To protect the fuel injectors and piston group from contamination and corrosion, it is necessary to thoroughly clean the incoming fuel from foreign particles, moisture and resins. This function is performed by a filter element that is installed between the tank and the pump.

The fuel filter in a car performs the function of purifying the fuel from foreign impurities.

... about the signs of a clogged filter

The most common signs of a clogged fuel filter are high fuel consumption and reduced engine power, so the layer must be changed regularly.

Causes of a clogged fuel filter

The most common causes of fuel filter contamination are:

- low quality gasoline or diesel fuel;

- penetration of water into the tank with subsequent formation of ice crystals at low ambient temperatures;

- surface corrosion with release of metal particles and oxides;

- accumulation of resins and foreign impurities from oil and additives;

- accumulation of dirt and bottom sediments in the fuel tank;

- very dusty air, frequent off-road trips.

Clogging of the fuel filter can occur due to its corrosion and poor quality gasoline.

Preventing fuel pump breakdowns

The best prevention for long-term operation of the fuel pump is its careful and proper operation, as well as compliance with the following rules:

- All scheduled vehicle repairs must be accompanied by the replacement of all fuel filters.

- It is necessary to monitor and ensure the cleanliness of the fuel tank and filters, as well as monitor the quality of the fuel being refilled (the absence of water, sand and other impurities in it).

- Eliminate the possibility of water getting into the fuel tank.

- Protect the fuel pump housing from mechanical stress that causes dents and cracks that contribute to the development of corrosion processes.

Self-diagnosis

Filter diagnostics include assessing engine performance during operation, measuring fuel pressure and visual inspection. Measurements are taken through the ramp fitting, which distributes fuel to the injectors.

For this you will need:

- hose with internal diameter 9 mm;

- fastening clamp;

- a device for determining gasoline pressure or a pressure gauge with a value range of 7-10 bar.

A special device can be purchased at a car store. The pressure gauge is connected to the hose and tightened securely with a clamp. To ensure the tightness of the contact, sanitary flax is used. The hose is connected to the fuel pressure fitting, after first removing the plug from it and removing the nipple.

You can determine the degree of clogging of the fuel filter using a pressure gauge.

After this, measurements are taken in various engine operating modes (at idle, after starting, with the drain tube pinched).

...about fuel system diagnostics

The indicator after turning on the ignition should be at least 3.8-4 bar. After the measurement, you need to turn off the engine and wait 20-30 minutes for the regulator to gradually reduce the pressure in the ramp.

After this, disconnect the pressure gauge and reinstall the nipple and plug.

The first symptoms of a dirty fuel filter depending on the engine type

The degree of influence of the filter on engine operation depends on its type. Carburetor gasoline engines practically do not react to contamination of the cleaning layer. Minor changes can only be observed in the power and stability of the internal combustion engine.

The injector is more demanding on the pressure in the fuel line, so a decrease in filter capacity is immediately manifested by a drop in engine power. The most obvious symptom becomes at high speeds.

A dirty fuel filter directly affects a decrease in car engine power.

Motors that run on diesel fuel are the most sensitive to foreign particles and impurities. Their power and stability of operation directly depend on the level of pressure in the fuel line. When it decreases, startup delays and sudden jerks while driving are observed. In some cases, the engine turns on only after several attempts.

... about the purpose of the fuel filter

The sensitivity of engines to pollution is largely due to their requirements for the degree of fuel purification. Filter elements for diesel engines should not allow particles larger than 4-5 microns to pass through, for injection engines - 10 microns, and for carburetor engines - 20 microns.

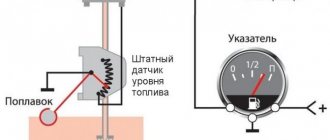

Purpose and principle of operation of the fuel pump

The fuel pump is designed to pump fuel from one point to another. In a car, the role of the first point is played by a fuel reservoir - the tank, and the second - by the engine, where the pumping takes place. This process occurs at a certain pressure, which is maintained by the pump reducer, which is a very important point.

Fuel pumps are divided into 2 types according to the type of drive: electric and mechanical. Inside the first there is an electric motor with a mini-pump, which operates from the mains and uninterruptedly pumps fuel into the engine. The second type is becoming increasingly rare, as it is installed on carburetor cars, and operates due to the reciprocating movement of the lever.

The main signs of a clogged fuel pump filter

The main signs of a clogged layer in front of the pump are a decrease in vehicle power, loss of control stability and increased failures when starting the engine. In the initial stages, these symptoms only appear under certain conditions (such as driving uphill, accelerating, or idling), but over time the problem begins to worsen.

Reduced engine power

A decrease in engine power when the filter is dirty is due to the fact that the fuel pump and cylinder do not receive enough fuel. In this case, under increased load, the engine begins to turn off and stall. Sometimes the power of the power unit is not even enough to start.

The engine runs rough at idle

A decrease in pressure in the supply system may be accompanied by uneven idling, spontaneous shutdown and delayed re-ignition of the engine.

Violation of the functional stability of the engine is caused by a poor air-fuel mixture.

Increased fuel consumption

When starting with clogged filters, the internal combustion engine and pump experience increased load, and the composition of the fuel-air mixture deviates greatly from the optimal one. This affects fuel consumption and the wear rate of parts.

A clogged fuel filter often causes increased fuel consumption.

When fuel consumption increases, it is necessary to check all installed filters: gasoline (diesel), oil and air.

Power loss when driving at high speeds

When accelerating, the car begins to move jerkily, and if there is a strong drop in pressure in the tank section, the pump completely stalls. For a short time, the engine completely stops responding to the accelerator. After this, the car picks up speed abruptly and continues moving.

Engine stalls when shifting to neutral

Another possible sign of clogged filters is the engine turning off when shifting into neutral. At this moment, you can notice a sharp decrease in speed on the tachometer.

...about fuel filter diagnostics

When this symptom appears, the air and fuel filters are checked first, but only because of the ease of diagnosis.

It may also indicate an incorrect signal from the crankshaft position sensor, valve failure, malfunction of the idle air control, etc.

The car doesn't go well uphill

If a decrease in engine power only appears when driving uphill and at high speeds, then a clogged filter is the most likely cause of the malfunction. Increased load on the engine requires more frequent pump cycles, and a clogged layer interferes with the flow of fuel into the fuel system.

If your car has difficulty going uphill, a dirty fuel filter may be the likely cause of the problem.

Gasoline pump. Symptoms of malfunction, fuel system problems.

Before we begin, it is necessary to make a small digression. No one can deny the fact that the fuel pump in a car’s design is one of the most important elements. Without which the car will not function, and malfunctions will lead to unstable engine operation.

It is worth noting that gasoline pumps can be divided into mechanical and electric. However, this article will not discuss mechanical fuel pumps due to the fact that they were used on older cars and cannot be found in modern cars.

Without fuel, the engine does not work, and without the engine, everything else does not work. Many car owners sometimes don’t even know that their cars are structurally equipped with such an electric fuel supply device, located either in the tank or not far from it, and if they know about it, it’s only in theory.

A fuel pump can give you serious thought about yourself when your car suddenly stands up like a stake in the middle of the road in an open field. There is gasoline, the oil is normal, there is a spark, but the car does not drive.

This is where the questions and search for reasons begin.

Loss of power. The whole point is that the fuel pump, although not considered a consumable item such as a filter or tire, however, has its own margin of safety. The car manufacturer takes this fact into account and creates a fuel pump that presses when the pump voltage is 12 volts, for example 8 bar, although the pump is equipped with a relief valve that releases excess pressure and operates at 5 bar.

Time passes and the pump ages; at the same voltage, the pump can already produce a maximum of 6 bar, and so on. Problems with loss of engine power arise when the maximum pump pressure is lower than that required in the fuel system for the normal operation of the fuel equipment after the pump (overcoming the resistance of the fine fuel filter, firing the injectors, etc., etc.).

Which generally leads to a lack of gasoline supply to the engine, and as a result, a drop in power. Poor starting. A car can start poorly for various reasons, but why could one of them be a faulty fuel pump? For normal engine operation, a certain pressure in the fuel system is required.

Ideally, after the engine is turned off, pressure is maintained in the fuel system, and when the ignition is turned on, the pump pumps fuel into the system for starting. However, with wear, there may be cases when the pump creates the required pressure over a longer period of time, and the valve does not maintain pressure in the system as it should.

As a result, the car is difficult to start. In some cases, the car may start after the car has been standing for a while, although before that it stalled and stubbornly did not start. This may indicate that the fuel pump screen is clogged, or something is preventing gasoline from getting normally into the flask, from where the pump pumps it.

If the car starts every once in a while, or even after knocking on the pump, the fuel pump armature or graphite brushes are most likely worn out. You should not change them yourself, since even after successfully flaring, removing the insides of the pump, replacing the brushes with new ones, rolling the pump, it is unlikely that it will work for a long time, since the graphite from a simple electric drill will be erased in a month, if not a week, or will destroy the armature of the fuel pump, being found to be of the wrong hardness, without the necessary additives, in gasoline.

1) Driving on a “dry” tank2) Operation of the fuel pump when driving on gas3) Contamination of the filter (mesh) of the fuel pump to the point of “vacuum packaging”, or even a violation of mechanical integrity.4) Water in the tank5) Dirt/rust/debris in the tank6) Jamming pump impellers/rollers due to foreign objects getting into the tank.

7) Wear of the armature/pump brushes 8) Deformation of the tank and, as a consequence, destruction of the pump/pump module. 9) Natural wear and tear. 10) Handicraft installation/removal of the fuel pump by the “Indians” And so, in order: When driving on an empty tank, the fuel pump heats up. This fact is at least obvious from the fact that gasoline is the only thing that surrounds the pump and cools it, and the only thing that passes through it lubricates it.

In the absence of gasoline or insufficient quantity, the pump heats up for two reasons: firstly, mechanical friction of the gasoline pump components, and secondly, due to the direct current passing in the pump (3-12 amperes). As a result, the pump heats up, the gaps between the rubbing parts decrease due to thermal expansion, and as a result, a completely new pump may stop, and if the fuse does not blow, it will work like a boiler in a tank until the pump housing, pump module, and other adjacent elements melt, until contact between the terminals is lost fuel pump.

When driving on gas, increased pump injury depends, just as in the above point, on the presence of gasoline in the tank. Car owners who have switched to gas have a habit of forgetting about gasoline without using it, and often the pump, without turning off, pumps gasoline from the tank (if there is still gasoline there) to the fuel rail to the engine, and since the car runs on gas, the hot rail is already hot gasoline goes back to the pump, usually into the pump flask, which adds fuel to the fire, promoting heating.

https://www.youtube.com/watch?v=VWfYUm1cCy4

If the mesh is clogged, a completely normal pump can break down in a matter of days. The pump grid, being clogged, does not allow gasoline to flow in the required quantity.

Everything is not so scary and difficult if you don’t ignore it. A clogged mesh can be cleaned, replaced, and most likely this can help the car drive normally, and the car owner can save on repairing or replacing the pump. Sometimes the car loses power slightly, and then suddenly the symptom goes away - a possible scenario is that the mesh was clogged and rubbed in the tank until such holes were formed that are equivalent to the absence of a mesh. This threatens to get everything that can into the pump and cause the latter to break down.

Water in the tank. Although gasoline is slightly soluble in water (0.001-0.004%), there are cases of water getting into the tank. This happens when refueling with low-quality fuel (it is even possible to refuel with an emulsion of water and gasoline after a recent visit of a fuel truck to a gas station), and during the natural process of condensation of atmospheric moisture inside the tank due to temperature differences.

Water leads to corrosion of the tank, and being heavier than gasoline, it collects other particles from the bottom of the tank, wetting them and carrying them with it. Water has a detrimental effect on the fuel pump and injector nozzles. If water ends up in the fuel lines in the winter, it can simply freeze and create a blockage that prevents the engine from starting.

Dirt/rust/debris in the tank Dirt usually gets into the tank in the same way as water - namely, refueling with low-quality fuel, but sometimes it ends up there after using special fuel with additives, or additives themselves. The fact is that after the ingress of special substances intended to dissolve the mud deposits on the walls of the tank, the deposit, being quite dense, does not dissolve, but flakes off in flakes from the walls of the tank, covering the mesh of the gas pump. Also, such additives can contribute to corrosion of the tank, with the participation of water, which leads to the appearance of rust, up to the loss of the tank’s tightness.

Jamming of the pump impeller/rollers by foreign objects that have entered the tank usually occurs if the fuel pump mesh has lost its integrity.

Wear of the pump armature/brushes usually occurs when driving without gasoline (on gas) or when it is at the bottom of the tank. Gasoline, being the only lubricant, lubricates the rubbing surfaces of the armature and brushes. Under inadequate operating conditions, the brush mechanism fails within two to three months.

The gasoline vapor adsorber is clogged, preventing air from entering the tank. This is because with a full tank of gasoline there is not much air left there, and as the fuel is used up, its place is taken by air passing through the adsorber, and if there is something wrong with the “air vent”, then the pump pumps fuel out of the tank, creating a reduced pressure in the tank, from which it can be flattened, and the vacuum can reach such degrees that the pump is no longer able to suck in fuel and supply it to the engine.

The armature-brush mechanism remains in excellent condition, current consumption is within normal limits, and increasing gaps between rubbing parts lead to a loss of performance and a decrease in pressure in the fuel system. And finally, a few words about what homemade installation/removal of a fuel pump by “Indians” is.

Signs of a clogged restrictor

Coarse filters (restrictive meshes) are designed to capture the largest particles. They are installed on the neck of the fuel tank, intake, inlet fitting or directly in the fuel pump. Diesel engines are additionally equipped with sedimentation tanks that capture not only dirt, but also condensate.

Signs of a clogged filter include unstable engine operation, engine shutdown without the driver's desire, and problems with starting. During the process, the protective mesh may partially clear spontaneously, which will allow the car to start, but the effect will not last long.

Tips and tricks

In the case when the gas tank is heavily contaminated, cleaning or replacing the fuel pump mesh will only be a temporary measure, and the rate of subsequent contamination of the mesh will not greatly depend on the quality of the fuel being filled. In such a situation, it is necessary to remove and wash not only the mesh, but also the gas tank.

To keep the fuel pump screen clean, try not to lower the fuel level in the gas tank below ½ unless necessary. Dirt and deposits that clog the mesh are usually located at the very bottom and are the last to be drawn in by the gas pump.

The causes of whistling and increased noise during operation of the fuel pump are overheating of the pump. How to diagnose and fix the problem yourself. Tips and tricks.

Why does the fuel pump grid need to be changed? How to remove the fuel pump yourself to replace the filter. Features of reassembly after replacing the fuel pump mesh.

How to determine why the fuel pump does not pump or works poorly. Fuel rail pressure, pump diagnostics. Wiring, relays, fuel pump fuses.

Why and when you need to flush the engine power system. How to flush the engine fuel system yourself: gasoline and diesel engines.

How to change a fuel pump. Location of the fuel pump, releasing pressure in the system, unscrewing the fuel lines, removing the pump, reassembling.

Mechanical and electric fuel pump, design and principle of operation of the device, types of pumps and main malfunctions, operating features

The nuances of replacing the fuel filter with your own hands

To replace the filter you will need a set of wrenches, a screwdriver, a fuel container, a pump and gloves. The location of the elements depends on the model and type of engine. For example, to repair the system on a car with an injection engine, it is often necessary to remove the rear seat, disconnect the hoses through a special hatch, remove the pump connector and dismantle part of the fuel line.

... about replacing the fuel filter

Disposable filter elements are replaced entirely, and sedimentation tanks and meshes for rough cleaning are thoroughly washed with clean fuel.

Disposable fuel filters must be completely replaced.

It is better to replace it in the fall or in preparation for the cold season. This will facilitate the passage of thickened fuel to the pump.

To extend the life of the filter, you must:

- refuel at trusted stations;

- do not fill the fuel supply into rusty and dirty cans;

- avoid refueling immediately after filling the gas station from the tank;

- wash the tank at least 1-2 times a year, regularly clean the coarse filter and drain the sump;

- When driving a diesel car, switch to winter fuel in a timely manner.

... about replacing the fuel filterBefore a long trip, it is advisable to include a fine filter in the list of spare parts that you need to take with you.

How to clean the fuel pump yourself

Let's start with the fact that the mesh filter for the fuel pump is a coarse filter and is designed to capture large particles and deposits that are in the fuel and inevitably accumulate in the fuel tank. It turns out that the fuel pump has its own additional fuel filter mesh, which prevents debris from entering the fuel system from the tank parallel to the usual fuel filter. The process of cleaning or replacing the fuel pump mesh is almost similar to the general scheme for replacing the pump itself:

- The fuel pump is installed directly into the gas tank. You can get to the pump from the passenger compartment, as it is located under the rear seat. To gain access to the fuel pump, you need to remove the rear seat cushion or fold down half of the sofa (if possible).

- The fuel pump is usually located on the right and covered with a special plastic cover. The specified cover must be removed.

- Before removing the fuel pump itself, it is necessary to relieve the fuel pressure in the system. To do this, you will need to disconnect the power connector from the fuel pump, and then turn the engine with the starter.

- The next step is to remove the negative terminal from the battery, after which the tubes from the fuel pump are disconnected. These tubes are “supply” and “return”, they are secured with clamps that need to be pressed out.

- Next, you need to unscrew the special pressure ring-cover of the fuel pump. It is very difficult to unscrew this cover manually. There is a special fuel pump cover puller for removal. If there is no such puller, then you can try to carefully unscrew the ring using improvised means. We strongly recommend that you first study on specialized auto forums how to remove the fuel pump cap on a specific car model.

- After unscrewing the cap, you can remove the fuel pump. Before complete removal, the remaining gasoline should be drained from its body, and the sealing ring should be removed.

- Now you can begin disassembling the fuel pump housing. To clean, you will need to remove the bottom part. There is often dirt in the indicated lower part of the housing.

- After this, remove the fuel pump screen. To remove the mesh, just pry out the filter at the place of attachment to the pump body using a regular screwdriver. The fuel pump strainer usually becomes completely clogged, especially on cars with high mileage.

- Then the fuel pump mesh can be replaced with a new one or cleaned. It is better to wash the fuel pump mesh first with carburetor cleaner. Mechanical cleaning is done with a soft brush. Then the mesh should be dried and blown. The bottom of the pump housing and the cleaned mesh are finally washed again with gasoline.

- The final step is to reassemble the fuel pump and install the device in the gas tank. To facilitate installation, it is better to invite an assistant, as it may be necessary to ensure high-quality pressure of the pump to the tank. The fact is that many gasoline pumps have a special spring, the force of which must be overcome. At the same time, you need to make sure that the rubber seal is in place and at the same time screw in the pressure ring-cover of the fuel pump. When tightening the clamping ring with a puller or improvised means, do not exceed the tightening torque. If you tighten it too tightly, the fuel pump cap may burst; if you tighten it too weakly, the fuel pump will wobble due to poor fixation.

In order to determine the correct position of the fuel pump, there are special indicators. Such indicators are made in the form of arrows and are located on the fuel pump, the gas tank body and the pressure ring. The correct installation of the fuel pump can be considered when all the arrows are in the same line. We would like to add that if the gasket is installed incorrectly, gasoline may leak out if you fill the tank full.

Now all that remains is to connect the fuel supply and return pipes to the fuel pump, while simultaneously checking that the clamps are securely fastened. The completion is to connect the electrical power connector to the fuel pump, after which you can start the car for testing.