system is insufficient. There may be a number of other factors that cause the indicator to light up.

If the handbrake light is on or flashes, flashes when the car is moving and does not respond at all to raising/lowering the brake lever, it means that the car has a problem with the brakes. This situation is very dangerous! You should immediately visit an auto repair shop and find out the reasons that caused the handbrake light to glow.

Manual brake lever - removal and installation, adjustment

Removal

Place the vehicle in the work station, apply the parking brake and turn off the ignition.

Remove the floor tunnel lining. (see here)

Cut the floor mat at the rear of the arm and move the mat pieces to the sides.

Figure 17-1 — Disconnecting the manual brake lever cables:

1— handbrake lever; 2— equalizer cable for the manual brake lever; 3— adjusting nut of the equalizer cable; 4— manual brake cable equalizer; 5— manual brake cables; X - adjustment dimension for cable tension, X = 16 ± 0.3 mm

Loosen adjusting nut 3, Figure 17-1, of the handbrake lever equalizer cable

... and disconnect both cables 5 from the equalizer 4.

Unscrew the two nuts securing the lever to the floor tunnel studs,

Move the front seats all the way forward, lift the lever and disconnect the wiring harness block from switch 2, Figure 17-2, warning light of the manual brake lever (replaceable head 13, extension and knob).

Figure 17-2 — Removing the manual brake lever:

1— lever attachment points; 2— signal lamp switch

Remove the handbrake lever.

Unscrew the adjusting nut from the end of the front cable and disconnect the short cable from the lever.

Remove the handbrake warning lamp switch by unscrewing the screw securing it.

Installation

Connect the wiring harness block to the warning light switch of the manual brake lever, install the lever on the mounting studs and secure with two nuts. The tightening torque of the nuts is 8 N.m (0.8 kgf.m) (replaceable head 13, extension and wrench, torque wrench).

Install the handbrake cables into the holes in the equalizer.

Tighten the adjusting nut of the manual drive lever so that dimension X, Figure 17-1, from the upper end of the adjusting nut to the end of the threaded part of the equalizer cable is 16 ± 0.3 mm (spanner 10, caliper).

Adjusting the hand (parking) brake drive

Note: The parking brake adjustment is shown here in more detail.

Place the vehicle on a two-post lift, apply the parking brake and turn off the ignition.

Lower the handbrake lever.

Tighten and lower the manual brake lever five times to its original position to bring the drive cables into working condition.

Make sure the rear wheels rotate. If this is not the case, check the following items and repair or replace them if necessary:

— manual brake cables;

— wheel cylinder piston;

— automatic gap adjustment mechanism.

Remove the rear wheels.

Loosen adjusting nut 3, Figure 17-1, cable tension (wrench 10).

Install the manual brake lever on the second cutout of the gear sector.

Tighten the adjusting nut until the brake drum stops rotating by hand.

Tighten and lower the handbrake lever 2-3 times and check the rotation of the brake drum. If the drum does not rotate, gradually loosen the adjusting nut until the drum rotates freely

Install the rear wheels.

Install the floor tunnel lining.

Check the effectiveness of the service brake system.

Instructions for tensioning and replacing the drive

Since the parking brake system mechanism is located under the bottom of the car, an inspection ditch, overpass or lift is needed to perform the work. In extreme cases, you can do without them, but then you will have to hang out the back of the car and lie under it, which is not only inconvenient, but also dangerous. Before tightening the cable, securely secure the front wheels of the vehicle with wheel chocks.

Then act in the following sequence:

- Set the handbrake lever to the down position.

- Jack up any of the rear wheels.

- Armed with two open-end wrenches that fit the tensioner nuts, go down into the inspection hole.

- While holding the main nut located on the stud near the rocker arm, loosen the locknut.

- Tighten the tension nut, periodically checking the rotation of the suspended wheel by hand. To prevent the pin from spinning, it must also be held with pliers or a wrench.

- Stop tightening the cable as soon as the pads begin to grip the wheel. Make 1-2 turns of the nut back and check the operation of the handbrake. It should fire after the second click.

- Tighten the locknut, lower the jack and test the handbrake on a slope.

Replacing the cable drive will require more time, especially to disassemble the drum brake system. To hang both rear wheels, prepare wooden blocks, and to replace them, use a standard set of tools; no special devices are required. The algorithm of actions is as follows:

- Place the car on the pit and loosen the cable completely, as described above. Unscrew both nuts and remove it from the rocker arm.

- Lift the rear of the car, place it on blocks and remove the wheels.

- Remove the drums and unscrew the bolts securing the cable to the rear casing.

- Remove the brake pads and spacer bar. When you reach the lever, remove the cable loop from it. Remove it from the casing and repeat the operation on the other side.

Install the new cable drive in the reverse order, starting with the wheel mechanisms. At the end, tighten it and check the operation of the handbrake.

A loose handbrake cable usually occurs due to two reasons:

- Pulling the cable itself from constant strong tension

- Most often - due to wear on the rear brake pads

If you compare the Largus handbrake adjustment design with other domestic cars, you can feel a strong difference. Yes, this is understandable, because in Largus from a Russian manufacturer there is only one assembly and a name. Now let's get down to business.

A necessary tool for tightening the handbrake.

Head for 8 for ratchet Set of keys for 13 Partner (preferably the coolest car mechanic)

- Two keys for 13. It is advisable that one of them be a socket.

- Head 8.

- A partner, but you can do without him. The truth is it’s more difficult without him.

The principle of adjusting the handbrake

- Fully lower the handbrake lever in the cabin.

Lower the handbrake handle

- Place the car on a pit or lift it on a lift. Some car owners manage to adjust the handbrake “from the curb” - but this is inconvenient and dangerous.

- Find the resonator from the bottom of the car and remove it from the rubber brackets.

Remove the muffler from its mounting to the body

Using a ratchet, unscrew the 4 bolts securing the protection of the handbrake adjustment mechanism (protective screen).

Checking the operation of the hand brake

There are two methods to find out whether the parking brake system on the Lada Granta is in order. They work separately: if at least any type of check shows something wrong, the handbrake needs adjustment. What will you need:

- The car is stopped on an ascent or descent with a slope of about 23-25 degrees, then the handbrake is put in the raised position and turned off; what remains for our client to do is transfer. At the same time, the car should remain in one place and not even roll down. If this happens, the handbrake

is working properly and nothing threatens you. Otherwise, the handbrake on your car needs adjustment. - manual braking accounting programs is checked . If the ratchet mechanism clicks 2-4 times before being completely moved to the parking position, there is no need to worry, the handbrake is working properly.

Parking brake device

Before replacing the handbrake cable or tightening it, you need to understand the design of the mechanism. It is designed quite simply and consists of the following main parts:

- Lever with spring-loaded button and latch. Located in the cabin on the right hand of the driver.

- A metal rod with a pin at the end and a rocker arm for installing the cable is located under the bottom of the car and attached to the lever. This is the “handbrake” tensioning device.

- The ends of the cable (or two cables), installed on the rocker arm, are attached to the brake levers of the rear wheels - disc or drum.

The parking brake works like this: when the driver lifts the lever in the passenger compartment, the rocker moves forward and acts on the pads through a cable drive. In drum mechanisms, the brake pads move apart, and in disc mechanisms, they converge. The “handbrake” holds only the rear wheels and functions independently of the main brake system, which is activated when the pedal is pressed.

The handle is fixed in several positions thanks to the latch. To unlock it and lower it to its original position, a special button is installed at the end of the handle. If the pads “grab” the wheels on the second click, and after the fourth click they hold the car securely, then the drive is considered to be working well.

Features of handbrake adjustment

The question of proper cable tightening is quite relevant. Before directly performing the procedure, it is recommended to first check the functioning of the system. Note that the experts recommend carrying out the inspection procedure after every 30,000th run of the Renault Logan.

We perform a performance check using the following algorithm:

- tighten the handbrake lever until it stops;

- start the engine, activate first gear in the transmission unit and slowly release the clutch pedal;

- If the engine has not stalled and the car is moving, then the parking brake is ineffective or broken.

How to tighten the handbrake on the Lada Largus video

Place the vehicle in the work station, apply the parking brake and turn off the ignition.

Cut the floor mat at the rear of the arm and move the mat pieces to the sides.

1 — manual brake lever; 2 — equalizer cable for the manual brake lever; 3 — adjusting nut of the equalizer cable; 4 — manual brake cable equalizer; 5 — manual brake cables; X - adjustment dimension for cable tension, X = 16 ± 0.3 mm

Loosen adjusting nut 3, Figure 17-1, of the handbrake lever equalizer cable

. and disconnect both cables 5 from the equalizer 4.

Unscrew the two nuts securing the lever to the floor tunnel studs,

Move the front seats all the way forward, lift the lever and disconnect the wiring harness block from switch 2, Figure 17-2, warning light of the manual brake lever (replaceable head 13, extension and knob).

1 — lever attachment points; 2 - warning lamp switch

Remove the handbrake lever.

Unscrew the adjusting nut from the end of the front cable and disconnect the short cable from the lever.

Remove the handbrake warning lamp switch by unscrewing the screw securing it.

Connect the wiring harness block to the warning light switch of the manual brake lever, install the lever on the mounting studs and secure with two nuts. The tightening torque of the nuts is 8 N.m (0.8 kgf.m) (replaceable head 13, extension and wrench, torque wrench).

Install the handbrake cables into the holes in the equalizer.

Tighten the adjusting nut of the manual drive lever so that dimension X, Figure 17-1, from the upper end of the adjusting nut to the end of the threaded part of the equalizer cable is 16 ± 0.3 mm (spanner 10, caliper).

Adjusting the hand (parking) brake drive

Note: The parking brake adjustment is shown here in more detail.

Place the vehicle on a two-post lift, apply the parking brake and turn off the ignition.

Sources

- https://avtovestie.ru/info/kak-podtjanut-ruchnik-na-larguse/

- https://avtotop.info/kak-otregulirovat-ruchnik-na-larguse/

- https://rezina48.ru/novosti/regulirovka-ruchnogo-tormoza-largus.html

- https://largus-mcv.ru/html/rychag-ruchnogo-tormoza.html

- https://mvpclub.ru/kak-podtjanut-ruchnik-na-lada-largus-video/