The Gazelle is exactly that hard-working car that is used all year round, regardless of the weather conditions outside. For the winter season, it is necessary to prepare such a car especially carefully so that it is comfortable to move around in even in severe frosts. A gazelle can carry not only cargo, but also people, so the heater must be in working order and provide a flow of warm air from the engine compartment.

How to repair the heater dampers on a Gazelle

The stove is an integral element of almost any car. If you live in a region where there is such a thing as winter or just cold, then it will be impossible to drive a car without a heater.

GAZelle cars are widely used in Russia, due to their low cost and ease of maintenance. It is quite possible to carry out a lot of repair and restoration work with your own hands, without turning to specialists for help.

One of the common problems is a malfunction of the stove. And there could be many reasons. One of them is problems with the dampers.

Symptoms of malfunction

To restore or reset the damper, returning it to a working state, you must first make sure that the fault lies in these elements of the heating system of the GAZelle car.

With the onset of cold weather, many GAZelle car owners note this situation. Staying in place with the heater on, the interior warms up quite well and the car is warm inside. But as soon as the car starts moving and starts driving, all the accumulated heat is gradually blown out, the cabin becomes cold, and the working stove cannot restore the previous temperature.

At the same time, everything works fine, there are no complaints about the electric fan of the furnace equipment, the regulators also work properly.

In a situation like this, when the heater is functioning, but the heat still disappears from the car while driving, there is a high probability that the heater is working, but the damper needs to be repaired or replaced. The repair itself cannot be called complicated, but for comfortable work it is recommended to remove the old or new type of heater casing on which the dampers are located, and replace them under more convenient conditions.

Where are the dampers located?

If the problem situation is related to the dampers of the GAZelle stove, they will need to be dismantled or repaired. In most cases, when it comes to mechanical malfunctions and breakdown of the unit, replacement is provided. It's not difficult to carry it out.

It is not difficult to understand the peculiarities of the operation of the stove dampers on a GAZelle. But they can be the main reason for the poor operation of the heating system if the electric fan and other main components, including the stove radiator, are working properly.

The dampers are located directly inside the heater. If you are from the driver's seat, the flaps can be seen on the right side of the electric fan housing. To get to it you will need to remove the large glove box on the passenger side. But this does not guarantee full access to the node.

To carry out more serious repair and restoration work, it is better to get to the electric fans of the heating system and carry out the repair in comfortable conditions.

Repair of main components

Repair of parts and the entire engine cooling system can be found in the ZMZ 405 repair manuals. The most common system breakdowns are the water pump and thermostat. Replacing the pump is quite simple:

- Drain the coolant.

- The drive belt is dismantled.

- The water pump mounting bolts are unscrewed.

- The old pump is removed and a new pump is installed. It is important not to forget to install the gasket.

- Install the belt into place.

- Fill the system with coolant.

Replacing the thermostat is carried out in the same way as a pump, only the element itself is located in a housing that consists of two elements. To change it, you just need to drain the liquid and disconnect the pipe. Then remove the cover and change the thermostat directly.

Recently, radiators have become a common malfunction; they become punctured by pebbles on the highways when the speed is high enough. Typically, motorists try to solder this element, but it does not always work.

How it works

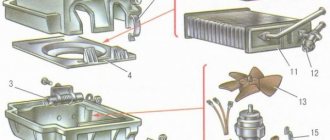

On the side of the electric fan unit there are 2 dampers on GAZelle cars. Between these dampers there is a special jumper, which changes its position depending on the operation of a special regulator located on the front panel. As you know, the furnace equipment control unit is located on the center console.

Both dampers close and open synchronously. They are driven by a special drive connected to an external regulator on the control unit. When air is taken in through the engine compartment, depending on the position of the dampers, it can pass through the heater radiator or bypass it. This directly affects whether cold or hot air will enter the cabin.

But if the dampers do not move synchronously, the stove will not work normally. In this situation, mandatory repairs are required.

Heating

Having figured out how the cooling system works, you can move on to heating the interior. The heater circuit on the Gazelle car is identical to the heaters on other cars with a liquid-cooled engine. Fluid can circulate through the heater core whether the thermostat is open or not. For better heating, the furnace fluid comes from the hottest part of the engine (from the head). Therefore, on an engine that has not yet reached operating temperature, hot air still comes out of the deflectors. The heater has a valve in its design that either allows liquid to flow into the radiator or drains it back. And the temperature of the air leaving the dampers depends on how open they are. The valve position is adjusted from the heater control panel. The crane is equipped with an electric drive that changes the position of the shock absorber. You can also change the intensity and direction of tightening from the control panel. The intensity is controlled by a motor with an impeller, the rotation speed of which changes the intensity of the puff.

Changing the position of the dampers changes the direction of the air flow (on the face, on the legs, on the chest, on the glass). The coolant heated by the engine flows through the lines into the heater radiator, which causes it to heat up. At this time, air blown by a fan passes through it. Then it passes through air ducts, the dampers of which are open. Warm air then enters the car interior and heats it up. To repair or diagnose a malfunction of this equipment, there is a connection diagram that shows all the components of the electrical devices. And in the event of a breakdown or incorrect operation of the devices, it is necessary to read it in detail in order to understand where the device is powered from and what regulates the faulty device.

When you know the principle of operation and the device, it is much easier to navigate in the event of a breakdown. After all, to successfully complete the repair, it is important to understand the cause of the malfunction, otherwise the repair will not be completed successfully. To make a correct diagnosis, it is also important to understand the algorithm of operation of the entire mechanism as a whole. Currently, the driver does not need to know how to repair a car; there are gas stations that perform repairs of any complexity. But it happens that you are caught in a breakdown along the way, and there is no opportunity to use the services of specialists. That’s when knowledge about the structure of a car and its mechanisms will come in handy. Knowing how the Gazelle stove works, if a malfunction occurs on another machine, it will be easier to navigate during repairs or diagnostics, since they are almost the same in all machines, with the exception of minor nuances. And you can easily diagnose the problem.

Causes of malfunctions

If the car owner has no complaints about the performance of other components of the heating system on a GAZelle, but while driving the air into the cabin is cold in the winter, or blows hot in the summer, despite moving the dampers to the appropriate position, then it’s probably all about the dampers.

There can be several situations in case of breakdown or malfunction of the dampers:

- The air passes through the radiator, while it is required to bypass it without preheating, which is important in the warm season.

- Due to faulty dampers, air bypasses the heater radiator, although the driver has switched the heater to heating mode.

- The flaps are stuck in an intermediate position. This does not allow you to get the necessary amount of heat in winter. The heater works, but it's still cold in the cabin.

A pair of dampers whose synchronous operation is disrupted cannot, in the event of a malfunction, supply outside air through the radiator or directly into the cabin without preheating for two main reasons:

- The drive is broken. It is mechanical and rarely fails. The drive is connected to the regulator on the front panel on the right side of the heater control unit, and goes to the dampers. The likelihood of it breaking is extremely low. Checking the work is quite simple. You need to visually reach the dampers and turn the regulator, changing the position of the elements. If they do not move, there is a possibility that the drive has broken. This problem is more relevant for heavily worn GAZelles with high mileage. To repair it, it will need to be disconnected or adjusted if the drive is stretched or weakened.

- The jumper is broken. There is a special jumper between the dampers. In fact, it is this that is driven by a special drive, and with the help of this jumper the dampers change their position. The breakage of the jumper occurs quite often, which is why car owners have to contact a car service center or repair the unit on their own.

When faced with such a malfunction, it makes sense to try to repair it yourself. No special skills or special tools are required here. The procedure is carried out in a garage with a minimum basic set of tools and materials.

Conclusion

The cooling system of the 405 Gazelle engine is quite characteristic and typical for power units. It includes a radiator, electric fan, water pump, thermostat, temperature sensor and other elements. The cooling system is easy to repair because it has a simple design. Restoring the functionality of the nodes can be done at home.

For correct diagnostics and repairs, it is necessary to know the structure and operating principle of the heater in order to diagnose a breakdown or carry out repairs at the first sign of a malfunction, preventing failure of the entire unit as a whole. Most faults can be predicted by indirect signs and their progression can be prevented. To do this, you need to know and understand what each element is responsible for and what the principle of its operation is.

Repair work

To repair the heating system dampers on a GAZelle car, you will first need to get to the problem unit.

In fact, here you need to gain access to the electric fan of the stove, since it is in this unit that the dampers are located along with jumpers and the drive for the heater damper position regulator.

Yes, GAZelle owners can completely remove the front panel, dismantle the trunk, remove the center console in order to fully get to the heating system housing, and see, check and repair everything as clearly as possible.

But in fact, the easiest way to do this is through the upper glove compartment. The sequence of actions will be as follows:

- Disconnect the negative terminal on the battery. Your personal safety is paramount in such matters.

- Open the glove compartment for documents, which is located on the dashboard.

- Lift the cover and lock it in the raised position.

- Once opened, you will see 4 screws or self-tapping screws around the perimeter of the glove compartment.

- Unscrew them using the appropriate tool.

- Now carefully lift the glove compartment up, releasing it from its seat.

- You now have access to the housing of the electric fan of the GAZelle heating system. In the future, you can use this to repair the electric fan itself, or perform other work related to the heating system motor.

- To remove the fan housing cover, you need to use a size 8 wrench. A socket with a long adapter will work best here.

- Unscrew a couple of fasteners and move the cover to the side.

- Now you can see the electric fan itself. To the right of it there is a rubber ring that should be removed, then remove the fan itself and move it a little to the side.

- Now turn the right regulator on the stove control unit to check whether the dampers operate synchronously and whether their position changes when the regulator operates.

- If the dampers do not move synchronously, you will need to dismantle them or change the position manually.

- For the second option, you will need to stick your hand to the right of the electric fan housing, reaching the levers. There is a special washer or some kind of nut that can be easily turned by hand.

For more serious repairs in the form of replacing the jumper, more complex dismantling work will have to be carried out.

Alas, to replace the dampers, when they are to blame for the problems with the heating system on the GAZelle, it will not be possible to do without completely disassembling the heater. Yes, the design of a domestic commercial vehicle is far from perfect. But sometimes you can get by with a little bloodshed.

On the gazelle, the stove stopped blowing hot air, error code E3, E6, E7 lights up

The owner of a long gazelle business came to us from the distant northern Urals, the city of Novy Urengoy, with a complaint about a faulty stove, he says the stove doesn’t heat at all, but he bought this workhorse second-hand the other day and didn’t check the functionality of the stove, so we need to figure out the fault. Errors E3 and E7 (E3 and E7) light up on the display.

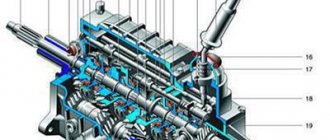

And so, we begin the check with a visual inspection of the heater control unit (HCU) 2705-8121020. E3 lights up on the display . Looking ahead, let's say that this malfunction is associated with the heater damper gear motor (90.3780) or MP-2-01 , which is located next to the driver’s right foot under the panel. Looking under the panel and deciding to check whether both connectors were latched, we did not find this gear motor, but only the connectors were dangling. Apparently the previous owner removed the gear motor, but did not install a new one. We install a new gear motor.

Video. Checking the heater damper gear motor (90.3780) or MP-2-01 .

2 errors with this gear motor ( 90.3780 ) E3 - malfunction of the damper position sensor ( rheostat ), which determines the current position of the damper. E6 - a malfunction of the motor itself, the gear motor that controls the damper.

We check the functionality of the heater and turn on the ignition. Error E3 disappeared, but error E7 . The stove still blows cold air, although the gear motor 90.3780 is working properly. Next, we check the heater tap, because it is responsible for supplying hot coolant to the heater radiator, and it is also the reason why error E7 . We set the temperature regulator on the control unit to the hottest position and check by hand the hoses going to the heater radiator.

Both of our pipes going to the heater radiator turned out to be cold, although the pump is working and the supply hose to the faucet is hot, which means for some reason the faucet does not open. The easiest way to check the operation of the faucet is to turn the temperature control to maximum and minimum with the car turned off. The stove tap should make characteristic clicks, indicating its operation. But we didn’t hear any sounds, so we’re conducting a more detailed check. We start by checking the heater tap connector.

First, let's check the +12 volt power supply (orange tap wire, white wiring connector wire), ground (black tap wire and black connector wiring wire) and control signals arriving at the heater tap: brown tap (brown wiring connector) - heat, white tap (green connector wiring) - cold.

For clarity and to check the operation of the control unit, we will assemble a simple probe using LEDs. It will clearly show us whether cold/heat control signals are being supplied from the control unit.

If one of the control signals is missing, then you should check the wiring from the heater tap to the control unit - these are the green and brown wires. In our case, there was no control signal on the brown wire, which is responsible for the heat supply.

When the ignition is turned on and the heater tap is connected, the green and brown wires should have a voltage of about +10. +12 volts coming from the heater tap. At the time of heat/cold adjustment, a control minus should appear on one of these wires. If there is no control signal, then the control transistor in the control unit itself has burned out. To check the control transistors, you need to disassemble the climate system unit and check the control keys.

The blue transistor is responsible for switching to the cold position, the red transistor is responsible for controlling the hot position

In this circuitry, npn SMD transistors in a sot23 package are used to control the crane. To replace a non-working key, you can use any NPN transistor designed for a collector current of at least 100 mA and a voltage of at least 20 volts, for example the common transistor BC547 . Or C945, which we just found. Here is a brief diagram of a power transistor.

In our case, the red control key, which is responsible for the heat supply, was faulty.

You can replace the SMD transistor in another package, for example in TO92, but you will have to solder and bend the legs.

After replacing the faulty transistor, the heater valve began to work as it should, error E7 disappeared, and the interior of our gazelle began to warm up