The VAZ "Seven" drive is carried out to the rear axle, which has a rather complex device. The most common failure of this unit is wear of the axle bearing. The external manifestations of such a malfunction on a VAZ 2107 car consist of a characteristic hum while driving. If the unit is not replaced on time, the bearing may be destroyed while driving and the wheel may jam.

Elimination of this malfunction of the rear axle on a VAZ 2107 car can be done in two ways. In the first case, the assembly is repaired with the installation of a new bearing; in the second case, the entire assembly is replaced. List of necessary tools and devices:

- a set of wrenches and screwdrivers;

- device for dismantling the unit from the rear axle;

- blowtorch or industrial hair dryer;

- device for removing the bearing thrust ring;

- pliers;

- mandrel for installing the retaining ring.

The listed devices are usually used at service stations. In garage conditions, slightly different techniques are used that do not require so much special equipment.

WHAT ARE HAMI SHAPS, WHY ARE THEY NEEDED AND HOW ARE THEY STRUCTURED

In rear-wheel drive cars, which the “seven” actually belongs to, the rear wheels are driving. It is they, rotating, that make the car move. The torque is transmitted to them from the gearbox through the drive (cardan) shaft, gearbox and axle shafts. There are only two axle shafts: one for each rear wheel. Their role is to transmit torque from the corresponding gear of the gearbox to the wheel rim.

HALF AXLE DESIGN

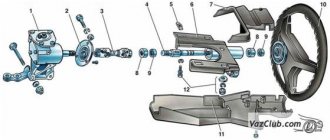

The axle shaft is an all-metal shaft made of steel. At one end there is a flange for attaching the wheel disk, and at the other there are splines for engagement with the gearbox gear. If we consider the axle shaft assembly, then in addition to the shaft, its design also includes:

- oil deflector;

- sealing gasket;

- oil seal (cuff);

- bearing.

In addition to the shaft, the design of the axle shaft also includes an oil deflector, a gasket, an oil seal and a bearing.

Each of the axle shafts is installed in the corresponding (left or right) rear axle housing. An oil deflector with a gasket and an oil seal are used to prevent lubricant from leaking out of the casing. The bearing is designed to ensure uniform rotation of the axle shaft and distribute shock loads coming from the wheel to the rear axle of the vehicle.

1 — oil deflector; 2 - gasket; 3 - seal; 4 - oil seal; 5 - axle shaft; 6 - casing; 7 — bearing mounting plate; 8 — brake shield; 9 — bearing; 10 — fixing sleeve

Refill containers

- Fuel tank (including 5 liter reserve) - holds 39 liters of gasoline

- Lubrication system (including oil filter) - holds 3.75 liters of oil

- Engine cooling system (including interior heater) - 9.85 liters of antifreeze

- Washer reservoir - 2 liters

- Gearbox housing - 1.35 liters of transmission oil (semi-synthetic GL-5 75W90) / for a 5-speed gearbox - 1.59 liters

- Rear axle housing - 1.3 liters semi-synthetic GL-5 (75W90)

- Clutch hydraulic system - 200 ml

- Brake system 660 ml

MAIN TECHNICAL CHARACTERISTICS OF VAZ 2107 HALF AXLES AND THEIR ELEMENTS

Axle shafts for the “seven” in Russia are produced under catalog number 21030–2403069–00. The right and left parts, unlike some other rear-wheel drive cars, are absolutely identical in the VAZ 2107. They have a diameter of 30 mm (for the bearing) and 22 slots. On sale you can also find so-called reinforced axle shafts with 24 splines, but to install them you will need to change the design of the gearbox.

AXLE BEARING

The bearing is the element that bears most of the loads. And although its declared resource is about 150 thousand kilometers, it can become unusable much earlier. It all depends on the operating conditions of the car, the serviceability of other transmission parts, as well as the quality of its manufacture. The most reliable today are considered to be bearings from the Vologda Bearing Plant, produced under article numbers 2101–2403080 and 180306. Imported analogues have catalog number 6306 2RS.

TABLE: DIMENSIONS AND TECHNICAL CHARACTERISTICS OF BEARING 2101–2403080

| Position | Index |

| Type | Ball |

| Number of rows | 1 |

| Direction of loads | Two-way |

| Outer/inner diameter, mm | 72/30 |

| Width, mm | 19 |

| Load capacity dynamic/static, N | 28100/14600 |

| Weight, g | 350 |

STUFFING BOX

The axle shaft cuff has a much shorter lifespan than the bearing, since its main working material is rubber. It needs to be changed every 50 thousand kilometers. Axle shaft seals are available under catalog numbers 2101–2401034.

TABLE: DIMENSIONS AND TECHNICAL CHARACTERISTICS OF THE VAZ 2107 HALF AXLE SEAL

| Position | Index |

| Frame type | Rubberized |

| Type of rubber according to GOST | 8752–79 |

| Internal diameter, mm | 30 |

| Outer diameter, mm | 45 |

| Height, mm | 8 |

| Temperature range, 0С | -45 – +100 |

Cost of spare parts

The price of a new rear axle bearing may vary slightly depending on the manufacturer (but everything is within reason). So, the product costs about 125 rubles per piece. More expensive ones are GPZ bearings. They are sold for 250 rubles. A set of bearings can be purchased for 450 rubles. At the same time, one piece sells for 300. As for the axle shaft seals, they can be purchased for 30-50 rubles. By the way, all these products are interchangeable on all classic VAZ models and on the Moskvich model 2141. This is a very big plus.

- Inner diameter – 30 millimeters.

- Length – 0.07 meters.

- Height – 0.02 meters.

- Width – 19 millimeters.

- External diameter – 72 millimeters.

- Product weight – 340 grams.

MALFUNCTIONS OF VAZ 2107 HALF AXLES, THEIR CAUSES AND SIGNS

The main failures of axle shafts include:

- shaft deformation;

- fracture;

- wear or cutting of splines;

- Damage to the wheel rim mounting threads.

DEFORMATION

The axle shaft, although made of high-strength steel, can become deformed under high loads. Such a malfunction is often a consequence of gearbox jamming, bearing problems, or the corresponding wheel falling into a deep pothole. A sign of deformation of the axle shaft is strong vibration of the wheel rim, sometimes accompanied by a hum, knocking, or crackling noise.

FRACTURE

The result of a wheel hitting a pothole or a strong impact on a bump can be a fracture of the axle shaft. In this case, the car loses control because one of the drive wheels stops rotating. If the axle shaft is broken, the gears of the gearbox may also fail, so if such a malfunction occurs, it must be checked.

WEAR OR CUT OFF SPLINES

Natural wear of the axle shaft splines may appear after 200–300 thousand kilometers. More often they are cut off, which occurs when one of the wheels jams and the gearbox malfunctions. Also, the splines are cut off due to wear of the axle gear teeth that mesh with them.

A sign of spline damage is a crunching noise from the gearbox.

A sign of wear or cutting of the splines is a crunch (crack) from the axle shaft, which usually occurs when starting or moving downhill. The crunching sound indicates that the gear teeth are slipping between the axle shaft splines.

DAMAGE TO WHEEL THREAD

It is quite difficult to damage the threads on the flange, but such troubles still happen. The reason for this may be non-compliance with the tightening torque of the wheel bolts, incorrectly set direction of the bolts when tightening, or violation of the thread pitch on the bolts. A sign of thread damage is vertical play in the wheel, or beating in the rear of the car while driving.

If the listed malfunctions are detected, the axle shaft (one or both) must be replaced. Continuing to drive a vehicle with faulty axle shafts is extremely dangerous.

Preparation

First of all, you will need to remove the rear wheels, brake drums and the axle shaft itself.

Place the car on a level surface (in case there is no pit or truck crane). The front wheels must be securely supported by chocks. Don’t forget that the “seven” has a rear-wheel drive and you can’t control its immobility by engaging a gear, it just won’t work. Using a jack, raise the rear of the car. Protect against accidental falls. You can place removed wheels, a metal canister or a safety bar under the body. Unscrew the bolts and remove the wheels. Use a 10mm end to twist the guides and remove the brake drums

You can help with a hammer, but be careful: you can only strike through a piece of wood. Wrench No. 17 removes the bolts securing the axle shaft and then removes it.

Most often at this stage, most mechanics are faced with the fact that it sits tightly in place and cannot be moved even a millimeter. In such cases, the following techniques may help:

- Install the wheel on a couple of bolts and use it to twitch the axle shaft several times. You need to make movements sharply in order to loosen the part.

- Spin it left and right several times until it loses immobility.

At this stage, the axle is inspected for distortions or deformations. Their presence is unacceptable.

Replacing the axle shaft and axle seal of a VAZ 2107

Hi all ! every classic has this problem 1. We remove the brake drum, if there are guides, unscrew them with a wrench 2. Then we put a block and knock on the drum through it and, so that there is no distortion, we gradually turn the drum 3. Using a 17 socket head, we unscrew the four nuts through the holes in the axle flange 4 anyway, you don’t have a device for removing the axle shaft and therefore we pry it from the inside with a pry bar and push it out from the gearbox 5. remove the axle shaft from the bridge (the axle shaft is removed together with the oil seal, mounting plate, bearing and locking ring) 6. Using sliding pliers, remove the axle shaft oil seal from the socket in the rear axle beam 7. Using light blows of a hammer on the end head, press the new oil seal into the stocking of the rear axle of the VAZ 2106. If the axle shaft is deformed, there are large radial and axial clearances in the bearing, the locking ring is displaced, the splines are worn, the axle shaft must be replaced with a new assembly. Independent replacement of the VAZ 2107 axle bearing and lock ring is not recommended. Installation of the axle shaft on a VAZ 2107 is performed in the reverse order of removal. Before installation, lubricate the working surfaces of the oil seal with Litol-24 lubricant.

Anti-lock braking system (ABS)

| GENERAL INFORMATION |

| The front wheel sensors are located in the steering knuckles as shown. They control the speed of the car's wheels through ring gears mounted on the front drives. |

| The rear wheel sensors are attached to the rear axle carrier as shown. |

REPLACEMENT OF ABS ELEMENTSREPLACEMENT OF ANGULAR SPEED SENSORS OF FRONT WHEELSRemoval

PERFORMANCE ORDER 1. Disconnect the ground cable from the battery. 2. Raise and place the front of the vehicle on stands. 3. Remove the wheel, allowing access to the sensor cable.

4. Remove the plug connection in the wheel housing from the holder and unplug it using a screwdriver.

5. If there are several plug connections, find out which one belongs to the ABS sensor.

6. Disconnect the cable from the mount.

7

Unscrew the sensor mounting bolt with a socket wrench and carefully separate it with a screwdriver. Installation

Installation

PERFORMANCE ORDER 1. Tighten the fastening bolt to a torque of 9 Nm. 2. Be careful not to twist the sensor cable. The cable is marked with a white line. 3

When tightening the cable mounting bolts, pay attention to the different tightening torques. 4

The lower cable fastening bolt is fastened with a torque of 27 Nm, the upper cable with a torque of 6 Nm

4. The lower cable fastening bolt is fastened with a torque of 27 Nm, the upper cable with a torque of 6 Nm.

5

Make sure that the speed sensor is not dirty or damaged.

6. After completing the work, set the ignition key to the operating position and check that the ABS warning light goes off.

REPLACING REAR WHEEL ANGULAR SPEED SENSORS Removal

| EXECUTION ORDER |

| 1. Disconnect the ground cable from the battery, lift and place the rear of the car on stands. |

| 2. Find the sensor cable and unplug the plug connection, disconnect the cable from the mount. |

| 3. Unscrew the sensor. The location of the sensor on the rear suspension is shown in the illustration. |

Installation

| EXECUTION ORDER |

| 1. Be careful not to twist the cable when connecting. For proper installation, the cable is marked with a white line. |

| 2. Tighten the sensor mounting bolts to a torque of 22 Nm, the cable mounting bolts to a torque of 27 Nm. |

INSTRUCTIONS ON WHEEL SPEED SENSORS Diagram explaining the principle of operation of the wheel speed sensor REPLACING THE FRONT WHEEL SENSOR ROTOR

| EXECUTION ORDER |

| 1. Remove the front hub as described in the appropriate section. |

| 2. Remove the rotor from the inside of the wheel hub. |

| 3. If the removed rotor is installed backwards, it is necessary to check the tooth surfaces. They must not be damaged. |

| 4. When installing, tighten the bolts to a torque of 18 Nm. |

REPLACING THE REAR WHEEL SENSOR ROTOR

| EXECUTION ORDER |

| 1. Raise and place the rear of the car on stands. |

| 2. Remove the rear drive as described in the appropriate section. |

| 3. Remove and install the gear rotor in connection with replacing the drive bearing. |

| 4. The specified work is also described in the Chapter Brake system |

What are axle shafts, why are they needed and how are they designed?

In rear-wheel drive cars, which the “seven” actually belongs to, the rear wheels are driving. It is they, rotating, that make the car move. The torque is transmitted to them from the gearbox through the drive (cardan) shaft, gearbox and axle shafts. There are only two axle shafts: one for each rear wheel. Their role is to transmit torque from the corresponding gear of the gearbox to the wheel rim.

Axle shaft design

The axle shaft is an all-metal shaft made of steel. At one end there is a flange for attaching the wheel disk, and at the other there are splines for engagement with the gearbox gear. If we consider the axle shaft assembly, then in addition to the shaft, its design also includes:

- oil deflector;

- sealing gasket;

- oil seal (cuff);

- bearing.

Each of the axle shafts is installed in the corresponding (left or right) rear axle housing. An oil deflector with a gasket and an oil seal are used to prevent lubricant from leaking out of the casing. The bearing is designed to ensure uniform rotation of the axle shaft and distribute shock loads coming from the wheel to the rear axle of the vehicle.

Diagnostics

To check the wheel bearings, you need to put the car on the handbrake and put wheel chocks under the rear wheels. When it is firmly fixed, you need to lift the front wheel using a jack and install a reliable stop under the lower arm. After which, of course, remove the jack. To ensure complete safety, it is better to install a stop under the car body parts, which will protect against accidental falling when the vehicle slips from the stop.

Safety precautions are often overlooked; unfortunately, they are very necessary when diagnosing defects in the front hub.

. Next, holding the top and bottom of the wheel with your hands, you need to perform a reciprocating movement, while no knocking should be heard or play should be felt. You should also spin the wheel several times.

If there are problems with the bearings, grinding, creaking, knocking and other unacceptable sounds will be heard.

Main technical characteristics of VAZ 2107 axle shafts and their elements

Axle shafts for the “seven” in Russia are produced under catalog number 21030–2403069–00. The right and left parts, unlike some other rear-wheel drive cars, are absolutely identical in the VAZ 2107. They have a diameter of 30 mm (for the bearing) and 22 slots. On sale you can also find so-called reinforced axle shafts with 24 splines, but to install them you will need to change the design of the gearbox.

Axle bearing

The bearing is the element that bears most of the loads. And although its declared resource is about 150 thousand kilometers, it can become unusable much earlier. It all depends on the operating conditions of the car, the serviceability of other transmission parts, as well as the quality of its manufacture. The most reliable today are considered to be bearings from the Vologda Bearing Plant, produced under article numbers 2101–2403080 and 180306. Imported analogues have catalog number 6306 2RS.

Table: dimensions and technical characteristics of bearing 2101–2403080

| Position | Index |

| Type | Ball |

| Number of rows | 1 |

| Direction of loads | Two-way |

| Outer/inner diameter, mm | 72/30 |

| Width, mm | 19 |

| Load capacity dynamic/static, N | 28100/14600 |

| Weight, g | 350 |

Stuffing box

The axle shaft cuff has a much shorter lifespan than the bearing, since its main working material is rubber. It needs to be changed every 50 thousand kilometers. Axle shaft seals are available under catalog numbers 2101–2401034.

Table: dimensions and technical characteristics of the VAZ 2107 axle shaft seal

| Position | Index |

| Frame type | Rubberized |

| Type of rubber according to GOST | 8752–79 |

| Internal diameter, mm | 30 |

| Outer diameter, mm | 45 |

| Height, mm | 8 |

| Temperature range, 0С | -45 – +100 |

Types of auto parts

Axle shafts for cars are divided into two types according to the degree of loading:

- Completely unloaded (placed mainly on buses and trucks).

- Semi-unloaded (installed on passenger car models).

By design, the drive shaft can be:

- Waferless.

- Flange.

According to their location, there are rear and front axle shafts. For a VAZ 2107 car, you can purchase an original or non-original drive. Analogs are sold at a more reasonable price.

Depending on the manufacturer, drive shafts are:

- Imported.

- Domestic.

Depending on the condition, you can buy a new or used spare part for the VAZ 2107.

Depending on the place of purchase, the drives are:

Malfunctions of VAZ 2107 axle shafts, their causes and symptoms

The main failures of axle shafts include:

- shaft deformation;

- fracture;

- wear or cutting of splines;

- Damage to the wheel rim mounting threads.

Deformation

The axle shaft, although made of high-strength steel, can become deformed under high loads. Such a malfunction is often a consequence of gearbox jamming, bearing problems, or the corresponding wheel falling into a deep pothole. A sign of deformation of the axle shaft is strong vibration of the wheel rim, sometimes accompanied by a hum, knocking, or crackling noise.

Fracture

The result of a wheel hitting a pothole or a strong impact on a bump can be a fracture of the axle shaft. In this case, the car loses control because one of the drive wheels stops rotating. If the axle shaft is broken, the gears of the gearbox may also fail, so if such a malfunction occurs, it must be checked.

Worn or cut splines

Natural wear of the axle shaft splines may appear after 200–300 thousand kilometers. More often they are cut off, which occurs when one of the wheels jams and the gearbox malfunctions. Also, the splines are cut off due to wear of the axle gear teeth that mesh with them.

A sign of wear or cutting of the splines is a crunch (crack) from the axle shaft, which usually occurs when starting or moving downhill. The crunching sound indicates that the gear teeth are slipping between the axle shaft splines.

Damage to wheel threads

It is quite difficult to damage the threads on the flange, but such troubles still happen. The reason for this may be non-compliance with the tightening torque of the wheel bolts, incorrectly set direction of the bolts when tightening, or violation of the thread pitch on the bolts. A sign of thread damage is vertical play in the wheel, or beating in the rear of the car while driving.

If the listed malfunctions are detected, the axle shaft (one or both) must be replaced. Continuing to drive a vehicle with faulty axle shafts is extremely dangerous.

How bridge malfunctions manifest themselves

The rear axle of the VAZ “six” is endowed with its own characteristic problems, which manifest themselves in one way or another.

Excessive noise from rear wheels

There may not be many reasons for the appearance of large noise from the wheels of the rear axle:

- The wheel has become loose. In this case, it is necessary to check and tighten the fasteners;

- semi-axial bearing failure. The axle bearing wears out over time, resulting in a characteristic noise. The axle shaft needs to be inspected and the faulty element replaced.

Constant noise from the rear axle while driving

Sounds unusual for the normal operation of the device in most cases indicate problems. The main causes of malfunctions include:

- stocking deformation. If the case is deformed, you can try to restore it, but it is better to replace it with a serviceable one;

- bent axle shafts and excessive runout. In this case, the part must be replaced;

- increased wear on splines. It is necessary to inspect the gears and splines of the axle shafts, and then replace the damaged elements;

- the gearbox is incorrectly adjusted, gears or bearings are worn or broken.

Complete disassembly, defect detection and repair of the mechanism is required; If the bearing rollers are damaged, extraneous noise may appear in the operation of the rear axle. - low oil level. You need to check the level, bring it to normal and make sure that there are no leaks through the lip seals and gaskets.

Noise when accelerating the car

The appearance of noise when accelerating a vehicle may be associated with the following reasons:

- Worn or incorrectly adjusted differential bearings. The gearbox needs to be dismantled, inspected and repaired;

- The gearing between the teeth of the bevel and planetary gears is incorrectly set. The problem is solved by proper adjustment;

- wear of semi-axial bearings. It is necessary to remove the faulty axle shaft and replace the bearing;

- little lubrication.

The problem is resolved in the same way as with constant noise. Lack of lubrication in the gearbox leads to increased production and jamming of the mechanism

Noise when accelerating and braking the engine

If noise from the motor side is present when the motor accelerates and decelerates, then the reason is possible in the following:

- Excessive wear or damage to the shank bearings. Requires disassembly and diagnostics of the gearbox;

- Incorrect alignment of the teeth of the bevel and planetary gears. Eliminated by checking the integrity of the parts and setting the correct gap.

Video: identifying the cause of noise in the rear axle

Noises when cornering

Extraneous noise can appear not only when driving straight, but also when cornering. This may be due to the following reasons:

- Difficulty turning the satellites on the axis. Requires disassembly, inspection of serviceability and replacement of elements whose condition does not allow them to be used further;

- jamming of side gears. If the gears and the surfaces with which they come into contact have minor damage, then they are cleaned with sandpaper. Otherwise, failed elements must be replaced;

- Incorrect alignment of the differential gears. Diagnostics and correct adjustment of the gap are required;

- failure of semi-axial bearings. Defective elements must be replaced.

Knock when starting to move

If the “six” rear axle gearbox (RAZ) makes a knocking sound as soon as the car starts moving, then this may indicate the following:

- Excessive clearance between flange and tip. Inspection of the spline connection and replacement of worn parts is required;

- increased gap between the shank and the planetary gear. Eliminated by setting a gap;

- increased wear of the landing site under the satellite axis. If such a breakdown occurs, the box must be replaced;

- The rear suspension rod fasteners have dropped. The bolts need to be checked and, if necessary, tightened.

Oil leak

Lubricant may leak from the gearbox for the following reasons:

- wear of the bevel gear cuff. If a leak appears from the shank side, the oil seal must be replaced;

- Damage to the axle seal. If traces of grease appear on the brake flaps, this indicates wear of the axle shaft seal, which requires its replacement;

- The fastening of the gearbox to the stocking has become loose or the gasket has been damaged. In such a situation, it is necessary to tighten the fasteners or replace the seal.

When oil leaks, gear wear accelerates.

Replacing the axle shaft

Let's look at the process of replacing the axle shaft, its bearing and oil seal in detail. Tools you will need:

- wheel wrench;

- a jack and a safety stand (in extreme cases, a stump or a few bricks);

- wheel stops;

- reverse hammer;

- wrenches 8 mm, 17 mm;

- slotted screwdriver;

- Bulgarian;

- round nose pliers;

- hammer;

- chisel;

- workbench with a vice;

- blowtorch or gas torch;

- spacer made of wood or soft metal;

- a piece of steel pipe with a wall diameter of 33–35 mm;

- Litol type lubricant;

- dry clean rag.

Removing the axle shaft

To dismantle the axle shaft, you should:

- Place the car on a flat surface and place chocks under the front wheels.

- Use a wheel wrench to unscrew the wheel bolts.

- Raise the car body with a jack.

- Unscrew the wheel bolts and remove the wheel.

- Using a size 8 wrench, unscrew the drum guide pins.

- Remove the drum. If it does not come off the blocks, carefully knock it down using a spacer and a hammer.

- Using a 17mm wrench (preferably a socket), unscrew the nuts (4 pcs) securing the axle shaft. They are located behind the flange, but you can access them through specially provided holes by turning the axle shaft.

- Using round-nose pliers, remove the spring washers that are located under the axle nuts.

- Disconnect the axle shaft from the rear axle by pulling it towards you. If it does not give in, use a reverse hammer. To do this, the tool flange must be screwed to the axle flange with wheel bolts. By sharply moving the hammer weight forward, knock out the axle shaft. If you don't have a reverse hammer in your tool arsenal, you can use a removed wheel instead. It needs to be screwed with the back side to the axle shaft flange and struck with a hammer on the tire from the inside until the axle shaft comes out of the casing.

- Remove the axle shaft assembly with the bearing and its retaining ring.

- Remove the sealing gasket located between the brake shield and the axle shaft flange.

- Using round nose pliers or pliers, remove the oil seal from its seat.

How to remove a broken axle shaft

If the axle shaft is broken, it will not be possible to dismantle it in the usual way. But there are other methods. If the shaft breaks directly in front of the flange and its broken end sticks out of the bridge casing, you can weld a piece of reinforcement to it, and then use it to pull out the rest of the axle shaft.

If the axle shaft breaks inside the casing, you can try to knock it out with a piece of reinforcement inserted from the back side of the bridge, after first removing the opposite axle shaft. In extreme cases, to remove a piece of shaft, you will have to disassemble the gearbox.

Removing and installing the bearing on the axle shaft

When replacing the axle shaft with a new one, it is recommended to replace the bearing, but if the old one is still fully functional, you can install it too. But to remove it you will need to remove the retaining ring.

To do this you need:

- Securely fix the axle shaft in a vice.

- Using a grinder, saw through the outer part of the ring.

- Crack the ring body using a chisel and hammer.

- Remove the remaining ring from the shaft.

- Carefully knock the bearing off the axle shaft using the same tools. Apply blows only to the inner race of the bearing. Otherwise, you will damage it and will no longer be able to use it.

- Inspect the new axle shaft and bearing for manufacturing defects.

- Remove the rubber boot from the bearing housing.

- Place grease between the bearing races.

- Reinstall the boot.

- Place the bearing on the axle shaft. Be careful: the bearing is installed so that the boot “looks” at the oil deflector.

- Place a piece of steel pipe against the bearing so that its walls rest against the end of the inner race.

- Applying gentle blows with a hammer to the opposite end of the pipe, seat the bearing in its place.

- Use a blowtorch or gas torch (you can use a burner from a regular kitchen gas stove) to heat the retaining ring. Don’t overdo it: you don’t need to heat it until red hot, but until there is a white coating on the surfaces.

- Using pliers, place the ring on the axle shaft.

- Shrink the ring by hitting it lightly with the back of the hammer. To make it cool faster, pour motor oil on it.

Installing the oil seal

To install a new oil seal:

- Wipe the seat with a clean, dry cloth.

- Lubricate the socket surfaces with grease.

- Lubricate the oil seal itself with grease.

- Install the part into the mounting socket.

- Using a hammer and a piece of pipe, carefully press in the oil seal.

Installing the axle shaft

Once the bearing and seal are installed, you can install the axle shaft. Installation is carried out in the following order:

- We install the sealing gasket.

- Insert the axle shaft into the housing until it stops. Check how the splines engage with the gear teeth by turning the axle shaft in different directions.

- Apply a few gentle blows with a hammer to the axle shaft flange to make sure it is seated correctly.

- Install spring washers onto the axle shaft studs. Install and tighten the nuts securing the axle shaft with a 17 mm socket wrench.

- Place the drum on the shoes and secure it with guide pins.

- Mount the wheel.

- Check to see if there is any play in the axle shaft or bearing by trying to shake the wheel along the vertical and horizontal axes.

- Lower the body and remove the chocks from under the front wheels.

- Tighten the wheel bolts.

- Check whether the signs of axle shaft malfunction have disappeared by driving on a flat section of the road.

Important points

The inner ring of the bearing is cut off with a chisel

Replacing a bearing is a difficult task, but it can be done. The main thing here is to avoid damage to the axle shaft when cutting off the bearing and distortions when installing a new part. In addition, you should take into account the fragility of the bearing rings and use the hammer with extreme caution. Otherwise, the procedure is quite within the capabilities of even a novice car enthusiast, who, by doing it with his own hands, can save a significant amount.

Repair of axle shaft on VAZ 2107

The VAZ "Seven" drive is carried out to the rear axle, which has a rather complex device. The most common failure of this unit is wear of the axle bearing. The external manifestations of such a malfunction on a VAZ 2107 car consist of a characteristic hum while driving. If the unit is not replaced on time, the bearing may be destroyed while driving and the wheel may jam.

Elimination of this malfunction of the rear axle on a VAZ 2107 car can be done in two ways. In the first case, the assembly is repaired with the installation of a new bearing; in the second case, the entire assembly is replaced. List of necessary tools and devices:

- a set of wrenches and screwdrivers;

- device for dismantling the unit from the rear axle;

- blowtorch or industrial hair dryer;

- device for removing the bearing thrust ring;

- pliers;

- mandrel for installing the retaining ring.

The listed devices are usually used at service stations. In garage conditions, slightly different techniques are used that do not require so much special equipment.

Purpose

The axle shaft is considered one of the important elements of the “seven” drive axle. It does not lose its functionality very often, but the bearing where it is attached is a problem area of the entire system.

The purpose of the element is simple. With its help, the axle shaft rotates smoothly when the car is moving. This part is located directly behind the brake system drum. Replacing the VAZ 2107 axle bearing will only be possible if the axle shaft is removed and the drum with brake pads is dismantled. There is no second option.

PROCEDURE FOR DISASSEMBLYING THE UNIT AND REMOVING THE BEARING

Repair of the rear axle of a VAZ 2107 is carried out in the following sequence:

- The machine is installed on a level surface, secured with a parking brake and stops. The desired side is raised with a jack, the wheel is removed and the body is lowered onto a strong support.

- The screws securing the drum to the hub are unscrewed and the part is removed. The brake mechanism is cleaned of dirt and disassembled. Using a socket wrench, unscrew the bearing cap bolts through the windows in the hubs.

- If the brake pads are worn excessively, they will need to be replaced together with the pads.

- At the next stage, we try to remove the faulty axle shaft; this is easy to do using a special tool. If there is no such device, then pressing is done using a wheel disk. We fasten it to the hub with two bolts and knock the bearing out of its seat with sharp blows on the rim.

- If the axle shaft assembly is being replaced, then we put a new one in place of the faulty unit and reassemble it in the reverse order.

If you plan to repair the unit of a VAZ 2107 car, then it is necessary to disassemble it and then replace the bearing.

Checking the oil in the gearbox

For the rear axle gearbox of the “seven”, semi-synthetics with viscosity parameters 75W-90 are suitable, for example:

- CASTROL Syntrans Transaxle 75W-90 API GL-4;

- "Lukoil 80W90 GL-5" and others.

1.35 liters of oil is poured through a special filler hole on the gearbox housing. If you need to drain the used oil, there is a drain hole in the bottom of the gearbox for this purpose. Before draining the old oil, it is recommended to warm up the car, place it on a flat surface and jack up the right side of the car. If there are metal shavings in the waste, you should rinse the gearbox container with a special liquid or spindle oil.

For the rear axle of the VAZ 2107, CASTROL Syntrans Transaxle 75W-90 API GL-4 oil is suitable

It is convenient to fill in new oil using a special syringe, which can be purchased at a car store. Both plugs (drain and filler) should be securely tightened, and then check the condition of the breather, which should move freely. If the breather jams, the contact of the container with the atmosphere will be disrupted, which will lead to an increase in internal pressure, damage to the seals and oil leakage. The oil level in the rear axle gearbox is considered normal when the liquid reaches the lower edge of the filler hole.

RESTORING THE OPERATION OF THE UNIT

To fix the problem, you need to remove the old retaining ring. If a special device is not available, then the operation can be performed using a grinder. The ring is carefully cut off without damaging the axle shaft. This part is for single use and must be replaced every time the unit is repaired. The new bearing is put on the axle and secured with a new ring, which is preheated.

Repairing a component such as an axle shaft on a VAZ 2107 does not take much time from an experienced specialist. At the same time, going to a service station does not always guarantee a good result; often, in the absence of special devices, they simply knock down the ring with a sledgehammer, which leads to runout and rapid destruction of the bearing.

Sequencing

- The car is jacked up, and the wheel is removed using socket wrenches, behind which there is a worn bearing.

- The brake disc and pads are removed.

- Now you need to unscrew the axle shaft itself with a 17 socket wrench.

The axle shaft is unscrewed with a 17 socket wrench. To remove it from the seat, you can use a crank. It should be inserted between the brake cylinder and the rear of the axle and used as a lever to push the axle out.

Pushing out the axle shaft using a wrench

Now you need to remove the bearing from the axle shaft. Often it turns out to be tightly welded to it, so you have to literally cut it off with a grinder. This must be done by first clamping the axle shaft in a vice.

The old bearing is cut off with a grinder

Once the old bearing is removed, the axle must be thoroughly wiped with a rag. And then a new part and a retaining ring are put on the axle shaft.

Installing a new axle bearing

Now, using a medium-sized flat-head screwdriver, you need to remove the worn oil seal from the seat.

The old oil seal is removed with a screwdriver

As soon as it is removed, a new oil seal is installed in its place (it is most convenient to drive it into the seat with a 32 socket head). The axle shaft with a new bearing is installed back into the seat and the entire assembly is reassembled.