Suddenly, out of the blue, while driving your favorite “Seven” in complete comfort, an incomprehensible “roar” appears at the throttle. The driver turns off the radio and listens. After every press on the gas pedal, the car growls and roars like a tank. After climbing under the bottom, it is discovered that the VAZ 2107 muffler is completely unsoldered, the pipe has moved away from the resonator, and the fastening is broken. If the inside of the exhaust pipe is “jammed” and the removal of exhaust gases is impaired due to a decrease in diameter, then the engine “chokes” and a loss of power occurs.

What to do? The muffler is hot, and it is impossible to simply connect and “wrap it” with something, since any winding will burn out. The main problem becomes somehow establishing a temporary fastening so that the muffler does not stick into a bump when you have to drive onto the country road. As a result, the driver trudges along at a speed of 45-50 km/h, stunning oncoming people, and thinks with longing about how he will drive into a sleeping holiday village on a diesel tank. So, part of the exhaust system needs to be replaced.

The above describes a common situation: many car enthusiasts do not think about the vulnerability of the exhaust system,

Few people pay attention to a serviceable muffler in a car, until a routine inspection of the chassis or rear axle reveals a hole, or a split at the seam, or a more serious breakdown.

What is a muffler for?

Naturally, making the car sound quieter. Physically, the combustion of a mixture of air and gasoline produces vibrations of different frequencies, from low to high. The sound from the exhaust manifold carries all the energy of sound vibrations into the muffler, which is equipped with several special chambers. Like any wave, the sound from a motor has energy, or amplitude. The higher it is, the noisier the motor is. When it enters the chambers, the sound “gets entangled” and gives up its energy, turning into heat. This is why the muffler parts are so hot, although they are far from the engine, and the exhaust itself from the exhaust pipe is slightly warm. So, the first function is to make the engine quieter.

The second important function is the removal of combustion products, otherwise the mixture will not ignite in the zone of high carbon dioxide content.

The third function is keeping the cylinders clean and ventilating them.

It must be remembered that the exhaust system takes on very large thermal and chemical loads, and parts can “burn out”, since toxic exhaust gases, mixing with condensate, form complex acids, which are very aggressive at high temperatures.

On the outside, moisture, impacts from gravel, salt in winter and other causes also contribute to wear. Those who use their car in winter need to replace the muffler much more often.

What is the design of the VAZ 2107 muffler

The muffler is only part of the exhaust system. Its structure is as follows:

- Exhaust gases penetrate through the exhaust manifold into the so-called “pants” 12, which are called the exhaust pipe. The “pants” are separated from the exhaust manifold by a special gasket 11, which is designed to seal their fastening.

- The pipe is attached to the gearbox using bracket 15.

- Then there is a series of additional resonators, or mufflers, front and rear, which are attached using clamps 7 to the “pants” and 6 to the main muffler. These mufflers cut off certain sounds from high engine frequencies. Together they are called "additional muffler" 13.

- The main muffler (main) 3 is movably fixed to the bottom so that its frequency is not transmitted to the body. This mount can additionally dampen vibrations due to the “sway” of the muffler itself. It is produced using parts 1-4.

- Next comes the exhaust pipe.

Here it should be said that by the color of the exhaust and the condition of the pipe, one can draw certain conclusions about the operation of the engine, just as doctors draw conclusions about the work of the intestines by analyzing stool. For example, if you run your finger inside the pipe and a greasy, oily residue remains, then the oil scraper rings have become unusable and the engine “eats” oil, which is indicated by the black color of the exhaust. Normally, the inside surface of the exhaust pipe is dry.

The exhaust system assembly is shown below:

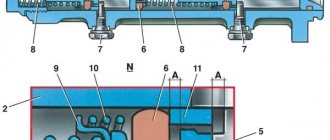

The main muffler contains numerous chambers consisting of perforated pipes.

The figure also shows the mounting pad and extensions of the main muffler. An important feature of the VAZ 2107 muffler is its complete “interchangeability” with the rest of the classics. If you purchase parts from a VAZ 2101, or any other modification, you will not go wrong.

If your muffler needs replacement, it is better to do this at a service center, and purchase spare parts there so that there is a guarantee for the installation. Simply replacing a muffler is a messy business, especially if you have to start from the “pants.” It is possible that you will need to cut off the stuck joints with a grinder.

A few words about sports modifications of the VAZ 2107 muffler

A conventional muffler is indirect, this increases the pressure in the exhaust manifold and can reduce engine power. At that time, a direct-flow, sports muffler filled with ceramic fiber is able to increase engine power by faster cleaning of the cylinders from exhaust gases. It should be said that the sports muffler of the direct-flow system will never “scream”, and the engine operating volume will be quite acceptable.

The exhaust system of classic VAZ models consists of three elements. The middle element is usually called a resonator. Any malfunction is accompanied by a roar coming from under the bottom of the car. Repairing and replacing the resonator with your own hands is quite simple. In this case, the choice of a new part becomes especially important - the manufacturer installed several types of resonators on the VAZ 2107, depending on the type of engine and power system.

DIY resonator

Before designing and assembling a resonator of your own design, you need to understand one simple thing. The thicker the material from which the exhaust system is made (including the resonator), the more effective the fight against vibrations and resulting noise will be. It is for this reason that the exhaust manifold, which is the first to receive gases from the cylinder head, has such an impressive weight.

However, when choosing a material, you should not overdo it and choose too massive blanks. Otherwise, the mass of the resonator will be significant, and this will affect the dynamic characteristics of the car and the load on its chassis.

There are a number of reasons why car owners make their own exhaust resonators. One of them is to reduce the noise that a standard factory muffler produces. Usually, for this purpose, an additional resonator is installed in the exhaust system. The second reason is the manufacture and installation of a direct-flow car resonator . Its features are as follows:

- reduction in engine power loss (actually insignificant, about 5.10%);

- changing the sound background of the engine and exhaust system (for lovers of low sound).

To make a direct-flow resonator you will need:

- a set of locksmith tools;

- welding machine (it is advisable to use modern semi-automatic machines or inverters);

- angle grinder with a set of cutting and grinding discs.

The design of the resonator will differ depending on the materials used and the imagination of the car owner. We offer you one of the options for self-manufacturing a direct-flow automotive resonator :

- Pre-prepare the pipe that will serve as the internal base of the resonator. It should be the same or slightly larger diameter than the factory one. Make sure that it can be easily welded to the existing system in the future, so do not choose a diameter that is too large (unless it is possible to connect the pipe using a flange).

- Next, you need to drill holes in this pipe, similar to the stock resonator.

- After this, you need to find a pipe with a slightly larger diameter (about 3.5 cm) that will serve as the outer casing. Its length needs to be made smaller (depending on the design, on average by 5.10 cm on each side).

- The plugs necessary to seal the housing at the ends are made. For this, sheet metal is used, where the outer diameters of the large and small pipes are drawn. Afterwards, the blanks are cut out and processed using a grinding machine.

- A pipe with a larger diameter is placed on a pipe with a smaller diameter, and the cavity between them is filled with glass wool (or better yet, modern mineral wool with good heat and sound insulation characteristics).

- Next, you need to weld the ends around the edges of the pipe with a large diameter using pre-made plugs.

- After welding work, clean the seams using an angle grinder. After this you should paint them.

- The last stage is welding the new resonator into the car's exhaust system. After carrying out the work, also clean the welding seams.

DIY resonator

The given algorithm is approximate . There are a wide variety of options for homemade resonators. In some cases, they are simply thrown out of the system, replacing them with a piece of pipe. However, we do not advise you to do this, since you will not receive a significant addition to the car’s power, but an additional roar from the exhaust pipe is guaranteed!

Additional problems

After installing a self-made resonator, the car owner will likely encounter a number of problems that must be solved. First of all, we are talking about increasing the mass of the gas exhaust system, and, accordingly, the car as a whole. This is true if you used heavy metal elements to make the resonator. Therefore, a situation may arise when it is necessary to replace the brackets and/or shock absorbers. That is, strengthen them. Otherwise, the car body will “sag”, and the chassis will experience additional load.

In addition, replacing the resonator entails a change in the ratio of air entering the engine and the amount of exhaust gases. Therefore, it is necessary to empirically determine which optimal settings to choose and make appropriate adjustments in fuel supply and air filtration.

Design and purpose of the VAZ 2107 resonator

The resonator is a cylindrical metal tank designed to preliminary reduce exhaust sound. Connecting pipes with a diameter of 40 mm are hermetically welded to it at the front and rear. The front pipe is equipped with a mating flange for the catalyst or exhaust pipe, and the rear pipe has two longitudinal slots for docking with the muffler section.

Resonator pipes for carburetor models VAZ 2106-2107 are equipped with one or two tanks. The first type was installed on cars with an engine displacement of up to 1.3 liters, the second - on modifications with more powerful engines of 1.5-1.6 liters.

The resonator consists of:

- a tightly sealed cylindrical body to which connecting pipes are welded;

- an internal pipe with a large number of holes (perforations) for passing exhaust gases;

- a transverse partition dividing the body into two internal chambers.

Main elements of the system

The muffler design includes several elements. In fact, it will be approximately the same for each car model.

- Collector;

- Neutralizer;

- Front muffler;

- Rear muffler.

The manifold is connected directly to the engine itself, performing the task of removing gases. The load in this case is very high and this applies to both mechanical and temperature effects (up to 1000 degrees). Special requirements are placed on the material from which this part of the car muffler is made. For this, the best alloys of cast iron and steel are used.

According to international standards, manufacturers must take care to reduce harmful effects. And this task is assigned to the catalytic converter or converter. It is a special chamber where the actual purification of the gas mixture occurs.

Nowadays, manufacturers often produce catalysts capable of purifying a wide range of harmful substances. For this purpose, the catalytic converter chamber is made multi-sectional. The body is made of metal or ceramic. Moreover, it has a cellular structure, due to which the contact area of gases directly with the catalytic layer increases.

Location of the VAZ 2107 resonator

The exhaust system of carburetor VAZ 2107 consists of three sections:

- double exhaust pipe connected to the exhaust manifold flange;

- resonator;

- main muffler.

A similar system was installed on the first seven with an injector that complied with Euro 0 standards. Later, injection modifications of the VAZ 2107 appeared, produced in accordance with the requirements of Euro 2 and Euro 3, in which the exhaust tract was supplemented with a fourth section - a catalytic converter located between the exhaust and resonator pipes .

The resonator, connected at the front to the exhaust pipe or catalyst, starts under the gearbox and ends in front of the rear axle beam. The resonator tank is located to the right (in the direction of travel) of the propeller shaft. The connecting pipe coming out of the body is bent upward and docked with the main muffler pipe that goes around the rear axle. The entire structure is supported by the engine exhaust manifold flange, a metal bracket and rubber hangers attached to the bottom of the car.

Choosing a resonator for VAZ 2107

Four types of resonators are installed on the VAZ 2107:

- Long section with one tank. Installed on all classic carburetor VAZ 2101-2107 with an engine capacity of no more than 1.3 liters. Catalog number - 2101–1202005.

The last two types of resonators are shortened due to the addition of an additional element - a catalytic converter. Parts for Euro 2 and 3 differ in length (spare parts for Euro 3 are shorter) and the number of mounting bolts on the flange. The second tank is missing - its functions are performed by the catalyst.

The choice of resonator depends on the specific modification of the VAZ 2107. When purchasing, you need to keep in mind the following recommendations:

- On the carburetor version with a 1.3 liter engine, you can easily install a long section with one (VAZ 2101-07) or two (VAZ 2106-07) tanks. In the second case, the sound of the running engine will become quieter, but the power will drop by about 3-5 hp. With. Shortened resonators will not work.

- Both long resonators are suitable for carburetor and injection VAZ 2107, corresponding to Euro 0. When installing a part with one tank, the exhaust noise will increase and the engine power will increase slightly. Short pipes cannot be installed.

- The exhaust system for Euro 2 is equipped not only with a catalyst, but also with an oxygen sensor (lambda probe) mounted in the exhaust pipe. For such cars, the original shortened resonator with a two-bolt flange or any long section is suitable. However, such a resonator is not suitable for the VAZ 2107 Euro - it is connected to another catalyst and differs in length.

- The exhaust system of the VAZ 2107, manufactured in accordance with Euro 3 standards, has two oxygen sensors. On the VAZ 21074 you can install the original short resonator or a long one, but with some modifications.

Once it was possible to modernize a 1.3 liter engine by increasing the displacement to 1.7 liters by replacing the crankshaft and boring the cylinders to size 82 mm. After which it was necessary to replace the “native” resonator with one barrel, because with an increase in engine power, the exhaust pipe began to roar more strongly, especially at speeds above 2500 rpm.

It makes no sense to install a resonator from other brands of cars and front-wheel drive VAZ models on the “seven”. You will have to strongly heat and bend a pipe made of refractory steel. An alternative option is to weld the resonator tank with your own hands based on the burnt-out element.

Installing long sections on the VAZ 2101-07 that comply with Euro 2 and 3 standards is advisable in cases where it is necessary to discard a failed catalyst. The latter is quite expensive, and not every car owner is ready to make a full replacement. In this case, after installing a long resonator pipe, you will have to install a snag instead of the second lambda probe or reprogram (reflash) the engine control controller.

Video: choosing a resonator for VAZ 2107

About direct flow or PG

A direct-flow muffler (PG) is an improved alternative to a stock exhaust, which is not capable of ensuring a quick and timely release of gases from the engine system (ICE). The standard exhaust system especially suffers (chokes) after installing a sports camshaft or after boring the cylinder head cylinders (in other words, on a forced engine).

A straight-through muffler is designed to improve the exhaust system

The GHG is designed to modernize the exhaust system, which increases gas emissions. In addition, a correctly installed PG will provide an increase in internal combustion engine power by 10–15 hp. However, you need to be prepared for drastic changes: everything will need to be replaced, from the catalyst to the tip.

Increasing the power of a power unit using a PG, unfortunately, also has a “other side of the coin”, associated primarily with a loud sound attack of about 120 dB. This is the norm for sports cars, but hardly for civilian ones. And this explains the mass of cases of fines issued by law enforcement inspectors to the owners of such cars.

To minimize this modernization flaw, craftsmen use various methods to reduce sound. Installing a flute muffler, oval or round resonator are all types of methods to improve the performance of a forward flow muffler. “Form and content” can make it quiet.

For example, craftsmen say that a square resonator installed in the middle of the path (the path for gases to escape into the aircraft) reduces noise much better than an oval or round one. And in general, it’s better not to use a round one, but to use an oval one as a last resort, since it has a larger volume of cans and, accordingly, a quieter sound.

Oval resonators from Volvo S60R and Saab have proven themselves to be quite good.

Before thoroughly understanding what GHG is, you should remember the functioning of the vehicle exhaust system. Many motorists do not even suspect how many tasks it performs, although it does not seem so at first glance.

The forward flow kit is a ready-made option for tuning

Of course, the main task of the exhaust is to remove gases. But an equally important function is to ensure timely and high-quality ventilation of the internal combustion engine cylinders.

Ventilation of the cylinders is carried out as follows. When the valves of one cylinder of the internal combustion engine are closed, a vacuum is created in the exhaust manifold. It moves through the system at high speed, and, having been reflected from obstacles, returns to the collector. At the moment the gases leave the cylinder, a reduced pressure is created here, which promotes better ventilation and purge.

Among other things, the exhaust system (ES) is designed to combat noise. This is what the muffler is designed for.

Compared to a conventional standard muffler, the PG does not have many separate sections inside. Accordingly, it has a more simplified design. It is this fact that allows craftsmen to make it at home or in the garage.

But is it even worth it for an ordinary motorist to change the standard muffler to a PG one? Certainly not. If he does not prefer active driving, does not intend to use the car for sporting purposes, does not have complexes about a “gray” car that does not stand out from the general traffic flow, then he should not carry out modernization.

On the contrary, if the bassy and thoroughbred roar of the engine resonates in the soul of the car enthusiast, then the installation of direct flow must be carried out. Moreover, this gives many advantages of the following nature:

- the power of the internal combustion engine increases due to increased throughput;

- The service life of the entire aircraft is extended due to the use of high-quality materials.

As for the disadvantages of modernization, these are:

- problems with the law due to loud noise (can be excluded if the installation of GHGs is carried out using a new system);

- possible difficulties with service maintenance;

- greater sensitivity of the power unit to low temperatures;

- decreased clearance.

Do not confuse forward flow with a muffler. The fact is that the entire exhaust system is called direct flow, and in most cases only part of it is subject to modernization - the muffler.

Manufacturers of resonators for VAZ 2107

In the post-Soviet space you can purchase resonators from many manufacturers. The production devices in greatest demand are:

- OJSC AvtoVAZagregat (manufacturer of original parts);

- OJSC Togliatti Plant of Technological Equipment;

- LLC "Izhora Silencer";

- TRANSMASTER UNIVERSAL (manufacturer of exhaust systems made of regular and stainless steel).

There are no big differences between the products of these brands. The service life of resonators made of refractory steel is approximately the same and amounts to 20-30 thousand kilometers. The service life of stainless steel products is approximately twice as long, but the price is one and a half times higher than the price of analogues made of ferrous metal.

Preventive measures

You can extend the life of the muffler by systematically caring for it, performing timely washing and treating it with anti-corrosion compounds. In addition, for preventive purposes, you can use a corrugated pipe, securing it between the manifold and the body of the part. Such a coupling will be able to absorb excess vibrations, reducing friction and the operating temperature of the muffler.

Sources

- https://ZnanieAvto.ru/gazy/kak-sdelat-pryamotok-tishe.html

- https://cartore.ru/2768-izgotovlenie-glushiteljami-svoimi-rukami.html

- https://avto-cool.com/remont-avtomobiley/kak-umenshit-zvuk-glushitelya-v-avtomobile-svoimi-rukami

- https://vyhlopnie-systemi.com.ua/ru/remont-vihlopnih/kak-sdelat-glushiteli-tishe/

- https://www.syl.ru/article/198000/new_kak-sdelat-glushitel-svoimi-rukami-remont-glushitelya-svoimi-rukami-bez-svarki

- https://ladamaster.com/ustroystvo-glushitelya-avtomobilya-v-ra

- https://pol-z.ru/kak-sdelat-pryamotok-svoimi-rukami/

- https://master-glushiteley.ru/articles/tuning_articles/basistyj-vyhlop/

- https://svarkaprosto.ru/tehnologii/kak-zavarit-glushitel-elektrosvarkoj-samostoyatelno

- https://master-glushiteley.ru/articles/tuning_articles/kak_sdelat_glushitel_tishe/

Resonator malfunctions and repairs

Resonator malfunctions include:

- pipe beating on protruding parts of the body and other elements;

- burnout of the end part of the tank at the welding site of the body and pipe;

- burnout of the housing or internal perforated channel;

- exhaust gases exit through the mounting joints.

An annoying knock coming from under the car's bottom is usually the result of a loose exhaust pipe beating against the body and other components. The reason for this is the rubber fasteners, which wear out and stretch over time and cannot provide rigid fixation of the exhaust tract when moving. The problem is solved by replacing these fasteners.

Typically, exhaust tract hangers last much less than the pipe itself. Check the condition of the rubber bands at intervals of 10 thousand km; if cracks are found, immediately install new suspension mounts.

Other problems can be resolved in the following ways:

- The burnout on the side of the resonator can be welded. There is no need to remove the pipe to do this. An experienced welder will do the work on site, covering the body with a sheet of asbestos.

- If exhaust gases are observed escaping through the joints of the exhaust system, the mounting clamp or flange should be tightened further. You can also loosen the fastening, fit the parts closer together and re-tighten the clamp.

- If the housing or internal channel burns out, the resonator is usually replaced with a new one. If the fistula is small, you can try to weld it without removing it from the car.

Car enthusiasts with experience in welding can make a resonator tank with their own hands. To do this you should:

- Remove the resonator from the car.

- Carefully cut the body with a grinder.

- Take all dimensions (channel and hole diameters, body dimensions).

- Make a new tank according to the measurements taken.

- Weld old pipes to the new tank.

- Install a new resonator on the car.

Video: malfunctions of the exhaust system of classic VAZ models

Ways to muffle the exhaust sound

Before tuning the exhaust system, you need to understand the reasons why the sound of the engine becomes louder over time. The operation of the engine itself is a fairly loud process, but the muffler and other components of the exhaust system perfectly suppress this loud noise. Without a muffler, the engine noise is very loud.

The noise occurs because the fuel mixture explodes in the combustion chamber, releasing gases that then exit into the exhaust pipe. We will not talk in detail about the operation of the engine, you can read about this in another article, but here we will talk specifically about how to muffle the exhaust sound.

The explosion releases energy that pushes the piston, and when the piston has moved the required distance, the exhaust valve opens, through which the exhaust gases exit and go further through the exhaust system. To effectively absorb noise, thick metal parts are used. So, the thicker the metal used in the exhaust system, the quieter the car will drive due to the fact that there will be less vibration.

The exhaust manifold is the first one to absorb the noise, which is why it is made so large and thick, so it best dampens the noise that comes from the cylinder block. Even if you compare the exhaust pipe of any more or less normal foreign car with the exhaust pipe of a domestic car, you can see that in foreign cars the pipe is heavier and thicker, which is why such a car runs quieter.

This is why when you drive an old VAZ 2114, the noise is such that you can’t hear what the passengers in the rear seats are saying, which is why you start thinking about how to muffle the exhaust sound.

The exhaust system also has a resonator, which is needed to reduce the speed of gases through the exhaust pipe. And after the resonator comes a muffler. When exhaust gases pass through the resonator, they lose some energy and continue to flow more slowly.

Gases lose the largest share of their energy in the muffler. If we consider a good muffler, then it contains several separate housings, after passing through which little remains of the noise.

Replacing the VAZ 2107 resonator

Replacing the VAZ 2107 resonator is carried out on an inspection pit, overpass or lift. To complete the work you will need:

- two keys for 13;

- powerful flat screwdriver;

- hammer and wooden handle;

- pliers;

- pipe wrench (gas);

- aerosol lubricant WD-40 or equivalent;

- fabric gloves.

Theoretically, disassembling the exhaust system is not very difficult. However, in reality, the problem of separating sections usually arises, since the joints of the joints are firmly stuck due to heating and the formation of internal carbon deposits.

The resonator is mounted at four points: at two joints (with the exhaust pipe and muffler) and at two rubber hangers, hooked directly to the tank. Its dismantling is carried out in the following order:

- Drive the car into a viewing hole (overpass), set the parking brake and secure it with wheel chocks.

- Apply aerosol lubricant liberally to the joints of the resonator section and wait 15-20 minutes.

- Using 13mm wrenches, loosen the rear and front fastening clamps. Carefully knock the mandrels off the thickened part of the joint onto the pipe.

When removing Euro 2 and 3 type resonators, instead of the front clamp, you need to unscrew the mounting flange bolts.

If you cannot disconnect the pipes in this manner, try bending the end of the outer pipe with the slots by driving a flat-head screwdriver under it. When the gap widens, spray the joint again with spray lubricant. If necessary, you can remove the rear suspension of the main muffler and have an assistant rotate this element while you hold the resonator with a pipe wrench.

The new resonator is installed in the reverse order. Before installation, it is recommended to carefully inspect the main muffler and intake section. If burns are detected on them, appropriate work should be performed.

During the assembly process, it is necessary to ensure that the pipe does not sag and at the same time does not touch the body. In the first case, the resonator may be damaged on a rough road, and in the second, it will hit the body while driving, causing a dull knock in the car's interior. Upon completion of the work, it is necessary to start the engine and, going down into the inspection hole, make sure that the joints do not allow exhaust gases to pass through.

Video: replacing the VAZ 2107 resonator

The VAZ 2107 resonator operates under difficult conditions - the temperature of the gases passing through the section is about 600 °C. If you do not monitor the condition of the rubber fasteners, the pipe will become loose and begin to leak gases. If a fistula appears in the body, the tank should be welded immediately, otherwise the damage will quickly increase. Replacing the VAZ 2107 resonator is quite simple. To do this, you will only need a minimum set of plumbing tools and step-by-step implementation of the instructions of professionals.

Over time, the exhaust system of the VAZ 2107 fails and the owner has to go to a service station or change it himself. In the latter case, you will need a standard tool and an inspection hole. You may also need a grinder and WD-40.

Checking the resonator

When identifying the problems listed above, every motorist should know how to check the resonator . This will not only normalize the operation of the engine and exhaust system, but also increase the comfort of using the car, including for the people around you.

To check, you will need an inspection hole (if you don’t have one, you can jack up the car). Diagnosis is made using visual inspection. During the process, it is necessary to carefully examine the integrity of both the device itself and the pipes connected to it (especially at their joints).

A clear sign of a problem is the formation of condensation in the cooling resonator, after which it begins to drip to the ground. This means that its body has lost its tightness and must be repaired, or better yet, replaced. You can check for condensation after some time, when you turn off the engine (to allow the resonator body to cool). Note! Some car enthusiasts, when making resonators on their own, specially drill a hole in its body to remove moisture . Therefore, if you bought a car with a similar resonator, then this testing method will not work for you.

Exhaust system design of VAZ 2107

Like most passenger cars, the VAZ 2107 has an exhaust system consisting of three main parts:

- a receiving pipe into which gases enter from the exhaust manifolds;

- VAZ 2107 resonator (additional muffler), where gases are directed from the exhaust pipe and where the exhaust sound is partially reduced;

- muffler, which absorbs most of the engine exhaust noise.

In addition to the above parts, the exhaust system includes:

- muffler mounting pad;

- pillow bolt;

- muffler suspension belt;

- clamp bolt and clamp securing the muffler to the resonator;

- clamp bolt and clamp securing the resonator to the exhaust pipe;

- clamp bolt and clamp securing the exhaust pipe to the body;

- nuts securing the exhaust pipe to the manifold;

- pad;

- locking plate;

Exhaust system functions and parts replacement intervals

Despite its apparent simplicity, the exhaust system performs several important functions:

- removal of fuel combustion products;

- reduction of noise level from the exhaust;

- maintaining air balance in intake and exhaust systems;

- ensuring ventilation and cleaning of cylinders;

- reduction of CO content (in the presence of a catalyst).

Exposure to high temperatures, moisture, fuel and oil combustion products leads to through corrosion of exhaust system parts. This is aggravated by the external influence of gravel, sand and salt solutions that are used to treat roads in winter. Therefore, parts of the system have to be changed. The frequency of replacement depends on the following factors:

- car use activity;

- frequency of machine operation in bad weather (rain, snow);

- fuel quality;

- quality of exhaust system parts.

What materials are used for catalytic reactions

The immediate working area of the car muffler neutralizer is coated with platinum and palladium. Upon contact with them, most of the harmful toxins in the exhaust gases are neutralized. Manufacturers place the catalyst itself closer to the engine, since high temperature speeds up reactions.

Of course, there is still no universal muffler capable of neutralizing absolutely all toxins and harmful substances, but manufacturers are still constantly improving technology.

Replacing the muffler VAZ 2107

The VAZ 2107 muffler (injector and carburetor) is connected to the resonator with a clamp, which is located in front of the rear axle. Before removing the clamp, it should be tapped with a hammer to make it easier to unscrew the threaded connection and uncouple the pipes. To change the muffler, you need to do the following:

- loosen the clamp bolt and remove (move) the clamp;

- pull the flared muffler pipe off the resonator (if that doesn’t work, knock it down with a hammer and chisel);

- remove the muffler from the cushion and mounting straps;

- install a new muffler on the VAZ 2107;

- tighten the clamp.

How to make the quietest muffler for a car yourself?

When the issue with noise during car operation has gone too far, and you have decided to make the quietest muffler for the car, then you need to start by preparing the tool. We will need:

- welding machine, an inverter or semi-automatic will do;

- angle grinder and discs for it;

- workbench with a vice.

The surest and most inexpensive way to make a muffler quieter is to weld in an additional resonator. This can be done in a garage yourself.

An additional resonator can be placed between the standard resonator and the muffler. You can install a ready-made resonator; you just need to weld it into the desired place in the pipe. Or you can assemble the resonator yourself. For those who doubt whether the exhaust will become quieter if an additional resonator is welded in, the answer is clear - the exhaust will become quieter. If everything is done correctly.

Replacing the VAZ 2107 resonator

The VAZ 2107 resonator does not have fastening parts to the car body, so it is necessary to hold it when replacing it. Otherwise the exhaust pipe will be bent.

The replacement work consists of the following steps:

- tap clamps and pipe connections with a hammer;

- loosen the bolts of the clamps and move the clamps fastening to the “pants” and the muffler;

- disconnect the resonator from the muffler by undocking the pipes;

- disconnect the resonator from the receiving pipe (“pants”);

- install the new resonator in the correct position;

- connect the parts and tighten the fastening clamps.

Note: the resonator tank must be parallel to the ground, otherwise the part will knock on the bottom of the car and cling to uneven road surfaces.

Replacing the exhaust pipe (“pants”) of a VAZ 2107

When replacing the exhaust pipe, be sure to replace the gasket between it and the exhaust manifold. It is also better to change the nuts securing the “pants” to the manifold. The procedure is as follows:

- loosen the clamp and disconnect the pants from the resonator;

- unscrew the four nuts securing the exhaust pipe to the manifold;

Important: unscrew the nuts carefully so as not to twist the fastening studs. Otherwise, you will have to drill out and replace the studs.

- remove the “pants” (exhaust pipe) and gasket;

- install a new gasket;

- install a new exhaust pipe;

- connect the exhaust pipe to the resonator, tighten the fastening clamp;

- tighten the nuts securing the “pants” to the manifold.

If, after installing a new exhaust pipe, the exhaust system sags or hits the bottom, the following options are possible:

- the resonator or exhaust pipe is fixed at the wrong angles;

- engine mounts sagged.

In the first case, it is enough to loosen the clamps and install the parts correctly. In the second case, the engine mounts will have to be replaced.

Material and manufacturing method

Before you make a muffler with your own hands, you need to decide on the budget and the option for reworking the exhaust system. There are several tuning methods:

- Modification of a new factory muffler.

- Making your own. By the way, you can make a muffler with your own hands using both stainless steel and ordinary steel.

Experts do not recommend using old mufflers or other parts of the exhaust system that have already been used. In this case, even if they look good (after all, they can be repainted before selling), the inside will be covered with corrosion or even burnt out. Remember that with each engine start, the metal in the system heats up and changes its properties. It’s easy to guess what condition a muffler will be in if it’s been used for about 2-3 years on a car. Therefore, do not fall for the tricks of “lightly used” sellers and do not buy a used muffler. Best of all, make it yourself.

A less expensive solution from a financial point of view would be tuning the standard muffler. Making a part with your own hands from stainless steel is a very reliable, but expensive option. However, such an element will be more durable and will not burn out at the most inopportune moment.

Exhaust System Mounting Parts

The clamps and suspension elements of the exhaust system are exposed to moisture and salt during machine operation. In addition to corrosion, metal “fatigue” accumulates in clamps. The clamps begin to loosely hold the connection, as a result of which exhaust gases begin to break out, creating noise. Old suspension cushions may break off, which can damage exhaust system parts. Therefore, it is advisable to change the mounting parts; whenever large parts are replaced, the mounting elements on which they are attached should also be changed. This will avoid unnecessary problems and expenses.

Why is a homemade element better than a factory one?

Due to the large number of fakes, it is very difficult to find a truly high-quality spare part today. And if such a part is found, the price for it will be simply exorbitant. Moreover, most of the complaints concern the elements of the exhaust systems. The muffler rusts and burns out very quickly. Its service life does not exceed 1-2 years. It doesn’t matter how intensively you use your car. It burns out not from mileage, but from time. Even if the car is driven once a week, this will not add life to the muffler. It will still have to be changed in a year or two.

After this time, car enthusiasts have a question about the need to replace or repair this part. If you repair the muffler yourself or make it from scratch, you can be sure that it will last much longer. After all, we will not skimp on important materials. Also, by making a muffler with your own hands, you can add your own configuration to the exhaust system. For example, make a forward flow to increase engine power. However, driving long distances with such a “can” will be uncomfortable. Therefore, you can remake the system in a different way by adding an additional resonator to it. This way the machine will run much quieter.