The panel on which all the instruments are located is a very important part of the car, since with its help you can really control how the injector works, the speed of movement and the operation of the braking system. In addition, the panel will help you understand why the car does not start. If the instrument panel does not light up, then it is impossible to easily take readings from them on a VAZ-2114, especially at dusk. The numbers will merge, and the motorist risks getting into an emergency. We'll tell you how to get rid of this problem.

Diagnostics of the speed sensor and the entire circuit

Checking for broken wiring

So, to find the cause of the malfunction, it is necessary to check both the speed sensor and the entire circuit as a whole. To do this, disconnect the block with 3 wires from the sensor and visually inspect it. A block with three wires - power, signal and ground. If all the wires are in order, we proceed to further inspection.

Checking the sensor drive

Next, we check the sensor drive that comes out of the gearbox. Let's jack up any front wheel of the car and start turning it, while looking at the sensor drive itself. It should spin easily without jamming or crunching. You can touch it with your finger to determine whether it is spinning or not. If everything is in order with the drive, we move on to further diagnostics. If not, the drive will need to be replaced.

Checking for an open circuit

Now, using a tester or a multimeter, let’s check whether power is supplied to the sensor block. We check with a screwdriver with an indicator. We hook one end to the + battery with the other into connector No. 3, turn on the ignition, look, the light should be on. Then we check the power supply, one end to the (-) battery, the other to connector No. 1, turn on the ignition, look, the light should be on. We put the sensor in place, check the signal one, connect one end to the battery power supply, the other to the signal one on sensor No. 2, spin the wheel, preferably quickly, the light should blink.

If after all diagnostic procedures no problems are identified, there is no open circuit, the sensor drive on the box is normal, then the sensor should be replaced.

The VAZ 2114 speed sensor is a measuring device, the main functional purpose of which is to determine the speed of the crankshaft and transmit information about it to the electronic on-board control of the VAZ 2114.

Speed sensor

From this article you will learn the principle of operation of a speed sensor, a method for checking its functionality and a technology for replacing the sensor with your own hands, which will allow you to significantly save on service station services in the future.

How to replace the backlight

Sometimes it is necessary to disassemble the dashboard if a car enthusiast decides to modify it. The backlight may simply not suit the car enthusiast with the color of the lamps and the intensity of their work. In order to completely update the backlight, you will need to calculate the number of lamps for each sensor and purchase them.

When installing LEDs into sockets, it is important to observe their polarity. You may need to carefully grind down the sockets to get the bulbs to fit into place. After you assemble the new backlight, check its functionality by connecting it to power. You can check the build quality with a special device.

The next step is to connect the new backlight to the main board and to the lamp circuit. Carefully secure the LEDs so that they do not interfere with your installation of the panel. When assembling, check the position of the instrument needles; they must be set to zero during assembly. The arrows should not bend or deform.

Next, all you have to do is secure the entire structure with screws and carry out the final reassembly. It is important not to try to assemble the panel completely at once; do not fasten the decorative parts so that you do not have to remove them again. After connecting the instrument panel to the electrical circuit, check the build quality and operation of the sensors using the on-board computer. If everything is normal, then finally secure the panel and complete the assembly.

Private situations

General signs do not always indicate specific breakdowns. There may be exceptions.

If individual devices refuse to work, it is quite possible that this is their personal problem. You'll have to parse the specific pointer. It may have a cracked gear that needs to be replaced.

Also, why doesn’t the instrument panel of the VAZ 2114 work? If the fuel gauge and tachometer are capricious (either they function, or they don’t react at all), the contacts and the mounting block are normal - you need to do a small check.

Reset is pressed and held, and the ignition is turned on at the same time. Raised arrows indicate the need for further searches. Lifeless - that microcracks have appeared in the shield itself. You will have to remove it and examine all soldering and traces under a magnifying glass. In principle, these are all the main options. If calling all the listed components and parts did not lead to the revival of the instrument panel, your case is individual, and you will have to determine the situation in the company of an experienced auto mechanic.

The speedometer of the VAZ 2114 does not work? A problem that is quite common not only for models of the fourteenth, almost every VAZ model suffers from this problem, from the classics to the new Prior, Kalin, and Grant. In today's article I will tell you about the three main reasons for the VAZ 2114 speedometer malfunction and how to fix them.

The dashboard of the VAZ 2114 is out of order, what should I do?

If on a VAZ-2114 car on the instrument panel none of the indicators installed on it work (speedometer, odometer, tachometer, fuel level and coolant temperature indicators), then the first thing the driver will have to do is check the integrity of fuse F3, which is located in the mounting block. If it has burned out, then before replacing it, you need to find the reason why it burned out, otherwise the newly installed new fuse will have the same fate as the previous one. Most often, fuses burn as a result of a short circuit.

Even if the fuse is intact, then do not be lazy to take it out and check the condition of the contacts. There are cases when the contacts oxidize, and the electrical circuit in this place is interrupted. After making sure that the fuse is intact, the next step is to check the ignition relay, which is located inside the car to the left of the steering column. It is attached to a pin upside down. In the block where this relay is inserted, you can try to short-circuit the power wires using a jumper. If the instrument panel comes to life, the ignition relay will have to be replaced.

If the ignition relay is working properly, there are only two possible reasons for the instrument panel not working: the ignition switch and the mounting block. Before installing the ignition relay on the VAZ-2109 car, the lock contacts burned quite often, and they had to be cleaned by disconnecting the contact group from the lock itself. After changes were made to the principle of supplying voltage to the ignition switch, its contacts began to burn very rarely, but the likelihood of this phenomenon still remained. On the mounting block, in its board, tracks may burn out; in order to see this, the mounting block will have to be removed from the car.

In addition to the reasons listed above, which can lead to failure of the instrument panel, it is also necessary to check the reliability of fastening the ground wire.

What to do if the VAZ-2114 speedometer does not work

If the speedometer of a VAZ-2114 fails, it is necessary, first of all, to understand the cause of the failure. According to experts, most often the Lada speed sensor is faulty; it is located on the gearbox. Look at the right inner CV joint, the device is wrapped on the drive box and has 2 gears made of plastic.

To check the functioning of the speed sensor, you need to use the on-board computer; your task is to enable self-diagnosis. The malfunction may consist in the absence of a contact that is located in the connector block, which occurs when liquid gets under the housing base. It is also possible that the wire that goes to the meter is broken, or there is no voltage in the supply contact.

You need to use the on-board computer, but in the absence of adequate functioning of the speedometer on the VAZ-2114, the error code does not give a specific answer. To get it, you will have to check the sensor yourself.

How to disassemble the dashboard of a VAZ 2114

Before embarking on this complex process, the driver must carefully familiarize himself with the design and arrangement of the instrument panel on his car. When disassembled down to the cogs, it looks like this:

If you carefully study this diagram, it becomes clear how to remove the panel on a VAZ 2114. Having determined the order for yourself, you can begin the process.

- Using a Phillips screwdriver, you need to unscrew the three screws holding the left console screen. For convenience, when doing this work, it is better to use a screwdriver with a short handle and blade.

- When removing the screen, carefully remove the lower edge of the trim from the body bracket.

- The right console screen is secured with five self-tapping screws. Using a Phillips screwdriver, carefully unscrew all the screws while holding the trim with your hand.

- Remove the screen without allowing it to get caught in the wiring harnesses that are hidden behind it.

- Disconnect the ground from the battery by disconnecting the connectors. If your car has a radio, disconnect it from the main bundle of wires by pulling out the connecting connector. If there is no radio installed on the car, then simply pull the wires out of the panel; they should be closed with a plug. Be sure to turn off the cigarette lighter and remove the socket with the ashtray light bulb.

- Remove the handles from the heater damper control levers. To make the process easier, pry them off with a flat-head screwdriver.

- Despite the apparent simplicity of this item, removing the handles from the levers can take a lot of time. To do this, a clear example is given of how this should be done on a removed unit.

- Remove the electric heater fan handle by simply pulling it towards you.

- Unscrew the cross-head screws securing the instrument panel to the brackets on the right and left with a screwdriver

- In the window on the instrument panel, where the instrument unit is located, there are two self-tapping screws at the top and two at the bottom - under the window. It is necessary to turn them out, loosening the cover (2) and the shield (8).

- Pull out the plug and unscrew the screw located behind it

- Remove the two screws from the bottom that hold the trim and remove it.

- Having marked the wires suitable for the switches, disconnect them.

- Remove the bolts from the steering wheel bracket

- Using the “8” key, unscrew the screws of the lower bracket fastening.

- Unscrew the self-tapping screw and remove the light guide.

- Remove the fasteners from the heating control unit and remove the cartridges from the back of the unit.

- remove the decorative insert, removing all external parts.

- Unscrew the nuts with a key set to “21”.

- Remove the hydraulic corrector illumination.

- Unscrew the upper and lower fastenings of the panel, and remove the fastening to the cross member on the left side.

- Now you can remove the VAZ 2114 torpedo.

- Installation is in the reverse order.

In order to clearly see the whole process in motion, you can watch a video on how to remove the dashboard on a VAZ 2114.

Fault repair

In fact, if the VAZ-2115 speedometer does not work, the reasons for which have already been established, no one repairs the speed sensor on these VAZ models. It is much faster and easier to replace this entire unit. Its cost is about 400 rubles, which is not that expensive. To begin the process of replacing the speedometer, you should drive the car into a pit and prepare:

- Screwdrivers.

- Pliers.

- Set of wrenches.

If there is no hole nearby, then you first need to remove the terminals from the battery, and then remove the air filter and only then the intake pipe. Next, remove the terminal from the speedometer sensor itself. However, if the car uses a cable drive for the speedometer, then it must also be removed.

Read more: Lada Priora engine removal

Next, you need to clean the work area of dust, debris and oil. Then proceed directly to replacing the part:

- Remove the terminal block using the buttons that deactivate the spring clip.

- Using a 21mm wrench, remove the speed sensor.

- Attach the new sensor so that its rod precisely hits the fixing sleeve.

- Tighten the thread back with a 21mm wrench. Do not overtighten, so as not to damage the integrity of the plastic speedometer housing.

Based on the results of the work done, the result can be assessed immediately: if the speedometer does not fit into the socket, it means that its rod has not moved into the bushing. Therefore, you will have to repeat the above procedure until success is achieved. When the speedometer is installed, you then need to return all the dismantled parts to their place, connect the power and check the operation of the new sensor while the car is moving.

I often get asked questions about connecting the speed sensor to the Europanel. I myself began to understand the circuits recently, but a detailed article with pictures will not harm anyone. In short, we screw the sensor into the box, connect it with power and ground, and output its signal to X7-7.

If in detail. We find a suitable electrical circuit diagram for the car. For example, circuit 21099 in a deluxe configuration - with a panel, wiring and an installer from four:

What to pay attention to!

If you install a 2114 instrument panel on a chisel, use 2114 under-dash wiring and a 2114 fuse block, then the speedometer connection is made only under the hood

.

You just need to connect three wires to the sensor. Then, through the block and wiring, everything will go where it needs to go. But

if you use under-torpedo wiring from 2109/2108 or left the old fuse box, then this article will help you only in general terms understand the essence of the connection, because the numbers of contacts and blocks will be different.

And so, connection. We take the diagram and look for the sensor itself on it. Position 27, found!

Now we follow the pattern where they lead. Orange

the wire goes down and connects to the brake fluid level sensor. This is a common plus along one wire from the mounting block ( not a signal!

).

Power through this wire does not come constantly, but from the ignition. Now black

.

This is mass, minus, body - call it what you want. Connects locally or from any ground wire under the hood nearby. And the most interesting thing is the gray

wire. It sends a signal to the speedometer needle, which shows our speed. The mileage of the electronic odometer also rotates based on this signal. As you can see from the diagram, the gray wire turns into white - this is the wiring harness. To understand where it will now come out of this harness, simply run your finger along it until you see a wire of the same color. The direction of movement along the harness is shown by the outgoing wire at an angle of 45. Our gray wire goes up at this angle. That's right, let's go up! We protrude the sausage and slowly walk up the white rope:

Read more: Oil change in Haldex Volvo XC70

To complete the story, I’ll add what and where it goes next. Nearby, on the fuse block diagram, we are looking for our incoming X7-7.

As you can see, the gray wire also fits there. It is used for injection machines, that is, it goes to the ECU unit. I also have this wire, and it does not interfere with the operation of the speedometer. That's actually the whole connection chain! Let me remind you that in the European panel under-the-hood wiring in the cabin, this is all already laid out and connected, you just need to connect the sensor itself under the hood to the installer and everything will work!

When operating cars of the “tenth” family from AvtoVAZ, the question often arises as to why the speedometer needle does not work on the VAZ 2115. After all, not every car enthusiast has such a developed sense of speed to drive with a non-working indicator. But this feeling is well developed in security cameras that record speed limit violations. The car enthusiast himself can diagnose and fix this malfunction if he finds a little time.

Replacement process

The rear lights are attached to the body of a VAZ 21099, 2108 or 2109 car using 4 nuts. To dismantle the lighting system you will need:

The operating algorithm is as follows:

- To access the nuts, remove the 21099 luggage rack at the appropriate location (if the rack is installed).

- Disconnect the power plug that is attached to the board.

- Unscrew the 4 nuts using a wrench.

- When removing the last nut, hold the taillight outside to prevent it from falling and breaking.

- After removing all 4 nuts, remove the light.

When installing a new headlight on the rear of model 21099, do not forget to connect the wiring to ground, which is attached to one of the studs.

In such cases, the ride becomes quiet, calm and relaxed, but how everything changes when at least one light bulb burns out. This causes inconvenience and emergency situations, and you can also get a fine from a road service employee.

The dimensions on the VAZ 2109 do not light up, then look for the reason in the wiring. Even experienced drivers recommend carefully checking the functionality of all devices and components before leaving. The nine is no exception, in which optics can often fail for various reasons, including:

The rear lights (headlights) of the VAZ 2108, VAZ 2109, VAZ 21099 have the following bulbs: 1) Brake lights. 2) Dimensions. 3) Reverse. 4) Turns. 5) Fog lamp.

Rear light board for VAZ 2108, VAZ 2109, VAZ 21099

A wiring harness goes from the mounting block to the rear lights. The purpose of each individual wire in the harness can be understood by its color: 1) Brake lights - red 2) Dimensions - yellow 3) Reverse - green. 4) Turns - blue. 5) Fog light - orange-black.

We remove the connector from the rear light board of VAZ 2108, VAZ 2109, VAZ 21099

Naturally, you need to understand that if the car VAZ 2108, VAZ 2109, VAZ 21099 is old and there are a lot of people doing the wiring, then the color match of the wire to its purpose may be violated. That is, the red wire can be converted not to brake lights, but, for example, to dimensions. But in general this is a very important point: the developers of the VAZ 2108, VAZ 2109, VAZ 21099 specifically marked the functional purpose of the wires with a certain color to make it easier to use.

Flashlight board VAZ 2108, VAZ 2109, VAZ 21099

If some light signal in the taillight of a VAZ 2108, VAZ 2109, VAZ 21099 does not work, then before climbing into the mounting block and opening the electrical circuit, we check the following: 1) The reliability of fastening the mass of the taillight to the body of the VAZ 2108, VAZ 2109, VAZ 21099.2)

We check the reliability of fastening the wire connector to the headlight. 3) Integrity of the light bulb 4) Quality of contact between the light bulb and the flashlight board. It often happens that everything is intact, the light bulb and the mass are good, and 12 Volts come to the light bulb, but it does not light. The reason is poor contact between the light bulb and the board. In this case, you need to clean both the light bulb base and the area on the lantern with fine sandpaper.

As one smart person said: “Electrics is the science of contacts.” To disassemble the rear light of a VAZ 2108, VAZ 2109, VAZ 21099, first remove the protective plastic cover. Then disconnect the black wire of the flashlight from ground. Then we remove the connector from the flashlight board and remove the board itself with the bulbs from the headlight housing. If it is necessary to replace the headlight itself, then unscrew the remaining bolts securing the headlight to the car frame and remove it.

Flashlight housing VAZ 2108, VAZ 2109, VAZ 21099

There is one important point that many owners of VAZ 2108, VAZ 2109, VAZ 21099 do not know. This is the rear fog light. It is turned on by a button between the hazard warning button and the heated rear window. The rear fog light will only work if: 1) The ignition is turned on. 2) Low beam headlights are on. 3) The flashlight power button is pressed. The fog lamp lamp for VAZ 2108, VAZ 2109, VAZ 21099 is the only one that has a reflector inside the headlight. Thanks to this reflector, the glow of the lantern becomes brighter.

The clearance of VAZ 2108, VAZ 2109, VAZ 21099 is included

Rear fog light on VAZ 2108, VAZ 2109, VAZ 21099

Power of rear light bulbs VAZ 2108, VAZ 2109, VAZ 21099: Dimensions 5 Watt Fog light 21 Watt Reverse 21 Watt Stop light 21 Watt Turn signal 21 Watt

Repair

Repair of the speed measurement system directly depends on the identified malfunction:

Speed sensor

- Clean from dirt;

- Clean the pad contacts from corrosion and oxides;

- If the above measures do not help, the sensor is replaced.

Wiring

- Check and clean “mass” contacts;

- Solder or secure with twists the places where the wires are broken, due to which the speedometer stopped working;

- Cover areas where the braid is damaged with insulating tape;

- Replace failed fuses;

- Clean the pad contacts from oxides and corrosion.

Speedometer

If the speedometer stops working, it must be replaced. On domestic cars assembled using an electronic type of speed meter, the speedometer changes along with the instrument panel. You can carry out this operation yourself. To do this, you only need a Phillips screwdriver and pliers.

Repairing an old speedometer can be much more expensive than completely replacing the old instrument cluster with a new one.

Causes and actions in case of breakdown

Among the reasons for the breakdown of the rear parts of the lighting system on a VAZ 21099, 2108 or 2109, the most common are:

- Bulb burnout. It happens due to wear or power surges and is almost the most popular reason for replacing rear headlights.

- Oxidation of contacts. Occurs due to poor quality of terminal contact, electrolyte leakage, or cracks in the battery case.

- Fuse failure. This cause of failure is due to voltage surges.

- The reverse sensor is broken or its wiring is broken.

- Burnt out contacts on the headlight film.

- Lack of ground on the board.

The most common and easiest fault to solve is a lamp burnout. The product must be replaced with a new one by turning off the light sources, opening the trunk and disconnecting the column of wires.

To do this, you will most likely have to remove the trunk trim of the VAZ 2108 or 21099, which is located behind the lamp. After this, squeezing the latches (they are located on the sides), you need to take out the panel and unscrew the lamp, after pressing on it. To install a new rear lamp, reverse the process.

Replacing lamps in the rear lights of a VAZ 2109

To clean the contacts from the white coating that accompanies oxidation, you need to clean them. To do this, remove the headlight unit. The ground must be returned to its place, and the nearby wiring must be tested for correct operation. Broken fuses on VAZ 2109 and 21099 are not difficult to find - their diagram is usually presented on the block cover.

If you are faced with the problem of constant lighting of the reversing lights, this may be caused by problems with the wiring or the cessation of operation of a special sensor located on the box.

When the car headlight switch stops working, you can get to it through the engine compartment or from underneath the car. You can diagnose the failure of this component of the lighting system as follows:

- start the VAZ 21099 and shift it into reverse gear;

- close the contacts. The rear lights should light up at this time;

- Use a multimeter to check if the contacts are closed when you turn on the rear headlight switch, having first removed the switch;

- make sure that the contacts are soldered securely, assemble the switch and check its operation again. If a normal short circuit is observed, replace it.

Why does the speedometer needle twitch?

This phenomenon is far from uncommon, especially when it comes to domestic cars. However, when talking about cars whose production is established abroad, many owners panic and estimate the cost of an approximate replacement of the dashboard along with the speedometer.

This decision is extremely rational. And in order not to spend extra money on unnecessary actions, you need to understand how the speedometer needle generally works and what problems may arise with it.

As they say, forewarned is forearmed.

If the arrow twitches, this indicates a specific list of faults:

Loosening the cable

Sensor failure

Wiring problems

Of the three points above, the first applies only to cars that have a mechanical speedometer. These are cars from the nineties, as well as earlier years of production, and domestic cars of the classic family, as well as early 2108 and 2109.

The mechanical cable connecting to the speedometer tends to wear out. As a result, the speedometer needle may jump and give inaccurate readings.

{chronoforms5}fora2{/chronoforms5}

The problem can be solved quite simply by replacing the failed cable with a new one. In some cases, of course, you can simply tighten it, but this will not solve the problem for a long time.

If the speedometer is not mechanical, then the main problem will be with the car's wiring. As a rule, the speed measurement sensor itself fails.

This may be due to many reasons. For example, on some types of cars such sensors last no more than 5 years, and after this time they require replacement.

Also, depending on the position in the engine compartment, such a sensor may fail due to mechanical damage.

And the last variant of the problem associated with the failure of the speed measurement sensor is its oxidation. In any case, the sensor must be replaced.

If none of the options work, and replacing the sensor did not lead to anything, then perhaps the problem should be looked for in the wiring itself. According to statistics, wiring in a car is changed quite rarely, and due attention is not paid to it.

In this regard, due to improper care, it can become unusable, which entails a huge number of problems for the car owner.

Our company deals with all problems related to the speedometer!

Call and entrust the repair to the best specialists in the region!

Main conclusions

If the dashboard backlight on a VAZ 2114 car does not turn on, then most likely the light bulb has burned out or the LEDs have failed. However, there are several other possible causes for this problem:

- Wiring is damaged.

- Oxides are formed at points of contact.

- The security side has failed.

- The connection circuit has burned out.

To establish the exact reason why the backlight does not turn on, you must, following the instructions, carefully disassemble the dashboard and sequentially call the entire circuit through the tester. The detected defective element, depending on the degree of damage, must be repaired or replaced with a new one.

Causes of speedometer malfunction

If the speedometer stops working, troubleshooting is carried out in several directions. The following failures may be the cause of failure:

- Speed sensor failure;

- Damage to electrical wiring;

- Oxidation of “mass” contacts;

- Malfunction of the speedometer itself;

- ECU malfunction;

- Incorrect installation of the instrument panel after removal.

A diagnostic sign of fuse F19 failure is:

- Failure of the entire instrument panel;

- Diagnostic unit failure;

- Failure of the automatic door locking system;

- Reverse lamp failure.

Before replacing the fuse, it is recommended to find out and eliminate the cause of its combustion. In most cases, this happens when there is a short circuit in the electrical wiring system of a VAZ-2110 or VAZ-2114 car.

Fuse box tracks burnt out

In a situation where the device “blinks” and periodically turns off completely, you should check the condition of the tracks in the fuse box. A short circuit, moisture and dirt getting into the block body - all this can lead to breakdowns on the tracks. The photo below shows a typical picture of a faulty fuse box in the “four”. Because the price of a new block board exceeds 2000-3000 rubles; it is much more profitable to try to re-solder the tracks yourself. This problem is not critical, so if you have the skills to use a soldering iron, you can restore damaged tracks. For prevention, you can treat all contacts to remove oxides and dirt. It is also possible to treat contacts with dielectric grease.

If a lighting malfunction occurs due to a blown fuse, before replacing it, you should determine the cause of its failure. Most often this is a short circuit. Damage to the tracks on the unit board also causes the fuse to constantly blow.

The dashboard is the driver’s first indicator of the car’s health, as well as a way to control various on-board systems. During the day, by and large, the instrument lighting is not needed, but at night it is a necessary component for safe driving. Thus, a malfunction of the backlight can even lead to an accident, so if a malfunction occurs, it must be eliminated as soon as possible.

Fault repair

In fact, no one is repairing the speed sensor on these VAZ models, since it is much easier and faster to replace this entire unit - it costs around 400 rubles, which is not that expensive.

In order to begin the replacement process, it is recommended to drive the car into a pit and prepare screwdrivers, pliers and a set of wrenches. If there is no hole nearby, you first need to remove the terminals from the battery, then remove the air filter and intake pipe, and then remove the terminal from the DS itself (if the car uses a cable drive for the speedometer, you need to remove that too).

Next, use a rag to clean the work area of debris, oil or dust, and then proceed directly to the replacement:

- Remove the terminal block using the button that deactivates the spring retainer.

- Using a 21mm wrench, remove the speed sensor from its socket.

- Install the new device so that its rod precisely fits into the fixing sleeve to transmit rotation.

- Tighten the thread back with a 21mm wrench, without pinching it, so as not to damage the integrity of the plastic housing of the DS.

Replacing the DS VAZ 2114

The result can be assessed immediately - if the sensor does not fit into the socket, it means that its rod has not moved into the bushing, so the procedure will have to be repeated until success is achieved. After this, you need to return the removed units to their place, connect the power and check the operation of the new sensor while the car is moving. Or, if the replacement was carried out in a pit and with a jack, you can evaluate the performance of the DS using the same multimeter and rotating the hung left wheel.

The speedometer needle jumps and twitches

In this situation, the diagnostic adapter will once again help us. It costs a penny, but with the right approach it often helps out.

How can the adapter help us?

The bottom line is that on cars with an engine management system, the signal from the speed sensor is supplied in parallel to the instrument panel and to the engine control unit (ECU). And in some cases, to the ECU, and from the ECU to the instrument panel.

Here I drew it in red for clarity

And as I always say, when we connect the adapter to the diagnostic connector, we begin to see everything “through the eyes of the computer.”

Therefore, it is no longer difficult to guess how to determine the direction of searching for the cause of the jumping speedometer needle.

A man is driving and watching the speedometer. I sit next to you and monitor the speed readings in the diagnostic program.

If the speedometer needle jumps, but the speed graph in the program is smooth, then the problem is in the direction of the instrument panel.

And if the arrow twitches, and the graph also has “dips,” then the problem is in the direction of the speed sensor and its drive.

This is exactly what happened in our case. These dips mean an unstable signal from the speed sensor.

This means that there is no point in going into the instrument panel. You need to move towards the speed sensor.

Hard case

Until now, situations have been sorted out when the torpedo still showed some signs of life. If non-working power windows, turn signals, and windshield wipers have been added to the devices, the issue is no longer a matter of relays and fuses.

There may be 2 options:

- The contacts on the ignition switch are burnt. In principle, after installing the relay (even on the VAZ-2109 version), this problem rarely arises. However, the possibility remains. The lock is removed, the contacts are checked and, if necessary, cleaned;

- Mounting block. There may be burnt tracks on its board. The only thing that will save you is replacing it with a new one. However, the cost is by no means astronomical, and the installation is available as a standalone option.

Why might the speedometer not work?

First on the list of reasons for speedometer failure is drive malfunction. Most often, it “licks” the edges of the shank gear in contact with the moving elements of the gearbox, which is why the drive stops rotating. On cars with a new type of sensor, this problem can be identified by diagnosing the ECU: there will be no signal. With this malfunction, neither the speedometer nor the BC work. The check engine light usually comes on as well.

On older cars, the needle often does not rise from zero due to wear or blockage of the drive cable inside the winding. In any case, the problem is solved by replacing the speed sensor.

The lack of a signal from the sensor on the VAZ 2114 may be due to other problems: for example, oxidation of the contacts on the sensor chip or a rupture of the boot and the ingress of moisture or dirt. Therefore, first of all, you need to remove the chip, assess the condition of the contacts and spray them with WD-40 or any other rust converter. If this does not help, you need to replace the drive.

Other answers to the question why the speedometer stopped working lie in the electrical circuit. Owners of cars with VDO instrumentation have access to factory diagnostics of the system. The odometer button is pressed, the ignition key is switched to mode 1 (power supply to the instrument panel), after which the button is released. The appearance of error 24 indicates that there is no signal from the speed sensor.

Arrow jumps on a VAZ 2114 are often associated with burnout of tracks. This is caused by increased voltage on the on-board network due to malfunctions of the stabilizer and time. In domestic instrument panels for Samara, low-quality solder was used, which gradually deteriorates due to thermal expansion. An unstable signal may appear as a jumping arrow.

There may be a discrepancy between the speedometer and BC readings: most often the BC shows correctly, but the arrow does not work. This is due to the failure of the drive on the speedometer itself. To repair, you will have to disassemble the tidy and remove the speedometer. Not all auto electricians, not to mention the car owners themselves, undertake such work, so it is easier and cheaper to replace the dashboard.

The speed sensor (DS) is installed on all cars and is designed to measure the speed of the vehicle. On a VAZ 2114, the speed sensor is located at the top of the gearbox. To dismantle it, you will need to remove either the air filter housing or the adsorber. In this article we will take a detailed look at diagnosing the sensor and replacing it if it malfunctions.

Dashboard VAZ 2114 – autotest

Some VAZ cars have a “dashboard check” function, which allows the arrows to make a full turn from start to finish. Such an auto-test of the tidy when the ignition is turned on is available on some foreign cars (Nissan, Subaru). In this article we will tell you how to do an automatic test of the instrument panel on a VAZ. Let's start with the fact that it is not possible to implement the function of checking the tidy when you turn on the ignition on every model. If you turn on the ignition while holding the mileage reset button and the arrows describe an arc, then this panel will work. As a rule, such calibration of the instrument arrows is available on AutoPribor models with one window (single-line), but again not on all versions. To modify the instrument panel you will need:

- Electromagnetic relay, small-sized (12V). For example, Tianbo HJR 1-2C.

- Transistor KT 503. Can be replaced with almost any npn structure.

- Capacitor 100uF, electrolytic (16V).

- Resistors for 1koma, 6.8koma, 22koma.

The principle of operation of the circuit: the relay, with its normally closed contacts, closes the tidy button. When you turn on the ignition, the circuit starts working after half a second, and then turns on the relay, which opens the button.

This test of arrows and dashboard indicators is already available on all modern models. The only thing is that it acts differently on different samples. For example, there may be 1 pass of the arrows, or three, or until the button is pressed, or even a pass only up to half the scales. The speed of the instrument panel arrows also depends on the manufacturer and version of the device. In other words, an autotest is a test button that automatically activates when the device is turned on. If there is a test during the standard test, then there will be one during the autotest. Therefore, doing an auto test of the VAZ 2114 dashboard is not a problem.

VAZ 2114. Why don't the power windows work?

The fuse and relay are ok, what should I do?

The fact is that after checking the relay and fuse, you forgot that external lighting is also involved in the power supply of the ESP. Personally, I had such a problem, I checked the fuse, relay, removed the door trim and checked the entire circuit. At the service station, the repair took 5 minutes, it turned out that the fog lights, which I don’t have, were burnt out.

Of course, the window regulators may not work if something just fell off. Yes, while driving, it also happens that a bolt comes out somewhere. After all, our roads do not really meet the standards. And even more so, if you have electric windows, then the contact may simply fall off. So the reason will have to be found out. And you just need to start by checking whether voltage is supplied to the motor, which raises the windows.

Well, then you’ll have to disassemble the lifting mechanism and see how it works and whether anything got in there.

And only after this is it necessary to check the motor itself. Since it can simply fail.

If the window regulators do not work, both at once, then the motors simply could not burn out and only the fuses of all other circuits and, first of all, the lighting are to blame. Check them and the problem will probably be fixed.

VAZ 2114 can be equipped with either conventional manual (mechanical) window lifters or electric windows.

If we are talking about electric windows, then as a rule (at least quite often) the cause of the breakdown is in the electric motor

The window lift motor on the VAZ 2114 is not dismountable, only replacement.

Perhaps the problem is in the fuse (the most simple failure) the fuse box, like in its predecessors (VAZ 2109, VAZ 2108), is located under the hood.

True, sometimes just replacing the fuse is not enough; sometimes you need to look for the reason why it (the fuse) blows.

This is interesting: Curtains on car windows: allowed or prohibited?

Perhaps the wires are shorted to ground, you need to remove the door trim and see what’s wrong, perhaps the insulation of the wires is broken.

Maybe the reason is in the relay, it is located in the same block under the hood, relay K5, here too only a complete replacement is required.

Or there may be a breakdown in pure mechanics, for example, a worm gearbox has failed, or a problem with the cable drive.

The window lifter system on the domestically produced VAZ 2114 car is quite simple and consists of the following mechanisms:

- motor or mechanical crank

- lifting mechanism with a set of gears

- adjustable lifting device

There are several reasons why power windows may not work:

- No current reaches the electric motor connector. The cause could be a blown fuse or a break in the electrical wiring.

- The problem is in the motor, this is either a loss of current through the electrical wiring or a failure of the motor itself. The motor is removed and current is supplied to it with reversal of polarity; the motor should rotate freely in different directions.

- Failure (mainly the teeth are worn out, resulting in the mechanism jamming) of the lifting mechanism. It is not repairable, only replacement.

- The bushings on the adjustable device come off due to wear.

- The glass has jumped off and rested against something, which is why the mechanism simply cannot raise it (or lower it)

- A foreign object has entered the mechanism.

Reasons for the failure of the instrument panel

Any component and unit on a used domestic car becomes unusable after a certain time. Poor road and climatic conditions, poor quality materials, untimely maintenance - all this leads to gradual wear and tear of all elements of the car. In a situation with a breakdown of the dashboard, everything is more complicated, because... There are no special rules for maintaining the panel. The only thing that can prevent early failure is to prevent moisture from entering the instrument body.

If the tidy on a VAZ 2114 does not work, it is worth carrying out a quick repair. The main reason is a non-working coolant temperature indicator. If the engine overheats, there is a high risk of getting it repaired. Let's consider each of the possible causes of the malfunction.

Fuse blown

In the absence of mechanical impact on the panel, its sudden breakage is very surprising. An inexperienced driver will rush to contact a service center, or will try to disassemble the body on his own in order to find out the location of the breakdown. Note that the first action that needs to be performed when all elements on the panel are inactive at the same time is checking the fuse. Depending on the year of manufacture of the vehicle, the mounting blocks with fuses may differ. In the old-style block, the fuse is located in the bottom row . If you count from left to right, then the desired element will be the ninth in a row .

On later 2114 models, cars began to be equipped with modified mounting blocks.

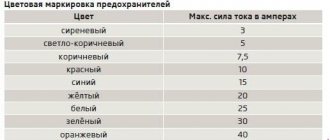

The safety element responsible for the tidy is located on the right side , the first in a row (from top to bottom) . In the photo it is located directly under the sliver. Regardless of the year of manufacture, 7.5 Ampere elements were installed in the right place. If the instrument panel fails, first carry out the procedure to replace the fuses. As a recommendation, we point out that kits with spare parts are sold in all automotive stores.

Wiring damage

The next point that is worth checking if there is a malfunction is wiring diagnostics. Power for the panel elements comes through wires and plugs hidden behind the housing. To check the wiring, you need to dismantle its assembly, and then take power measurements with a multimeter.

The diagnostic process is quite simple, but for those who want to consider the instructions for using the multimeter in more detail, we recommend visiting the YouTube video hosting site. A break in the power supply circuit of the panel devices causes its complete breakdown, or the failure of only some elements. In any case, checking the wiring is the second thing to do after replacing the fuse. If the devices on the VAZ 2114 do not work, then the reasons lie in the following points.

Damage to the board

The most important part of the design is the board. Even partial damage to its surface causes serious disruptions in the readings of the tachometer, speedometer, temperature and fuel level. The board burns out due to a short circuit. Re-soldering contacts on the VAZ board is a waste of time. The fact is that after such a repair the board will not last long and will fail again. The solution to the problem is to completely replace the element with a new one.

The entire fuse box is faulty

Another reason why the instrument panel does not work may be a malfunction in the mounting block. Burning of the contact point leads to permanent burnout of the safety element. This interferes with the correct operation of the device. This problem is eliminated by replacing the entire block assembly. There is nothing complicated in this procedure, and the cost of ready-made replacement options is low. You can also try to restore the fuse box by resoldering the tracks. A non-working VAZ 2114 dashboard is a problem for the driver. When it malfunctions, it happens that the wipers do not work. All of these are links in one fault chain, so if you observe a simultaneous failure in two of these nodes, carry out diagnostics.

The direct cause of the malfunction can be indicated by the on-board computer (if equipped). Built-in capabilities diagnose all systems and determine the source of the problem.

Fix problems immediately after they are discovered, because... If the instrument arrows do not show, it is difficult to determine some indicators of the car’s condition.

The search for possible reasons why the VAZ 2114 instrument panel does not work periodically worries one or another owner of cars of this model. It’s clear that if you don’t see a single parameter on the dashboard, you can only drive, as they say, by touch. True, there are certain specialists who still managed to somehow crawl to the base without all the evidence, but somehow I don’t want to follow their example.

And is it necessary to create additional troubles and the risk of accidents on the road? So the majority of those to whom this incident happened still get to work (or wherever they were going) by public transport in order to return to solving the problem in the evening on their own or with the help of a familiar mechanic.

Why does the VAZ 2114 instrument panel not work? Offhand, we can name several reasons. However, they may not exhaust the entire list, since the individual characteristics of the car may appear. We will try to talk about this and many other equally interesting things in our article today.

Signs of a malfunctioning speed sensor

During the operation of a car with an electronic on-board device, many motorists have encountered a situation where one or another signal lights up in the error block; it often happens that after turning off the engine and restarting this signal does not appear again, so Russian drivers sometimes develop distrust in readings from this ECU. However, every driver should know what errors indicating problems with the DS light up on the on-board computer display.

- P0500 - lack of speed sensor signal.

- P0503 - intermittent speed sensor signal.

Indeed, quite often the cause of the appearance of such signals is problems in loose contacts or even broken DC wires. It is necessary to take into account where the speed sensor is located on the VAZ 2114

The manual transmission experiences strong vibration during operation, so special attention must be paid to the preventive inspection of this sensor.

In addition to the appearance of error signals on the BC display, other signs of a malfunction of the DS may appear; experts include these signs:

- Unstable, “wandering” idle speed, spontaneous shutdown of the internal combustion engine is possible when the gas pedal is not pressed.

- The speedometer on the VAZ 2114 is unstable or does not work at all.

- Fuel consumption increases significantly.

- Engine power decreases.

Of course, this is not a definite diagnosis for DS; there may be other reasons, for example, problems with the fuel system. However, you should check the functionality of the DS. And the first thing to do is to ring the circuits and make sure the wiring is in good condition. Make sure there is grounding and a 12 V signal is supplied to the contacts.

There are several ways to check the performance of the DS:

- remove the problematic sensor. Using a voltmeter, measure the output voltage and signal frequency. To do this, put plastic tubes on the sensor axis and spin the housing to a speed of 3-5 km/h. The faster the sensor rotates, the higher the voltage and frequency;

- the second method does not require removing the sensor.

Raise the front wheel on a jack so that it can be spun. Connect a voltmeter to the sensor contacts. Spin the wheel and take readings from the device; if the voltage and frequency increase adequately to the spin, then everything is fine with the sensor.

The third method involves checking using a “control” or a light bulb.

Raise the front wheel on a jack so that you can spin it. First, you need to disconnect the pulse wire from the sensor. Turn on the ignition. Use the “control” to find “plus” and “minus”. Connect the “control” to the “Signal” wire and spin the wheel. When the sensor is working normally, the “minus” light should light up. If you don’t have a control tool, you can use a light bulb. To do this, you need to connect wires to it.

Connect one wire to the battery positive, and the second to the “Signal” connector output. Spin the wheel. If the light blinks, then the sensor is working.

Car enthusiasts have worked out a technique for checking the DS drive.

To do this, you need to jack up one wheel and remove the speed sensor. Feel for the sensor drive and rotate the wheel. When the drive is working normally, you can feel it rotating with your fingers. And if there are no jams, then the drive is in order.

If, as a result of the test, it is determined that the speed sensor does not work, then it is necessary to remove it and replace it with a new one. This spare part is not in short supply, so you can easily find out how much the speed sensor on a VAZ 2114 costs.

Troubleshooting steps

To diagnose and repair the dashboard lighting system on a VAZ 2114, you will need a pair of wrenches of sizes 8 and 21 and a set of screwdrivers. The general procedure for dismantling and commissioning boils down to the following steps:

- Remove the cover by unscrewing the three mounting screws and removing the tab from the housing bracket.

- Unscrew the five mounting screws on the right side of the console and remove the screen.

- Disconnect the battery terminal that goes to the negative power supply, as well as the wiring harness connector from the cigarette lighter system.

- The lever mechanism handle is removed.

- The plug for the stove ventilation system is removed.

- The screws securing the steering column brackets are removed.

- The sockets are unscrewed, the light guide and the decorative panel insert are removed.

- The hydraulic corrector illumination lamp is removed with button 21.

- Finally, the screws securing the top and bottom of the instrument panel itself are unscrewed so that it can be removed.

Once the dashboard is removed, you can begin to look for the reason why the backlight does not turn on. First of all, it is customary to check the lamps on the VAZ 2114. If they are in good condition or after replacing the damaged unit, the system still does not work, you need to clean all contacts from the oxide film. To speed up the process, it is better to use special mixtures, for example VD-40.

After completing all these manipulations, be sure to conduct a continuity test to detect an interruption. To do this you will need a multivoltmeter or tester. If all monitored elements are working normally, but the backlight is off, the safety module is faulty. It must be replaced with a unit with similar technical characteristics (and preferably from the same manufacturer.

Upon completion of the repair work, it is necessary to install all equipment, observing the reverse sequence described in the instructions for the VAZ 2114. In this case, special care should be taken not to damage the connected diodes, not to deform the arrows of the device, and not to disconnect the conductors.

Note! If the backlight disappears, but the car radio and other electrical appliances remain fully operational, most likely the cause of the malfunction is in the fuse box; it must be replaced with a new one.

Diagnostics of speedometer operation at fourteenth

Troubleshooting begins by disconnecting the wiring block from the speed sensor harness and checking them using a test light.

To make a control light bulb, you need any car lamp that can operate at a voltage of 12 V, and two wires about 1 meter long each. One of the wires is attached to the positive terminal, the second - to the negative terminal of the lamp. The resulting device also includes a Krona battery.

To carry out the test, one wire of the warning lamp is attached to the ground of the body or battery, and the second is made with short, frequent touches to the middle contact of the DC connector. If there are no faults in the connector-speedometer section, the speedometer needle will slightly tremble or rise. If the needle shakes, the answer to the question why the speedometer does not work can be considered found - the speed sensor requires replacement.

In cases where the needle’s response to tapping on the central contact of the block cannot be detected, it is necessary to “test” the speedometer power circuit. The procedure is carried out using a multimeter (multitester), or by using the same light bulb - a control.

If the tester in the “continuity” mode indicates a violation of the integrity of the circuit, further troubleshooting is carried out in this direction. It is necessary to check the fuses, the connection points of the wires, and their integrity inside the insulating braid.

The search area can be reduced by gradually “ringing” individual sections of the circuit. On model 2114 and other VAZ products, the cause of speedometer failure is often oxidation of the “mass” contacts attached to the car body.

In cases where the speedometer needle does not work, but there is no evidence of malfunctions in the electrical supply circuit, a logical conclusion is drawn about the malfunction of the device itself. Additional testing can be done by temporarily installing a known good instrument panel.

- Posts: 1

- From: Klintsy

- VAZ 2114 1.6i 8 valves

February 5, 2022, 00:48 #1 123

Hi all. This is the problem: I start the engine, warm it up, everything is fine with the tidy. I start moving and the speedometer needle spontaneously begins to rise to 5 km/h, then to 60, then to 80, to 120, sometimes higher and even climbs onto the odometer and freezes, then during acceleration it begins to rise as expected, but from the place where stopped (5.60 km/h, etc.) That is, according to the speedometer 100 km/h, in fact 40 km/h. In this case, the odometer shows the actual mileage in km. I do a dashboard test, the needle only drops to 50-60 km/h. I remove the “-” terminal, put it on and the arrow drops to 0, but this does not help for long, soon it repeats again, and the arrow always hangs at a different mark. I changed the speed sensor, it didn't help. The connector wires are not broken, everything is fine. It happens that if I skid in the snow (with the arrow at 0), it begins to rise, but it does not rise smoothly and constantly, but in segments. That is, it will rise to 40, then to 70, etc., always differently. And it will continue to rise until I stop the car, then the needle will freeze in the last position and when it starts moving, thinking that it is at zero, it will rise in accordance with the increase in speed. In short, he lives his own life. I'm sinning on the speedometer needle mechanism itself. Please tell me what is the secret of this problem of this miracle of technology of the Russian automobile industry?

PS I forgot to write. Before the problem started, I removed the tidy, because not all the lights illuminated it, so I decided to change everything to LED ones. That is, without fanaticism, I removed the bases and installed diode ones instead of the usual ones.

- Posts: 548

- From: Kursk

- Lada 2115

February 5, 2022, 10:33 pm #2 123

try removing all the backlight bulbs, how will the tidy behave?

well, or drive without dimensions, until you turn on their power, the backlight will not work, I changed the usual ones to LEDs - the flight is normal, without glitches.

Maybe the device is dying, maybe some tendril broke off from the lamp and lies between the tracks creating a short circuit in the circuit

conclusions

If the light in the dashboard goes out, it is recommended to contact a car service center, where everything will be fixed or replaced quickly and efficiently. The main reason can rightfully be considered a short circuit, and if the fuse fails, or the impulse passes before it burns out, then the consequences can be very diverse.

According to these Rules of the Road, on any moving vehicle, including the VAZ-2114, the headlights must be turned on, along with which the side lights must also be turned on. In addition, they must be turned on when the car is stopped or parked on the road in the dark and in conditions of insufficient visibility. Therefore, they must always be in good working order.

The electrical circuit of the side lights of the VAZ-2114 is not so complicated and, if desired, any self-respecting driver will be able to find a malfunction associated with the failure of its operation. To do this, you need to know that terminal No. 1 of the side light switch is always supplied with positive voltage from the battery, bypassing the ignition switch. If the side light switch key is in the on position, then electric current flows to two fuses F10 (7.5A) and F11 (7.5A), which respectively protect the electrical circuits of the left (F10) and right (F11) side lights. The further path of the current lies to relay K4 (lamp health monitoring relay), and then to the front and rear side lamps.

When only one of the side light bulbs does not light, then we check whether it has burnt out. If it burns out, then we replace it with a new one of similar power, but if it is intact, then we will have to look at the condition of the contacts of the cartridge in which it is inserted. In the rear lights, due to moisture getting into them, oxidation is possible, both of the tracks and the pads through which voltage is transmitted to the terminals of the side light lamp.

Another reason why the headlight lamp does not light up may be the lack of voltage at the corresponding terminals of the rear light blocks or headlight blocks. Then, using a tester, you will have to ring the corresponding wires:

- The right front marker does not light up (check the yellow wire from terminal No. 4 of the headlight to terminal No. 8, block X6 of the mounting block);

- The right rear light does not light up (check the yellow wire from the right rear light block to terminal No. 9, block X9 of the mounting block);

- the left front marker does not light up (check the yellow-black wire from terminal No. 4 of the headlight to terminal No. 10, block X6 of the mounting block);

- the left rear light does not light up (check the yellow-black wire from the right rear light block to terminal No. 17, block X9 of the mounting block);

If both lamps on the right or left side of the car stop working, then troubleshooting should begin by checking the corresponding fuses located in the mounting block under the hood of the VAZ-2114 car, since the simultaneous burnout of two dimensional lamps at once is unlikely. The blowing of fuse F10 is very easy to determine, since it will lead to the cessation of combustion of the backlight lamps of the instrument switches. Also, the reason for turning off the side lamps may be the failure of relay K4.

3 comments

When you press the brake pedal, the rear turn signals turn on. When you turn on the turn signals, the rear lights begin to switch and shine like garlands?

On the right side, the dimensions do not light up, the fuses are intact, and the light bulbs are intact. Could it be K4?