Main technical characteristics of the VAZ 2107 box

The “seven” gearbox works in conjunction with the clutch.

The VAZ 2107 is equipped with a single-plate dry clutch, which has only one (central) pressure spring. This is quite enough for convenient control of vehicle speeds. The device weighs quite a lot - 26.9 kg without oil.

What kind of gearbox can be put on the “seven”

The VAZ 2107 will willingly work with both a four-speed and a five-speed gearbox, so only the driver decides which model to choose.

If we talk about domestic “VAZ” gearboxes, then initially the “seven” was equipped with a four-speed unit, so you can always buy and install this particular unit. The main advantage of such a box is its increased performance - the driver drives 200 - 300 thousand kilometers without ever investing in repairing the device. In addition, the four-speed gearbox is more suitable for low-power 1.3-liter engines or for drivers who often transport heavy loads by car, since the gearbox is initially designed for high traction.

Five-speed gearboxes allow you to reach higher speeds. Younger drivers like this, since at the start and when overtaking you can squeeze maximum power out of the car. However, over time, such boxes began to be made from low-quality materials, so switching is not always clear.

Foreign gearboxes can also be installed on the VAZ 2107. Boxes from Fiat are most suitable, since it was this car that became the prototype of domestic models. Some car enthusiasts install boxes from older versions of BMW, but the installation procedure can take a lot of time, since the car’s original design does not provide for non-standard units.

Installing/removing the VAZ 2106 gearbox

To repair or replace the gearbox, it must be removed. Today we will tell you how to remove or install the gearbox on a VAZ 2106 yourself.

Installation and removal of the VAZ 2106 gearbox

1. Work must be carried out on an inspection ditch or lift.

2. Disconnect the negative cable from the battery.

3. Disconnect the cardan drive from the gearbox and remove it from the car.

4. Remove the exhaust pipe from the mufflers.

5. Disconnect the terminals from the reverse light switch.

6. In the salon, carefully remove the decorative cover from the ring.

7. Use a screwdriver to pry off the rings holding the mat.

8. Moving and lifting the mat, unscrew the four screws securing the cover.

9. Take out the cover with the foam rubber seal from under the mat and lift them up.

10. Pressing down on the gear shift knob, use a thin screwdriver to remove the locking sleeve from the groove of the lever rod...

11. ...and remove the handle.

12. By striking the mounting blade inserted between the engine and the engine compartment partition, we bend the eye washer of the upper clutch housing mounting bolt.

13. Using a 19mm wrench, unscrew the bolt.

14. It is more convenient to use a special curved wrench with a head for this purpose.

15. Using a wrench or a 13mm socket with a cardan joint, unscrew the two upper bolts securing the starter to the clutch housing.

16. Using a 13mm socket with an extension, unscrew the lower starter mounting bolt.

17. Using a 10mm wrench, unscrew the four bolts securing the clutch housing cover.

18. Using your hand or sliding pliers, unscrew the nut securing the flexible speedometer drive shaft to the drive housing.

19. Install a stop under the lower part of the gearbox housing. Using a 19mm socket with a universal joint on the wrench extension, unscrew the remaining three bolts securing the clutch housing.

20. Using a 13mm wrench, unscrew the two nuts securing the cross member.

21. Remove the gearbox by sliding it back.

22. To replace the gearbox, disconnect the clutch housing. We install the gearbox in the reverse order of removal. Before installation, apply a thin layer of CV joint-4 lubricant to the splined end of the input shaft.

Let us remind you that the previous article was about removing and installing the instrument panel on a VAZ 2106 with your own hands.

Step-by-step instruction

So, when all the preparatory steps have been made, you can proceed directly to the removal itself. To do this, unscrew the brake fluid supply pipe to the gearbox, as shown in the photo below:

Then remove the fixing plate and release the hose:

When the cardan is disconnected, unscrew all the bolts securing the gearbox to the engine, including the small bolts of the tin protection. Then you can unscrew the hanging bar, which actually holds the gearbox.

Be careful not to let anything fall on your head. Use insurance while performing this work. You can place a special stop under the box to secure it.

Device location and characteristics

The gearshift lever of the VAZ 2107 is located directly in the car's interior. It is used to be able to change gears while moving. The gear lever fails only in rare cases, and the reason for this is negligence towards the product. If the product fails, it must be replaced. But before replacing, it is necessary to remove the product in question. We’ll find out in more detail how to remove it, as well as replace it on the “seven”.

On the “seven” the gear shift knob has a common problem - rattling and chattering. If you fix such a malfunction using improvised means, then replacing the device will not be necessary. Before you begin replacing the device, you will need to find out the exact causes of the malfunction. After all, sometimes not only the part in question can “fail,” but also the gearbox or clutch.

If you are convinced that it is the gearshift lever that is faulty, then only then should you start replacing it.

Replacement features

Before you begin the replacement, you need to stock up on tools such as wrenches and a screwdriver. We start with the following steps:

- Set the lever to neutral position.

- After this, you need to slide the top cover up. There is no need to completely remove the cover.

- The next step is to move the cover, which is located below, to the top. This cover is also called a thermal protection valve. In the photo below it is shown with a red arrow.

- Now you need to press the device, pushing it to the bottom. After this, you need to insert a screwdriver into the lower part of the product, where the plastic sleeve is located. The bushing is located at the very bottom of the device, as shown in the photo below.

- It is necessary to move the locking sleeve to the lower part, and then remove the product from the box.

- If the device emits strong vibrations, it needs to be replaced with a new one. In this case, you can exchange the part for a product of shorter length, as on foreign cars. A short device is much more comfortable to operate than a standard product.

Many motorists replace the standard gear shift levers with more modern ones, which allows them to uniquely customize the interior of the Seven.

After the standard product is dismantled, we install a new handle in its place. Let's look at what the installation is.

How to do without repairs?

The search allows you to get an idea of the prices offered by specialists and the conditions for performing work. Any repair requires a certain amount of time.

If you are severely limited in this, we recommend that you pay attention to alternative solutions to the problem.

You can buy a new gearbox VAZ 2106, gearbox 2107 without much effort. There is no shortage of parts on the market. But a new box won't be cheap. Want to save money? Buying a used VAZ 2107 gearbox is an excellent option. But there are risks to consider here. Buying spare parts secondhand is not always successful.

Do you need parts quality guarantees? Replacing a VAZ 2107 box or another model directly in the workshop is an excellent solution. You receive a guaranteed working transmission unit and save time on repairs.

In our workshop, transmission replacement for VAZ 2104, 2107 and other models is carried out by highly qualified specialists. We also carry out the reassembly of units and their preparation for exchange ourselves. This allows us to guarantee the quality of the result. Gearboxes with a large safety margin are offered for exchange. Car locksmith work is carried out as quickly as possible. Reasonable prices for boxes and expert services make repairs profitable.

Price of a used manual transmission VAZ 2106 on the secondary market

Since this box has not been produced for a long time, it can only be purchased on the secondary market. However, to find a decent copy there, you will have to sift through thousands of advertisements, since the offer is simply off the charts. The cost of the presented units ranges from 2 to 12 thousand rubles.

| State: | BOO |

| Originality: | original |

| For models: | VAZ 2101 - 2107 |

* The price for this gearbox is for reference only

Detailed video with analysis of the manual transmission from the six Zhiguli.

- You can contact the site administrator by email: [email protected]

All texts were written by me, are authored by Google, included in the original Yandex texts and notarized. For any borrowing, we immediately write an official letter on company letterhead in support of search networks, your hosting and domain registrar.

Next we go to court. Don’t try your luck, we have more than thirty successful Internet projects and have already won a dozen lawsuits.

Four-speed and five-speed manual transmissions

So, the so-called “four-step” was quickly replaced by a “five-step”. Let us immediately note that the five-speed manual gearbox is not very different from the 4-speed gearbox in design (the shape of the rear cover and other elements are similar). The main distinguishing feature is the placement of the fifth stage (speed, gear), which is located at the end of the secondary shaft.

The five-speed gearbox has the same ratios as the four-speed gearbox. Most of the parts are also the same, since the five-speed gearbox is based on the four-speed one. The 5MT gearbox has a primary, secondary and intermediate shaft. Structurally, the input shaft is the same as the four-speed gearbox, but the output shaft has a slightly different rear end where the fifth gear components are installed.

More precisely, at the rear end of the intermediate shaft there is a threaded hole into which a bolt is screwed in to secure the fifth gear gear block, as well as the reverse gear. The fifth gear itself and the reverse gear are located in the cavity of the rear cover; the hub of the fifth gear synchronizer clutch is installed together with the reverse driven gear on the secondary shaft. Next, behind the hub, a thrust washer and a bushing are installed where the fifth gear gear is located.

This additional fifth gear was used to allow the engine to operate at lower speeds when driving at high speeds. On the one hand, this solution increases the service life of the internal combustion engine and gearbox, and on the other hand, it saves fuel.

In simple words, owners of cars with a 4-speed manual transmission are very familiar with the situation when, when driving on the highway at a speed of 100-120 km/h and above in fourth gear, the engine speed is high, the engine and gearbox are very noisy under load, and fuel consumption is increased. To increase comfort, all that remains is to reduce the speed.

It was to solve this problem that the designers introduced 5th gear to reduce the load on the engine and gearbox, reduce noise and increase fuel efficiency.

As a rule, fifth gear is an overdrive (overdrive), it is recommended to engage it at a speed of 80-100 km/h on a flat road. At the same time, a further increase in the number of stages is possible and practiced (for example, MT6), but often most manual transmissions have 5 gears. The reason is the need for the driver to constantly change gears, which makes it difficult to control the vehicle.

Speaking of disadvantages, a 5-speed gearbox is more demanding on the oil level in the gearbox than a four-speed gearbox. If there is not enough oil in the box, it often happens that it is the 5th gear that fails first, and the gearbox begins to howl and make a lot of noise under load.

Why change the gearbox?

There are quite a few reasons to replace the transmission on a car, but usually they are a significant argument when repairing the car’s power plant. First of all, the gearbox is replaced in the event of serious malfunctions that are associated with widespread disruption of its performance.

Another reason to replace a transmission is to improve its performance. All Zhiguli fans know that the VAZ 2106 was produced in several modifications, which were equipped with 4 and 5-speed gearboxes. Those drivers who got a “six” with a 4-speed gearbox have already clearly noticed its significant shortcomings when driving on the highway, so they change this element to a more advanced analogue - a transmission with 5 speeds.

One way or another, the procedure for replacing a gearbox is performed the same way, regardless of the reason for the replacement. Below you will find detailed instructions for replacing the gearbox.

The installation of the VAZ 2106 box must be carried out taking into account the requirements and recommendations of the concern. It is permissible to use two types of boxes:

- manual, 4-speed transmission;

- manual, 5-speed transmission.

Both types of VAZ 2106 gearboxes are interchangeable, but the 5-speed version is more expensive, and this gearbox is more demanding to maintain. For example, the original “Etalon” is preferable to its Fiat Polonaise counterpart.

How to remove the gearbox on a VAZ 2106

Gearboxes and related products for VAZ cars

- home

- Products

- Remove/install gearbox

- About company

- Contacts

- Shipping and payment

- To come in

PRODUCTS

- VAZ gearbox

- Spare parts for gearbox

- Related products

Andrey, Mr. Ulyanovsk 04/09/2020

Now the gearbox is grinding in, light noises disappear before our eyes. But one thing is for sure - the shifts are clear, everything works as it should. So I recommend it! This is such a boring review :) Gearbox VAZ 21083

New opportunities for residents of Novosibirsk 10.29.2018

All residents of Novosibirsk now have the opportunity to purchase a VAZ gearbox in retail auto stores.

st. Rassvetnaya 17/2

All residents of St. Petersburg have the opportunity to purchase and install a VAZ gearbox from our partners.

Request a call back

Enter your Name and Phone Number and we will definitely call you back!

- Home >

- How to remove and install a gearbox >

- Removal and installation of the Gearbox (Gearbox) VAZ 2101, 2104, 2105, 2106, 2107

Removal and installation of the Gearbox (Gearbox) VAZ 2101, 2104, 2105, 2106, 2107

We carry out the work on a car lift.

Lower the parking brake lever to the down position. Remove the gear shift rod.

Align the two screws securing the parking brake lever boot and remove the boot from the lever.

Remove the front carpet.

Remove the floor tunnel cover.

Disconnect the battery.

Remove the warm air wire hose from the air filter housing.

Remove the two upper starter mounting bolts.

Unscrew the nuts securing the exhaust pipe to the exhaust manifold and remove the locking plates. (If you have difficulty removing the nuts, complete the operation from underneath the vehicle.)

Unscrew the lower starter mounting bolt and...

...move the starter forward.

Drain the oil from the gearbox housing. Close the drain plug.

Disconnect the parts securing the main muffler to the body.

Disconnect the additional mufflers from the exhaust pipe without disconnecting them from the main one.

Remove the exhaust pipe from the car downwards.

Remove the driveline safety bracket.

Unscrew the three nuts from the bolts securing the flexible coupling to the gearbox flange.

Remove the bolts from the flange and coupling one by one by turning the driveshaft.

Using a screwdriver, pry the coupling away from the flange and lower it down.

Disconnect the wires from the reverse light switch (located on the right rear of the transmission).

Unscrew the nut and disconnect the cable from the speedometer drive gearbox (located in the left rear part of the gearbox).

Remove the slave cylinder from the clutch housing without disconnecting the hose from the cylinder.

Unscrew the four bolts securing the clutch housing cover and remove the spring washers.

Place a support under the crossbar.

Unscrew the two nuts (the second one is not shown) securing the cross member to the body and remove the washers.

Remove the stop and smoothly lower the gearbox down.

Place a stop under the front of the engine to secure it in position.

Using extensions and universal joints, remove the left and right upper bolts securing the clutch housing to the engine. Remove the spring washers and eyelets.

Unscrew the left and right lower bolts securing the clutch housing to the engine. Remove the spring washers.

(An assistant must support the rear of the transmission.)

Remove the gearbox by first moving it backwards until the input shaft leaves the clutch, and then downwards.

Install the gearbox on the vehicle in the reverse order of removal. Fill in the required amount of oil.

Before installing the gearbox, apply a thin layer of LSC-15 or Litol-24 lubricant to the splined part of the input shaft and engage 1st or 3rd gear

Disassembling the VAZ 2106 and 2103 engine.

Once you have moved the removed engine to a bench, you can begin disassembling it. It is best if the engine is installed and secured on a special rotary table - moving it during disassembly is a very inconvenient operation. When starting disassembly, you should stock up on a standard set of sockets and open-end wrenches, as well as a hammer and screwdriver. We will need keys for “10”, “13”, “14”, “17”, “19”, “21”, “22”, “36”. Socket wrenches for “12” and “13” will also not be superfluous. To remove the crankshaft pulley if you do not have a special wrench, you can use a gas wrench. It’s a good idea to also stock up on an oil filter remover, because it is with the removal of this filter that the disassembly of our engine begins.

- Once you have removed the oil filter, remove the cylinder head cover, and, using the special cylinder head removal manual, remove the engine cylinder head itself.

Also remove the generator. To do this, loosen the lower nut on which the generator is attached, the tension nut, and, moving the generator towards the engine, completely remove the tension bar. Then remove the belt and the alternator itself.

We unscrew the limiting bolt and remove the drive chain together with the sprocket, completely unscrewing the previously loosened bolt.

Gearbox servicing

The service life of even the most reliable mechanisms depends on their correct operation and the quality of the oil used. Therefore, do not forget that high-quality oil is the key to long-term operation of the gearbox. During improper operation, rotating metal elements in contact with each other wear out. As a result of this, metal shavings get into the oil and, accordingly, are distributed throughout all elements of the box, further increasing the wear of gears and other parts. However, the gearbox has methods of passive protection against such harmful effects. For example, the drain plug in the bottom cap has a magnet that catches metal shavings. The primary and secondary shafts are sealed at the ends with rubber cuffs. The volume of oil that needs to be poured into the box is 1.35 liters. Long-term operation of the gearbox is possible with regular visual inspection to timely eliminate oil leaks, if any. In addition, it is necessary to measure the oil level in the box. It is advisable to carry out this procedure once a year or after every fifteen thousand kilometers. The oil must be changed every five years or after every fifty thousand kilometers. If it is necessary to repair the gearbox of a VAZ 2106 car, it is necessary to completely drain the oil, after which this device can begin to be disassembled.

Design Features

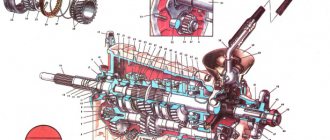

The five-speed gearbox of the VAZ 2106 is based on a four-speed gearbox, which ensures the interchangeability of parts. The unit is three-shaft and consists of the main components:

- Carter;

- Back cover;

- Bottom cover;

- Intermediate, primary and secondary shafts;

- Gears, couplings.

The VAZ 2106 car has good dynamic and speed characteristics thanks to a high-quality and simple gearbox. All gears, except the reverse mechanism, are helical and have constant mesh. This device allows the gears to transmit large torques with their small design. The reverse gears are spur gears, which prevents the car from developing high speed when moving backwards. This is explained by the weight and size of the gears and the maximum possible transmitted torque.

Drive gear

The forward gears are engaged thanks to clutches with inertial synchronizers. The direct switching mechanism consists of forks with rods. After the gear is engaged, fixation occurs thanks to spring-loaded balls that fit into the holes of the rods. VAZ designers also provided for the use of locking blocks as protection against engaging two gears at the same time. To reverse, engage reverse gear. In this case, the gear in the gearbox will move along its axis into engagement with the teeth of the gears of the intermediate and secondary shafts. Structurally, the gears of this transmission are located inside the rear crankcase cover. In the 5-speed gearbox, the elements of the last gear are also located there.

To replace the lubricant in the box (oil), there are special plugs in the housing that have a self-sealing conical thread

Please note that all characteristics of metal elements are selected taking into account the fact that the driver pours high-quality oil into the gearbox

Backstage at the checkpoint - what is it for?

In the language of service station specialists, the rocker is called “gearbox control drive rod.” The shift lever itself is mistakenly taken for the backstage when the backstage is a multi-component element:

As part of the gearbox, the link plays the role of a connecting link between the lever and the driveshaft. Being a mechanical device, it can wear out, so the driver will immediately begin to notice problems in driving the vehicle. Current breakdowns are usually associated with the exhaustion of the life of the link, and less often with a drop in the oil level in the gearbox.

Self-adjustment of the scenes

If you have the first problems with shifting gears, you can first try adjusting the rocker. It is quite possible that some connections have become loose and a little intervention can fix this problem:

Usually these actions are quite enough to return the car to its original controllability.

Video: instructions for adjusting work

How to remove and install the rocker on a VAZ 2107

In fact, the process of dismantling the old stage and installing a new one is quite simple. Car enthusiasts themselves explain in accessible language on forums exactly how to carry out the work.

Magadan

https://vaz-2106.ru/forum/index.php?showtopic=7549&st=40

Thus, it is not for nothing that the gearbox on the VAZ 2107 is considered one of the most complex design elements of the model. The owner can do some of the operation, inspection and repair work with his own hands, but do not overestimate your strength in the event of serious large-scale problems with the gearbox - it is better to pay for the services of specialists.

Main faults on the VAZ 2106 gearbox and how to fix them

Malfunctions of the “six” gearbox have more than one cause. Accordingly, the methods for eliminating them will vary.

| Cause of malfunction | Remedy |

| Presence of noise in the gearbox (may disappear if you depress the clutch pedal) | |

| Lack of oil in the crankcase | Check the level and add oil. Check for oil leaks, clean or replace the breather. |

| Worn bearings or gears | Replacement of damaged or worn elements |

| There is no noise, but the speeds are difficult to switch on | |

| The shift lever is damaged, the spherical washer is worn out, the gearbox lever travel limiting screw is worn out, the lever is bent. | Replacement of damaged parts |

| The lever joint jams | Replace the worn element, lubricate the joint with the recommended lubricant |

| Rusks and dirt get stuck in the fork rod sockets. | Replacing parts |

| Difficult movement of the coupling on the hub | Cleaning splines, removing burrs |

| Fork deformations | Replace with new ones |

| Clutch won't disengage | Troubleshoot clutch problems |

| Between third and fourth gear there is no way to lock the gear lever in neutral | |

| Breakage of the release spring | Replace the spring or replace it if it has come off |

| Spontaneous gear shutdown | |

| Loss of elasticity of clamps, wear of balls or rod seats | Replacing parts |

| Worn synchronizer rings | Replacement |

| Clutch teeth or synchronizer ring are worn out | Replace damaged parts |

| The synchronizer spring has failed | Install a new spring |

| There is a noise, crackling or squealing sound when shifting gears | |

| Incomplete clutch disengagement | Troubleshoot clutch problems |

| Insufficient oil level in the crankcase | Check for oil leaks, add oil, clean or replace the breather |

| Gear teeth worn | Replace parts |

| The synchronizer ring of a particular gear is worn out | Replace worn ring |

| Presence of shaft play | Tighten bearing fastenings, replace worn ones |

| Oil leak | |

| Worn cuffs | Replacement of worn elements. Cleaning or replacing the breather |

| Wear of shafts and nicks in places where cuffs are installed | Cleaning with fine grain sandpaper. Replacing cuffs. In case of severe wear, replace parts. |

| Breather clogged (increased oil pressure) | Cleaning or replacing the breather |

| Weak crankcase cover, worn gaskets. | Tightening fasteners or replacing gaskets. |

| Oil drain or fill plugs that are not fully tightened | Tightening traffic jams |

It is worth considering that some of the faults are related to other components and assemblies of the car.

Malfunctions

The main breakdowns of the gearbox mechanism of the VAZ 2106 model primarily include: random switching off of the lever, characteristic noise, and oil leaks. Let's start in order. Spontaneous gear disengagement can occur when there is severe wear on the teeth of the spline ring, gear clutch, retaining rings, spring, or fork rod teeth.

Also, the cause of this malfunction may be loosening of the mounting nuts on the engine mount, or on the box itself. Or, an equally common reason may be dirty clutch levers.

If the noise is not constant and appears only when one of the gears is in operation, then the reason can only be one: wear of the synchronizers or gears. If the noise does not go away when any gear is engaged, the cause may be a loose connection between the crankcase and the gearbox, or wear of the locking ring.

Well, liquid leakage can only happen in two cases: weak fastening of the filler or drain plug, as well as defects in their design that affect the tightness of the system.

Gearbox oil for VAZ 2106

The coordinated operation of the gearbox elements depends on the quality of the lubricant that washes them, as well as on its volume. The oil in the VAZ 2106 gearbox must be changed every 50 thousand kilometers. At least, these are the requirements of the manufacturer. But you need to check the lubricant level at least once a quarter.

What kind of oil to pour into the VAZ 2106 gearbox

In accordance with the requirements of the plant, only gear oil from groups GL-4 or GL-5 according to the API classification must be filled into the VAZ 2106 gearbox. As for the viscosity class, the following SAE classes are suitable:

The required oil volume for a four-speed gearbox is 1.35 liters, for a five-speed gearbox - 1.6 liters.

Checking the oil level in the gearbox

To find out what level of lubrication is in the box, the car must be driven onto a horizontal overpass or inspection hole. The engine must be cold. The oil level in the gearbox is determined by unscrewing the oil filler plug. It is unscrewed using a 17 key. If oil pours out of the hole, everything is in order with the level. Otherwise, it needs to be topped up. But there is one nuance here. You can only add oil of the class and type that is already in the box. If you do not know what kind of lubricant is in the gearbox, it must be drained completely, and only then a new one must be filled in.

Draining oil from the VAZ 2106 gearbox

To drain the lubricant from the “six” gearbox, the machine must be installed on an overpass or pit. The engine must be hot. This way the oil will drain faster and in full.

The oil drain plug is located in the lower crankcase cover. It is unscrewed with a 17 key. Before unscrewing it, you need to place a container under the hole to collect the oil. When the lubricant drains, the plug is screwed back on.

How and with what to fill the gearbox of a VAZ 2106

To fill the six gearbox with oil, you will need a special syringe or a thin hose (must fit into the oil filler hole) with a funnel. In the first case, lubricant is drawn from a container into a syringe, and then squeezed out of it into the filling hole. The process continues until the lubricant flows out of it. After this, the oil filler hole is screwed in.

When using a hose and funnel, you need to insert one end into the hole and raise the other end at least half a meter above it. The lubricant is poured into a funnel inserted into the other end of the hose. When oil begins to flow out of the box, stop pouring, remove the hose and tighten the plug.

How to install a new gearbox?

As soon as the old one is removed. Clean the junction between the engine and the gearbox. Be sure to check the clutch. If it needs replacing, it is better to do it now to avoid these difficulties in the future.

With the help of a partner, install the new transmission and drive it into the engine. It is worth noting that one of the most difficult procedures is inserting the transmission input shaft into the rear crankshaft bearing, so you will need a lot of physical strength and a little patience. After the box is attached, tighten the nuts securing the gearbox to the engine.

Install the crossbar and tighten it. Now the front box is securely fixed. At this time, you can already hang individual elements. These include: the speedometer drive, contacts for turning on the reversing lights and the clutch drive. After all this “trifle” has been installed, you can put the driveshaft in place. To do this, insert it into the slot of the elastic coupling and put on the fixing seal. Next, using a screwdriver and pliers, bend the metal antennae to the oil seal.

The final step is to install the cross member and tighten it. After this, you can install the exhaust system and connect the battery terminal

VAZ 2106 gearbox diagram

The VAZ 2106 transmission has a specific design diagram - you can see it in the picture. Speed shifting occurs as a result of the interaction of the clutch with synchronizers. Automatic shift levers and working mechanisms are represented by forks with rods. As the speed changes are completed, they are fixed with springs and balls - they are needed to hold the rod. Additionally, engineers use protection against accidentally turning on a couple of speeds at once.

The operational parameters of gearbox parts are selected taking into account the characteristics of the transmission oil. Poor quality fluid negatively affects the operation of the gearbox.

Gearbox VAZ 2106 and their design

This car was equipped with two types of gearboxes, one of them was a manual 4-speed transmission. The second is an improved version of the previous one, designed for 5 speeds, also of a mechanical type. At the same time, the five-speed gearbox, due to its modernization, was more expensive and more demanding to maintain. In addition, both of these gearboxes (5-speed and 4-speed) can be interchangeable.

The VAZ 2106 gear shift diagram is shown in the photo.

The device of any of them is a simple structure consisting of several shafts (primary, secondary, intermediate), a crankcase and a gear shift mechanism with synchronizers. On the input shaft there is a firmly seated gear, which is in constant mesh with all other gears. The shaft rotates due to two bearings located at the front and rear; the front one is also located in the crankshaft socket at the end. The rear one is located inside the crankcase and is sealed with an oil seal. The presence of the latter is explained by the fact that there is transmission oil in the crankcase.

The secondary shaft rotates due to three bearings. The front needle bearing is firmly seated in the input shaft socket, the ball bearing in the center is located in the crankcase seat, and the rear bearing is pressed into the socket on the rear wall. It also has a seal element that prevents possible oil leakage from the gearbox housing.

The intermediate shaft is a shaft with a gear block that rotates on two bearings. There is a ball bearing at the front and a cylindrical roller bearing at the rear. On the side there is a gear with reverse motion. As for synchronizers, they are structurally the same and consist of a hub, springs and couplings, equipped with locking rings.

Largely thanks to the simple, reliable and high-quality gearbox, the VAZ 2106 can boast of good dynamics and speed characteristics. All gears, with the exception of those at reverse speed, have an oblique tooth and are in constant mesh. Such a design, with its small size, allows more torque to be transmitted to the shafts, especially since the gear ratios of the VAZ 2106 gearbox are selected correctly. In reverse, gears with straight teeth are installed, so the car cannot gain high speed when the reverse gear is engaged, since such gears cannot transmit large torque.

VAZ 2106 gearbox device

Speed shifting occurs as a result of the operation of clutches with synchronizers. The shift lever itself and the entire mechanism are forks with rods. After switching, the speed is fixed by balls with springs that hold the rod. The engineers also provided protection against the possibility of turning on two speeds at once, using special blockers or, in common parlance, “crackers” for this. In order to change the oil, the gearbox has special holes with plugs with threads and rubber seals.

Please note: the performance characteristics of metal parts are selected taking into account the use of high-quality gear oil.

Speed box diagnostics

The gearbox on the VAZ 2106 should be systematically serviced. This procedure includes changing the oil. The choice of fuel for a VAZ should be approached as responsibly as possible. 80W90 oil is in demand, for example, from the domestic TNK brand, Lukoil. As a rule, about 1.5 liters are required for replacement. The need for replacement arises after 30,000 km of VAZ operation.

In order to save money, many car owners carry out the replacement themselves. Tools required: wrench, hexagon. In this case, vehicles must stand on a level surface. New fluid can be added to the car system using a special filling syringe.

During diagnostic procedures, service center technicians must pay attention to the condition of the coupling spline connections, synchronizer springs, and shaft seals. As a rule, complete disassembly of the box is required if any of its component parts are deformed

It is better to entrust the replacement of a VAZ 2106 gearbox to professionals.

Gearbox servicing

The service life of even the most reliable mechanisms depends on their correct operation and the quality of the oil used. Therefore, do not forget that high-quality oil is the key to long-term operation of the gearbox. During improper operation, rotating metal elements in contact with each other wear out. As a result of this, metal shavings get into the oil and, accordingly, are distributed throughout all elements of the box, further increasing the wear of gears and other parts. However, the gearbox has methods of passive protection against such harmful effects. For example, the drain plug in the bottom cap has a magnet that catches metal shavings. The primary and secondary shafts are sealed at the ends with rubber cuffs. The volume of oil that needs to be poured into the box is 1.35 liters. Long-term operation of the gearbox is possible with regular visual inspection to timely eliminate oil leaks, if any. In addition, it is necessary to measure the oil level in the box. It is advisable to carry out this procedure once a year or after every fifteen thousand kilometers. The oil must be changed every five years or after every fifty thousand kilometers. If it is necessary to repair the gearbox of a VAZ 2106 car, it is necessary to completely drain the oil, after which this device can begin to be disassembled.

https://youtube.com/watch?v=YW2EsAU8i7c%2520