If the car cannot start, the engine compartment begins to hum and howl, or the car periodically stalls with or without load, this may indicate a breakdown of the generator. Removing and disassembling your humming generator is the last thing; first you need to understand the main faults and causes. There may be two types of breakdowns that require repair of generators - mechanical and electrical types.

The main mechanical damage includes breakdown of fasteners, the device body, problems in the operation of bearing devices, pressure springs, and belt drive. In principle, there are very different reasons for the malfunction of a mechanical generator, but one way or another, they are not related to the electrical part. As for electrical breakdowns, these include malfunctions of windings, diode bridges, failure of brushes, short circuits, breakdowns, problems with relay operation, etc.

As practice shows, quite often symptoms indicating a failure of the generator device may appear as a result of other problems. For example, if there is a poor connection in the fuse connector, you may think that the problem is with the device. But the same symptom can appear as a result of burnt out contacts in the ignition switch. In addition, if the device failure lamp is constantly on, this does not mean that there are problems with the generator, since this may indicate a relay failure.

A short list of typical generator malfunctions

To begin with, we will briefly list the characteristic malfunctions of a car generator without any explanation. This will make it possible to assess in general terms, so to speak, the scale of the disaster. It is quite possible that some of the breakdowns listed are already familiar to you. As a rule, these include those that occur very often, and almost every first-time car enthusiast with little experience has encountered them at least once.

So, here are 10 typical car generator malfunctions:

- Poor contact or damage in the battery charging circuit.

- Slipping or broken drive belt.

- Worn or damaged rotor bearings.

- Worn or stuck brushes.

- Wear of slip rings.

- Incorrect operation or failure of the voltage regulator relay.

- Interturn short circuit or break in the generator windings.

- Breakdown of the rectifier bridge diodes.

- Broken rectifier bridge diodes.

- Insufficient generator power.

We will return to a detailed consideration of each of these breakdowns later. As well as the symptoms by which these malfunctions can be identified.

Common battery problems

Modern batteries are quite reliable and simple to use. Most often, their malfunctions are associated with violation of operating rules or mechanical damage.

The most common failures that occur are:

- A crack in the housing through which electrolyte leaks.

- The top panel is dirty causing current leakage.

- Incorrect polarity setting.

- Damage or shedding of plates.

- Short circuit between plates.

- Contact corrosion.

- Break or short circuit of the current-carrying cable.

- Lack of reliable mass.

In addition to improper operation, the reasons for unsatisfactory battery performance can be manufacturing defects and natural aging of the product.

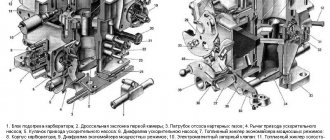

Design and principle of operation of a car generator

First, it would not hurt to at least get acquainted in general terms with the structure of the generator, as well as with the operating principle of this component of the car. Many car enthusiasts, unfortunately, always skip this stage and immediately begin diagnostics and repairs. As a result, due to a misunderstanding (or misunderstanding) of the operating principle, things often reach a dead end, serious mistakes are made, short circuits and more serious breakdowns are provoked than before. It follows from this that the search for and elimination of any malfunctions of a particular component of the car must begin with studying its structure and operating principle.

The car generator is designed and works as follows. Actually, the electricity used to power the on-board network and charge the battery is generated through electromagnetic induction. It is removed from the terminals of the stator windings, inside which the rotor rotates on two bearings. The rotor is driven by the engine crankshaft, to which it is connected by a belt.

The first feature that you need to know about is the uneven rotation speed of the generator rotor. It completely depends on what speed the engine is running at. Accordingly, if the rotor were powered (for excitation) by the same voltage, then at the output of the generator we would receive a jumping voltage, which is unacceptable for the vehicle’s on-board network.

This problem can be solved quite simply. The rotor is not supplied with a stable voltage, but with an adjustable one. A relay-regulator is responsible for this, which “monitors” the voltage at the battery terminals and, depending on the current indicators, adjusts the power supply to the rotor. Roughly speaking, when the voltage at the generator output reaches the upper permissible level (for example, 14.4 volts), the relay-regulator circuit stops powering the rotor. The output voltage drops, the RRN resumes excitation of the rotor, and so on in a cycle with a very high frequency. Due to this, the voltage of the on-board network is constantly maintained at the same level, and does not depend on what speed the car engine is running at.

The second feature of a car generator is that it generates three-phase alternating voltage. And to power the on-board network and charge the battery, it must be constant. To solve this problem, the generator is equipped with a rectifier bridge consisting of diodes. As a rule, the rectifier has six main diodes (two for each phase), as well as three additional ones.

In principle, this knowledge will already be enough to understand the characteristic generator malfunctions described below. Although, for successful self-repair, it doesn’t hurt to delve into the topic using additional sources of information.

Generator repair kit

In order to repair a generator yourself, a motorist will most likely need certain spare parts. However, it can be difficult to find them in a kit - commercially available repair kits for PG contain, as a rule, only washers, bolts and nuts.

Therefore, a craftsman who undertakes the restoration of this unit is often forced to independently assemble the necessary repair kit. Such a set may contain:

- brushes and fastenings for them: from 70 rubles;

- bearings: from 80 rub.;

- voltage regulator: from 330 rub.;

- straightener: from 720 rub.

The entire generator will cost the car enthusiast from 3800 rubles.

Poor contact or damage in the battery charging circuit

In order for the generator unit to operate, it must be securely connected to:

- The positive terminal of the battery.

- Ignition switch.

- "By the mass."

Let's start with the last one. The generator is in contact with ground due to its metal casing, with which it is attached to the car engine. As a rule, in this place the contact is always good, and almost never causes a unit malfunction. However, it should be remembered that the engine itself is connected to the negative terminal of the battery using a wire. And problems very often arise with it.

The most common one is poor contact. In most cars, the ground is connected to the engine somewhere at the bottom. Dirt, moisture, temperature changes, leaking oil and other factors lead to oxidation and corrosion of the connection. This manifests itself in the form of several symptoms.

Firstly, due to poor grounding, voltage drops in the vehicle’s on-board network may occur. The result is a systematic undercharging of the battery. Secondly, significant voltage drops are observed when a serious load is turned on - a stove, air conditioner, subwoofer, headlights, and so on.

Checking the engine ground is very simple. To do this, using a multimeter turned on in ohmmeter mode, measure the resistance between the negative terminal of the battery and any point on the engine. If the device shows more than 0.05 Ohm, the “ground” should be cleaned of dirt and oxides. It may be necessary to replace or even add another wire connected in parallel with the main one. Due to this, the cross-section of the ground wire increases, and very often problems such as voltage drop or undercharging of the battery are solved.

Absolutely the same with the positive power wire of the generator. It goes directly to the battery, and is quite thick. If this wire is damaged or has poor contact at the attachment points, the symptoms described above appear. The malfunction can be eliminated by simply cleaning the contact pads. If the wire is mechanically damaged (as a result of carelessness, corrosion or vibration), then it must be replaced with a new one, respecting the cross-section.

Additionally, the condition of the contacts of the control wire coming to the generator from the ignition switch (thin), as well as the signal wire (on the relay regulator), is checked. Poor contacts at these points also lead to unstable and incorrect operation of the entire battery charging unit.

Main symptom of malfunction

The driver is notified of alternator failure only when the charge level drops below battery voltage. The indicator lamp for lack of battery charging lights up on the dashboard. The danger of the situation is that the vehicle’s on-board network is powered by a battery, which has a limited and, in the event of a generator malfunction, irreplaceable capacity.

Extraneous noise

It is very easy to catch a generator creating extraneous noise when the engine is running - just remove the belt that rotates the generator pulley. If the noise disappears, then the source has been identified correctly. Possible malfunctions and their characteristic symptoms:

- whistling (possibly only when cold) - slipping of the alternator belt. In most cases, squeaking can be eliminated by correct belt tension. Sometimes the cause of the squeak is technical fluids getting on the belt, pulley misalignment, or excessive tension;

- metallic creaking, noise – dry friction of generator bearing parts. Ignoring signs of a worn bearing can lead to it jamming and breaking the service belt. The malfunction is eliminated by installing a new bearing;

- noise bordering on rattling - a malfunction of the overrunning clutch. The inertia pulley is designed to absorb shock loads and extend the life of the alternator belt. As practice shows, a faulty overrunning clutch very quickly leads to a break in the alternator belt.

Stator winding

There are only 3 possible malfunctions:

- short to ground or to the stator housing;

- break;

- short circuit between turns.

For a quality check, you should use a megger, but since the device has a rather narrow specialization, initial diagnostics can be done with a multimeter in resistance measurement mode. Since quite large currents pass through the winding, the best way to check the unit is to use a 220 V light bulb.

When checking, be sure to follow electrical safety rules!

It is more difficult to check an interturn short circuit, since the resistance of a working winding is very low, which does not allow obtaining reliable results when diagnosing with a conventional multimeter. In the case of an interturn short circuit, the winding resistance will be less compared to a working unit. A short circuit can be identified by calculating the resistance using the formula. To check, you need to use a laboratory power supply to pass current through the winding, measure the voltage and current (the method is shown in the video).

Field winding

The condition of the generator rotor winding is checked in a similar way. When checking for a short to the rotor housing or a break, one of the contacts will be the collector. You can detect a break by applying “-” to one contact ring of the collector, and “+” to the other (if the winding is intact, the lamp will light up). Faults in the stator and rotor windings quite rarely lead to generator breakdown, but in the case of comprehensive diagnostics, checking them should not be neglected.

Diode bridge

Cars are equipped with an alternating current generator, but DC current is needed to power the on-board network. It is the diode bridge that serves to rectify the current. There is only one sign of a malfunction - a drop in charging voltage, but it can manifest itself, for example, only when consumers are turned on. It is noteworthy that the breakdown may be accompanied by a hum that increases with increasing engine speed.

Unfortunately, it is not possible to fully check the diode bridge with a multimeter. Using a universal meter, you can find breakdown of diodes and broken contacts, but floating faults that can affect the operation of the generator can only be found using specialized equipment.

The operating principle of a diode bridge is based on the property of a diode to pass current in only one direction (in the event of a breakdown, the current will flow in both directions). Diagnostics can be done with a multimeter in resistance measurement mode. A simple method for checking a diode bridge is well demonstrated in the video.

Voltage regulator relay

The voltage regulator is one of the parts that most often causes generator malfunction. The unit is designed to maintain the charging voltage within limits that are safe for the battery and on-board network. If the design of the generator did not include a relay-regulator, the charging voltage would increase in proportion to the increase in engine speed. It is precisely this consequence of a breakdown of the voltage regulator that is most detrimental to the battery and control units of the vehicle’s electronic systems.

Characteristic symptoms of failure:

- charging voltage drop. Due to a faulty regulator, the voltage on the brushes turns off at lower voltage, so undercharging occurs;

- recharge. The charging voltage should not exceed 14.5 V. Exceeding this value for a long time can lead to overheating of the battery and boiling off of the electrolyte. Therefore, if you notice liquid leaks on the battery case, be sure to check the charging voltage with a multimeter.

The most convenient way to check the voltage regulator is with a laboratory power supply.

Brush unit

During operation of the generator, the brushes are constantly in contact with the commutator plates, which naturally leads to a decrease in their length (the commutator also wears out, but to a much lesser extent). When wear becomes critical and the spring force is no longer sufficient for good contact, the excitation of the armature winding deteriorates. As a result, brush wear leads to a drop in charging voltage.

It is typical that the decline occurs gradually, so it can manifest itself at the most inopportune moment. Under a certain set of circumstances (a dying battery, severe frosts, a large number of cold starts, short-distance trips with many consumers turned on), the emf of the battery on a frosty morning will not be enough to start the engine. Owners of diesel cars should pay special attention in this regard, since the starter requires more current to start the internal combustion engine of the Diesel cycle.

Drive belt slipping or breaking

Drive belt slippage can be caused by several reasons. Firstly, its insufficient tension. Secondly, water from puddles or motor oil gets on the generator pulley. Thirdly, the belt stretches over time, sags, and also begins to slip periodically. As a rule, at first this malfunction appears only when the generator begins to operate under serious load. This happens because as the load increases, the rotor resistance increases.

Very often, belt slippage is determined by a characteristic squeak that is heard when the engine starts, as well as immediately after turning on the load. Quite often this whistle can be heard in rainy weather, which indicates water has gotten on the generator pulley. If this happens, the belt must either be tightened or replaced with a new one.

A broken alternator belt is a more serious malfunction, which it is highly advisable to notice immediately after its occurrence. The primary symptom is the warning light on the instrument panel coming on, indicating that the battery is not charging. This lamp should only light when the ignition is on and the engine is off. In all other modes it does not light up.

A secondary symptom of a broken alternator belt is low voltage on the on-board network. When everything is working normally, the voltmeter should show at least 13.8-14.5 volts. If while driving the voltage drops to 12 volts, this means that the on-board network is powered only by the battery. Conclusion - the generator is faulty.

Check the generator with a multimeter

If a problem occurs, it is fairly easy to check the generator. The charging voltage of the generator is checked with a multimeter:

1. Set the voltage range on the multimeter (up to 15 or 20 V);

2. Connect the black probe to the negative terminal of the battery, and touch the “plus” with the red probe;

3. With the engine off, the car battery voltage should be between 12.2 and 13.6 volts (if the voltage is significantly lower, that is, below 12 volts, it is recommended to charge using a charger);

4. Turn on the engine, the charging voltage should increase and be between 13.4 and 14.8 V at idle;

5. Then repeat the measurement at 4,000 rpm, the voltage should remain constant.

If the voltage does not rise to the specified values when the engine is on (after a few seconds), this indicates a malfunction of the generator. To prevent damage to the wiring, you can check the measurements on the generator contacts. If there is a clear difference, the wiring must be checked! If the voltage is noticeably higher than the value measured at idle and 4,000 rpm, this indicates a problem with the alternator regulator. In this case, the battery may overheat and damage the on-board electronics.

Worn or damaged rotor bearings

When the generator rotor bearings wear out, several problems can arise. Firstly, due to a violation of the axis of rotation of the armature shaft, it begins to touch the stator with its windings. Secondly, due to significant wear, the bearings may even jam and the rotor will stop. The first problem will first lead to voltage drops in the on-board network, and later to an interturn short circuit in the stator. What happens when the bearings jam is already clear. The rotor will stop.

In most cases, wear of the generator bearings can be detected in advance by a characteristic hum coming from under the hood. This sound can change volume and tone depending on what load is currently placed on the vehicle’s on-board network. That is, for example, when the headlights are turned on, the hum can increase significantly, which makes it possible to identify a malfunction in advance.

To avoid the problems described, it is highly advisable to periodically check the bearings for play. To do this, just grab the generator pulley with your hand and shake it from side to side. If the bearings are in good condition, there should be no play.

How not to break the generator

The previously popular method of testing PG with disconnecting the battery is completely unsuitable for modern cars and is even dangerous for them. Sudden voltage drops resulting from such studies can render the entire electronic content of the machine inoperative. Therefore, the generator should be diagnosed either by measuring the battery voltage or using a special stand.

In addition, in order not to once again expose the generator to the risk of breakdown, it is advisable to avoid:

- using a voltage of more than 14 V to test the electrical circuit of the unit;

- contact of the generator pole with its body even for a short time;

- flooding the device with water, oil, coolant and other liquids;

- damage to the power unit housing when installing it on a machine or as a result of the device being dropped;

- equipping the machine with additional equipment if this leads to energy consumption exceeding the capabilities of the power plant;

- using the unit with a faulty or discharged battery, unreliable electrical wiring of the car, problems with the car computer.

Conclusion

In principle, repairing a car generator should not be particularly difficult for a car enthusiast, although this process is not quick and requires due attention. And before disassembling this device, it is advisable to carry out a detailed diagnosis of it, which includes an external examination of the control unit, as well as checking its electronic components. Most often, brushes with bearings break in the unit; the rectifier and relay are less capricious. And to prevent the drive belt from breaking at the most inopportune moment, you should periodically check the tension and condition of this part.

Video about generator problems:

Worn or stuck brushes

Brushes are needed to supply power to the constantly rotating generator rotor. As a rule, together with the relay-regulator they are one separate part. The brushes are made of conductive graphite and are spring-loaded to ensure reliable contact with the commutator. If the contact between them and the slip rings is poor (or absent), the generator will not be able to work normally (or will not work at all).

The most common problem with brushes is their natural wear. When the graphite wears away, the brushes are simply not long enough to power the rotor. As a rule, at the initial stage, this malfunction manifests itself in the form of abundant sparking inside the generator. Due to wear, the brushes do not always come into close contact with the commutator, and sparking occurs between these parts.

The second characteristic malfunction of the generator is associated with the so-called freezing or sticking of the brushes. This happens due to graphite dust or other dirt getting into the brush guides. The latter become motionless, and therefore can no longer be pressed by springs to the collector. As a result, increased sparking is first observed, and then the generator stops generating electricity altogether.

Along with sparking, critical wear or sticking of brushes can be detected by voltage drops in the on-board network (if there is a voltmeter in the cabin) or by a warning lamp on the instrument panel. It should also be noted that this malfunction can be identified visually without removing the generator from the car. The brush assembly, as a rule, can be easily removed together with the relay regulator, as it is secured with two screws. If the brushes are worn out, then this is only a replacement. Sticking can be eliminated by cleaning the guides of graphite and other dirt.

Where are the generator brushes located?

Changing generator brushes is not difficult. They are located in the rear half of the device and are held in place by a single bolt. The brush assembly itself is located next to the slip rings and is connected to the voltage regulator. The brushes are held in place by springs next to the rings. Knowing the circuit diagram of the generator, it is not difficult to find the brushes. To replace, you will need a standard set of tools:

- Several wrenches;

- A pair of screwdrivers;

- New brushes;

- Liquid WD-40 (in order not to strip the threads of the bolts).

The brushes can be replaced in two ways, by removing the generator or without removing it. The design of the car, or rather the location in the engine compartment, will tell you which method is best to use. If there is free space, it is not difficult to repair the generator brushes without removing the unit, and if the engine occupies the entire engine compartment, it is impossible to do without removing the generator.

Wear of slip rings

The slip rings are located on the generator rotor shaft. They are designed to transmit power from the brushes to the armature winding. The rings are made of copper and therefore are subject to wear and tear over time. The symptoms of this malfunction are absolutely the same as in the case of brushes - sparking, voltage sags, as well as complete generator failure. To clarify the diagnosis and eliminate the breakdown, dismantling and complete disassembly of the unit is required. Fortunately, on many common generators these parts can be changed without problems and are relatively inexpensive.

Features of generator repair

In case of problems with the PG, the parts that cause the breakdown are usually replaced. Broken brushes and bearings are replaced with serviceable ones without any hesitation. A reason to update the belt may be:

- break;

- loss of elasticity;

- deformation;

- expiration of the established period of work.

Rewinding of faulty generator windings is sometimes found in the list of services offered by car mechanics or services. But taking into account the cost of such repairs and the reliability of the result, as a rule, the entire rotor or stator is replaced.

Incorrect operation or failure of the PRN

The voltage regulator relay “suffers” from several types of breakdowns, which are quite easily diagnosed even without disassembling the generator. The first sign of its malfunction is low voltage on the on-board network. Drawdowns can be observed both without load and with it. This happens due to the fact that the electronic components in the relay-regulator circuit burn out.

The second known sign of a unit malfunction is that the generator does not work at all. This is determined both by the warning lamp on the instrument panel and by the readings of the on-board voltmeter. The latter in such cases begins to show a voltage of around 12 volts. As the battery discharges, the performance decreases noticeably.

It is worth noting that most of the described generator malfunctions manifest themselves in approximately the same way. In particular, low voltage and a lit warning lamp may indicate either a failure of the relay-regulator or other failures. To identify the fault more accurately, there is a fairly simple method for checking the voltage regulator relay. It is performed using an adjustable power supply and a multimeter according to the following algorithm:

- The relay regulator is removed from the generator.

- A multimeter is connected to the brushes in voltage change mode (you can also use a 12-volt test light).

- The negative of the power supply is connected to the ground of the relay regulator.

- The plus is fed to the wire that comes out of the relay regulator.

- The power supply voltage rises to 14.0-14.5 volts.

- When this voltage is reached, a working relay-regulator should operate - the control lamp connected to the brushes goes out.

If the control lamp does not light up at all at any voltage, there is a break in the relay-regulator. If the lamp does not turn off when the control voltage is reached (14.0-14.5 volts), but continues to glow further, this is called a breakdown of the relay regulator. In practice, the first outcome means the battery is undercharged, and in the second, it is overcharged (with boiling, swelling of the case, and even an explosion).

The so-called new type relay regulators (with two wires) are a little more difficult to check, but possible. The difference is that the second wire must be supplied with a simulated alternating voltage during testing. How to do this at home can be found on the Internet.

Self-test of the generator

First check the fuse box. Then the wires leading to the generator are inspected for breaks, short circuits, etc.

The contact assembly is inspected. Check whether the rotor rotates normally and that there is no damage to the housing or pulley.

If charging disappears completely or becomes unstable, check the tension and wear of the drive belt.

Visually, it may be quite working, but due to the maximum output, it slips on the pulley, which is why the generator, although it rotates, cannot provide normal charging.

To check, you can loosen the mount of the generator and briefly tilt it with a lever so that the belt is very tense.

If the warning light goes out, the belt needs to be changed. Please note that you cannot tighten the generator in such a position that the belt is constantly tensioned without deflection - there is a risk of breakage.

With the engine not running, unscrew the brush assembly. The brushes may be worn out or burnt out. At the same time, check the slip ring for wear.

To do this, shine a flashlight and rotate the generator pulley by hand.

Checking the generator slip ring.

If the generator makes a rattling hum or howl while the engine is running, then this is a sign of problems with the bearings. They need to be replaced.

If this is not yet possible, then try removing the sealing cap and applying high-temperature grease (Litol) to the balls.

20 best lubricants for cars

Replacing the grease on the bearing.

If everything is fine, but there is still no charging, you need to check the rotor and stator.

Turn the multimeter into resistance test mode and touch both slip rings with the probes. The device should show 1.8-5.0 Ohm.

If the value is higher, there is a break in the winding; if it is lower, a short circuit has occurred. Also connect one probe to the steel mass, and the second to the first, then to the second slip ring. If the resistance is close to 0, there is a winding short circuit to ground.

Checking the rotor with a multimeter.

The stator check is carried out in the same way. The winding leads must be disconnected from the rectifier unit (to do this, you need to remove the back cover of the generator).

Measure the resistance between the winding terminals in pairs - they should be around 10 Ohms. If less, there is a short circuit in the turns; if more, there is a break.

Also check the resistance between the terminals and ground - if it is low, then a breakdown has occurred.

Checking the stator with a multimeter.

In order to check the diodes, their leads must be disconnected from the stator windings.

Testing with a multimeter is carried out in diode or resistance test mode. Each diode is tested by connecting probes to both terminals.

Then the position of the probes changes. If there is no resistance in one position, but in another it is close to infinity, the part is working properly.

If the resistance in both positions is close to 0, the diode is broken; if it is close to infinity, a break has occurred. The diode needs to be changed.

Checking diodes with a multimeter.

The relay regulator can only be checked on a bench. Usually, if all other nodes are fine, then the problem is there.

Breakdown or breakage of the rectifier bridge diodes

Let us recall that the diode bridge serves to rectify the alternating voltage generated by the stator windings of the generator. Since there are three phases in a car generator, the bridge also consists of three branches - two diodes in each. When a breakdown of one of the diodes occurs, a sharp increase in voltage in the vehicle’s on-board network may be observed. A breakdown is when a diode begins to pass current in both directions, but should only pass in one.

A break in the diodes of the rectifier bridge does not threaten anything catastrophic, unlike a breakdown. For example, if one of the diodes breaks, then only two of the three phases continue to work. If there is no heavy load on the on-board network, then this malfunction may not be noticed. However, when the load is turned on, the power of the two phases is no longer enough, and therefore there is a drop in the on-board voltage.

It is clear that if all the diodes break, which does not happen very often, the generator stops functioning completely. This can be seen both in the voltage of the on-board voltmeter and in the warning lamp on the instrument panel. To more accurately check the bridge diodes, you will need to dismantle the generator and partially disassemble it.

Generator brushes: what function do they perform?

When in contact with the slip rings located on the rotating rotor shaft, the generator brushes transmit current from the battery to the rotor field windings. This is how an electromagnetic field is created.

Popular brands:

Audi Q7, Chevrolet Cobalt, Citroen C5, Hyundai Elantra

Under the influence of the alternating magnetic field of the rotating rotor, an electromotive force is induced in the coils of the stator windings and an alternating electric current is created. The current passing through the diode bridge (rectifier block of the generator) is converted into direct current. This is exactly what is needed to recharge the battery and ensure the functionality of the car’s electrical equipment.

Insufficient generator power

A fairly common problem nowadays, which, in fact, is not a malfunction. It lies in the fact that after installing any powerful non-standard equipment on a car, wild voltage drops are observed. These symptoms may well indicate that the power of the existing generator for the load placed on it is not enough.

This is most often observed after installing powerful acoustics, xenon headlights, an inverter that allows you to get 220 volts on board the car, and so on. This “malfunction” can be eliminated very simply - by selecting and installing a more powerful generator. Unfortunately, such a decision is often reached when the standard generator cannot withstand the load and burns out.

How to remove brushes from a generator located on a car

If the previous owner installed a brush block with a relay regulator in the generator, then the question of how to change the brushes on the generator without removing it from the car is much easier to solve than replacing individual brushes. If there is sufficient space in the engine compartment, it is also possible to replace the brushes separately without having to remove the generator.

All work on the vehicle's electrical equipment should begin by disconnecting the battery.

- The voltage regulator is removed;

- The production of brushes is measured;

- Old brushes are unsoldered;

- Contacts are cleaned;

- New brushes are soldered;

- The free movement of the generator brushes is checked;

- The regulator is installed in place;

- We connect the battery and start the car.

If everything went without errors, you won’t have to worry about how to check the generator brushes for a long time. Now, knowing perfectly the structure of the generator after disassembling it, it will not be difficult for you to fix other generator malfunctions with your own hands.

Brief summary

Most of the typical malfunctions of a car generator are very easy to identify and fix even without relevant experience. If the generator is working, but the problem is reduced only to voltage sags or sparking in the brush assembly, it can be solved by cleaning the contacts or replacing the relay regulator. Extraneous sounds from the generator can be eliminated by tightening or replacing the belt, as well as installing new bearings. Other faults - short circuits in winding turns, breakdowns and breaks of diodes, etc. - are best left to specialists, since their elimination requires not only bare knowledge, but also experience.

Repair and troubleshooting

Almost all generator malfunctions can be corrected by replacing components. Most of them are beyond repair.

This applies primarily to such parts as brushes (the entire brush assembly is often replaced), relay regulator, bearings, drive belt, pulley, and housing parts.

Most often the belt needs to be replaced. This must be done every time its service life expires, even if it seems to be working.

Brushes also require periodic replacement. On older generators it was also necessary to grind the rings.

On new models, if the rings wear out or burn out, the entire rotor will have to be replaced.

The windings are changed as a whole unit. Previously, they were usually rewinded, but this only makes sense for very rare models, otherwise rewinding would cost more than replacement.

It should also be taken into account that problems with undercharging the battery may not be caused by the generator.

If you recently installed a new electrical appliance, the reason may not be this, but specifically too many consumers for which the generator power is not enough.

The battery also requires checking. Perhaps the contacts are burnt, oxidized or weakened, electrolyte has leaked through a crack, the battery does not take a charge due to old age, etc.

Conclusion

Any malfunctions with the vehicle's power supply require the fastest possible correction.

It is permissible to continue driving to the nearest place where the fault can be repaired or to a garage if it is nearby.

Too much voltage can lead to damage to batteries and electrical appliances.

The generator is the most actively loaded electrical component

While the car is moving, the generator shaft speed reaches 10-14 thousand revolutions per minute.

This is the highest rotation speed among all car components, 2-3 times higher than the engine speed. The service life of the generator is approximately two times less than that of the engine: approximately 160 thousand kilometers.

There are two types of generators:

- alternator (used in most passenger cars)

- DC generator (used on most commercial vehicles)

Diagnostics of the voltage supplied by the generator

If, as a result of a visual inspection, you do not find anything suspicious, further checking of the generator on the car should be carried out using electrical measuring instruments. They allow you to measure the output voltage under various operating modes of the device, on the basis of which you can judge the likelihood of certain problems occurring. It is best to use multifunctional testers for these purposes, since with the help of a multimeter you can analyze all the parameters of the current generated by a car mini-power station.