Good day. Before you start repairing the front suspension of the VAZ 2101 - 2107, you need to buy yourself or borrow from a friend spring pullers and tensioners. To eliminate the waste of time and nerves, as well as dancing with a tambourine near the car :)).

I bought myself: 1) Spring ties. 2) Ball puller. 3) Steering wheel end remover (2 pcs.). My first one broke immediately without removing even one pull. I took another one, which seemed to be better, pressed out all the steering rod fingers and was left intact.

Since the levers were being changed and the silent blocks were being pressed in, I found on the net that there is a silent block remover, but after going around the auto shops I couldn’t find it, everyone has heard of it, but no one carries it :)). It was decided to order it to be turned out, since the thing needed can be used to not only press in, but also press out silent blocks without removing the lever (lower) from the machine; the upper one will need to be removed. I found a drawing on the net and made it using it.

I also took a compression gauge, and later I’ll take measurements to see what’s wrong with the compression, although there are no questions about the operation of the engine, so to speak, for information.

Last time I completely disassembled the front suspension, replaced the ball joints, and it was time to replace the silent blocks. Since you can’t just replace them, and buying pullers is not cheap, I decided to use improvised materials.

We will need: - a piece of water pipe with a diameter of approximately 45-50 mm (can be made from a 40 mm pipe) 3-4 cm long - a large washer or plate with a diameter of at least 50 mm - an M12-14 bolt 6-7 cm long with washers - two pieces of pipe with a diameter of 40 mm, 5-10 cm long - a hammer, a vice - a WD-shank or other liquid wrench, lubricant

What is a silent block

A silent block is a rubber-metal hinge (RMH) - an element that connects two suspension parts, in this case, a car. Consists of metal and rubber. Rubber serves to dampen vibration, smooth movement, and eliminate wear caused by metal-on-metal friction.

Silent blocks or RMS - receive and dampen axial, radial, torsion and cardan vibrations. Withstands radial vibrations up to 300 kN (kilo Newton), that is, up to 300 kg.

Classification of rubber-metal silent blocks that work in torsion:

- with outer ring;

- from the inside;

- double cage;

- eccentric.

Silent blocks of this type are installed in car suspensions so that the levers and springs can move.

Classification of RMSs that work in compression with bending:

- supports;

- pillows.

Hinges of this type are installed under the engine (mounts, cushions) to dampen vibration oscillations of a running and moving engine. Protects the body from vibrations.

MASTAK 110-20026C

Another good option made in Taiwan. This impressive set consists of 26 elements, which allow it to be used to remove a wide variety of silent blocks and bearing races.

Characteristics:

- Availability of 20 mandrels with ø 44/34 (11 pieces) and ø 48/38 (9 pieces).

- The set also includes thrust washers (2 pieces) and 350 mm power bolts (M16x2.5, M14x2.0, M12x2.0, M10x1.5).

- Type: universal tool.

- Weight: 18 kg.

Pros:

- High-strength material for all parts.

- Possibility of universal use (suitable for various brands of cars).

- Suitable not only for silent blocks, but also for external and internal races of bearings.

- Convenient storage case.

Minuses:

- Price.

- The latches on the case do not always fit tightly.

- Weight.

Replacing silent blocks

Depending on the driving style (careful or sporty) and the quality of the roads, the lifespan of silent blocks differs. They can wear out in one summer, or they can last for several years.

Also, the service life of the RMS depends on how they were installed. In the absence of a puller, some people hit them with a hammer. If you plant silent blocks with a hammer, the rubber may be damaged and the metal bushing may move.

The average resource of silent blocks is from 100 to 150 thousand kilometers.

What is a puller for installing silent blocks?

- Bolt with nut. The diameter and pitch of the thread are at your discretion. If the thread is small, you will have to turn it longer, but it will work easier and smoother.

- We select a cylinder with a diameter such that the silent block fits into it.

- Washers. Some. One washer should tightly cover the cylinder hole. You can even weld the washer on one side. We take the remaining washers with a smaller diameter than the diameter of the silent block.

A RC puller is needed not only for removal, but also for installation, so as not to damage the new silent blocks. And when removing with a puller, there is no need to hit with a hammer and there is no risk of damaging the paws (levers). If you knock out rubber-metal hinges with a hammer, microcracks may appear on the lever.

On cars with 4-link suspension, the wheel alignment angles may be disrupted if the levers or new silent blocks are damaged. In this case, you will have to change the rubber-metal bushings and, possibly, the wheels again.

In terms of cost, pullers for automobile silent blocks can be purchased at prices ranging from 800 rubles to 30,000 rubles (a set of different pullers). But, it is easy to make from improvised means. The principle of operation of a mechanical puller is that when the nut is tightened, the silent block itself is squeezed out of the eye of the lever. Hydraulic ones are more complex in design, they are more powerful, but it is better to buy them when necessary; it is impossible to make them from scrap materials.

Pressing out at home

Replacing these parts is not as difficult as it might seem at first glance. For example, many car owners made sure of this when they replaced parts, using special equipment for self-replacement. It is for this reason that there are many people who have decided to replace silent blocks with their own hands and at home.

First method

First of all, let's learn about how it should be ideally.

The lever in which the rubber-metal hinge needs to be replaced is installed on a special spacer for the press. The old silent will be squeezed onto this spacer. Then another spacer is installed on top - it squeezes out the old bushing. This method is used by service station workers, since they have the necessary set of spacers and a powerful press of 10-20 tons.

Second method

Almost all car owners, naturally, do not have a powerful press, but many have a jack or a good vice in their garage. If you use a powerful vice, you can successfully squeeze out the old bushings according to the principle that is already familiar to us: a spacer for the original bushing and a spacer for pressing on the bushing.

At first glance, it becomes unclear how you can squeeze out the silent tape with a jack? Everything is very simple: you need to weld a frame in the shape of a rectangle from a channel or corner so that its height is slightly higher than the lever and the jack. The operating principle is as follows: place the jack in the frame, then install the lever eye on top of the rod, as well as the two spacers mentioned above. We create the required pressure, after which the bushing is squeezed out of its seat. It must be emphasized that most often a jack with a capacity of 3-5 tons is not able to cope with such work, therefore it is recommended to use 10-ton jacks.

Third method

If you have neither a press nor a jack, but still have a strong desire to replace the silent blocks on your own, you can use the third method - using a simple press puller (bolt with nut or stud).

The principle of operation is to create pressure by gradually tightening the nut on the stud; this method can be called an analogue of a vice. This pin with a washer of suitable diameter is inserted into the eye through the silent block, then on the other side you should put on a spacer with a washer and tighten the nut. Rotating along the thread, the nut creates the necessary pressure and forces the silent to be squeezed into a special spacer.

This “method” requires the use of a strong, hardened stud and an equally strong nut. If you take a soft pin or nut, you will most likely fail. For example, there are cases when, due to strong pressure, the stud becomes bent, as a result of which the thread on the nut breaks. However, there are thousands of those who managed to change silent blocks using this particular method. After all, everything depends on the quality and strength of the material used.

How to make a puller

After preparing the above parts, we proceed to assembling the removable device:

- We close one end of the cylinder with one washer, with a hole for the selected bolt.

- We insert the bolt into a cylinder selected in diameter, slightly larger than the diameter of the silent block.

- After putting it on the silent block, tighten the nut.

Procedure for working with the puller:

- Remove the RMS axle. You can completely dismantle the paw and secure it in a vice, or you can press it out directly in its installed form.

- We install the puller cylinder to the silent block.

- Insert the bolt. We take the bolt of such length that you can throw on a couple of washers and tighten the nut.

- We put the washers on the bolt and begin to tighten the nut.

- Gradually the hinge will begin to slip.

If you remove silent blocks without a puller, you must use a wooden strip to avoid damaging the rods.

Video

This video shows how to make a silent block remover and how to work with it.

How to change silent blocks without a puller.

How to change silent blocks on the “classic” VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107.

How to make a puller for VAZ 2113, 2114, 2115.

How to make a puller for removing and installing rubber-metal hinges on Skoda Fabia, Skoda Rapid, VW Polo Sedan cars.

Silent blocks VAZ 2107

On the Internet, the specifics of replacing the silent blocks of the suspension of the VAZ 2107 and other cars of the domestic and foreign automobile industry are often discussed. The problem is actually urgent and is due to the poor quality of our roads. Since the silent block is one of the important elements of the vehicle suspension design, special attention must be paid to its selection and replacement.

What are silent blocks

The silent block (hinge) structurally consists of two metal bushings connected to each other by a rubber insert. The part is designed to connect suspension elements, and the presence of rubber allows you to dampen vibrations that are transmitted from one unit to another. The silent block must perceive and endure all deformations to which the car suspension is subjected.

Where are they installed?

On the VAZ "Seven" silent blocks are installed in the front and rear suspension. At the front, levers are attached using this part, and at the rear, reaction rods (longitudinal and transverse) connect the axle to the body. To ensure that the car's suspension is always in good condition and handling does not deteriorate, you need to monitor the condition of the silent blocks and replace them in a timely manner.

What types of silent blocks are there?

In addition to the purpose of silent blocks, you need to know that these products can be made of rubber or polyurethane. It is generally accepted that replacing rubber suspension components with polyurethane ones, where possible, will only improve the characteristics and performance of the suspension.

Silent blocks made of polyurethane are characterized by a longer service life, unlike rubber ones.

The disadvantage of polyurethane elements is their high cost - they are about 5 times more expensive than rubber ones. When installing polyurethane products on a VAZ 2107, you can improve the car's behavior on the road, reduce deformations in the suspension, and also eliminate the so-called squeezing, which is characteristic of rubber elements. This means that the suspension will operate in the condition intended by the designers at the factory. With the correct selection and installation of polyurethane parts, noise and vibration are reduced and shocks are absorbed, which indicates the better performance of such hinges compared to rubber ones.

Reasons for failure

When encountering failures of silent blocks for the first time, it is quite difficult to imagine what can happen to these products after long-term use. Over time, the rubber begins to tear, resulting in the need to replace the hinge. There may be several reasons why a product becomes unusable:

- High mileage of the car, the consequence of which was the drying out of the rubber, loss of its elasticity and the appearance of cracks and tears.

- Contact of chemicals with the rubber of the silent block. Since the suspension element in question is located near the engine, it is likely that it will be exposed to oil, which leads to the destruction of the rubber.

- Incorrect installation. Fastening the bolts of the levers should only be done after the car is installed on the wheels and not hung on a lift. If tightened incorrectly, the rubber of the silent block becomes strongly twisted, which leads to rapid failure of the product.

Puller type - WEDGE

The simplest puller is the so-called “wedge”. It does not belong to any type of removable mechanism, but at the same time it is a fairly effective device for pressing out.

To make it, you only need an angle grinder (“grinder”), you can also use a machine with an abrasive wheel.

The blank will be a metal plate the size of a matchbox.

First, it is necessary to give the workpiece a wedge shape, for which we grind the metal with a grinder or machine so that the profile of the plate looks like a triangle. Then, using the same “grinder”, we make a cut in the middle 2/3 of the length of the workpiece from the side of the apex of the triangle, that is, from the thin side of the wedge. The width of the cut should be slightly larger than the thickness of the support pin, that is, you should get a kind of bracket.

If desired, you can weld a metal rod to the bracket, which will make it easier to work with the wedge in the future.

Pressing out a finger with a wedge is very simple. It is installed in the gap between the eye and the support body. And then the wedge is simply driven in with a hammer, which leads to the finger popping out of the socket.

The disadvantage of the wedge is that the boot will be damaged during the pressing process. Therefore, the wedge can only be used when replacing supports or tips.

If the suspension and steering mechanism are being repaired, which does not involve replacing the ball elements, it is better not to use a wedge.

Replacing silent blocks of the lower arm

When silent blocks fail, as a rule, they cannot be restored; this is due to their design. To carry out work on replacing the rubber-metal joints of the lower arm on a VAZ 2107, you will need the following tools:

- silent block remover;

- ball joint remover;

- keys for 13, 22, 24;

- hammer;

- chisel;

- mount;

- lubricant (for example, WD-40).

The procedure for dismantling the lower arm is as follows:

- Raise the car using a lift or jack.

- Remove the wheel.

- Loosen the lower arm axle nuts.

During assembly, new nuts should be used to tighten the lever shaft and ball pin.

Video: how to replace the silent blocks of the lower arms of a VAZ 2101–07

The same puller is used to remove and install silent blocks. You only need to change the position of the parts depending on what operation is intended (pressing in or pressing out).

Necessary materials

To press this part into place at home, you will need the following tools:

- Mount;

- Jack;

- Set of wrenches;

- New hinges.

It is recommended to use machine oil or other types of lubricant as a lubricant.

Among other things, you will need special mandrels designed for pressing silent blocks; as an alternative, you can use a piece of pipe with the required diameter. You also need to get a press to press in a new rubber-metal hinge . When it comes to home use, an ordinary vice can serve as a press. In addition, you can stock up on a set of sledgehammers, but with this approach it is necessary to maintain high precision in the work.

Replacing the upper arm joints

To replace the silent blocks of the upper arm, you will need the same tools as when repairing the lower elements. The car is lifted in the same way and the wheel is removed. Then carry out the following actions:

- Unscrew the front bumper bracket fasteners.

Replacement of silent blocks of reaction rods

Tie rods are an integral part of the rear suspension of classic Zhiguli cars. They are secured by a bolted connection, and rubber bushings are used to reduce loads and compensate for impacts from uneven road surfaces. Over time, these products also become unusable and require replacement. It is best to change them comprehensively, rather than individually.

Tools and materials you will need:

- keys to 19;

- new silent blocks;

- penetrating lubricant;

- metal brush;

- mounting blade.

Let's consider replacing torque rod bushings using the example of a long longitudinal rod. The procedure with other suspension elements is carried out in a similar way. The only difference is that to remove the long rod, you need to remove the lower shock absorber mount. The work consists of the following steps:

- Clean the fastener from dirt with a brush, treat it with a penetrating liquid and wait for a while.

If the inner race protrudes slightly on one side, it needs to be leveled with a hammer.

After replacing the silent block, the rod is installed in the reverse order, not forgetting to lubricate the bolts, for example, with Litol-24, which will make it easier to dismantle the fasteners in the future.

Video: replacing torque rod bushings on a VAZ 2101–07

Consequences of consumables malfunction

It should be noted that silent blocks and bushings are consumables.

Due to heavy loads, it is possible that the rubber part of the silent block may be pressed through, detached from the metal bushing, and the rubber itself may delaminate. As a result, they are no longer able to work properly.

This results in knocking from the suspension, the appearance of creaks, when driving, especially over uneven surfaces, the car can throw from side to side, and the more wear on the silent blocks, the stronger the tossing will be.

Also, due to worn silent blocks, the angles of the wheel position - camber and toe - change, because of which the car will no longer hold the road, it will begin to drift in any direction, the tires will quickly wear out due to incorrect angles.

So, the condition of all rubber elements of the car suspension must be constantly monitored, and if signs of malfunction appear, they must be promptly replaced.

With certain knowledge and the availability of tools, you can replace silent blocks yourself without contacting a service center.

It should be noted right away that even if damage to one or two silent blocks is detected, it is better to completely replace all rubber parts of the suspension, and not just the damaged ones.

Also, all elements are replaced immediately on the left and right sides of the car.

Do-it-yourself silent block remover

The VAZ 2107 hinge puller can be purchased ready-made or made by yourself. If you have the right equipment and materials, every car enthusiast can make the tool. It is also worth considering that the quality of purchased devices today leaves much to be desired. You can replace the rubber-metal hinge without special tools, but this will require much more time and effort.

Sequencing

To make a homemade puller you will need the following:

- a piece of water pipe 3 cm long with an internal diameter of 40 mm and an external diameter of 50 mm;

- washer with an outer diameter of at least 50 mm;

- M12 bolt 7 cm long with washers;

- two pieces of pipe 10 cm long and 40 mm in diameter;

- vice;

- hammer;

- lubricant

The puller manufacturing process consists of several stages.

- By striking with a hammer, they ensure that a 40 mm pipe section has an internal diameter of 45 mm, i.e., they try to rivet it. This will allow the lower arm joint to pass freely through the pipe.

In order to drive your car confidently and without accidents, you need to periodically inspect and repair the chassis. Wear of silent blocks affects driving safety, as well as tire wear. To replace damaged hinges, you will need to prepare the necessary tools and perform repairs in accordance with step-by-step instructions.

How to change front suspension silent blocks

Replacing silent blocks on a VAZ 2107 is a rather labor-intensive task that can take more than one day. Replacing silent blocks can be done with a purchased puller or with a puller made from improvised means.

What are they

The silent block is a hinge. Translated as “quiet block”. Structurally, it consists of two metal bushings connected to each other by a rubber insert. The part is designed to connect suspension elements, and the presence of rubber allows you to dampen vibrations that are transmitted from one unit to another. The silent block must perceive and endure all deformations to which the car suspension is subjected.

On the VAZ 2107, silent blocks are installed in the front and rear suspension. At the front, levers are attached using this part, and at the rear, reaction rods (longitudinal and transverse) connect the axle to the body. To ensure that the car's suspension is always in good condition and handling does not deteriorate, you need to monitor the condition of the silent blocks and replace them in a timely manner.

Varieties of “quiet blocks”

Silent blocks can be made of rubber or polyurethane. It is generally accepted that replacing rubber suspension components with polyurethane ones, where possible, will only improve the characteristics and performance of the suspension.

What are the reasons for failure

It is imperative to monitor the condition of silent blocks, since all parts have a lifetime. And rubber wears out both during operation of the machine and when it is idle.

The service life of the hinges is approximately 90-100 thousand kilometers (if the rubber or polyurethane is of high quality).

When do hinges need to be replaced:

- lack of “responsiveness” of the car when turning the steering wheel sharply;

- During the inspection, deformations of the devices are revealed;

- knocking from the suspension while driving over uneven surfaces;

- play in the locations of parts.

If you are not sure that the devices should be replaced, you can visit a service station, where the technicians will carry out diagnostics and inform you about the need to replace the joints on the machine.

Additional reasons for replacement:

- High mileage of the car, which causes the rubber to dry out, lose its elasticity and cause cracks and tears to appear;

- Contact of chemicals with the rubber of the silent block. Since the suspension element in question is located near the engine, it is likely that it will be exposed to oil, which leads to the destruction of rubber;

- Incorrect installation. Fastening the bolts of the levers should only be done after the car is installed on the wheels and not hung on a lift. If tightened incorrectly, the rubber of the silent block becomes strongly twisted, which leads to rapid failure of the product.

How to replace upper control arm joints

The described method does not require complete removal of the element from the car.

- To gain access to the lever, jack up the front wheel on the side where the work is being done and remove it. You will also have to unscrew and remove the plastic wheel arch protection (if equipped);

- We unscrew the nut of the upper arm mounting bolt, having previously treated it, as well as the hinges themselves with WD-40;

- We unscrew the bumper mounting bolt, since it will interfere with the removal of the lever fastening element;

- Remove the mounting bolt. After this, the hub will go down, which will make it possible to rotate the lever on the ball joint, so that the side with the hinges is on the outside. This will provide full access to the silent blocks, without the need to completely remove the lever;

- Using a puller, we press out the worn element: we put a washer on the long bolt, and then a piece of pipe with a diameter larger than the silent block. We pass the bolt through the hinge, so that the pipe begins to rest against the lever, and the hinge itself is inside it, put on the second washer and screw on the nut. We take two keys - with one we tighten the nut, and with the second we hold the bolt. When twisted, the nut and washer will push the hinge into the pipe until it comes out completely;

- Before installing a new element, clean the seat and lubricate it with soapy water. For planting, we use a puller with a tube of smaller diameter so that it rests against the side;

- Pressing is done like this: we put a washer and a tube on the bolt, into which we insert a new element. We pass the bolt through the hole in the lever, add the second washer and nut. Before tightening, center the silent block relative to the hole. We tighten the nut until the hinge rests on the washer. Unscrew the puller and install a piece of larger diameter on it. We position the device so that the pipe is on the side where the hinge moves. By tightening the nut, we seat the silent block until the bulges on its outer ring rest against the lever;

- We change the second hinge in the same way. After this, we turn the lever back, lift the hub to align the holes of the lever and the car body, install the mounting bolt, lubricating its body and threads with nigrol (or other lubricant), tighten the nut, put the wheel in place and remove the car from the jack.

Replacing silent blocks on the lower arm

- We place the car on the inspection hole and immobilize it using the handbrake and wheel chocks installed under the rear wheels;

- We do not remove the wheel on the side where the replacement is being made, but it will have to be jacked up;

- We install wooden stands under the ball joint of the lower arm. After this we lower the jack. The height of the stands should be such that the wheel hangs out. So we unload the lower lever;

- We unscrew the nuts securing the lever to the axle, having previously treated them with WD-40;

- You can press out silent blocks on this lever without any tools. Let's look at how to remove the front hinge (which is located closer to the front of the car). Before starting the process, you should generously treat the silent block with WD-40, making sure that the product gets inside between the axle and the inner race of the element;

- We take a pry bar that will be used as a power lever, rest it on the rear bolt securing the axle to the body (which is closer to the rear hinge). Using a pry bar, we move the lower arm back, while the silent block will rest against the car body.

- Using a pry bar to create force, we strike the side surface of the lever with a hammer. We do this until the hinge comes out of the socket as much as possible.

- Then we remove it by prying it with the same pry bar or a reinforced screwdriver;

- Before planting the new element, generously lubricate the seat and the silent block itself with soapy water;

- After removing the old rubber element, the seat will lower slightly relative to the axis, so before doing this you should lift it, centering the position of the hole;

- For pressing, you will need a piece of pipe whose walls will rest against the side of the holder (it will act as an extension). We put the silent block on the axle, having first moved the lever back as much as possible with a pry bar. We put a piece of pipe on the hinge and hit the attachment with a hammer until the side rests against the body of the lever.

Making a puller with your own hands

If there is no special tool, we will make a puller ourselves from scrap materials. We will need:

- a piece of 40 mm water pipe

- large washer or plate with a diameter of at least 50 mm

- M12-14 bolt 6-7 cm long with washers

- hammer, vice, anvil, grinder

We cut off 2.5-3 cm from the water pipe, use a hammer to beat the scrap on an anvil, bringing its internal diameter to 45 mm, so that the silent block of the lower arm passes through it freely, or we find a tube of suitable diameter.

We take the bolt, put a thick-walled washer (or washers) on it, no smaller than the diameter of the inner and no larger than the outer bushing of the silent block (preferably).

We insert the bolt into the block from the inside of the lever, put on the large mandrel we made on the outside so that it rests against the walls of the lever, insert a large washer and tighten the nut.

As you tighten it, the mandrel will rest against the lever, and the bolt with washers will begin to pull the silent block into it. The main thing is to tear the block out of place, and then it’s a matter of technique - remove it with a large screwdriver and hammer.

Definitely, when replacing silent blocks you will have to work hard. Here, in addition to dexterity and flexibility of thinking (in the technical aspect), you also need strong nerves. Therefore, it is no wonder that many car owners entrust such work to car services, but everything is in your hands!

Links to sources of information:

Video about replacing lower silent blocks without a puller

Video about replacing the upper hinges with a puller

Alternative method

Finally, we note that it is possible to press out the support pin or tip even if it is not possible to make a removable mechanism. But this method should be used only in extreme cases. To remove the finger you will need a pry bar and a hammer.

The pry bar is used as a lever and must be installed in such a way as to create a force to press the support or tip, for example, place it between the steering rod and the rack eye.

After creating force with the mount, it is necessary to apply powerful blows to the body of the eye with a hammer. If everything is done correctly, then after 2-3 hits the finger will pop out.

The disadvantage of this method is that the eye can be damaged due to shock loads, so it is advisable to use pullers rather than knock out the support.

Replacing silent blocks of VAZ front control arms

- 156 0 216k

A photo report demonstrating a DIY repair procedure such as replacing the silent blocks of VAZ front control arms, from 2101 to 2107.

The silent block is necessary in order to reduce various noise and vibration in the area of the connection points of the suspension units. Considering the state of domestic roads and the load the car suspension takes on when driving on them, wear of the silent block will not be a big surprise. There is no point in postponing the replacement of faulty silent blocks on VAZ 2101, VAZ 2102, VAZ 2103, VAZ 2104, VAZ 2105, VAZ 2106 VAZ 2107.

Replacing the silent blocks of the front control arms of a VAZ Classic may be necessary if there are the following symptoms :

- knocking and noise in the front suspension when the car is moving;

- Wheel alignment angles are not adjustable;

- self-exciting angular oscillation of the front wheels.

see also

Could there be a knocking noise in the VAZ 2110 due to the silent blocks of the rear beam?

- 0 4 515

Replacement of rear silent blocks of VAZ 2110

- 1 0 6k

Replacing the rubber-metal bushing of the rear shock absorber of a VAZ 2110

- 0 2 2k

The rubber bands flatten when the tension nut is tightened

- 0 3 938

What are the signs of worn silent blocks?

- 0 2 2k

Car silent blocks require monitoring and timely replacement. The service life of a silent block is up to 100,000 km , but Russian conditions dictate their own rules; silent blocks have to be replaced every 50,000 km .

Broken silent blocks of the front suspension arms on VAZ-2110 vehicles are indicated by a characteristic knocking or grinding sound that is heard when the car is moving. The car not only begins to rattle, but also loses stability on the road and becomes more difficult to control. It happens that when a car undergoes a wheel alignment, it is discovered that the silent blocks are faulty.

It is quite possible to change the silent blocks of a VAZ 2110 with your own hands. Of course, you will have to get dirty and spend several hours of your time to repair the car. The same procedure for replacing a set of silent blocks at a service station will cost 1100-1400 rubles . You can decide whether to take on the work yourself or entrust it to others after viewing this photo report.

It is worth noting that the photo instructions are based on the experience of car enthusiasts and contain tips for drivers with a minimum set of necessary tools. In the repair instructions you can find another solution to this problem.

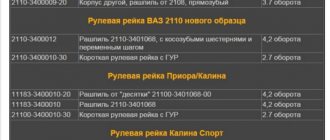

Which front control arm silent blocks should I install on a VAZ?

The original number of the upper arm silent blocks is 2101-2904180, the average price is 44 rubles, the lower arm silent blocks are 2101-2904040, the average price is 51 rubles.

Analogue sets of upper and lower front silent blocks:

- BelMag BM.0705 — 350 rub.

- Trialli SB S 201 — 1004 rub.

- SEVI 1203 — 394 rub.

Problematic worn silent block, with deep rubber cracks.

Devices for replacing silent blocks. Of these - for pressing and pressing, ball joint remover, steering tip remover. You will also need a jack, 22, 13 or 24 wrenches, a hammer, a chisel and a pry bar.

Loosen the wheel bolts and use a jack to lift the required wheel. Then remove it and use a 24mm wrench to loosen the nut on the axis of the upper arm.

Unscrew the nut on the upper ball joint using a 24mm wrench.

Using a press puller, remove the support pin from the bipod. If there is no puller at hand, the support is unscrewed from the lever using a pair of 13mm keys.

Unscrew the steering tip nut.

And we unpress it. Unscrew the upper arm axle nut and remove it. If repairs are carried out on VAZ 2104, 2105 or 2107 models, the vertical bumper mounting bolt is unscrewed to remove the axle.

We carry the lever to the workbench and clamp it in a vice. Using a tool for replacing silent blocks, we press out and install the silent blocks of the upper arm.

Reinstalling the lever is done with the upper lever axis pre-lubricated. The axle nut is not fully tightened.

Tightening is carried out with the vehicle completely lowered to the ground.

We fix the support. We put on and spin the wheel. We lower the car from the jack.

We've dealt with the upper lever, let's move on to the lower one.

Unscrew the lower arm axle nuts with a 22 wrench.

We install the puller and squeeze out the silent block from the eye of the lower arm.

If you do not remove the steering knuckle, you will not be able to install a puller.

We take out the old silent block, lubricate the axle and thread with oil and insert a new one into the eye.

Then, between the lever and the nut securing the lower lever axis to the beam, insert a thrust bracket.

We install the device and press in the silent block.

The procedure for each of the silent blocks is similar. The steering ends are installed in place and secured with cotter pins.

List of new spare parts and tool kit required for replacement

The domestic spare parts market offers a wide range of new parts of several types, with polyurethane and rubber filling, and to replace the front silent blocks on a VAZ 2107, the automaker recommends using the former, namely:

- a set of polyurethane silent blocks for the upper arm (art. 2101 - 2904040);

- a set of polyurethane silent blocks for the lower arm (art. 9RU01N);

- upper front arm mounting bolt;

- lower front arm mounting nuts.

Installation of new spare parts is carried out using standard tool kits and some specialized pullers, which significantly simplify the entire work process, namely:

- silent block remover for classic VAZ models;

- ball joint remover;

- open-end spanners with 13, 22 and 24 mm diameter;

- socket heads in a set from 10 to 24 mm and wrenches;

- hammer;

- medium mount;

- bottle WD – 40 for cleaning threaded connections;

- brush;

- gloves for hand safety.

The process of replacing the upper silent blocks on a VAZ 2107 is very different from the lower ones, both in terms of the volume of work performed and the cost in auto repair shops. Official service stations at the end of 2022 estimate this service at 1500-2000 rubles for the upper and lower levers, respectively, and private services at approximately 1300-1800 rubles.

Independent removal and installation of new parts on the upper arm

Work on replacing silent blocks on a VAZ 2107 without a specialized puller begins by placing the car in a room with a flat floor, and placing stops under the rear wheels, lifting it on a jack and removing the front wheel, after which:

- It is necessary to remove the front bumper, which is attached from the inside of the lower skirt of the engine compartment with four bolts. This is done because the bumper will not allow you to remove the upper arm mounting bolt completely, and in this case it will not be possible to change its silent blocks.

- Having removed the bumper, a stop is placed under the lower arm, after which the car is slightly released from the jack, and the nut of the upper arm fastening axis is unscrewed, then the nut on the ball joint is unscrewed and, using a puller, the ball joint is removed from the steering knuckle. Next, by removing the bolt securing the lever, it can be dismantled.

The removed lever is clamped in a vice and the old silent blocks are pressed out of it, replacing which new ones are installed. This can be done either with a specialized puller or with the help of a hammer; the silent block is driven through the spacer with gentle blows into its seat in the lever.

- After installing new parts, the upper arm is mounted in the reverse order. At this point, all work with the upper levers is completed and work begins on the lower ones. The important point here is that the nut on the axial mount of the upper arm is fully tightened only after the car is removed from the jack on all wheels; this is done to avoid excessive twisting of the polyurethane filler in the silent block, which can cause its rapid breakdown.

Replacing consumables, eliminating axial play

Having dismantled the suspension elements, you can begin to press out the worn silent blocks and install new ones.

Using a special device prepared in advance, old silent blocks are removed from the crossbar, levers and racks and new ones are pressed into their place.

To facilitate installation, new consumables can be moistened with soapy water.

But the use of petroleum-based lubricants is not recommended, since they have a negative effect on rubber elements.

Regarding the stabilizer struts, before pressing out, they will need to be knocked off the stabilizer, since they are tightly seated on it.

When knocking down, it is better to use a hammer and strike through a wooden spacer.

Also, after removing the struts, the rubber bushings are pulled off the stabilizer and new ones are installed in their place.

Often a phenomenon called axial play occurs at the lower arm.

It is formed when the body bracket to which the lever is attached, for one reason or another, loosened and a gap appeared between it and the metal bushing of the silent block, which is why the silent block itself was able to move along the fastening bolt.

This axial play negatively affects the performance of the suspension, so it should not exist. But if it appears, then there are two ways to eliminate it.

You can try to compress the bracket. But this is very difficult to do, since it is better not to apply impact with a hammer, even through a spacer, and using clamps or a vice is not very convenient.

It is much easier to get rid of axial play using washers that are placed between the bracket and the silent block.

But according to the manual, it is recommended to replace the entire lower control arm with joints

After replacing all consumables, the removed suspension elements are installed in place.

After replacing all the silent blocks on the front suspension, the vehicle must have its wheel alignment angles adjusted.

Independent removal and installation of new parts on the lower arm

Removing the lower silent blocks on a VAZ 2107 begins with the following steps:

- The anti-roll bar mounting bracket is unscrewed and through the upper stud of its mounting, it is moved to the free position.

- The two nuts securing the lower arm axis are unscrewed, after which the ball joint is removed, unscrewing its nut and using a puller or hammer, it is removed from the steering knuckle.

After replacing the silent blocks on a VAZ 2107 with your own hands, the car is completely lowered onto all wheels, and under a standard load on the suspension, all axle nuts are finally tightened. Also watch the video of the work in progress:

Suspension design features

A feature of the suspension design is that many of its elements should not be rigidly connected, otherwise it will transfer all the vibration to the body.

How does the VAZ 2110 suspension work?

Therefore, some composite suspensions are connected by means of rubber bushings and rubber pads with metal bushings inside, i.e. silent blocks.

So, in the front independent suspension of the VAZ-2110 the following are connected to each other through silent blocks:

- Lower arm;

- Stretching;

- Anti-roll bar.

Each of these elements plays an important role in the suspension design.

The lower arm prevents lateral movement of the wheel, the extension prevents the wheel from moving longitudinally relative to the body, and the anti-roll bar prevents the body from swaying when performing maneuvers or when driving over uneven surfaces.

But the loads on these elements coming from the wheels are very large, so their displacement, although small, must be provided in order to partially absorb the loads and partially absorb them, and not transfer them to the body.

The possibility of displacement of suspension elements relative to each other and relative to the body, as well as partial damping of vibrations, is provided by silent blocks and rubber bushings.

On the VAZ-2110, silent blocks and bushings are installed in the front suspension:

- Lower arm (two silent blocks - through one it is attached to the body, and through the second a stretcher is connected to it);

- Stretch bar (one silent block through which it is attached to the crossbar);

- Anti-roll bar (it is connected to the lower arm through a strut with two silent blocks, and to the car body through brackets with rubber bushings).