Many of us have heard about such a thing as car chip tuning. The thing is very good, it allows you to improve the characteristics of the car without resorting to any physical changes. Do-it-yourself chip tuning is possible, but in order to do it efficiently and not break the unit, you will have to buy some equipment, which, by the way, is not that expensive.

Of course, if you change the engine, install sports camshafts, forged pistons, etc. and at the same time perform chip tuning, then it will drive even better. In this article we will not consider this option, but will consider do-it-yourself chip tuning of a stock car.

Equipment for chip tuning

In order to implement chip tuning of VAZs, we will need special equipment. I became interested in this topic for a very long time, but there was no opportunity to test it thoroughly, since there was no suitable equipment, but recently I was lucky enough to become the owner of such a set of equipment for chip tuning (PAK loader v.3.0). Naturally, I immediately wanted to flash something. And the first car I flashed was a VAZ 2107.

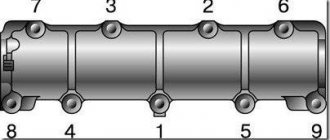

The seven was 2007 and the brains there were January M7.3 Avtel 21067-1411020-21 open type. The native firmware was A327RC07.

After reading various forums, we decided that we would install the firmware based on our native software; the choice fell on the Euro 2 firmware from Sergei Vasilyevich. According to the author, this firmware provided good dynamics and optimization of consumption.

Cleaning and preventing plaque in the system

The injector device is very sensitive to large inclusions in gasoline. If you are using a cheap brand of fuel, be prepared to change your injectors soon. So the first thing you should do for your VAZ fuel pump is change the brand of fuel. The power supply system of the VAZ 2107 should become cleaner; the possibility of plaque formation in the system is still not excluded. Since the flammable liquid in the channels occasionally stagnates and sometimes even freezes, an early breakdown can be prevented only in one way - regular cleaning.

Approximately every 35-40 thousand km it is necessary to carry out preventive cleaning work on the fuel system. You need to wash the channels with your own hands. The performance of the engine will depend on the quality of cleaning. If this procedure is carried out irregularly, then soon you can say goodbye to one injector and look for a new one, and then you will have to change the remaining elements of the VAZ fuel pump.

In 4-cylinder types of injection engines, different intensities of injector clogging are observed. The temperature in the area of cylinders 2 and 3 is always elevated, so sediment accumulation occurs there faster.

A special admixture of polyetheramine is considered a prophylactic agent in such cases. It prevents the accumulation of burning for a long time.

Flashing process

At first they wanted to install the Euro 0 firmware, but then they found out what the difference is between Euro 2 and Euro 0 and the choice became obvious. The fact is that firmware Euro 0 completely disables engine regulation from the catalyst sensors, and the engine’s adaptation to changes in gasoline, wear, etc. is also lost. Euro 2 still has one working catalyst sensor and engine adaptation is not lost, while Euro 2 does not choke the engine as much as, say, Euro 3 (two DCs). By the way, the native firmware is adapted for Euro 3.

So, we decided on the firmware for chip tuning the car, but there was one small problem. The basic configuration did not include a loader or a module that would allow sewing M73 blocks. I had to buy it separately. After this, the ECU was flashed.

We flashed it directly in the car by connecting to the car outlet. Since a special program for flashing came with the equipment, we flashed it using it. The whole process took no more than 5 minutes. After the firmware, we turned off the equipment and went to test and see the results.

Injector purpose

Installing an injector in the VAZ 2107 made it possible to significantly improve engine performance. Changing the type of fuel system increases the amount of energy that is produced during the combustion of gasoline. Compared to a carburetor engine, a fuel injection system is more efficient in the initial stages, but over time its performance decreases. What does this depend on?

VAZ 2107 injector plays the role of the final element in the fuel system of the car. The air mixture, together with a cloud of atomized gasoline, creates a huge amount of energy. Over time, this atomization may become less effective, the fuel jets will become weaker, and all due to low-quality gasoline.

The main cause of injector failure is poor fuel. Car fuel consists of many chemical components; in addition, various impurities are added to it, which should improve the overall performance of the engine. This factor cannot be ignored, since such gasoline leaves sediment on the walls of the fuel system. The thinnest channels are in the injectors, and it is these devices that suffer first. VAZ 21074 injector has the same problem. During operation, deposits from fuel only accumulate. What needs to be done to stop this?

Chip tuning results

According to the OpenDiag program, the consumption became approximately 0.8-0.9 liters per hour. I don’t know how accurate this figure is, but in other similar firmware (including from the icebreaker) the consumption was 1-1.2 liters. per hour, that is, more.

As for increasing the dynamics of the car, at first glance nothing has changed for the better. I was even a little upset that there was no result. A few hours later my friend called me and said in a joyful voice that she had gone. According to him, there were changes, and they were colossal. The car began to tear from first and second gears, the gaps between gear changes stopped - the car came to life. In general, everyone was very pleased. Apparently, after reflashing the ECU, there was no such result from the very first start, due to the fact that adaptation to the new program had not yet taken place.

A little information from the author of the firmware: Firmware properties

1. Idle speed – 880. Idle speed during air conditioning – 1000. Slightly increased idle speed (by 40 rpm), combined with some of our own developments and solutions, gave smoother and softer engine operation at idle. This was not done by enriching the composition of the mixture in the XX mode (usually it is the mixture that is greatly enriched for “softness”). This solution is especially relevant for eight-valve engines with their eternal imbalance of output across the cylinders due to the poor quality of the timing belt. 2. Maximum engine speed. On all firmwares, the electronic rev limiter is set to 7000 rpm. No comments, if we don’t need so much, we don’t play it. But almost everyone asked to raise the bar to this level. 3. Turning the coolant fans on and off. Classic: on — 99 gr. off — 96 gr. As you know, the operating temperature of the engine when driving is usually around 85 - 95 degrees. All main modes in the ECM control program are based on this temperature. But the switching on of the coolant fan is shifted to a higher temperature - 101 (in new systems) and 103, 105, 107 degrees. in most older systems, this is motivated by improved engine efficiency. What kind of engine efficiency and what improvements can we talk about if these high temperature conditions usually occur in the hot season, when driving slowly or in traffic jams. The movement of liquid is not an instantaneous process and in order to reduce the engine temperature from 107 degrees, it takes some time until the hot liquid is squeezed out of the engine by the pump, passes through the radiator and returns to it cooled, the engine is exposed to an unreasonably high temperature regime. In addition, at low speeds, the pump has a minimum rotation speed and therefore minimum performance. Observing the temperature in the scanner, you can see that it does not decrease immediately when the fan is turned on, but continues to rise for some time - by a couple of degrees (displacing the hottest liquid from the cylinder head), then freezes and then begins to decrease. The most common malfunction in old cars is a leak in the cooling system (bad expansion tank cap, etc.). At the required pressure in the cooling system, liquid or water boils somewhat later than 100 degrees. Rarely does anyone pour good antifreeze or antifreeze into such cars; they often drive on ordinary water, so in the summer these cars begin to boil. At 100 gr. the liquid quickly expands and is thrown out through the expansion tank plug, and the fan is silent... There is no need to heat the engine above the boiling point of the liquid, there are no benefits in this, only problems. 4. Gasoline. All firmwares were tested on 92 gasoline. There is no detonation on all the presented firmware with a minimum grade of 92 gasoline, this can be seen from the reviews. The firmware is capable of handling even less-than-high-quality gasoline; the regulation margin is sufficient. If desired, you can use the 95th. 5. Oxygen sensors (lambda probes). Only the Bosch MP7.0 ECU does not allow you to physically disable the DC. There must be a DC in the ECM wiring whose heater is working; the sensor itself may be unusable and not generate a signal. All other ECUs and firmware allow you to physically remove the DC. If the firmware is equipped with Euro-2 (with the original configuration of the car E-3), then DK-2 can be physically removed from the wiring. If the firmware is Euro-0, then you can delete both DCs. You don’t have to physically remove them; they won’t interfere with anything. 6. Dynamic and static characteristics. Much attention was paid to the “little things”, the fight against hard impacts to the transmission in all M73 software for modifying engines 1.6l 8kl, 1.6l 16kl. It was necessary to recalibrate such innovations that were not accepted and not understood by car owners, such as a delay in the drop in speed when changing gears, leading to a jerk forward when releasing the clutch pedal or the speed “hangs” in the region of 1100-1300 rpm. when driving slowly in 1-2 gears with the gas pedal released. By recalibrating all torque characteristics, static modes, dynamic corrections of SOP and fuel supply, changing the principle of enriching the mixture depending on speed and load, and introducing a combined injection phase, it was possible to significantly increase the dynamics of acceleration in all modes and at the same time slightly reduce the average fuel consumption. In systems with a cable-actuated throttle valve, in my firmware, the mixture maps and transient modes are configured so that the increase in richness depends on the speed and load, and the mixture does not suddenly fall into a very rich state when the gas pedal is pressed at low speeds and high loads. In such cases, other calibrations work, designed for this purpose - calibrations of transient modes and enrichment during acceleration. They work only when the ECU sees the acceleration mode, and not constantly - during uniform movement. The composition of the mixture is smoothly enriched depending on the increase in load and speed, thus achieving rational and complete use of fuel with maximum efficiency. Perhaps someone likes it better when, when entering the power mode, there is a push forward and a kind of pick-up is felt (in this case, shocks inevitably appear in the transmission in transient modes), but this is an extremely suboptimal operating mode, leading to ineffective excessive fuel consumption for the sake of fraudulent impression. Acceleration is considered ideal when, throughout the entire travel of the gas pedal, the speed and torque increase linearly, evenly and powerfully. Without “pecks” and “plugs”, sharp pick-ups leading to impacts in the transmission. With this approach, the car accelerates “softer” at small throttle openings and faster at further openings, and the acceleration itself is predictable and easily controlled, and fuel is consumed most optimally.

Damage diagnostics

How to understand that an injector needs to be replaced, checked or repaired? Even without sensors, you can understand that repair of fuel system elements is required if there are 1 of 2 main signs in models 2107, 21074:

Sometimes it is impossible to determine on your own where the damage is, and only then will diagnostics at service centers come in handy. A blockage can cause quite serious damage to the VAZ 2107 injector, as well as rupture of channels. The pressure that arises inside the system can easily destroy the most fragile parts. Here you won’t be able to fix the situation with your own hands, even if you have a complete diagram of the car at hand. There is only one conclusion - you need to devote a lot of time and attention to cleaning injectors and do it regularly.

What does chip tuning give?

The Togliatti model (VAZ 2107) is popular, despite the large number of modern cars of this class. This is explained by the low price of the car, low cost and ease of repair and maintenance, and high reliability. The engine characteristics are similar to other domestic models, so chip tuning differs little from the tuning process of other VAZ or GAZ models.

Dynamic characteristics and gasoline consumption on “classic” VAZ models have always been at a low level. Many owners of fuel-injected "sevens" strive to adjust power, "gluttony" and other indicators using chip tuning.

16-valve engine for the "seven"

The VAZ 2107 is equipped with an 8-valve power unit from the factory. Of course, one of the easiest tuning methods is to replace it with a 16-valve engine. Traditionally, the engine from the VAZ 2112 is chosen, since it is almost identical in size to the engine from the VAZ 2107 and meets all the requirements for power and efficiency.

Installation of a 16-valve engine on a “seven” is carried out according to the following algorithm:

- Prepare the motor for installation. To do this, you need to remove the flywheel and grind the crown from the inside. Turning is necessary so that the starter parts are more easily connected to the flywheel clutch. In addition to turning, you will need to replace the input shaft bearing with a bearing from 2112, otherwise the new engine simply will not fit into the seat.

Video: installation procedure

A 16-valve engine instead of an 8-valve is the best option for those drivers who want to feel quick feedback from their actions while driving, optimize engine power and the resource of the entire car as a whole.

Thus, any type of tuning of the VAZ 2107 engine can turn the car into a faster and more durable model. However, when performing any type of work, you must adhere to regulations and safety precautions; otherwise, it is better to contact experienced specialists.

Selecting a chip tuning program for the injection model VAZ 2107

Specialists from tuning studios and enthusiasts have developed many versions of software for chip tuning the VAZ 2107. However, not all existing programs are recommended for use. The firmware can be “specialized”, for example, significantly increasing the dynamics with a sharp increase in fuel consumption and a decrease in engine life. Some firmware simply does not meet quality standards and does not perform the declared functions, sometimes even worsening engine performance.

It is better to use proven programs recommended by experts. Poor quality software can cause problems in the operation of the electronic control unit, injector, exhaust tract and other parts of the machine.

Therefore, it is advisable to carry out chip tuning of the engine ECU in specialized workshops. In this case, specialists will first carry out diagnostics of the engine, injection system, exhaust gas removal and other systems, after which they will offer the optimal firmware version for a particular car. High-quality tuning does not in any way impair the life of engine parts, electronic control unit or injection system. Installing tuning software helps reduce gasoline consumption and increase the wear resistance of the power unit.

Chip tuning is a reversible, but very responsible operation. Therefore, if you do not have the necessary skills and equipment, the best decision would be to contact a car repair shop that specializes in software tuning of cars.

ECU 21067-1411020-21 VAZ 2106-07 (8V; 1.6L, E 3) (electronic engine control unit) M73

Dear customers, in order to avoid errors when sending an electronic engine control unit (ECU, ECM, controller), in the “Comment” line please indicate your car model, year of manufacture, emission control system that complies with Euro 2, Euro 3 or Euro 4 standards » engine volume and number of valves.

The Electronic Engine Control Unit (ECU) is the “computer” that controls the entire vehicle system. The ECU affects both the operation of an individual sensor and the entire vehicle. Therefore, the electronic engine control unit is very important in a modern car.

The controller firmware in the photo and availability in the warehouse may differ. When ordering, please specify the required firmware.

The following firmware versions are available:

M73 controllers / 21067-1411020-21

| Software ID | ECU | VAZ number | Engine | Toxic norms. | Note |

| M73 EURO-III. ECU manufactured by Avtel | |||||

| A327RA02 | M73 | 21067-1411020-21 | 21067 | Euro-3 | 1 Serial for classics. |

| A327RB06 | M73 | 21067-1411020-21 | 21067 | Euro-3 | 2 Serial version of the classics. |

| A327RC07 | M73 | 21067-1411020-21 | 21067 | Euro-3 | 3 Serial for classics. |

| A327RD08 | M73 | 21067-1411020-21 | 21067 | Euro-3 | 4 Serial for classics. |

Product Features:

The electronic engine control unit (catalog designation from NPP AVTEL, Kaluga 21067-1411020-21), using various signals from engine sensors, controls the composition and amount of fuel supplied to the engine.

Electronic engine control system for cars of the LADA 110, LADA SAMARA, LADA 2105, 2107 families with an M73 EURO-3 controller - device and diagnostics

Click to open

Other article numbers of the product and its analogues in the catalogues: 21067141102021, 21067141102022.

VAZ 2104, 2105, 2106, 2107 with engine 21067 (8V; 1.6L, E 3).

Varieties of electronic engine control systems (ECM, controllers), which are installed on different models of the VAZ family car.

How does a malfunction of the electronic engine control unit (ECU, ECM, controller) manifest itself in a VAZ family car.

How to independently replace the electronic engine control unit (ECU, ECM, controller) on a VAZ family car.

With the online store Discounter AvtoAzbuka, repair costs will be minimal.

Don't forget to share the information you find with your friends and acquaintances, as they may also need it - just click one of the social networking buttons below.

Tags: m7.3

Comments 51

It feels like two cylinders are failing while driving, but after turning the ignition key off on it starts to work normally

I had the same problem. Replaced the ignition unit. And I also changed the wires for the spark plugs. One wire almost fell off there. This is not visible visually, but when I pulled it, it tore without much effort. It helped...

hello dear, please give me a hint VAZ 21 07 inzhetor you pick up speed 90 fifth goes km 2 then there is a loss of power while driving, turn off the ignition key after a second, turn on the car again normally

While walking around a Chinese online store I came across this thing: ELM327 OBDII V1.5 CAN-BUS Bluetooth for $9. The device supports: ISO15765-4 (CAN) ISO14230-4 (KWP2000) ISO9141-2 J1850 VPW J1850 PWM Will this thing work on a VAZ 2107 2008?

Source