Replacing the release bearing Lada 2106 (VAZ 2106)

We prepare the same tool that we needed when replacing the clutch and proceed to the removal and subsequent installation of the clutch release bearing.

- Remove the transmission from your vehicle.

- The ends of the connecting spring must be disengaged from the fork.

- Next, moving a little along the shaft, you need to remove the bearing assembly with the coupling.

- Unclench the ends of the connecting spring and remove it from the coupling. Check the condition of the spring and, if necessary, replace it with a new one.

At this point, the work on removing the clutch release bearing is completed, then take a new bearing, check it for any various mechanical defects and install it in its place in the reverse order of removal. Reinstall the transmission onto the vehicle and all previously removed components and assemblies. At this point, the DIY repair of the VAZ 2106 can be considered complete.

All VAZ clutch malfunctions are divided into two groups:

-removable only by repair or replacement of failed parts.

Noise when pressing the clutch pedal of a VAZ . The cause is wear or destruction bearing . To eliminate this, repairs with replacement of the bearing are necessary.

Repair box VAZ, replace the release bearing on the box VAZ, replace the release bearing, repair the VAZ gearbox. Subtleties of installing and dismantling the release bearing of the VAZ gearbox. Repair box VAZ, replace the release bearing on the box VAZ, release bearing replacement, transmission repair VAZ .Tonkosti installation and removal of the release bearing gearbox Vaz.

Source

Bleeding the system

Draining fluid from the clutch drive system is very simple:

- Using a blower, pump out the liquid from the expansion tank.

- Unscrew the fitting on the working cylinder and wait until all the fluid is gone.

- Press the clutch pedal several times to remove any remaining brake fluid.

- Change tubes if necessary.

- Tighten the fitting.

- Fill the reservoir with fresh brake fluid.

- Place a transparent tube onto the fitting.

- Have an assistant press the clutch pedal several times. With the last press, you need to hold it in the extreme position.

- Unscrew the fitting half a turn, allowing fluid and air to escape.

- Repeat the procedure until liquid begins to flow without air bubbles. Don't forget to monitor the level in the expansion tank.

In fact, two or three passes are enough to get rid of air in the system. As you understand, pumping the clutch on a VAZ 2106 is not difficult. The procedure is very similar to bleeding the brakes, only it is much faster - the line is very short.

After replacing the clutch, it will need to be adjusted. Pay attention to the working cylinder rod - it has a thread along which you can move the nut. It is by moving it that the clutch is adjusted on VAZ 2106 cars and the rest of the classic series. It is also possible to adjust the free play of the clutch pedal; for this purpose, a special bolt is provided directly above it.

AutoNews / Reviews / Tests

How to change the clutch disc on a VAZ 2106

Replacing the clutch in a VAZ 2106 with your own hands

The clutch, like any other automotive assembly, must be replaced or repaired if it malfunctions. The time, number of cycles of turning off/on the device or starting the car, after which the VAZ 2106 clutch needs to be replaced, is not set. Yes, and this cannot be done due to the influence of certain factors on his life. Here it is necessary to take into account the manufacturer of the installed clutch, the mileage of the vehicle, the operating conditions of the unit and the driving style of the vehicle.

Replacing the VAZ 2106 clutch with your own hands

It is quite difficult to imagine a car engine without a clutch. The main task of a car clutch is to ensure a smooth engagement of speeds by briefly disconnecting the engine from the transmission. Thanks to the clutch, the car can move off smoothly without overloading the engine and preventing premature wear of all its parts, as well as gearbox parts. Overloads are caused by inertial moment, which is formed due to the rotation of engine parts during a sudden sharp slowdown in crankshaft speed.

Replacing the VAZ 2106 clutch disc, as well as the clutch basket, is usually done at the same time. This process is not simple and requires certain skills and dexterity, so if you have only recently learned how to change spark plugs yourself, it is better not to take risks and entrust the work to specialists. Replacing the clutch can be done in two ways, with or without removing the gearbox; it is this less labor-intensive and convenient method that we will use today. This work is carried out on a lift or inspection pit.

Features of clutch functioning

In general, although the approximate service life of the VAZ 2106 clutch before its replacement is about 150 thousand km for the basket and about 70-90 thousand vehicle kilometers for the driven disk.

Prerequisites for repair:

- clutch;

- incomplete disengagement (clutch terminals);

- the appearance of extraneous noise generated by the release bearing, fork or basket;

- malfunctions in the hydraulic clutch system.

Clutch slip is characterized by loose engagement of the driven disc on the surface of the flywheel and pressure plate of the basket with the clutch pedal fully released in the cockpit. In this case, the engine speed increases with increasing load on it, but in some cases the car cannot move at all at the beginning of the movement or weakly, uncharacteristically slowly increases its speed while driving. This malfunction is clearly visible when driving uphill, overtaking, or trying to jump sharply. This occurs when the friction lining of the driven disc is worn or the clutch drive is not adjusted correctly.

Replacing the VAZ 2106 clutch with your own hands

- Secure the vehicle with wheel chocks.

- Disconnect the cardan shaft from the gearbox, as well as the clutch slave cylinder.

- Remove the reverse light switch wires from the contacts.

- Disconnect the clutch cover from the side of the cylinder block, unscrew the yoke from the bottom side.

- Using a socket on “13”, unscrew the two fastening nuts that secure the gearbox mount, then remove it.

- Move the gearbox as far as possible from the engine until the shift lever rests against the rear of the bottom hole.

- The transmission will hang from the downpipe of the muffler as a safety net, install an additional support under the rear of the box.

- Grasp the flywheel with a mounting tool and unscrew the 6 bolts securing the clutch basket using a 13mm wrench. Continuously turn the crankshaft to ensure you have access to the bolts.

9. Move the clutch basket towards the box, using the resulting opening, remove the clutch disc.

10. After this, move the basket towards the engine and remove the clutch basket.

11. After pulling it out of the clutch housing, remove the clutch fork and remove the release bearing from the transmission input shaft.

Installation of clutch parts is carried out in reverse order. Before installing them, you need to wipe the working surface of the basket, flywheel, and clutch disc with a clean rag soaked in gasoline. Center the clutch disc in relation to the bearing at the end of the crankshaft, using a special mandrel that imitates the splined part of the transmission input shaft. When you are finished tightening the basket mounting bolts to the flywheel, pull out the mandrel; it should come out easily by hand.

Apply a thin layer of CV joint-4 lubricant to the splines of the input shaft, then install the box in place. After replacing the VAZ 2106 clutch disc is completed, it is necessary to adjust the stroke of the clutch working cylinder rod; it should be free.

Watch also the video on how to replace the clutch on a VAZ “Classic”

Home

Source

Preparing for repairs

Before putting the car in a pit and removing the box to replace the clutch, you need to visit the store and buy all the necessary spare parts:

- Clutch disc.

- Basket (drive disk).

- Release bearing.

- If necessary, clutch fork.

- If there is significant wear, the crown on the flywheel will also need to be replaced.

- Bolts securing the basket to the flywheel.

It is also important to have a good set of tools on hand, WD-40 penetrating lubricant, sometimes even a gas torch is necessary (if the bolts and nuts are very rusty).

It is advisable to carry out all the work in an inspection pit or overpass (it is unlikely that the average driver of a six will have a lift in the garage, so we do not mention it). If everything goes smoothly and the nuts unscrew well, you will complete all the work very quickly.

Place the car on the pit, fix it in one position by placing stops under the wheels. All work is divided into two stages: under the car and above it. Please note that there is no need to drain the oil, since if you dismantle it carefully, you will not spill a drop.

And don't forget about the alignment of the clutch disc. The price of a special device is quite high - about 500 rubles. but you can use a small piece of pipe without any problems, as long as the diameter is suitable.

Replacing the release bearing on a VAZ 2101-VAZ 2107

Removal: 1) At the very beginning of the operation, you will have to remove the box from the car. (see details in the instructions: “Replacing the box on a VAZ”)

2) Now take a screwdriver in your hands and remove the springs securing the bearing to the fork.

3) Gradually pull along the shaft, in other words, pull the release lever towards you - it is removed from the shaft.

4) After removing the bearing, unclench the ends of the spring attached to the gear shift fork. After decompressing, simply remove this spring. If you find the bearing is in good condition, but the spring is not, replace the spring with a new one and continue to use your bearing. The spring is fine, but the bearing is not - take the spring and insert it into the new part.

Note! Please note that sometimes the bearing is still intact, but has already traveled quite a few kilometers, so you should not exclude the possibility of failure in the near future.

Installation

The new spare part is installed on the vehicle in the reverse order of removal.

Note! Before installation, it is necessary to lubricate the splined part of the input shaft, indicated by the arrow, with the lubricant described in the set of necessary tools, because over time the lubrication of the shaft disappears, and malfunctions with the splined part may occur due to friction between non-lubricated parts.

Below is a link to a video with a visual demonstration of the replacement process:

Source

Clutch VAZ 2106

On modern cars, the clutch may have a design slightly different from older cars, but the essence of the application of this mechanism remains the same. Like any other vehicle component, the clutch consists of a number of parts that wear out and become unusable over time. Therefore, it is worthwhile to dwell in more detail on identifying the causes and eliminating malfunctions of the VAZ 2106 clutch.

What is the clutch used for?

Equipping a car with a clutch is necessary to separate the gearbox and power plant, their smooth connection at the start of movement, as well as when changing gears. The mechanism is located between the gearbox and the engine, with part of the clutch elements fixed on the engine flywheel, and the other part in the clutch housing.

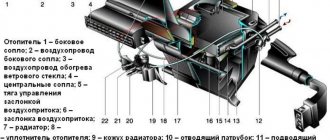

What does it consist of?

The main structural elements of the node in question are:

- master cylinder;

- working cylinder;

- basket;

- driven disk;

- release bearing;

- fork.

Master cylinder

The clutch master cylinder (MCC) ensures effective transmission of force from the pedal to the clutch fork through brake fluid and the working cylinder, interacting through the release bearing with the spring elements of the basket. The main circulation pump is located under the hood near the expansion tank and communicates with the working cylinder using a hose. The unit in question consists of a housing, two cylinders with seals and a spring.

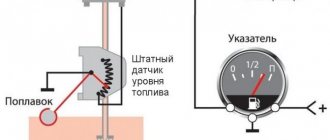

Clutch drive system

There are only two main components in the VAZ-2106 clutch system. The clutch master cylinder allows pressure to be created in the pipes using the driver's muscular strength. The worker acts on the fork, which drives the release bearing. Briefly, the operation of the entire system can be described as follows:

- When you press the pedal, the rod in the master cylinder moves. Since the system is closed, the pressure rises sharply.

- Under the influence of this pressure, the piston is extruded in the working cylinder, which is installed on the clutch housing.

After releasing the pedal, the reverse process occurs:

- When the pedal is released, the master cylinder rod returns to its initial position, as a result of which the volume inside the system increases and the pressure decreases.

- A return spring acts on the working cylinder, which allows the rod to move to its initial position.

- The system has an expansion tank into which liquid is filled.

DOT-3 type brake fluid is used as the working fluid. It contains many additives, they contribute to the normal operation of the mechanism. These additives have a beneficial effect on the metal and allow the cylinders to cool better.

Try to fill the system only with those fluids recommended by the manufacturer. Effective operation depends directly on the quality of the liquid that is poured into the system. Never allow the level to drop to the minimum level. Add fluid if necessary.

Clutch problems

The VAZ 2106 clutch, although rare, still causes problems for the owners of this car. Malfunctions can be of various types and they also manifest themselves in different ways. Let's take a closer look at them.

Brake fluid leak

The working medium of the “six” clutch mechanism is brake fluid, which sometimes leads to some problems:

- Fluid leakage due to damage to the hose between the master and slave cylinders. The connecting element may become unusable when installing a low-quality product or as a result of rubber aging. To eliminate the problem, the hose will need to be replaced;

Drives the clutch

The concept of “clutch drive” is used when the mechanism is not completely disengaged. This can happen for several reasons:

- The driven disk was damaged, causing axial runout. The most correct solution is to replace the part;

- Cracks have formed on the driven disk linings. The appearance of defects is reflected in the inability to engage the clutch in a timely manner. In this case, you should replace the entire disc or the pads themselves;

- The rivets of the friction linings have failed. When the rivets wear out, the fixation of the linings weakens, which leads to problems when the clutch is disengaged and increased wear of the linings themselves;

- Air has entered the hydraulic system. The problem is “treated” by pumping fluid;

- basket distortion. Although the malfunction is rare, if it occurs, you will have to purchase a new pressure plate.

The clutch is slipping

When clutch slip occurs, the mechanism does not engage completely, but this happens for the following reasons:

- oil got on the friction elements of the driven disk. You will have to remove the gearbox and disassemble the clutch mechanism to clean the linings with white spirit;

- The compensation hole in the main circulation system is clogged. To fix the problem, you will need to remove the cylinder, remove the blockage, and then rinse the product in kerosene;

- Friction linings are burnt. The malfunction is eliminated by replacing the driven disk.

Clutch pedal squeaks

The pedal may squeak due to lack of lubrication in the bushings or when the bushings themselves are worn out. To fix the problem, the pedal will need to be removed, the bushings checked for wear, replaced if necessary, and lubricated.

Noise when depressing the clutch pedal

On a VAZ 2106, noise when releasing the clutch pedal may appear for the following reasons:

- bearing failure on the gearbox input shaft. The problem appears in the form of a characteristic cracking sound when the clutch pedal is released. In this case, the bearing will have to be replaced;

- release bearing wear. The part fails due to lack of lubricant, which is squeezed out over time. To eliminate the malfunction, the bearing must be replaced.

Noise when pressing the clutch pedal

The clutch may also make noise when you press the pedal. The reasons may be as follows:

- loss of rigidity or breakage of the springs of the driven disk. This leads to vibrations that cannot be extinguished in a timely manner. The solution to the problem is to replace the driven disk;

If, when noise occurs, the problem is not resolved within a short time, then the broken part may damage other elements of the mechanism.

The pedal falls

There are cases when on a VAZ “six”, after pressing the clutch pedal, it does not return to its initial position. There are few reasons for this phenomenon:

- air entering the hydraulic drive system. In this case, the pedal “falls” after several presses, so the system will have to be pumped;

- the spring responsible for the pedal return fell asleep. It is necessary to check the spring and, if necessary, replace it.

Major clutch failures

Diagnosing clutch malfunctions is quite simple; you need to pay attention to the behavior of the car when driving. If the clutch is slipping, then you can indicate an accurate diagnosis - excessive wear of the friction linings

There are two ways out of this situation. The choice depends on how long ago the clutch disc was installed and what the operating conditions were.

Part replacement

- If the disc is fairly new and the operating conditions are normal (rare off-road trips, in traffic jams), then adjusting the VAZ clutch will help. For this purpose, the VAZ sixth model has a special nut on the rod of the working cylinder.

- If the disc has been changed quite a long time ago, and the operating conditions are on the verge of extreme, then first we adjust the position of the rod. If this does not help, the clutch is repaired and replaced.

Operating a VAZ 2106 with a deteriorated clutch disc is extremely undesirable, as you can get into big trouble. When the friction linings wear out, rivets are exposed, which can ruin the surface not only on the basket, but also on the flywheel. If a layer of metal is removed from the flywheel, it will cause an imbalance in its weight. The result is increased vibration from the engine.

Another problem is related to the release bearing. This small detail can create a lot of problems. Firstly, the noise level will be high, as the bearing makes a strong noise. Secondly, when you press the clutch pedal, grinding and squeaking noises may be heard. It is imperative to change this part when replacing the clutch.

You can make a short list of what should be done when disassembling the clutch:

- replace the disk;

- change cart;

- install a new release bearing;

- Take a quick look at the ring on the flywheel.

The last point is optional. But it’s worth looking at the crown to protect yourself from troubles associated with starting the engine. If there is significant wear on the teeth, you need to either install a new crown, or knock off the old one and, after heating it up a little, put it on the other side.

Replacing the VAZ 2106 clutch

It is necessary to remove the clutch infrequently and, as a rule, due to the occurrence of certain problems. To carry out the work, you first need to prepare the tools:

- set of keys and sockets;

- wrench and extension;

- support under the gearbox.

Removing the gearbox

To repair the clutch mechanism, you will need to dismantle the gearbox. We do this as follows:

- We install the car on the inspection hole, remove the negative terminal from the battery and place wheel chocks under the wheels.

- We unscrew the fasteners and remove the cardan from the car.

Removing the clutch

We remove the clutch mechanism from the car in this order:

- Using a 13mm wrench, unscrew the bolts holding the basket to the flywheel, turning the latter using a pry bar.

Video: replacing the clutch on a “six”

Rejection of parts

After the clutch is removed, all elements are thoroughly inspected. To do this, perform the following steps:

- We clean the clutch elements, as well as the working surface of the flywheel, from dirt.

- Inspect the clutch disc. The presence of cracks is unacceptable. If the thickness of the linings to the rivet heads is less than 0.2 mm or the rivets are weakened, the driven disk or the linings themselves must be replaced. We check how securely the disk springs are fixed in the sockets. If there are damaged springs, the disc must be replaced.

The basket is a non-separable and non-repairable unit and in case of any damage must be replaced.

Fork and spring

The fork and spring element, like other components of the clutch mechanism, must be in good condition. Cracks on the fork are unacceptable, and if they are found, the part is replaced with a serviceable one.

Release bearing play

Since there is no such tool for checking the release bearing, during diagnostics it is necessary to visually inspect the condition of the mechanism, rotate it to identify play, jamming, loud noise, and possible damage. If large play or defects of any other nature are detected, the bearing needs to be replaced. If the part has no visible damage, but still makes noise, then it must be cleaned of dirt and filled with lubricant, for which molybdenum lubricant is suitable.

Replacing the clutch bearing

For convenience, replacing the release bearing is done with the box completely removed. The only tool you need is a flathead screwdriver. The procedure consists of the following steps:

- We remove the ends of the spring from engagement with the fork.

Replacing linings

If the driven clutch disc of a VAZ 2106 has serious damage to the friction linings, it is not necessary to replace the disc with a new one - it can be repaired by installing new linings. For this you will need:

- a set of overlays and rivets for the “six”;

- electric drill with a 6–7 mm drill;

- flat screwdriver.

The sequence of actions is as follows:

- We rest the disk against a wooden block and drill out the old rivets on both sides, avoiding damage to the disk itself.

Video: replacing clutch disc linings

Work on top of the car

So, a start has been made, the goal is to remove the gearbox to replace the clutch. On VAZ 2106 and similar cars this is done quite quickly, it is only important to follow a certain sequence:

- Inside the car, remove the gear shift knob. It is attached using plastic latches. Sometimes difficulties arise with dismantling, and it gets to the point where the latches break off. The price of a new set of fastenings is no more than one hundred rubles, and you can purchase it even after repairs have been carried out. Therefore, do not be afraid if you suddenly break the plastic antennae.

- Go to the engine compartment, unscrew the four nuts that secure the exhaust pipe to the manifold. The fact is that the exhaust pipe will interfere with the removal of the box, but it is enough to move it a little to the side.

- Disconnect the battery and remove it from the car.

- Unscrew the two top bolts of the starter, disconnect the power wires for the windings and the solenoid relay from it.

- Disconnect the ground wire that goes to the gearbox.

Carefully inspect whether there are any “upgrades” on your vehicle specifically that will interfere with the removal of the transmission. If there are any, then make sure that they do not complicate further repairs.

Choosing a clutch for VAZ 2106

The “six” is equipped with a clutch with a pressure plate diameter of 200 mm and 130 mm for the driven one. Today there are many manufacturers of these mechanisms, but the most popular ones are still worth highlighting:

- VALEO (France). Manufactures clutches whose operation is distinguished by its softness and precise operation. Car owners who use kits from this manufacturer note the high reliability of the mechanism, which runs without any nuances for more than 150 thousand km. The only disadvantages include the high cost of about 2600 rubles;

About the selection of clutch master cylinders

If the owner of a “six” starts having problems with the clutch and decides to purchase a new cylinder, then he will inevitably be faced with the question: which cylinder is better to get? The answer is simple: the clutch master cylinder on all VAZ “classics” from VAZ 2101 to VAZ 2107 has undergone virtually no changes. Therefore, on the “six” you can easily install a cylinder from a “penny”, from a “seven” or from a “four”.

Drivers consider the best option to install standard VAZ cylinders on the “six”.

The cylinders on sale are also universal; they fit the entire range of classic VAZ cars. As a rule, car enthusiasts try to install original VAZ cylinders. The problem is that the VAZ “classic” was discontinued a long time ago. And there are fewer spare parts for it every year. This rule also applies to clutch cylinders. As a result, car owners are forced to use products from other manufacturers. Here they are:

- FENOX. This is the most popular manufacturer of spare parts for VAZ “classics” after VAZ. Cylinders from FENOX can be found in almost any major parts store throughout the country. These cylinders are reliable and in constant high demand, despite their somewhat inflated price. If a driver can purchase a standard VAZ cylinder for 450 rubles, then a cylinder from FENOX can cost 550 rubles or more;

- Pilenga. Cylinders from this manufacturer are much less common on store shelves than FENOX products. But with due diligence, you can still find such a cylinder. The price for Pilenga cylinders starts from 500 rubles.

And these are all big ones today. Of course, today there are many other, lesser-known brands on the aftermarket. However, contacting them is strongly discouraged. Especially if their cylinders cost half as much as the above ones. There is a very high probability of buying a fake that will not last very long. In general, clutch cylinders for “classics” are often counterfeited. Moreover, in some cases, fakes are made so skillfully that only a specialist can distinguish them from the original. But for the average car enthusiast, the only criterion for quality is price. You should understand: good things have always been expensive. And clutch cylinders are no exception to this rule.

As for installing cylinders from other cars on a VAZ 2106, such experiments are almost never practiced by car enthusiasts. The reason is obvious: the clutch cylinder from another car is designed for a different hydraulic system. Such a cylinder differs both in size and technical characteristics, the most important of which is the ability to create pressure. The level of pressure created by the “non-original” clutch cylinder may be either too low or, conversely, too high. Neither in the first nor in the second case does this bode well for the hydraulics of the “six”. Thus, the installation of “non-original” cylinders on a VAZ 2106 is an extremely rare occurrence. And this is done only when it is completely impossible to get a normal VAZ cylinder.

Clutch installation

After repairing or replacing the clutch, installation is carried out as follows:

- We lightly lubricate the gearbox input shaft, as well as the ball joint of the fork, with CV joint-4.

Shifting gears without clutch

Not every driver of a VAZ 2110 imagines how to not only start, but also drive a car without using the clutch pedal. Of course, this skill is very specific, but it can be vitally important when the clutch cable breaks at the most inopportune moment.

Driving for a long time in first gear can cause the engine to overheat. If there is a considerable distance to be covered, it is better to learn how to shift higher gears without using the clutch, for which:

- release the gas pedal and, at the moment of least resistance, switch off the gear, moving the transmission lever to the neutral position;

- then engage the next gear, continuing acceleration.

The proposed algorithm for downshifting in the event of a non-working clutch requiring replacement is somewhat different:

- Having switched to neutral gear, we revise the throttle, thereby increasing the speed of the input shaft;

- and only then switch to a lower gear.

Adjusting the "six" clutch

The procedure is carried out in an inspection pit using the following tools and materials:

- open-end wrenches for 8, 10, 13 and 17;

- measuring ruler;

- pliers;

- mites;

- WD-40.

Clutch pedal adjustment

Adjusting the pedal comes down to setting the correct free play, which should be 0.5–2 mm. The operation is carried out from inside the vehicle by adjusting the required height of the pedal stop. The event consists of the following steps:

- Using a 17-size open-end wrench, we loosen the limiter nut, and with another of the same size we turn the limiter itself, setting the required length.

Adjusting the working cylinder rod

The free play of the fork rod is determined by the distance between the heel of the basket diaphragm spring and the release bearing. To make adjustments, the car is placed on the inspection hole, after which the following steps are performed:

- Use pliers to tighten the return spring.

Video: adjusting the clutch drive

When adjusted correctly, the clutch should operate clearly and without jamming, and the gears should engage without extraneous noise or any difficulties. The driven disk should not slip while driving.

Troubleshooting clutch problems on a VAZ 2106 is not an easy task. However, to carry out repair and adjustment work, a standard set of tools, minimal skills in auto repair and following step-by-step instructions will be sufficient.

Source

Checking and replacing the hose on the clutch cylinder

The hose on the clutch slave cylinder is an extremely critical part that is exposed to high brake fluid pressure. Therefore, the car owner must monitor its condition especially carefully.

The clutch cylinder hose is a very important part, the condition of which must be carefully monitored

Here are signs that indicate that the hose should be changed urgently:

- cracks and other mechanical damage visible to the naked eye have appeared on the hose;

- the hose looks intact, but there are visible leaks of brake fluid on it (this means that it is still damaged and microcracks have appeared on it, which the driver simply cannot see);

- The threads on the hose ends are partially or completely stripped.

If you notice any of the above, the hose should be replaced immediately. It is better to install standard VAZ clutch hoses, their catalog number is 2101–16–025–90, and the cost is about 80 rubles.

Hose replacement sequence

Before starting work, you should stock up on an empty plastic bottle and two open-end wrenches: 17 and 14 mm.

- The car is driven into the pit and secured with wheel chocks. Open the hood and find the place where the slave cylinder hose is screwed to the clutch hydraulic tube.

- The main hose nut is held firmly with a 17 mm wrench, and the fitting on the hydraulic tube is unscrewed with a second wrench - 14 mm. After unscrewing the fitting, brake fluid will flow out of it. Therefore, there should be a container in the inspection hole to collect it (a small basin would be the best option).

- The second end of the hose is unscrewed from the working cylinder body using the same 17 mm wrench. There is a thin O-ring in the cylinder under the hose nut, which is often lost when removing the hose. This ring should also be changed (as a rule, new seals come with new clutch hoses).

- A new hose is installed in place of the old one, after which a new portion of brake fluid is added to the hydraulic system.

So, even a novice driver can change the working cylinder on a six. All you need to do for this is to carefully prepare the necessary tools and strictly follow the above recommendations.