The issue of ensuring safe and quick engine starting worries every motorist. And the leading role in this matter is played by the car’s starting system, which is essentially a kind of start when operating the car. For this reason, in order to avoid unpleasant situations, this system must always be in good condition. And special attention should be paid to such an element of the ignition system as the distributor. Such a mechanism can be called indispensable in the overall design, and therefore, it is very important to understand the signs of its malfunctions and have a good understanding of how they can be eliminated in the future.

Distributor design

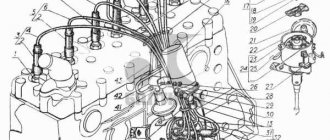

The distributor circuit assumes the presence of such elements as:

- low voltage current breaker;

- high voltage current distributor;

- centrifugal ignition timing regulator;

- vacuum ignition timing regulator.

The distributor circuit is designed so that at a certain moment the breaker opens the primary ignition circuit, as a result of which a high voltage current is created in the secondary winding of the ignition coil. Through the distributor, this current is transmitted to the spark plugs in certain cylinders. The regulators automatically adjust the ignition timing, which depends on the current operating mode of the engine.

The distributor breaker is an electromechanical part and consists of the following parts:

- shaft;

- movable contact plate;

- movable contact plate;

- capacitor;

- frame.

The breaker shaft consists of two main parts. On one of them, depending on the type of breaker, cams are installed, the number equal to the number of cylinders in the engine. This distributor device is not very reliable, since a large number of contacts, as well as the presence of moving parts, lead to regular problems with this unit.

The distributor device, as well as its use in general, are outdated from the point of view of modern electrical equipment, but in our country there are still a lot of carburetor engines, so the problem of the performance of this unit is currently relevant.

As for where the distributor is located in the car, most often it can be found under the hood next to the engine, near the cylinder head or on it. Although the exact location of the node depends solely on the model of the machine.

avtoexperts.ru

One of the most important parts of a gasoline engine is the distributor, officially called the ignition distributor.

Thanks to the distributor, electrical impulses are supplied to each spark plug separately. As a result, a discharge and corresponding ignition of the fuel mixture are produced in each chamber of the piston. The nature of the work to date is not much different from the first prototypes.

Distributor of the GAZ 21 car

The type of device, its dimensions, dimensions, and “fit” in the engine compartment may change, but the task of distributing discharges among the cylinders will not change. Keep in mind that there is much more than one cylinder in a car, which is why a distribution mechanism is required that evenly divides the charge among the “compartments.”

Remember the main thing, the functioning of some internal combustion engines of the gasoline or gas cycle is impossible without a distributor. In modern cars they try to get rid of them, due to their lack of reliability. They are replaced with individual coils (ignition modules), attached to the spark plug separately or in pairs. As we already understood, they are designed in modules containing from two to four coils. Having got rid of the distributor, the current began to be supplied directly from the ECU through transistor switches, which alternately transmitted 12 V to the coils. From the last impulses “went” to the candle. In this case, controllers control the coils. Thanks to various sensors, the ECU receives and analyzes information about the engine, and based on this it sends the necessary signal to the module. Modern models from manufacturers Mercedes, BMW, Skoda, Citroen, Peugeot, Honda, Subaru and others are equipped with such ignition modules.

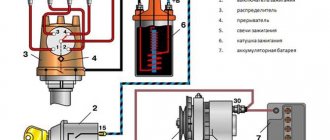

Ignition system. At number 2 - just like a distributor

The exception is diesel units; as is known, a spark is not required for ignition. Ignition occurs due to the compression of air and diesel. This principle of operation is not appropriate for “gasoline”, because if the latter is compressed, a banal explosion will occur.

Device

There are two dispenser options, contact and non-contact. The design of both is basically identical, with the exception of a couple of nuances. First, let's analyze the contact system. It is important to understand the configuration of only the main components:

1. The housing into which the shaft is inserted, also known as the device drive.

2. The drive, often called a rotor, is due to the existing gear, which is in engagement with the shaft (also known as an intermediate shaft that adjusts the speed) or directly with the camshaft. It all depends on the design and modification of the motor.

3. Coil with winding.

Device

4. Breaker, with a group of terminals and a pair of couplings or a Hall sensor, depending on the specification.

5. The runner is a dielectric that is attached to the shaft and rotates with it. A discharge is transmitted to it, which, through a contact (bunny) on the lid, “goes” to the high-voltage wires.

6. In older cars (VAZ, Moskvich, Volga, some foreign cars), there is an octane corrector that allows you to adjust the shaft speed, depending on what octane number of gasoline is used.

In addition, in addition to the listed elements, there is also a voltage regulator. It protects the contacts from excess current, since part of this charge is absorbed by the capacitor.

Many people will probably want to know how this system works. So, at the moment when the driver turns the key, the circuit closes and the voltage is sent to the starter. That, in turn, thanks to the bendix (a kind of gear) engages with the flywheel crown, causing the rotation of the crankshaft to be transmitted to the distributor. Next, a short circuit occurs in the windings and a low-voltage current is formed, after which the terminals open, and a high-voltage current appears on the secondary circuit, flowing to the cover, through the contact, and then, accordingly, the voltage is transmitted to the “armor”. This type of operation and type of device are typical for models from VAZ, Moskvich, and some old foreign cars from BMW and Fiat.

But, do not forget about more modern versions of the distributor, with a non-contact ignition system, paired with a pulse regulator, instead of a breaker. Not infrequently, owners of domestic cars VAZ 2110, 2107, Gazelles installed contactless distributors. There are three types in total, but only the Hall sensor has become widespread in the automotive industry.

Hall sensor on distributor

It includes a magnet, semiconductor wafers with chips, as well as special gate systems that allow the magnetic field to pass through.

The Hall sensor completely replaces the breaker that was used in the first versions of the unit. The regulator must be paired with a device such as a commutator, that is, it performs the task of breaking the circuits in the coil.

In general, the principle of operation is completely similar. The rotating crankshaft acts on the distributor with the regulator, the latter generates pulses and transmits them to the switch. And the commutator already creates voltage in the coil itself. Next, the voltage is received by a distributor that directs it along the armor wires. Such devices are typical for models from Skoda, BMW (previous years), Toyota and others, and modern models from VAZ are also equipped with this type of ignition.

Non-contact sensor distributor

Distributor malfunctions

There are more than enough problem areas for such a part, given its complex work in the car system. Any part can fail. So:

• Problems with the lid. Malfunctions can be associated with damage to the cover, such as mechanical damage, for example, a crack or the formation of oxide on the contacts.

Distributor cover

It is not uncommon for the “bunny” to break; the only solution for this is to buy a new cover.

Oxidized parts will have to be cleaned with an alcohol solution and dried. Often the problem is due to excess moisture in the area, so make sure there is no moisture there.

• The most common problem with distributors is the slider. The fuse-resistor may blow.

Distributor slider

• Capacitor. If it is faulty, increased current is supplied to the spark plugs.

Capacitor

• Another malfunction that occurs rarely, more often after serious mechanical damage. It consists of a change in the plane of rotation of the shaft, its deflection or jamming. The only solution is to replace the entire part.

Distributor shaft

• Wear of the housing itself, a malfunction as such, is rare, because, as in the previous case, the cause is mechanical damage to the unit. The solution is a complete replacement.

How to check if it's working properly?

There are several ways to check the functionality of a node, some of which directly indicate problems with a particular part. For example, if you have any doubts about the correct operation of the capacitor, checking it is quite simple.

We disconnect it and touch the ground, if a cracking sound is heard, then the part is working. If there is no cracking or other noise, a replacement is needed.

It is more difficult to check the condition of the internal parts, especially the old version. Some signs may indicate malfunctions or complete wear of some parts. For example, loss of power, loss of idle (idling), the appearance of jerks may indicate problems with couplings, bushings, and contacts on the breaker.

Check the contact group, the gaps between them, the condition of the wire insulation, and the condition of the terminals. Don’t forget to check the slider, because in fact it is the one that transmits the current to the wires. The check is quite complicated. You need:

• Remove the slider and small wire and strip it on both sides.

• Wrap one end of the runner plate, secure the other to the ground.

• Next, bring the tip of the armored wire to the plate.

If a spark appears, then the unit is working; if not, replacement will be required because the resistor, which serves to connect the two plates of the runner, has failed.

In other cases, the check may consist of a visual inspection, for example, burnout of the cover, damage to the body, etc., can be easily diagnosed externally, without the need for a detailed analysis of the unit.

Distributor malfunctions

The following signs indicate that the distributor is malfunctioning:

When there is a spark on the central wire, but not on the spark plug wires, this indicates a breakdown of the slider.

In most cases, the causes of distributor failure are:

Breakdown of the roof and ignition coil occurs due to large gaps in the contacts of the distributor cover and slider, spark plugs and bad candlesticks.

In each of these cases, replacement is required. But at the same time, for almost any car, it is possible to change not the entire distributor, but only its failed part, which is an advantage, since it significantly reduces the cost of repairs.

The most basic check of the distributor is a visual assessment of the condition of the slider, contacts and cover.

In a contactless distributor, the main malfunction is the failure of the hall sensor or inductive sensor.

To check the ignition system and distributor, among other things, observe the spark on the unscrewed spark plug after starting the engine. In garage conditions, you can also check using measuring instruments or indicators.

The distributor capacitor is also one of the parts that often fail. It helps to increase the voltage supplied to the spark plugs when the engine starts. And in order to check it, you need to disconnect it and touch the “ground”, and if a characteristic crackling sound is heard and a voltage drop is observed, the capacitor is working, if this does not happen to the replacement part.

Features of operation of the ignition distributor cap

The “sore spot” of the ignition distributor cap and rotor is the electrodes pressed into it. Due to the fact that there is no direct contact between them and the central electrode of the slider, and the spark passes through the air as they approach, the electrodes become charred quite quickly.

A used distributor cap for a Ferrari 458 with a V12 engine can be purchased for $608

To ensure reliable operation of the distributor cap, it must be kept clean both inside and out. It is necessary to regularly check the condition of the electrodes. When carbon deposits or oxide form on them, the contacts are cleaned with a flat file. It is not advisable to use sandpaper due to the likelihood of abrasive particles getting into the distributor mechanism. It is also worth monitoring the general condition and mobility of the contact (“carbon”) of the central electrode of the cover.

Malfunction of the contact distributor.

Malfunction of the distributor during contact ignition is due to a change in the gap in the contacts or their contamination. The operation of a contact distributor, in contrast to a non-contact distributor, is greatly influenced by the condition of the contacts, which must be checked after 10,000 km. Distributor malfunctions include wear of the shaft cams and the stop of the contacts sliding along them, wear of the bushings in which the shaft rotates, destruction of the bearing of the movable contact plate, weakening of the contact spring, jamming of the contacts on the axis, burning, erosion or contamination of the contacts.

All these faults lead to a change in the gap or a violation of contact between the contacts. As a consequence, loss of engine power, engine idling stops, throttle response decreases, jerking is possible when the gas pedal is sharply pressed.

In case of significant wear or destruction of the bearing of the movable contact plate, critical wear of the bushings, breakage of the negative shunt, a violation of the contact of the contact pair lever and the contact itself leads to popping noises in the intake manifold and muffler. This is also possible if the radio interference resistor located in the distributor runner burns out.

When the engine does not start, this may be due to a lack of contact or gap in the contact pair, or a breakdown of the slider. The absence, contamination or burnout of contacts is determined visually if there is no spark discharge on the high-voltage wire coming from the ignition coil. If there is a spark on the central wire and no spark on the spark plug wires, this indicates a breakdown of the slider. Malfunctions also include malfunction of the centrifugal and vacuum regulators. If there is a weak spark on the central wire and large sparking between the contacts, the capacitor is most likely faulty. Do not install additional capacitors or capacitors of larger capacity. The capacitance of the capacitor should be in the range of 0.15 - 0.35 µF.

Malfunction of the contactless distributor.

When operating contactless distributors, the main malfunction is a malfunction of the hall sensor or inductive sensor. Minor wear and play in the bushings and bearing of the movable contact plate do not affect the operation of the distributor until the sensor rotor touches the stator.

Such malfunctions as breakdown of the slider, burning of its resistance. It can also break through the distributor cap between the cylinders. This malfunction is typical for non-contact distributors, since the secondary voltage in these systems is twice as high as in a contact one.

Determining faults in the ignition system

Malfunctions of the ignition system lead to the fact that either the engine does not start, or runs intermittently at idle or in all modes, or does not develop full power.