The differential bearings are mounted with a preload of 0.25 mm. The tension is ensured by selecting the thickness of the adjusting ring installed in the gearbox housing socket under the outer ring of the differential bearing!

So, if the bearings are good, then it’s better not to touch them, since I started looking all over Kharkov for these rings, not every store has them, and if they do, then, as always, they don’t have the required thickness!

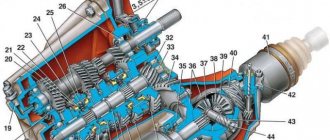

secondary shaft assembly

secondary shaft assembly

A small manual from the encyclopedia for assembling the gearbox:

1. When assembling the gear selector lever and the joint with the gear selector rod, first degrease the threaded holes in the joint body and the lever hub, as well as the mounting mounting bolts. 2. Apply thread sealant to the bolt threads. 3. We press the oil seals of the input shaft, drives and gear selection rod using mandrels or suitable pipe sections. 4. Lubricate the working surface of the oil seals with a thin layer of Litol-24 lubricant. 5. We install an oil seal with a right notch in the clutch housing (for right-hand drive), and an oil seal with a left notch in the gearbox housing (for left-hand drive). The arrows on the oil seal housings must coincide with the direction of rotation of the drives when the vehicle moves forward. 6. When assembling the secondary shaft, we replace the retaining rings of the synchronizer hubs with new ones. We press the outer and inner rings of roller bearings, ball bearings, gears and synchronizer hubs with mandrels or suitable pipe sections. 7. When assembling the hub with the synchronizer sliding clutch, before installing the retainer, apply a little grease to it and put it in the cracker. 8. Using a screwdriver, press the installed synchronizer spring towards the hub and put the block with the lock in place. In this case, the deepest socket should be located opposite the latch in the sliding coupling. 9. When assembling the differential, lubricate the satellites and drive gears with oil. 10. We mount the differential bearings with a preload of 0.25 mm. The tension is ensured by selecting the thickness of the adjusting ring installed in the gearbox housing socket under the outer ring of the differential bearing. 11. Selecting the thickness of the adjusting ring is necessary if replacing one of the following parts: differential box, differential bearing, clutch housing and/or gearbox housing. 12. After installing the differential into the clutch housing, it is necessary to secure one of the drive gears with a mandrel (plug) so that they do not move from their seats during further assembly. 13. Before assembling the gearbox housing with the clutch housing and the rear cover, apply a layer of sealant around the perimeter of the mating surfaces.

mileage 15 km after repair

I have already driven almost 1000 km . Catalog numbers and manufacturers of spare parts:

1. Input shaft: 1.1. Front single-row radial roller bearing: Catalog number

: 2108 - 1701031, 42205, NJ 205 (international name)

Manufacturers:

• EPK plants (Saratov, Volzhsky, Aviation Bearing Plant) produce the following varieties: 42205 KM (SPZ), 42205D1 (ZAP), 6-42205 A1E1USH1 (SPZ and VPZ), the latter is the most common and in demand.

• 10 GPP (Rostov-on-Don) offers modification 42205 AEM. These products occupy an intermediate position in the quality-price range. • The Samara SPZ-4 plant produces the simplest modification of this type, with a polyamide separator. They are very cheap, but knowledgeable motorists prefer not to use them. • If you are offered a “Vologda bearing” of this type, then it is a Chinese counterfeit (23 GPZ does not make them now). Catalog numbers

: SKF NJ 205 ECP; KOYO NJ205; Toyota 97123-06205; 6205ZZ; 93306-205U6-00 (Yamaha); 6205ZZCM

1.2.

Rear single-row radial ball bearing: Catalog number

: 2108 - 1701033, 50305, 6305 (international name) Quantity: 2 pcs.

Manufacturers:

• 3 GPP (Saratov) and VBF (Vologda), as well as HARP (Ukraine) - prices and quality are higher.

• GPZ (Moscow), SPZ-4 (Samara) (low quality, low price), • It is not recommended to buy bearings with other markings, since these are most likely Chinese products, which bear the markings of the companies ordering their production. The imported analogue is designated 6305. Closed 6305 ZZ and 6305 2RS (metal or rubber plugs). A bearing with a thermal gap is designated 6305/C3 (analogous to 76-305). Metal plugs - ZZ, rubber plugs - 2RS. Products of the SKF, FAG, KOYO brands are much more expensive and reliable than others. Catalog numbers

: SKF 6305 N; NTN-SNR 6305N; Toyota 90099-10142; 6305DDU; 6305NR; 90601-0012 (Subaru); 97100-06305; 5-81229-104-0

2. Secondary shaft:

2.1. Front single-row radial roller bearing: Catalog number

: 2108 - 1701180, 42305, NJ 305 (international name)

Manufacturers:

• EPK plants (Saratov, Volzhsky, Aviation Bearing Plant) produce the following varieties: 42305 KM (SPZ), 42305LM (SPZ), 6-42305 A1E1USH1 (SPZ and VPZ), the latter is the most common and in demand.

• 10 GPP (Rostov-on-Don) offers modification 42305 AEM. These products occupy an intermediate position in the quality-price range. • The Samara SPZ-4 plant produces the simplest modification of this type, with a polyamide separator. They are very cheap, but knowledgeable motorists prefer not to use them. • Some suppliers will also offer you the Craft brand. These Chinese bearings are the cheapest, but are completely unsuitable for installation in car gearboxes. Catalog numbers

: Koyo NJ 305; Coram NJ 305

3. Bearing of the secondary shaft of the gearbox, single-row needle without rings in a plastic separator (for speed gears):

Catalog number

: 2108 - 1701108 Quantity: 5 pcs.

Dimensions: 30x36x25 Catalog numbers

: K32X37X27 (SKF), PW-P1108 (Pilenga)

4. Single-row tapered roller differential bearing:

Catalog number

: 2108 - 2303036, 7207, 30207 (international name) Quantity: 2 pcs.

Catalog numbers

: NSK 30207, KOYO 30207JR; HR30207J; MB 393957; MT 202119; MA 125934 (Mitsubishi)

5. Seals:

5.1. Drive oil seal: Catalog number

: Corteco 12015250\Corteco 12015250B

5.2. Input shaft oil seal: Catalog number

: Corteco 19034619B\Corteco 19034619

5.3. Gear selector rod oil seal (yoke oil seal): Catalog number

: Corteco 12010803\Corteco 12010803B

6. Reverse gear Pilenga

Catalog number

: GB-P 0850

7. Engine mounts.

Manufacturer: BRT 7.1. Side engine mount bracket for LADA Samara 2108-1001040-10RU 7.2. Rear engine mount bracket for LADA Samara 2108-1001031-10RU 7.3. Front engine mount bracket for LADA Samara 2108-1001015-10RU

How to remove the box on a VAZ 2115

All VAZ 2115 cars are equipped with a five-speed manual gearbox, which is paired with a differential. The input shaft consists of a set of 1st-4th gear drive gears and one removable 5th gear gear. All of them are connected to drive gears, which are located on the secondary shaft. They are intended for forward gears only.

Gearbox for VAZ 21115

The control device includes: a shift lever, a ball joint, a set of rods, a mechanism for selecting the gear to be switched for a VAZ 2115 car. This is a separate mechanism located on the clutch housing. Two axles for switching are built into the housing and are connected to a three-arm lever.

Lubricant viscosity

It is necessary to pay attention to the kinetic viscosity of transmission oil first of all. You can select a suitable lubricant by knowing the climatic characteristics of your region; if you live in a region where the temperature often drops significantly below zero, then you should purchase class 90 oil, which is quite reasonable for most regions of Russia. In hotter climates, SAE grade 140 lubricant is suitable. Based on these principles, you must decide for yourself which oil is best to fill into the VAZ 2115 box in your region.

A domestic manufacturer has released a special gear oil for the VAZ 2115 gearbox called Reksol T; it meets the parameters 0W-85 API GL-4. Then another brand, Lukoil, released an analogue with the same parameters.

The last digit in the numerical designation indicates the temperature range permissible when using a particular lubricant. The higher the number, the hotter the climate in which it is recommended to be used.

Determining the malfunction and how to fix it

There can be many reasons for the malfunction, but the main ones can be identified independently. You can find out what happened to the box by the following factors:

- Loud noise;

- Poor gear shifting;

- Spontaneous shutdown;

- Crackling noise during shifting;

- Oil leak.

The reason for the constant noise while driving may be wear of the gears or failure of the bearings. The problem is solved by replacing them. But before the box is removed for further repairs, make sure there is oil. There are times when it just needs to be topped up or replaced.

Inadvertently shifting gears while driving can cause wear on the synchronizer teeth or severe vibration due to damaged rear bearings. Damaged support seals and synchronizers can always be replaced with new ones.

The reason for the gear not engaging may be the following:

- Clutch wear;

- Damaged drive rod;

- Loose fastening of the hinge and rod lever;

- Unadjusted shift drive;

- Damage or wear to the plastic parts of the drive.

A cracking noise when turned on can be caused by an unpressed clutch and a broken synchronizer ring of the VAZ 2115. If a leak is detected, it must be repaired immediately. Typically, oil begins to leak from the drain plug or from a crankcase mount weakened by constant vibration.

Recommendations

For reliable operation of the VAZ 2115 gearbox, the manufacturer recommends a scheduled replacement of lubricants after every 60 thousand km. To eliminate the possibility of accidental failure of the gearbox, the car owner should adhere to the following rules:

- Replace lubricants on time and according to regulations;

- Use only a high-quality product suitable for a given car model and recommended by the manufacturer;

- Periodically monitor the lubricant level in the gearbox and, if necessary, add gear oil to the system.

- The VAZ 2115 gearbox has a capacity of 3.3 liters; when replacing, it is better to purchase lubricant in one 5-liter canister. Prepackaged lubricant is sold in containers of 1, 3 and 5 liters.

Sometimes it makes sense to purchase lubricant on tap from a barrel, but this can only be done if you are completely confident in the quality of the product being sold. Beware of fakes!

Box removal process

Removing the VAZ 2114 box is quite simple, although there are some peculiarities, so it is still advisable to have an experienced partner next to you for the first time.

Tools

- a set of keys;

- Screwdriver Set;

- WD-40 fluid in case you can’t unscrew some part;

Rust converter WD-40

- container for draining old transmission oil;

- new oil (if the replacement was carried out a long time ago);

- rags;

- board.

Gearbox VAZ 2114 disassembled

Stages

Since you will have to work under the car, it is better to place the VAZ 2114 car on a pit or overpass; a car lift would be a good solution, otherwise you will have to resort to jacks.

- First you need to remove the terminals and remove the battery.

- Drain the oil from the gearbox into a prepared container by unscrewing the drain plug.

- We remove the starter.

- Remove the clutch cable.

- We disconnect the block with wires from the speed sensor, after compressing the spring.

- We unscrew the bolt attaching the ignition bracket to the gearbox. Then unscrew the remaining bolts.

- Under the car we find and disconnect the block of wires leading to the reverse sensor.

- Unscrew the bolts securing the linkage bracket to the gearbox.

- Having first loosened the gear shift rod clamp, we pull it out, pushing it back.

- We dismantle the wheel drives. You can leave the right one.

- In order for the gearbox to be removed without any complications, unscrew the bolts with which the left ball joint is attached to the steering knuckle.

- We disconnect the lower mount of the gearbox to the engine - sometimes you can get by by simply loosening the tightening of the bracket.

- After unscrewing the bolts, remove the transmission housing cover.

- Unscrew the bolt on the left of the gearbox.

- We carefully and carefully hang the engine using a board or other device.

- At the bottom of the car, unscrew the nut securing the left motor mount.

- We unscrew the two nuts with which the rear motor mount is attached to the body.

- We unscrew the two bolts with which the rear engine support is attached to the transmission (the second key is used to keep the nuts from turning), and remove the support.

- We move the box along the guides.

- This completes the process of removing the box; after completing all the necessary tasks, assembly occurs in the reverse order.

- When you put the box in place, do not forget to adjust the clutch and fill it with new oil.

VESKO-TRANS.RU

AutoNews / Reviews / Tests

VAZ 2115 Replacing the Clutch Without Removing the Box

replacement Clutch VAZ-2115 Do it yourself: detailed notes and repair methods

On a VAZ-2115 car, replacing the clutch is usually carried out if the box is removed. Much easier. work comfortably, nothing interferes. The article describes in detail the process of removing and replacing the secondary gearbox oil seal on a VAZ 2121 and Niva 2131. Replacing the clutch master cylinder on a VAZ 2101-VAZ 2107. But the repair can be performed without removing the gearbox. However, you should try it. the jewelry work remains to be done. But before repairing, make sure that the coupling has failed. Very often a particular gearbox breaks down, and drivers make mistakes with the clutch.

Symptoms of Failure

If the clutch is engaged, this is a clear sign of wear on the friction linings on the disc. This leads to the fact that when the engine speed increases sharply, the speed slows down, as if not all the movements are transmitted to the wheels. The only correct decision. replace clutch . Replacing 2114 VAZ clutches without removing the box. And you can do this without outside help, without resorting to an expensive car service.

Repair tool

You will need the following tools and accessories:

- Clutch kit. disc, output bearing, basket, bolts. Be sure to change the driven disk. The leader (basket) changes less frequently and has a much larger resource.

- Set of wrenches, winding keys, sockets.

- Screwdrivers, pliers, chisels.

- Drain pan out of the box. This will be required in any case, regardless of the replacement method you choose.

- Two nests are better. When removing a drawer, place a second drawer under the tray to keep it level and prevent it from falling.

- Car mounts and wheel covers.

- The presence of an overpass, pit or lift is welcome.

With all these devices you can start repairing. If you are experienced, the entire procedure should take an hour or two. But if you are doing it for the first time, it will take longer.

What to do before removing the gearbox

remove the gearbox for In order to replace the VAZ-2115 clutch yourself, you need to do the following:

- Drain the oil completely. it will destroy the descent of 2 birds with one stone. Firstly, the weight of the box will be less. Secondly, you will not lose lubrication during operation. Pay attention to the mileage of the car that was filled with oil. If it has developed its own resource, change it after installation.

- Remove the left wheel by lifting its side up towards the jack.

- Remove the two ball mounting bolts.

- Remove the pin and unscrew the nut from the tie rod. Replace the clutch slave cylinder from VAZ 2101-VAZ 2107. Remove the tip using a puller.

- Carefully remove the inner left hinge from the hole in the box. To do this, use a chisel and a small hammer.

- Leave the correct disc in place and it should be removed as soon as you begin to remove the box.

- Hang the left handlebar so it doesn't get dirty and get in your way.

- Remove the starter by first disconnecting the negative terminal from the battery.

Replacing the clutch on a VAZ 2114 without a hole

In this video we will look at how to change the clutch

on

VAS

2108. 15

without

a pit, how to set it up, what to pay for.

Replacing the clutch and releasing the bearing of a VAZ 2114 without removing the underpants

Clutch replacement

and releasing the bearing

VAZ

2114 (

VAZ

2108, 2109)

without removing the box

, discs (grenades) and sewerage.

That's it, almost everything is ready to dismantle the gearbox. But before you can completely remove it, you need to take a few more steps.

Disassembling the final box

Finally, do the following:

- Unscrew the nut according to the weight of the wire.

- Remove the clutch cable. If it is broken or damaged, be sure to replace the clutch cable on the VAZ-2115.

- Remove the bolts and nuts that secure the side and rear airbags. Summary of the article: Replacing the clutch on a VAZ 2112 without removing the joints; Replacing the clutch on a VAZ 2110, 2111, 2112 Replacing the clutch. In this case, it is advisable to install a jack or support under the crankcase so that the box does not sag too much.

- Loosen the scene clip and remove it.

- Now all that remains is to unscrew the three bolts and nut that tighten the gearbox and cylinder block.

- Separating the engine and transmission requires a mount and a lot of effort. If the assembly has not been disassembled for a very long time, it will be difficult to remove the input shaft from the grooves.

- Being careful not to damage the aluminum components, slide the box towards the left wheel. It is at this point, when he begins to move away from the block, that the inside right grenade must be removed.

When carrying out repairs, it is advisable to hang the box with a cable from a crossbar installed under the cover. Pre-treat all threaded connections with WD-40. This will help loosen the bolts and nuts much faster.

Remove and replace clutch block

To remove the basket and drive, you will need to unscrew the bolts in a circle. Please note that replacing the VAZ 2106 clutch requires replacing the front brake pads; it is advisable to do this across, this will not damage the basket. Instructions for replacing the VAZ 2110 clutch with your own hands, without removing the box and without requiring draining the oil, video report. The output bearing is located on the input shaft of the box and is fixed with a spring clip. It should be removed and a new one installed immediately. It is recommended to apply some new graphite based lubricant. this will slightly extend its service life.

Install in the following order:

- Insert the guide into the crankshaft. a small piece of pipe or piece of the transmission input shaft.

- Install the clutch disc and basket on it.

- Tighten the bolts, but do not tighten them.

- Make sure the disc and basket are in focus.

- Tighten the bolts crosswise.

Replacing the VAZ-2115 clutch disc is complete; remove the guide sleeve at the end of the entire procedure. Now you are ready to put the box in place. It is much more difficult to install it, because even with a slight deviation in the centers of the holes in the disk and crankshaft, the first one will not fit at all. Make your own clutch replacement on a VAZ 2107 (video). Everything will need to be collected and aligned. So do all the work correctly before installing the box.

Removing and installing the gearbox of a VAZ 2115 - 14

Removal

Place the VAZ 2115 - 14 car on a lift or inspection ditch. Raise the engine hood and lock it in this position. Next, follow these steps:

-disconnect the wires from the battery, from the starter traction relay

-disconnect the ground wire from the clutch housing

- disconnect the lower part of the clutch cable

- unscrew the two upper bolts securing the clutch housing to the engine block and the two upper nuts securing the starter, attach a bracket for lifting the power unit to the left stud of the engine exhaust manifold

Fig. 1 Installing a cross member to support the power unit

-install a cross member on the gutters to support the engine and hook it to the bracket installed on the exhaust manifold stud. If there is no cross member, hang the power unit with a hoist.

Next, perform work on the bottom of the car:

-remove the engine splash guard and the lower clutch housing cover

- drain the oil from the gearbox

-disconnect the wires from the reverse light switch

Fig.2 Mounting the gearbox on the car

1-engine, 2-power unit mounting bracket, 3-extension arm suspension bracket, 4-extension arm, 5-gearbox, 6-wheel drive shaft, 7-suspension arm, 8-anti-roll bar, 9-rear power unit support , 10-clamp, 11-rod gear lever drive, 12-inner joint housing

- loosen clamp 10 (Fig. 2) and disconnect rod 11 from the gear selection rod hinge

- unscrew the nut of the stud securing the gearbox to the engine

- disconnect the ball joints of the suspension arms from the steering knuckles

- using a puller or sharply hitting the body 12 of the internal joint with a hammer through a drift, knock out one hinge from the side gear, then fix the side gear with a technological mandrel or plug used when transporting the differential (otherwise the unfixed side gear may fall into the gearbox housing), after which knock out the second hinge

- move the wheel drive shafts to the sides

Useful replacement tips

The manual supplied with the VAZ 2115 car indicates the period for changing the oil in the gearbox - it is every 60 thousand kilometers. To avoid breakdowns and malfunctions of the gearbox, the owner of a VAZ 2115 must follow the following recommendations:

- change the gearbox oil in a timely manner;

- use only high-quality and recommended gear oil;

- monitor the oil level in the gearbox while operating the vehicle.

The amount of oil that needs to be poured into the gearbox is also indicated in the same manual. According to the instructions, you need to fill 3.3 liters.

Having chosen the brand of lubricant poured into the box, you should also decide on its packaging. Gear oil is most often sold bottled in cans, the volume of which is 1, 3 or 5 liters. In recent years, proposals to sell bottled oil from barrels have become increasingly common. In this way, you can profitably purchase only the actually required amount of lubricant, but you should carefully check the quality of the product offered, otherwise the imaginary savings can result in serious costs for repairing the gearbox.

VAZ 2114 gearbox malfunctions

First, it is worth considering faults that can be removed without dismantling. If the reverse gear does not press, it is worth checking the clamp and the mechanism itself for blocking. Another common problem is a rattling gearshift lever. The sound comes from a bushing that hits the surface of the wings. You can solve a manufacturing defect using a file - the error is determined and excess metal is removed.

It is recommended that you carry out the removal repairs together with a friend. During work, there will be times when you need to unscrew the fasteners both under the hood and in the interior of the VAZ 2114. It is also more convenient to check with an assistant whether the gearbox was installed correctly.

Repair and, accordingly, removal of the gearbox is required when, when changing gears, a grinding or crunching sound appears in the gearbox, a hum is heard, and the lever moves with difficulty. Also, dismantling is indispensable when some gears are switched off randomly (the problem is caused by a drive adjustment failure or a synchronizer failure).

Step-by-step instruction

- Warm up the car, it is better to do this on a lift, but if there is none, then you need to drive the car for about 10 km, while switching all gears;

- Raise the right front part of the car using a jack;

Important to remember! Be sure to play it safe and place a safety bar under the car, which will save your life if the jack becomes warped or weakened.

- Taking a container for draining waste and a wrench No. 17, unscrew the plug on the lower flange on the left side of the gearbox;

- If the plug is not visible (this also happens), then you will have to remove the engine protection and find the plug under it;

- Substituting the drainage container, wait about 15 minutes until all the liquid has drained, and screw the plug back on;

- Next, remove the intake pipe and air filter that prevent the assembly from being removed;

- After removing the dipstick from the gearbox, insert a funnel or the cut-off neck of a bottle into it and begin pouring new oil. You should immediately pour no more than 2 liters of liquid;

- When the lubricant is filled, you should make sure that there are no leaks and only then return the motor protection to its place;

- Add oil to the required level, periodically checking it with a dipstick, return the air filter and pipe to their place.

- The lubricant in the VAZ 2115 gearbox has been replaced, and you can start running it in.

What oil is better to fill?

When choosing a lubricant for the gearbox of a VAZ 2115 car, you need to take into account the following factors:

- climatic conditions of vehicle operation, seasonal air temperature plays a particularly important role;

- transmission design features: automatic or manual gearbox, the magnitude of mechanical forces in the units, specific loads placed on the units, especially when the engine is running at maximum speed;

- transmission oil viscosity corresponding to the first two points;

- the use of chemically active additives that can affect the operation of various transmission units and components.

After analyzing these criteria and familiarizing yourself with the range of available retail outlets, you can choose the optimal oil for your car. For cars such as the VAZ 2115, it is necessary to use GL 4 lubricant, classified in Russia as TM 4. The manufacturer recommends using Lukoil TM 4-12 SAE 80W85 fluid. It is excellent in its performance characteristics, but is not an off-season lubricant. Accordingly, in particularly severe frosts this lubricant thickens, causing certain problems in the operation of the gearbox.

In 1998, a set of requirements for fuels and lubricants was in force, which shows the temperature range for normal operation of transmission fluids. In the case of 80W85 lubricant, temperatures from -26 to +40° are considered normal. In this regard, in our country it is recommended to pour out-of-season transmission oils SAE 75W80 or 75W90, designed for use at air temperatures from -35 to +40°. In turn, high-viscosity fluids 85W90 and motor lubricants 5W50 and 10W50 are not permissible for use as transmissions for the VAZ 2115. Transmission gears with such oils will not be sufficiently lubricated even in hot weather, and in cold weather they will simply function at break.

What tools are needed?

In addition to the video or text instructions, when changing the oil in a VAZ 2115 gearbox, the following tools are required.

- 17mm wrench or socket.

- Empty five-liter bottle or canister.

- Empty one and a half liter plastic bottle.

- Work clothes with gloves.

- Knife.

- Jack.

- Car stand.

- 3.5 liters of lubricant.

- Rags.

- Wire brush.

- For concrete or steel garage floors, it is recommended to use a sheet of plywood as underlayment.