Payment for goods and downloading of the book in electronic form (PDF format) is made on the website.

To do this, you need to find the book you are interested in and click on the “Buy” button. The price of the book is indicated on the button.

For convenience, the price on the website for residents of Russia, Belarus and Kazakhstan is presented in rubles.

For residents of Ukraine in hryvnias, and for all other countries - dollars.

After clicking on the “BUY” button, a payment window will open where you can select a payment system with which you can pay for the selected book using any bank card (Visa, MasterCard, MIR, etc.)

When you click on the “Pay by bank card” button, the Portmone payment system will open, which is the easiest way to make a payment.

In addition, the website offers four payment systems for payment:

- Yandex (payment from any bank cards, Yandex Money account, QIWI Wallet, terminals, etc.);

- Portmone (payment from any bank cards, Portmone account);

- PayPal (payment from any bank cards, PayPal account);

- WebMoney (payment from any bank cards, payment from WebMoney wallets).

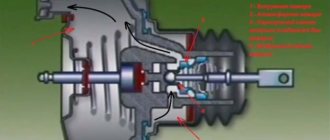

Vacuum brake booster device

The vacuum brake booster is designed to improve the usability of the braking system. A car without VUT would brake very hard - the force transmitted to the pedal in this case would be very significant, which would affect driving safety for the worse.

The VUT is usually located directly behind the engine shield. Structurally, this element is made in the form of a non-separable metal block connected to the main brake cylinder and the brake fluid reservoir.

The vacuum sealer includes the following elements:

- Frame.

- Separating membrane (made from flexible material).

- Check valve.

- Brake pedal pusher.

- Hydraulic cylinder rod.

- Return spring.

- Follow-up valve.

The principle of operation of the vacuum seal is based on the difference in atmospheric pressure, as a result of which a vacuum is created, which ensures the formation of pressure (and at the same time the transmitted force) in the brake system.

Inside the VUT there is a diaphragm in the form of a partition. Each of the chambers (cavities) separated by a diaphragm is sealed. Moreover, the chambers are equal to each other in volume.

One of the chambers communicates freely with the atmosphere (it is called the atmospheric part), the second is connected to a hose leading from the engine exhaust pipe. On this side, a lower pressure compared to atmospheric pressure is formed. This cavity is called vacuum; it is located on the GTZ side.

The atmospheric chamber, located closer to the brake pedal, contains a reverse valve. It is designed to prevent a decrease in pressure in the intake manifold of the engine. Due to this, fuel cannot enter the VUT mechanism.

The amount of vacuum in this cavity is controlled by a follow-up valve. The vacuum chamber, thanks to the reverse-acting valve, maintains the pressure at the same level. In other words, the membrane experiences the same pressure values from both chambers. The follower valve moves through a pusher, which is connected to the brake pedal. The purpose of the spring is to ensure that the diaphragm returns to its normal state after stopping braking.

In some situations, when the car is equipped with an emergency braking mechanism, the rod is equipped with a specialized electromagnetic drive.

As you can see, the design of the vacuum unit is not so complicated - in some cases, troubleshooting some VUT faults can be done on your own.

Cast iron brake drums

Needless to say, this metal is much stronger, but also many times heavier than its opponent. Some manufacturers sacrifice suspension lightweighting and still install cast iron on their cars.

There are a number of reasons for this, but as you probably guessed, they stem from the competitor’s disadvantages, let’s list:

- Durable. A very durable option in terms of wear and tear.

- The sticking is not so strong; in extreme cases, you can beat them off with a hammer; here you are unlikely to damage them.

- Do not deform from temperature loads.

That's all! Of course there are more disadvantages.

- It is much more difficult to cool down, because of this, braking efficiency decreases.

- Heavy. Create a large load on the vehicle axle.

- Prone to rust. You have to paint the outside , they don't look aesthetically pleasing.

By the way, here is a short video after painting such a drum.

The process of replacing the vacuum booster on a VAZ-2110

Vacuum brake booster.

To replace a vacuum brake booster, you must have some knowledge of vehicle design. On a VAZ-2110 it is not so difficult to replace a part with your own hands.

You need to stock up on a set of tools - keys and screwdrivers and you can begin the procedure. Let's consider, step by step, the process of replacing the vacuum brake booster of the VAZ-2110:

- Remove the negative terminal from the battery.

- Disconnect the wire block on the brake fluid level sensor.

Disconnect the power from the brake fluid level sensor.

- We hold the vacuum booster return valve and with the other hand remove the hose from it.

Unscrew the hose from the check valve.

- Remove the master brake cylinder. There are only two nuts, but they can stick.

In the engine compartment, you need to unscrew the two fastening nuts of the brake master cylinder.

- Without disassembling the brake, namely, without disconnecting the brake pipes, we move the master brake cylinder to the side.

We remove the cylinder with tubes from the amplifier.

- From the interior side, unscrew the four nuts securing the brake pedal bracket.

We remove the vacuum booster mounts from the passenger compartment.

- After this, you can dismantle the vacuum booster.

- Using a screwdriver, remove the locking plate of the pin. We push out the finger and disconnect the vacuum booster pusher from the pedal.

Remove the locking plate with the finger.

- Next, we are interested in the two nuts securing the amplifier to the plate, unscrew it, most likely you will have to use wd-40. We dismantle the bracket.

After unscrewing the fasteners, remove the bracket.

- Assembly is carried out in the reverse order of disassembly.

This is what the engine compartment looks like without an amplifier!

Part selection

Amplifier Torgmash.

The original catalog number of the VAZ-2110 vacuum brake booster is 21103510010.

The price of this part is 4000 rubles. In addition, there are a number of analogues that can be used. Thus, the automotive market offers the following non-original parts:

- Pekar 2110-3510010 with an average cost of 2500 rubles.

Pekar 2110-3510010 is an amplifier with a sporty twist.

- DK 2110-3510010 - low quality and cost around 2000 rubles.

- Master-sport 2110-3510010 is an expensive but high-quality product.

Vacuum brake booster master-Sport

Symptoms of malfunction (check options)

There are several signs of a malfunction of the vacuum brake booster, and, accordingly, diagnostics of performance. Let's consider each of the options:

- We start the engine and let it run for a few minutes, after which it is necessary to turn it off. Press the brake pedal several times. During normal operation of the amplifier, the pedal will be depressed the first time, but subsequent times the stroke will be less and less. If the pedal stroke does not decrease the second and subsequent times, then there is a breakdown in the system and the part is not sealed. This means that the vacuum booster needs to be replaced.

- The second option assumes that the first option did not produce any results, and doubts have crept in. Depress the brake pedal and start the engine. With this turn of events, after starting the power unit, the pedal should go all the way down. If this does not happen, then there is an air leak and the amplifier does not work.

- With the engine running, hold down the brake pedal and then turn off the engine. Hold the pedal for another 1.5-2 minutes without releasing it. If there are malfunctions, the pedal will rise.

The amplifier has gaskets and O-rings, and these are the ones that most often fail.

Purpose of ball joints VAZ 2107

A ball joint (BJ) is an ordinary hinge built into the VAZ 2107 suspension and allows the wheel to move only in a horizontal plane. At the same time, it limits the possibility of wheel movement in the vertical direction.

Ball joints of the VAZ 2107 are very short-lived, so they have to be changed often.

Design of ball joints VAZ 2107

Previously, passenger cars did not have ball joints. They were replaced by bulky king pins that had to be lubricated frequently. The mobility of such compounds left much to be desired. This, in turn, negatively affected the car's handling. The designers of the VAZ 2107 abandoned the kingpins and installed ball joints. The first SHO consisted of:

- housings;

- ball pin;

- springs;

- anther

The finger was pressed into a fixed eye, fixed with a powerful spring and covered with a boot. This structure also needed to be lubricated periodically, but quite rarely (about twice a year). The lubricant on the pins had to be changed every week.

Subsequently, the VAZ 2107 SHO was constantly improved:

- the spring disappeared from the structure;

- the steel boot was replaced with a plastic one;

- the fixed eyelet in which the finger was fixed became more compact and received a plastic external finish;

- SHOs have become non-separable, that is, practically disposable.

One driver I know assured me that he had found a great way to extend the life of plastic boots. Before installing new ball joints, he always applied a thick layer of silicone ointment to the boots, which car owners use to prevent the rubber bands on car doors from freezing in winter. From his words, it turned out that the anthers after such a procedure become practically “indestructible.” When I asked how an ointment intended for rubber could improve the quality of plastic, I was recommended to just try it and see for myself. Unfortunately, we never got around to it. So I leave it to the reader to check this driver’s find.

Reasons for failure of VAZ 2107 ball joints

The main reasons for SHO failure are as follows:

- Alternating shock load. As a result, the ball pin pressed into the suspension eye is destroyed. The support is designed in such a way that the shock loads on the pin ball are very high. When the quality of roads is poor, these loads increase manifold. In such conditions, even a high-quality SHO will not be able to fully exhaust its resource.

- Lack of lubrication. Under the influence of shock loads, the lubricant is gradually squeezed out of the SHO. In addition, over time, the lubricant loses its original properties.

- Anther destruction. The boot protects the hinge joint from dirt. If a crack appears in it, the dirt that gets into the joint turns into an abrasive material and grinds down the surface of the ball pin.

Signs of malfunction of VAZ 2107 ball joints

The main symptoms of a VAZ 2107 SHO malfunction include:

- Extraneous sounds. While driving, a knocking or grinding noise begins to be heard from the wheel. This is especially pronounced on uneven roads at a speed of about 30 km/h and is usually a consequence of partial destruction of the ball on the support pin.

- Wheel rocking. When accelerating, the wheel begins to sway slightly in different directions. This happens due to the backlash that occurs in the SHO due to its wear. The situation is quite dangerous, and the backlash must be eliminated quickly. Otherwise, the wheel may turn at a right angle to the body at speed.

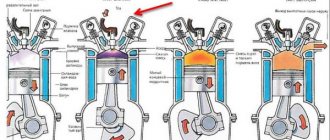

Device

Hydraulic brakes are installed on the machine and operate generally reliably. They are double-circuit and have a diagonal distribution. That is, if one part suddenly fails, then braking by another circuit is possible. For the sake of safety, the VAZ 2110 brakes operate diagonally, one circuit is the right front and left rear wheels, the other is also diagonal.

This device allows you to brake efficiently (without skidding and other troubles) even in the event of a malfunction, if the brakes in one of the circuits are lost.

Let's consider the design of the brake system. The hydraulic drive includes a vacuum booster, as well as a dual-circuit regulator that creates pressure in the rear brakes.

In addition, the hydraulic drive is equipped with pipelines divided into two circuits, hoses and brake mechanisms that provide braking to the front and rear mechanisms.

The hydraulic drive is activated by a pedal located in the cabin (middle). Here are the main components of the hydraulic drive:

- Vacuum booster. It is designed in such a way that it creates pressure on the master cylinder piston, and thus causes braking; Vacuum brake booster

- Pressure regulator drive. It is through it that the working brake fluid flows to the rear brake mechanisms; Brake pressure regulator drive

- The pressure regulator itself. Already from the name it is clear that this device is responsible for the force of pressure, its decrease or increase. He does this depending on how loaded the rear axle of the car is; Pressure regulator

- Main cylinder with pistons, equipped with a reservoir. The filler neck of the tank is equipped with an emergency fuel level sensor; Master brake cylinder

- Brake mechanism for the front wheel. Its main parts are the disc, pads and wheel cylinders. The mechanism also provides an indicator to prevent complete wear and malfunction of the linings; Front wheel brake

- Brake mechanism for the rear wheel. Unlike the front disc brakes, the rear ones are drum brakes. This is the factory configuration. However, many car owners believe that their device does not provide high-quality braking, and change them to disc ones. Rear wheel brake

The brakes require attention. Without waiting for the warning light to come on, indicating a critical level of fuel fluid or wear of the linings, and even more so, without allowing the brakes to completely disappear, you need to carry out preventive checks.

Particular attention should be paid to all connections and hoses, since the “escaped” brake fluid will not make it possible to brake, and from here it’s not far from tragedy.

Selection of ball joints for VAZ 2107

The main element of any SHO is a ball pin, the reliability of which determines the operational life of the entire assembly. A high-quality ball pin must meet the following requirements:

- the finger should be made only of high-alloy steel;

- the ball of the finger must necessarily undergo a cementation procedure (surface hardening), and the body of the finger must be hardened and then cooled in oil.

Other support elements are produced by cold heading followed by heat treatment.

This technology for manufacturing SHO is quite expensive. Therefore, there are only a few companies that produce high-quality supports for the VAZ 2107. These include:

- Belebeevsky;

When choosing ball joints for the VAZ 2107, you should beware of fakes. There are quite a lot of such products on the market. Some of them are made so well that they can mislead even a specialist. The only criterion to distinguish a fake from the original is the price. Low-quality SHOs cost half as much as real ones. However, saving on details on which the driver’s life literally depends is unacceptable.