Apart from the ABS system, the disc brake caliper becomes the most complex and critical component of all, responsible for quickly and safely stopping the car in work and emergency situations.

For all its apparent simplicity, the optimal design of the unit took a long time to form, since the transition of cars from a drum brake system to a disc one.

What is a brake caliper

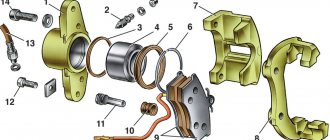

A brake caliper is a part mounted on the brake disc, which is mounted on the steering knuckle or rear beam. The middle class car has front calipers. Brake drums are installed on the rear wheels.

More expensive cars are equipped with full disc brakes, so they also have calipers on the rear wheels.

The action of the brake caliper is directly related to the driver's efforts when he presses the brake pedal while the car is moving. Depending on the force applied to the brake pedal, the response speed will be different. Drum brakes work on a different principle, but the braking force also depends on the driver's efforts.

Where is it located?

Based on the name, it is not difficult to guess that the rear brake caliper of Opel and other cars is located on the rear axle. This element is attached to the hub using bolted connections. There are pads inside it (both on the left and right sides). The Chevrolet Lacetti rear brake caliper is driven by a hydraulic drive. The same scheme is used on other passenger cars.

But as for trucks, here the rear brake caliper (left and right as well) is driven by a pneumatic system. Not long ago, trucks used a combined drive system. So, the rear right and left brake calipers worked first from hydraulics, and then from pneumatics. But now this design is no longer used. If we talk about minibuses and SUVs, hydraulic drive is also used here.

Purpose of the brake caliper

As already mentioned, the brake caliper is installed above the brake disc. When the system is activated, the pads clamp the disc tightly, which helps stop the hub, and, as a result, the entire car.

This part is dismountable, so if different elements of the mechanism wear out, you can buy a repair kit and replace the failed spare part.

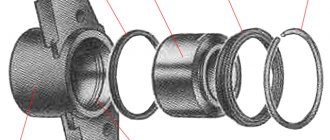

Basically, the brake caliper structure includes the following elements:

- Frame;

- Guides on the calipers, which allow you to set the uniform impact of the pads on the disc;

- Piston boot to prevent solid particles from entering the brake drive so that it does not jam;

- The brake caliper piston drives the movable pad (most often the pad on the opposite side is mounted on a floating bracket and is installed as close as possible to the disc);

- A bracket that prevents the pads from dangling and touching the disc in a free position, causing a grinding sound;

- A caliper spring that moves the pad away from the disc when the brake pedal is released;

- Brake shoe. Basically there are two of them - one on each side of the disk.

Problems

One of the common problems that arises when using rear brake calipers is squeaking pads. Moreover, they can be new and from a trusted manufacturer. The creaking occurs due to the fact that the elements are installed skewed. It only takes a small deviation for new pads to cause a terrible squeak. How is this problem solved? This problem is usually solved by installing anti-creaking metal plates. They are placed in the cavity between the pad and the caliper.

Working principle of brake caliper

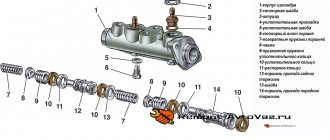

Regardless of the car model, the braking system in most cases works on a similar principle. When the driver presses the brake pedal, fluid pressure is created in the brake master cylinder. The forces are transmitted along the line to the front or rear caliper.

The fluid drives the brake piston. It pushes the pads towards the disc. The rotating disk is clamped and gradually slows down. During this process, a large amount of heat is generated. For this reason, the car owner needs to pay attention to the quality of the brake pads. No one would like to find themselves in a situation where the brakes fail or are stuck.

If the car has disc brakes on all wheels, then the rear calipers, just like in a drum system, will be connected to the handbrake.

Types of brake calipers

Although today there are many developments aimed at improving the reliability of the braking system, there are two main types:

- Fixed brake caliper;

- Floating brake caliper.

Although the design of such mechanisms is different, the operating principle is almost identical.

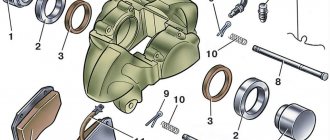

Fixed design

Such supports are installed motionlessly. They have at least two working pistons. Two-piston calipers on both sides clamp the disc, which increases the efficiency of the system. Basically, such brakes are installed on sports cars.

Automotive manufacturers have developed many fixed design caliper options. There are four-, six-, eight- and even twelve-piston modifications.

Floating brake caliper

This type of caliper was created earlier. In the design of such mechanisms there is one piston of the brake cylinder, which drives the pad installed behind it on the inside of the disc.

To ensure that the brake disc is clamped on both sides, there is also a pad on the outside. It is fixedly mounted on a bracket connected to the body of the working piston. When the driver presses the brake pedal, hydraulic force forces the piston toward the disc. The brake pad rests on the disc.

The piston body moves slightly, driving the floating bracket and block. Thanks to this, the brake disc is fixed with pads on both sides.

Budget cars are equipped with such a braking system. Just as in the case of the fixed one, the floating modification of the calipers is collapsible. You can purchase a repair kit for the caliper and replace the broken part.

Professional diagnostics

The most effective way to avoid the problems listed above is professional diagnostics performed by highly qualified specialists using specialized tools and equipment. The diagnostic process usually includes two stages of work:

- Checking the brake performance of each wheel. It is carried out on a special computer stand under the supervision of qualified experts.

- Visual inspection of calipers. This operation requires the removal of the rear wheels. The condition of the brackets, housing, cylinders and anthers is checked. If damage is detected, parts must be replaced immediately.

Malfunctions and repairs of brake calipers

Since the car's braking system takes on a large load when the vehicle slows down (to increase the service life of the brakes and avoid emergency situations, experienced drivers use the engine braking method), some parts need to be replaced. But in addition to routine brake maintenance, the system may fail.

Here are common malfunctions, their causes and solutions:

| Problem | Possible manifestations | How to solve |

| Wedge of the caliper guide (due to wear, dirt or rust, deformation of the bracket) | The car smoothly moves to the side, “grabs” the brakes (braking continues even when the pedal is released), great efforts are required to brake, the brakes jam when the pedal is pressed hard | Caliper overhaul, replacement of worn parts. Change the anthers. You can clean elements damaged by corrosion, but if there is wear, the problem will not be eliminated. |

| Piston wedge (most often due to natural wear or dirt, sometimes due to a worn boot, corrosion forms on the surface of the piston) | Identical | Some people try to grind the piston mirror, but replacing the part will have more effect. Cleaning will only help with minor corrosion. |

| Broken mounting plate (holds the pad in place) | Identical | Replace at every service |

| Pad wedge or uneven wear | Identical | Check the caliper guide bolt and pistons |

| Brake fluid leaking through the fitting | Soft pedal | Check where the fluid is leaking and change the seals or tighten the hose onto the fitting. |

When repairing a caliper, it is important to choose the right repair kit that matches the model of the mechanism. Most brake caliper problems are caused by failed boots, seals, and guides.

Depending on the car model and the calipers used in the brake system, the service life of this part can be about 200 thousand kilometers. However, this is a relative figure, since it is primarily influenced by the driver’s driving style and the quality of materials.

To repair the caliper, it must be completely removed and cleaned. Next, all channels are cleaned and anthers and seals are changed. The rear caliper connected to the handbrake requires special care. Often, mechanics at service stations incorrectly assemble the parking system, which accelerates the wear of some of its parts.

If the caliper is severely damaged by corrosion, there is no point in repairing it. In addition to scheduled maintenance, you need to pay attention to the brake system if the problems listed in the table are observed, as well as if the calipers rattle or knock.

About the piston

The next problem is the rear brake caliper piston. It can become unusable if there is no lubrication. Why is this happening? The most popular reason is the destruction of the rubber boot. It is through this that dust and water will get inside, which provokes corrosion processes. The lubricant dries out or is simply washed away. As a result, the piston runs dry. Why is this phenomenon dangerous? At one point, the piston may simply jam and not return to its original position. This will cause the wheel to completely lock at speed. The higher it is, the more dangerous the consequences will be. The way out of the situation is to purchase a rear brake caliper repair kit. This piston is not subject to further use. But if the problem is detected in time, you can limit yourself to just replacing the rubber boot. How much does it cost to repair a rear brake caliper? The cost of restoration in this situation ranges from five hundred to a thousand rubles.

How to choose a brake caliper

It is very important that the caliper is selected to match the technical characteristics of the car, namely, its power. If you install a low-performance option on a powerful car, then at best the brakes will simply wear out quickly.

As for installing more efficient calipers on a budget car, this is already a matter of the financial capabilities of the car owner.

This device is selected according to the following parameters:

- By car make. The technical documentation must include all important information. At specialized retail outlets, specialists already have this data, so if the car was purchased on the secondary market without technical documentation, they will tell you which option is suitable for a particular car;

- By VIN code. This method will allow you to find the original spare part. However, budget analogues are selected according to this parameter with no less efficiency. The main thing is that the owners of the resource where the device is being looked for enter the data correctly;

- Caliper code. To use this method, you need to know this information yourself.

You should not immediately purchase budget analogues, as some manufacturers of auto parts are dishonest in the manufacture of their products. More guarantees - from purchasing a device from trusted manufacturers, such as Meyle, Frenkit, NK, ABS.

note

The usual “graphite” or “Litol” is not suitable as a lubricant for the caliper. The material for calipers must meet high requirements, in particular, be resistant to temperature changes. Conventional lubricant, even in a boot, dries out quickly. Therefore, you only need to purchase a specialized product. Typically, this caliper lubricant is sold in 45 gram bags. They are enough to completely process the mechanism.

Procedure for replacing the brake caliper

To replace the front or rear caliper, it does not require any special skills. First, the machine must be on a level surface. Part replacement should always be done as a set.

The wheel rims are loosened, the car is jacked up (you can start from any side, but in this description the procedure occurs starting from the driver's side). When changing the rear gear, you need to lower the handbrake, put the front-wheel drive car in gear and install wheel chocks under the wheels.

In this case (the caliper on the driver's side is changed), the shoes are installed under the wheels on the passengers' side. The machine should not swing forward/backward during work.

The brake system bleeder screw is unscrewed and the hose is lowered into an empty container. To remove remaining fluid from the caliper cavity, use a clamp to press the piston so that it is hidden in the body.

The next step is to unscrew the caliper mounting bolt. In each model this element has its own location. If the handbrake is raised, you will not be able to remove the caliper. At this point, the appropriate mechanism for the desired side is selected. The brake hose mounting thread must be at the top. Otherwise, an incorrectly installed caliper will suck air into the system.

When changing a caliper, you immediately need to pay attention to the discs. If there are uneven surfaces, the surface must be sanded. The new caliper is connected in the reverse order.

In order for the brake system to work correctly, you need to bleed the brakes (after replacing all the calipers). Read about how to do this in a separate article .

Can it be repaired?

I have a large and wonderful article on repairs , be sure to read it, everything is there on the shelves. The calipers break, there is no escape from this, it may simply be that the boot has simply been “missed”, or the working piston has gone sour. In general, if you buy a new one assembled, it is expensive. But this one can be repaired too.

To do this, purchase a repair kit. Essentially these are all new internals that need to be replaced.

There is no point in repairing working pistons (cleaning them of rust or oxide), the surface is often already eaten away, and even if you remove a part on a special machine, the dimensions will no longer fit.

Therefore, the sequence of actions should be like this:

- We purchase a repair kit.

- We remove the caliper from the car and disassemble it.

- We remove all the old rubber bands and clean the body if necessary.

- We install new parts.

- We install it on the car and bleed the brake system.

I would like to note separately the guides; in fact, these are two long bolts along which the moving part of the structure runs. If they wear out or their rubber seal breaks, the caliper’s operation may also be disrupted; it is also advisable to replace them.

Now we are watching a short useful video.

I’ll finish here, read our AUTOBLOG.

( 13 votes, average: 4.69 out of 5)

Similar news

Which brake drums are better, cast iron or aluminum? Read .

How and with what paint to paint the brake drums. So as not to rust.

Rust converter composition. Can I do it myself?

Add a comment Cancel reply

Comments

Good day everyone, I decided to write my review of the 2010 Toyota Avensis. Just want…

Recommendations for maintenance and repair

Considering that these assembled mechanisms are quite expensive, they require periodic care and maintenance. Most often, souring of the guides (floating design) or pistons occurs in the calipers. The second problem is a consequence of untimely replacement of brake fluid.

If the pistons are not completely acidified, they can be cleaned. As already mentioned, if there is extensive oxidation (rust), there is no point in repairing the part - it is better to replace it with a new one. It is also worth paying attention to the condition of the spring on the caliper. Due to corrosion, it may lose elasticity or even burst.

Painting can often protect the caliper from corrosion. Another advantage of this procedure is the aesthetic appearance of the node.

Anthers, bushings and other sealing materials can be replaced if you purchase a rear caliper repair kit. The front mechanisms can be serviced with the same success.

In addition, watch a video on how to maintain brake calipers:

Repair and maintenance of CALIPER

Care

In order for the mechanism to serve for a long time and properly, the condition of the caliper should be regularly monitored. Below are some useful tips:

- Once every six months, inspect the visual condition of the caliper. Pay special attention to drips. They should not be on the hoses or at the connections. If there are any, you need to urgently look for the source of the problem. This is usually a frayed or worn hose. It has a two-layer design, but even if the first layer is damaged, such an element must be replaced. Why is this dangerous? Due to leaks, the fluid level in the system constantly drops. This will make it impossible for the piston to work, as it will not have enough pressure.

- Check how freely the piston moves. If you do not change the brake fluid for a long time, it may turn sour due to rust. At best, you will experience poor braking performance. At worst, you will have to replace the entire cylinder.

- Keep an eye on the remaining friction material on the pads. Modern manufacturers equip them with mechanical sensors. When the thickness of the pads approaches two millimeters, the metal plate begins to touch the edges of the disc when braking. As a result, the driver hears a characteristic squeak. This indicates that the pads have become unusable. If they are not replaced in time, the metal itself – the pad lining – or even the caliper will rub against the disc. This leads to increased wear of both elements. If significant scuffing occurs, such mechanisms can no longer be used.